A Fast Extraction Method for Camera Space Stereo Calibration

A spatial three-dimensional and three-dimensional calibration technology, applied in the field of visual measurement, can solve problems such as insufficient depth of field information and difficulties in automatic recognition of spatial points, and achieve the effect of sufficient number of spatial points, improved repeatability accuracy, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with technical methods and accompanying drawings.

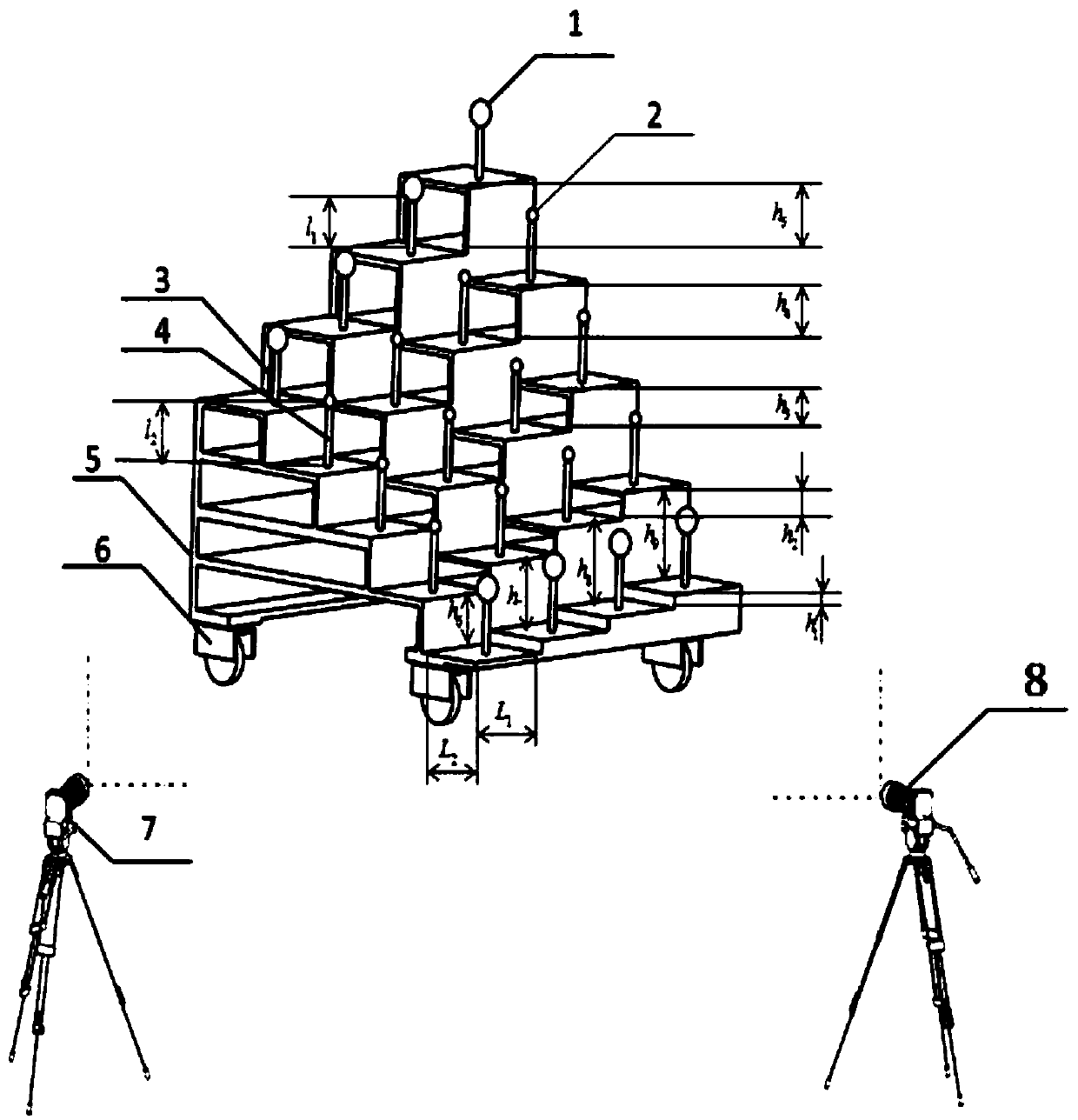

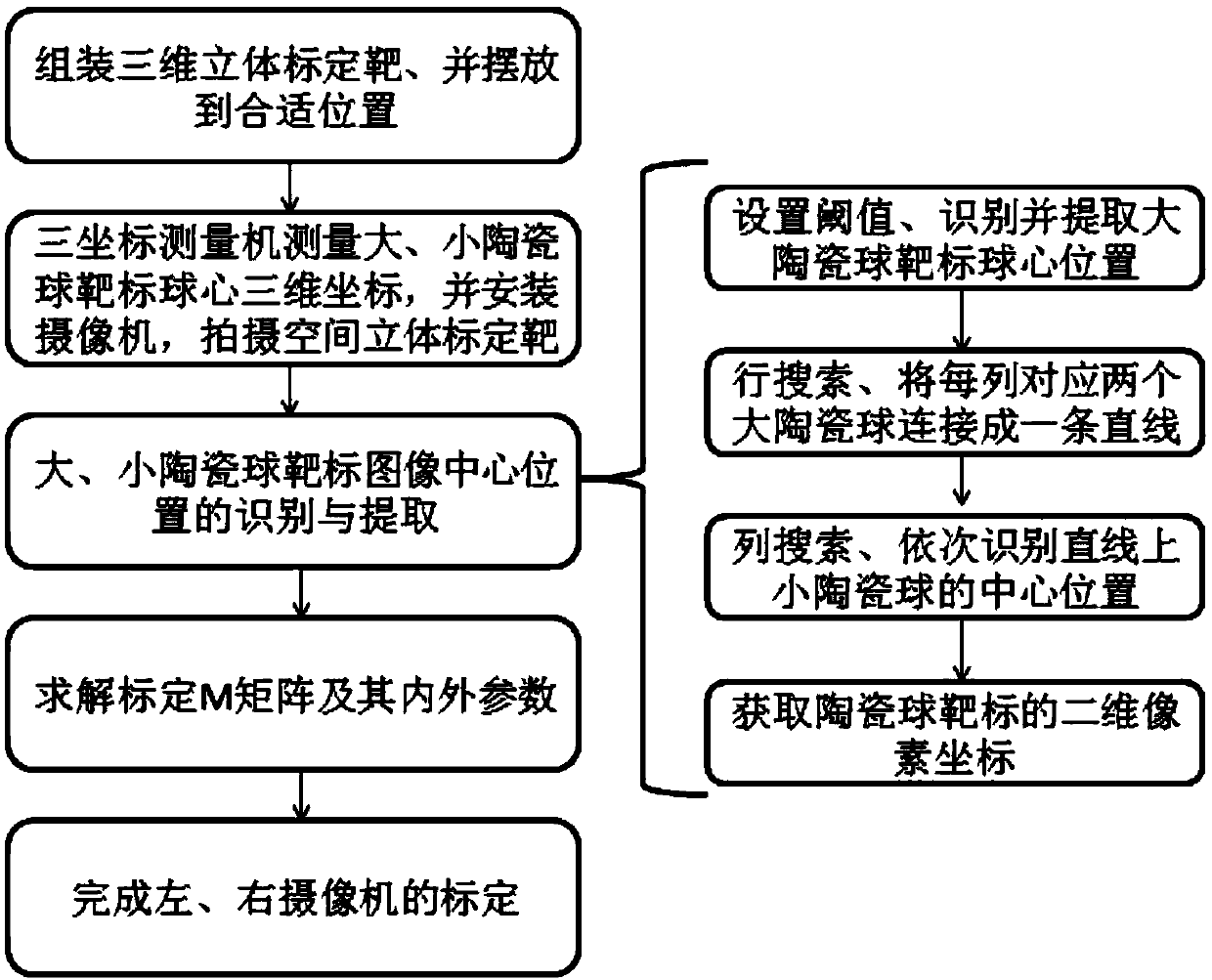

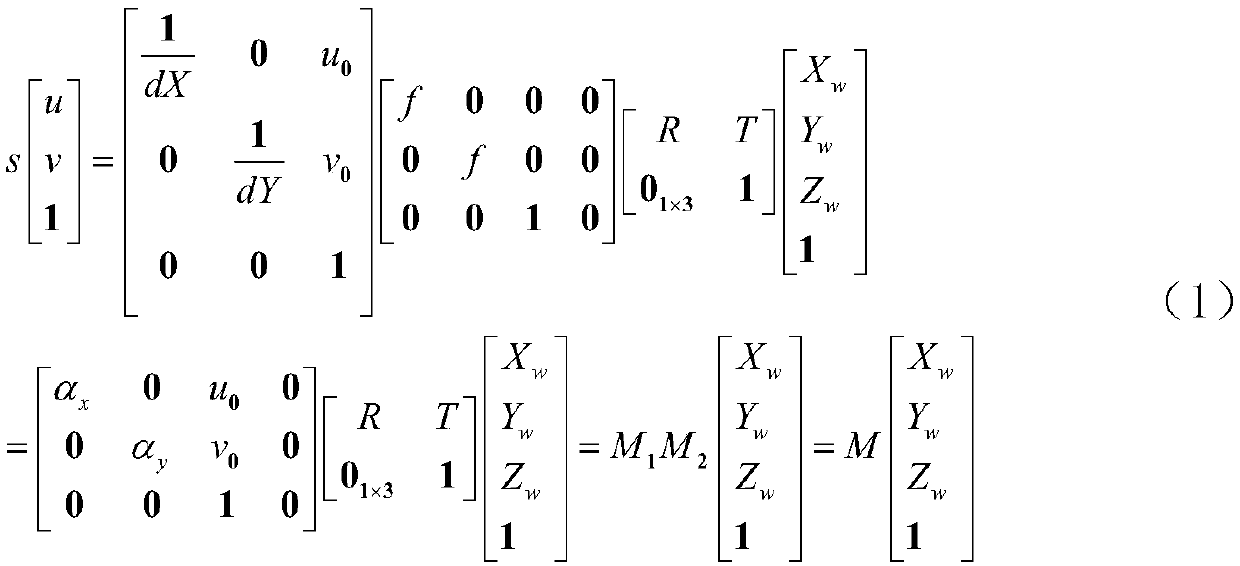

[0031] Install the three-dimensional calibration target before the calibration, and then use the three-coordinate measuring machine to measure to determine the precise three-dimensional position information of the centers of the large and small ceramic ball targets 1 and 2, and through the left and right cameras 7 and 8 of the binocular vision system. The large and small ceramic ball targets 1 and 2 are photographed, the characteristic information of the centers of the large and small ceramic ball targets 1 and 2 in the picture are extracted, and the two-bit pixel coordinates of the centers are obtained. Finally, on the basis of the direct linear transformation method, the internal and external parameters of the left and right cameras 7 and 8 of the binocular vision system are obtained to realize the stereo calibration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com