Novel vortex street flowmeter sensor

A vortex flowmeter and sensor technology, which is applied in the direction of volume/mass flow generated by mechanical effects, and through the detection of dynamic effects of fluid flow, etc., can solve problems such as easy aging, poor shock resistance, and high temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

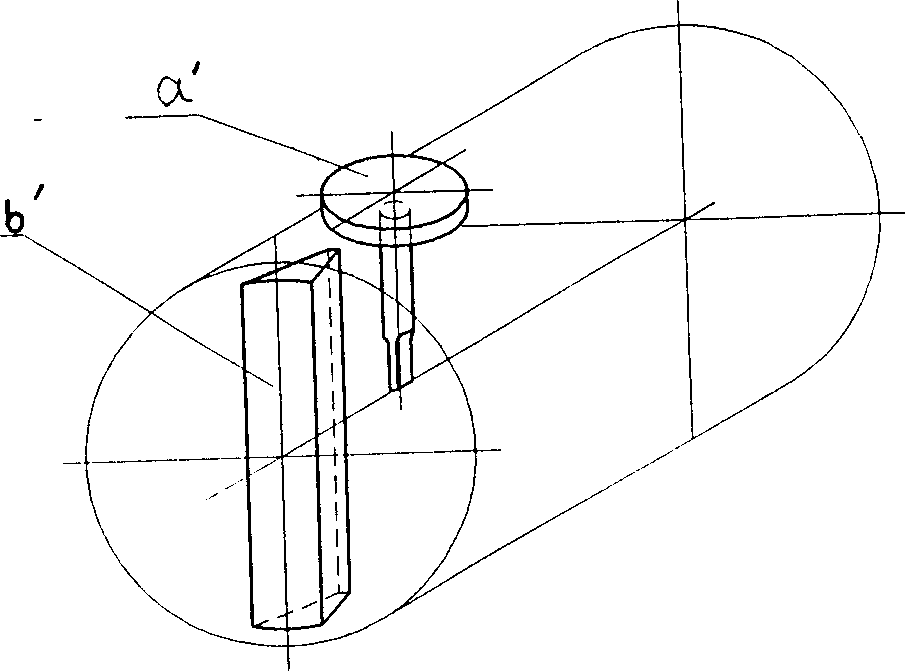

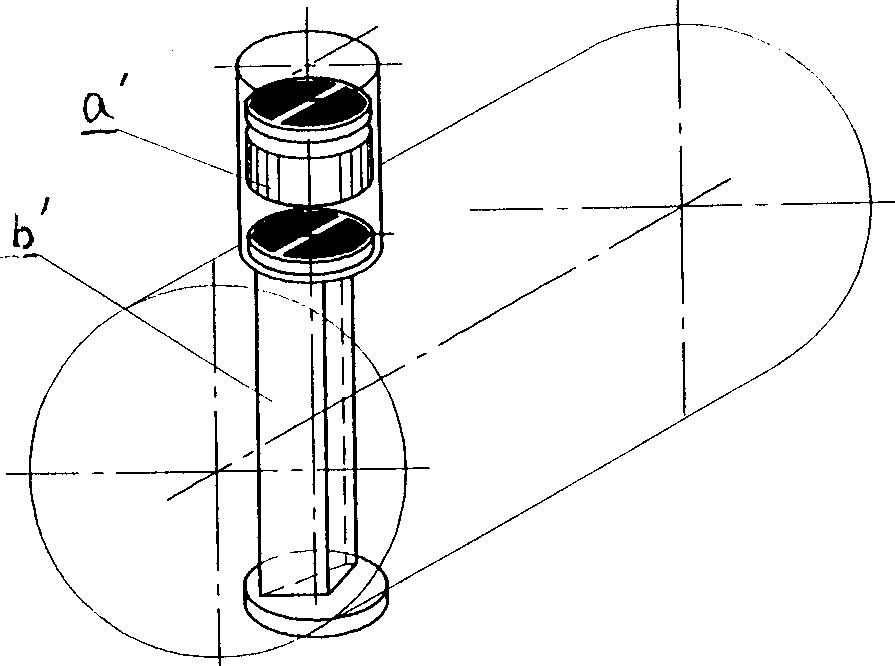

[0022] The figure is the detection element in the prior art is a structure diagram of thickness bending vibration, image 3 It is a schematic diagram of the structure of the wafer thickness vibration type used in the prior art.

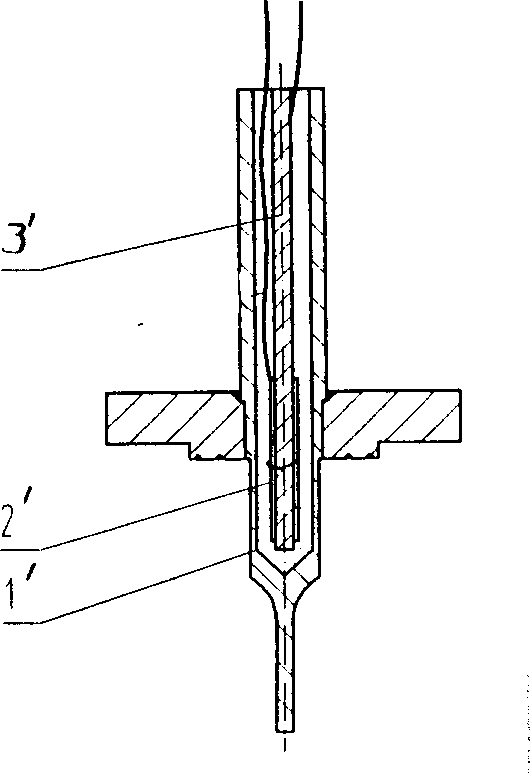

[0023] Figure 4 is a structural design diagram of the present invention, the signal detection element a is located behind the triangular block cylinder b, please refer to Figure 7 --- Figure 14 , which is a cross-sectional structure diagram of several signal detection elements in the present invention, Figure 7 The bottom of the middle probe shell 1 is a plane structure 12, the probe 1 is designed as a round rod, and there is an annular groove 13 on the probe shell 1 to ensure better work of the detection element, and the inner cavity 10 of the probe shell is directly put into the press The electric ceramic garden piece 2, so that one end of the piezoelectric ceramic garden piece 2 is directly attached to the bottom of the inner cavity 10 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com