Method for detecting position and attitude of micro cylindrical cavity target by using target collimating sensor

A detection method and sensor technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of roughness, inability to meet the needs of multiple beams to guide quickly and in parallel to the target point, and low detection accuracy of the target position, so as to achieve convenient operation and detection The effect of fast speed and reduced error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

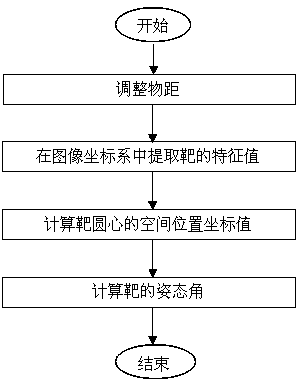

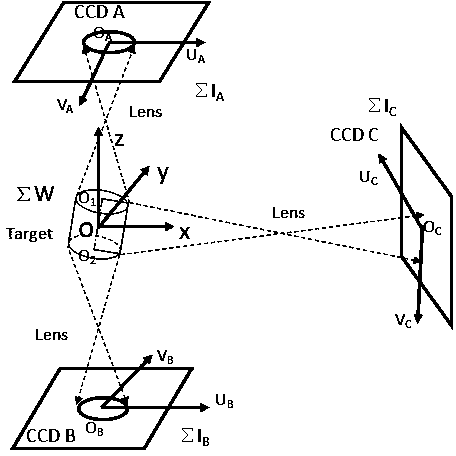

[0020] refer to figure 1 , figure 2 , the steps of the method for detecting the pose of a micro-column cavity target using a target alignment sensor in this embodiment are as follows:

[0021] (1) Object distance adjustment

[0022] A target alignment sensor composed of three orthogonally arranged CCD image sensors A, B, and C is used, and the intersection of the optical axes of the three CCD image sensors A, B, and C is used as the reference point for the detection of the target alignment sensor. , the micro-column cavity target is placed on the reference point detected by the target alignment sensor, and the object distances of the three CCD image sensors A, B, and C are respectively adjusted until the upper and lower end faces of the micro-column target and the upper and lower edges of the side are imaged clear;

[0023] (2) Feature point extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com