Image acquisition device for small magnetic material part

An image acquisition device and a technology for magnetic materials, which are applied in the field of image acquisition devices and image acquisition of small-sized parts, can solve the problems of false detection, high missed detection rate, limited development of the magnetic material industry, and high detection subjectivity. High efficiency, good detection effect, and the effect of avoiding repeated debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

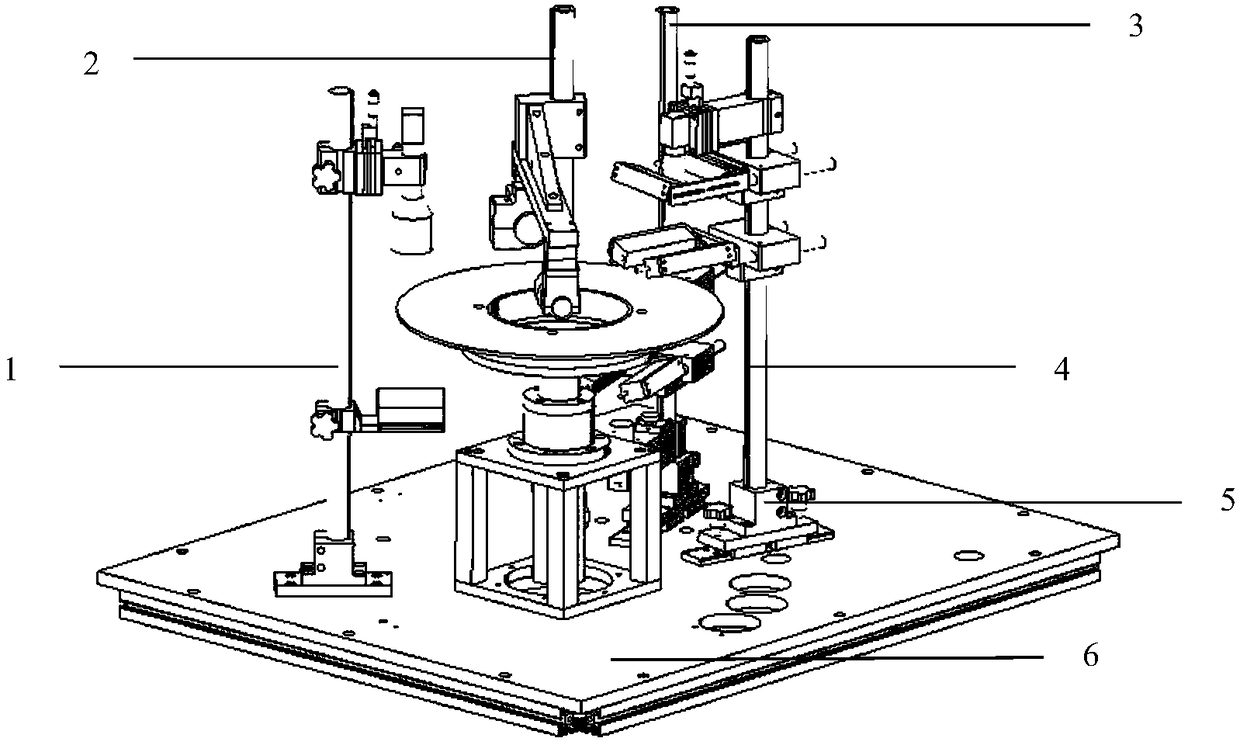

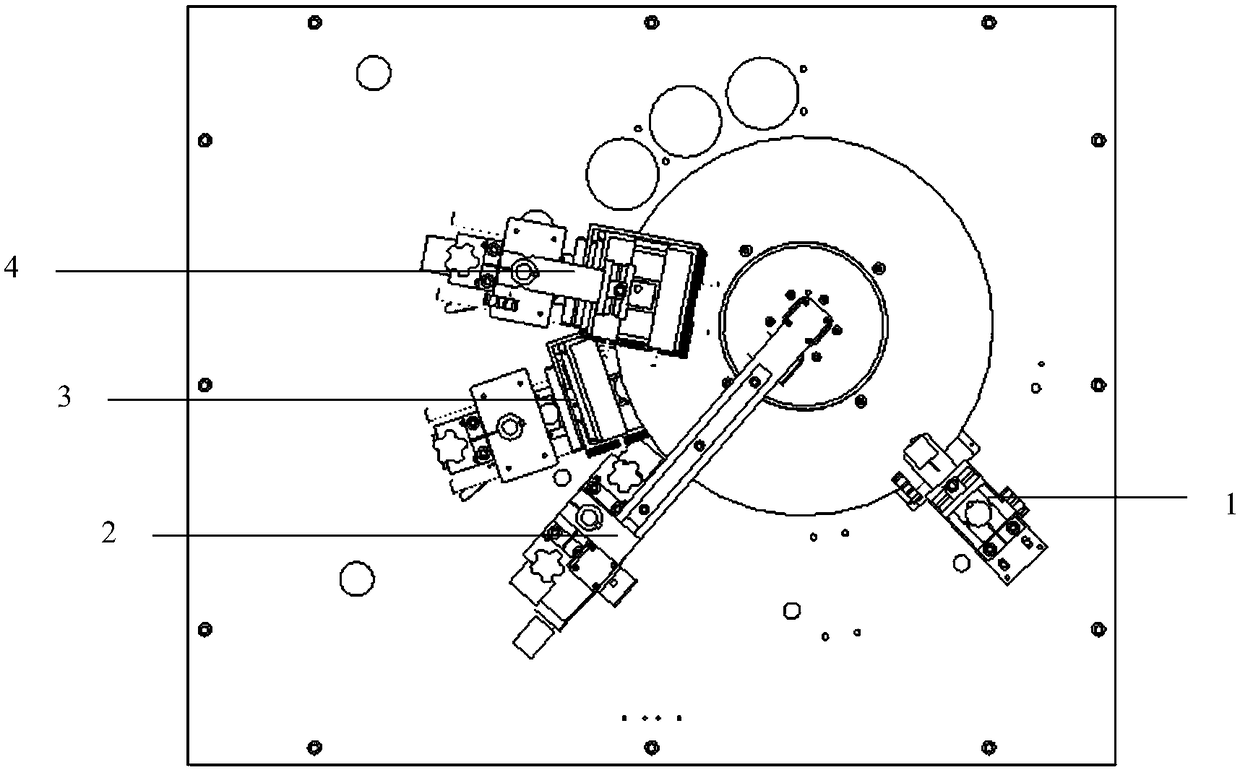

[0029] like figure 1 As shown, a machine vision part size and appearance measurement system includes a side length dimension drawing mechanism 1, a thickness dimension drawing mechanism 2, an upper view appearance drawing mechanism 3, a lower appearance appearance drawing mechanism 4, and a slide rail mechanism 5 , the bottom plate 6 is fixed, and corresponding light sources, camera components and adjustment devices are sequentially fixed on the support rods of different stations.

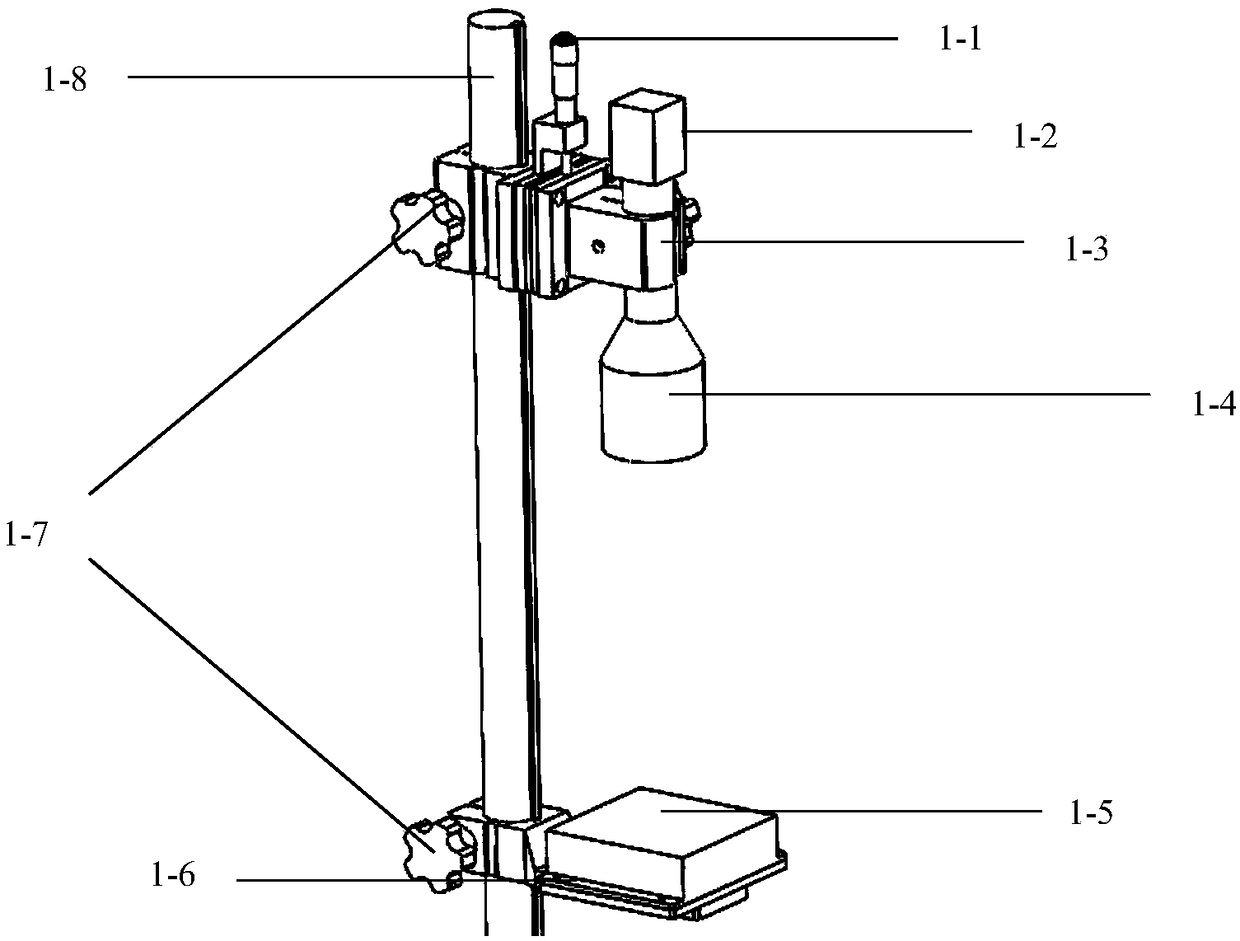

[0030] like image 3As shown, a backlight module and a camera assembly are sequentially fixed on the side length dimension detection station, wherein the backlight 1-5 is fixed on the backlight supporting board 1-6 by screws, and the backlight supporting board 1-6 is fixed by a plum blossom The clamping block of the thumb screw 1-7 is fixed on the support rod 1-8, and the up and down distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com