Grinding machine with a grinding tool for roller grinding two workpieces

A technology for grinding tools and grinding machines, which is applied in the direction of grinding bed, grinding tools, grinding machines, etc. It can solve the problems of inaccuracy and vibration of workpieces, achieve good precision and realize the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Terms used in connection with this description are also used in related publications and patents. However, it is to be noted that these terms are used for better understanding only. The concept of the present invention and the protection scope of the patent claims should not be limited when interpreted due to the specific choice of terms. The invention is readily transferable to other terminology systems and / or technical fields. Terminology will be applied accordingly to other technical fields.

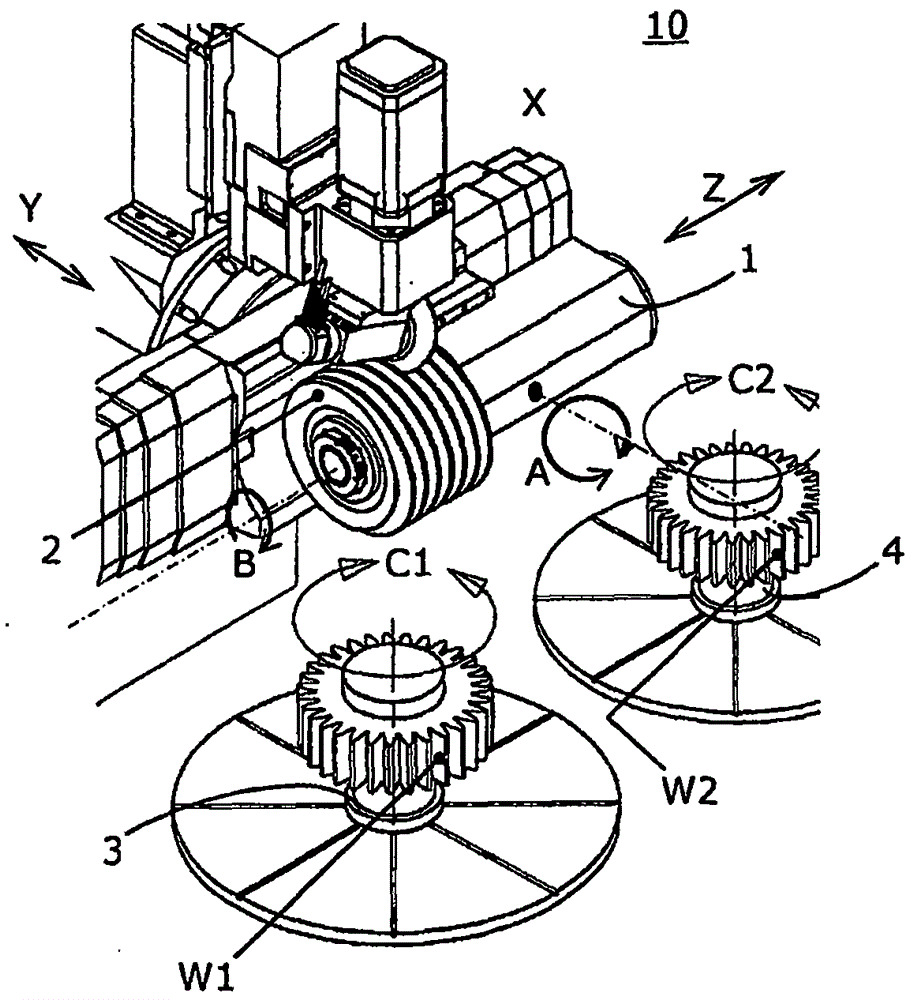

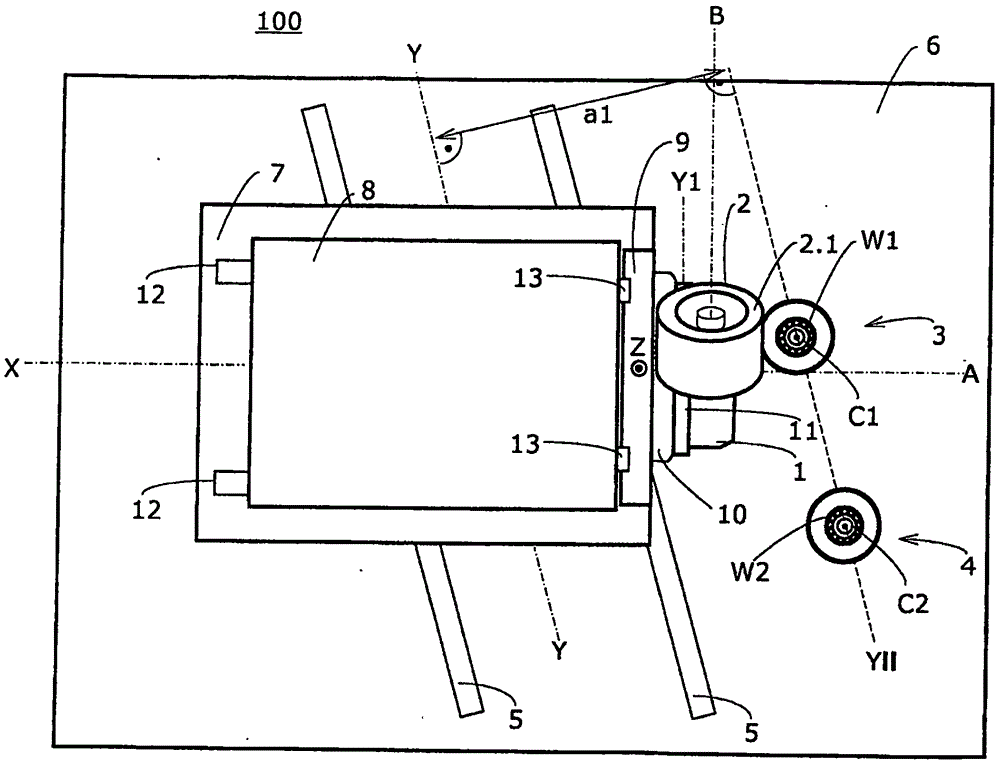

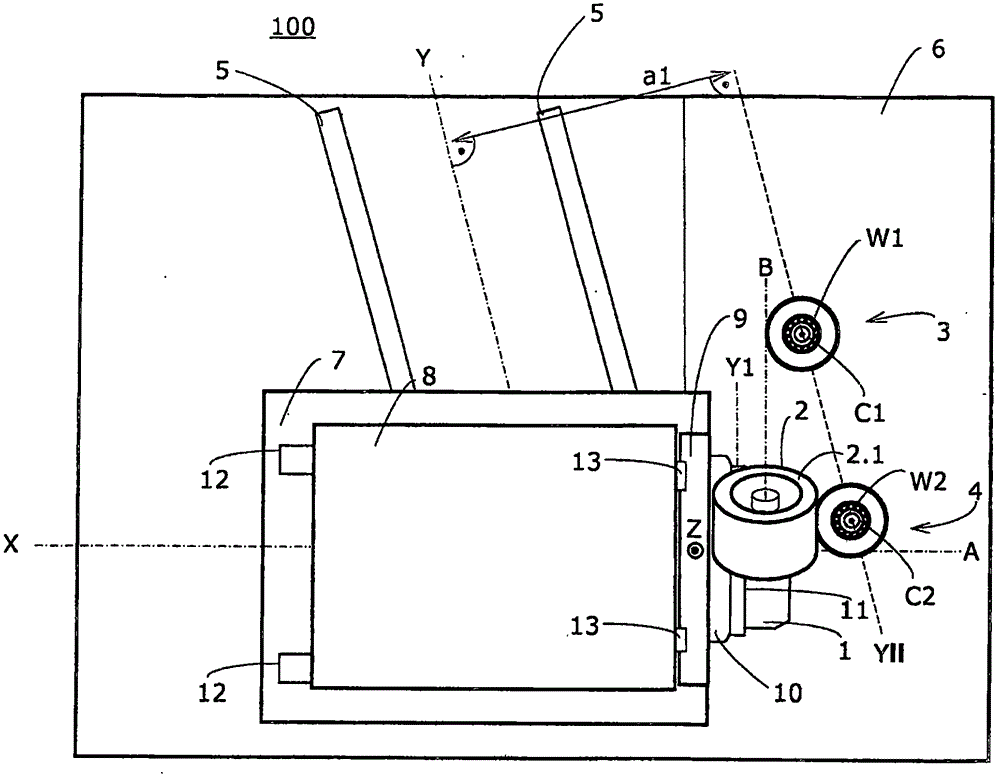

[0036] The grinding machine 100 according to the invention is equipped with a tool spindle 1 for receiving a grinding tool 2 and driving the grinding tool in rotation about a tool axis of rotation B (also called tool axis in short). In addition, the grinding machine 100 comprises a stationary first workpiece spindle 3 for receiving the first workpiece W1 and a stationary second workpiece spindle 4 for receiving the second workpiece W2. A first axis of rotation C1 associated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com