CMOS (complementary metal-oxide-semiconductor)-machine-vision-based component size measuring system and measurement test method

A measurement system and machine vision technology, applied in measurement devices, instruments, optical devices, etc., to achieve the effects of good economy, good linearity, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

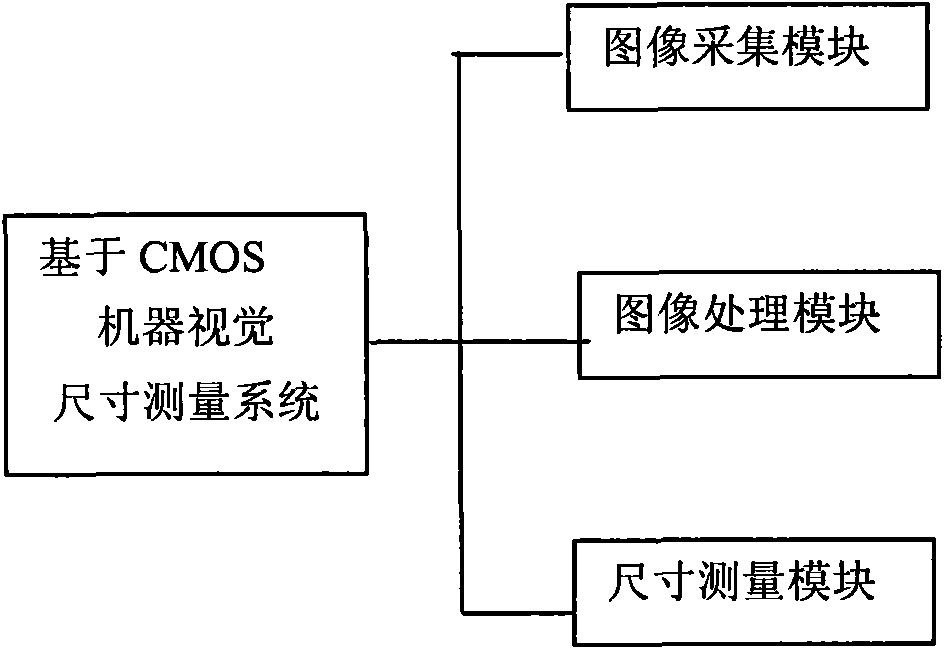

[0028] A dimension measurement system based on CMOS machine vision includes an image acquisition module, an image processing module and a dimension measurement module. figure 1 The overall frame diagram of the automatic part size measurement system based on CMOS machine vision is given. The image acquisition module completes the image acquisition function of the contour edge of the captured part; the image processing module binarizes and filters the collected image, and then passes edge detection to obtain the edge of the part image; the size measurement module extracts and calculates the The pixel value of the edge contour of the measured object can be obtained, and through calibration, the pixel value can directly reflect the size of the part.

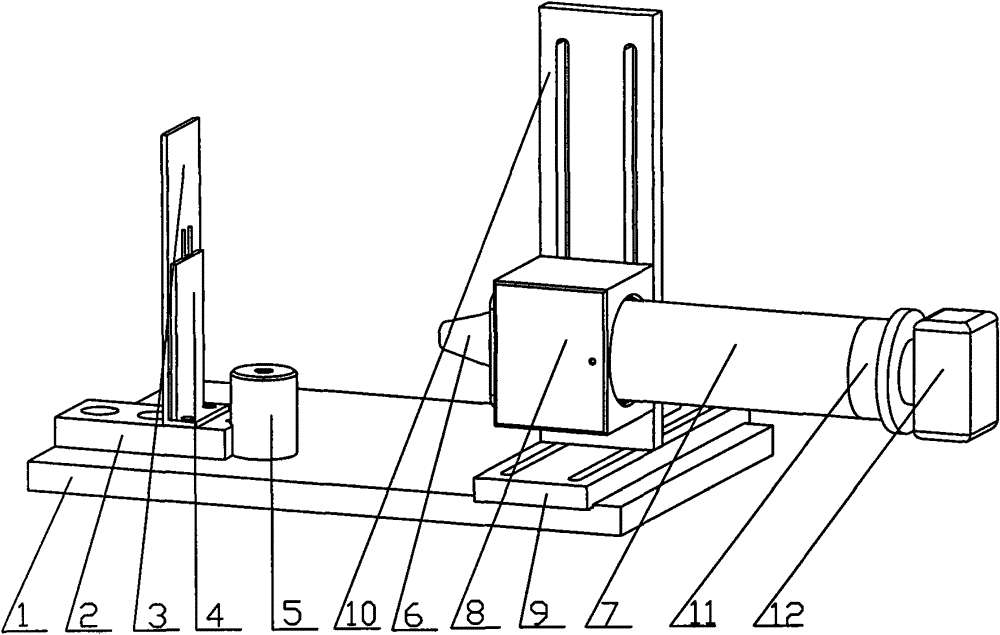

[0029] The structure of the image acquisition module is as follows: figure 2 , including an imaging system and a mechanical part, the mechanical part includes a base plate 1, a positioning block 2, a vertical plate 3, a backlight 4...

Embodiment 2

[0042] The inspection method for whether the part size is qualified or not. A part size measurement system based on CMOS machine vision is composed of a base plate, a positioning block, a vertical plate, a backlight, an imaging system, a horizontal adjustment plate, a vertical adjustment plate, etc. The imaging system is composed of a camera assembly and a camera installation block. The camera assembly includes eyepiece, objective lens, lens barrel and CMOS camera, the positioning block is fixedly installed on the base plate, the vertical plate is fixed on the positioning block by screws, the backlight is fixed on the vertical plate, and the horizontal The adjustment plate is fixedly installed on the base plate, the vertical adjustment plate is installed on the horizontal adjustment plate, and there is a track on the horizontal adjustment plate, and the vertical adjustment plate is installed on the horizontal adjustment plate. The vertical adjustment plate can move on the hori...

Embodiment 3

[0045] A method for measuring the diameter of micro-vias. A part size measurement system based on CMOS machine vision is composed of a base plate, a positioning block, a vertical plate, a backlight, an imaging system, a horizontal adjustment plate, a vertical adjustment plate, etc. The imaging system is composed of a camera assembly and a camera installation block. The plug-in CMOS camera is fixed at the rear end of the camera assembly. The camera assembly is installed on the camera mounting block, which is roughly the same height as the backlight source. The workpiece to be measured is located between the imaging system and the backlight source. The middle area of the image can thus adapt to the size measurement requirements of different parts; the clarity of imaging can be achieved by adjusting the installation position of the mounting block and the camera mounting block, thereby changing the distance between the measured workpiece and the imaging system. Compared with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com