Electric proportional variable axial plunger pump

A technology of axial plunger pump and plunger pump, which is applied in the direction of pumps, multi-cylinder pumps, liquid variable displacement machines, etc., can solve the problem that the output displacement cannot be changed, achieve good reliability, reduce impact, and simple control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

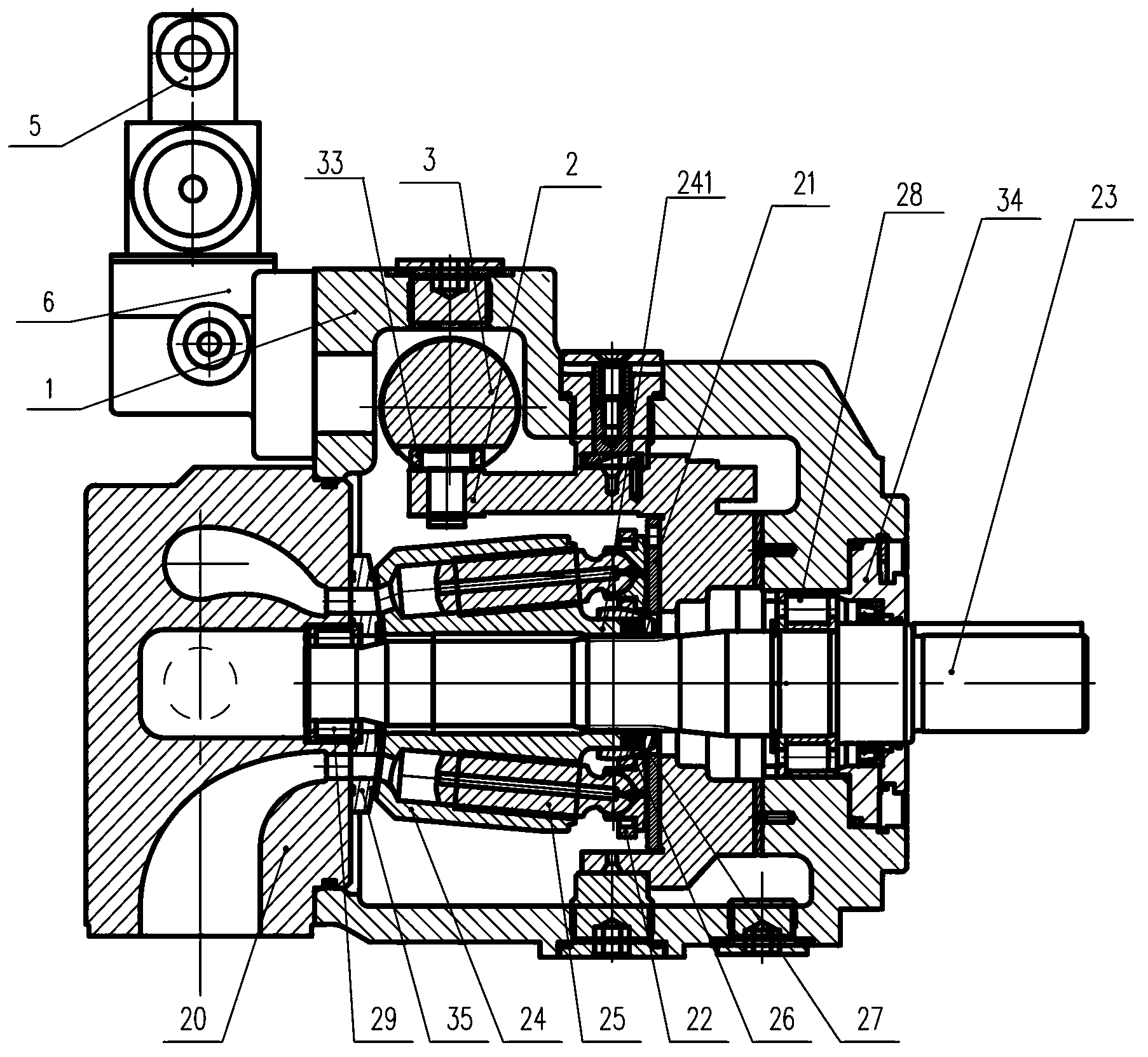

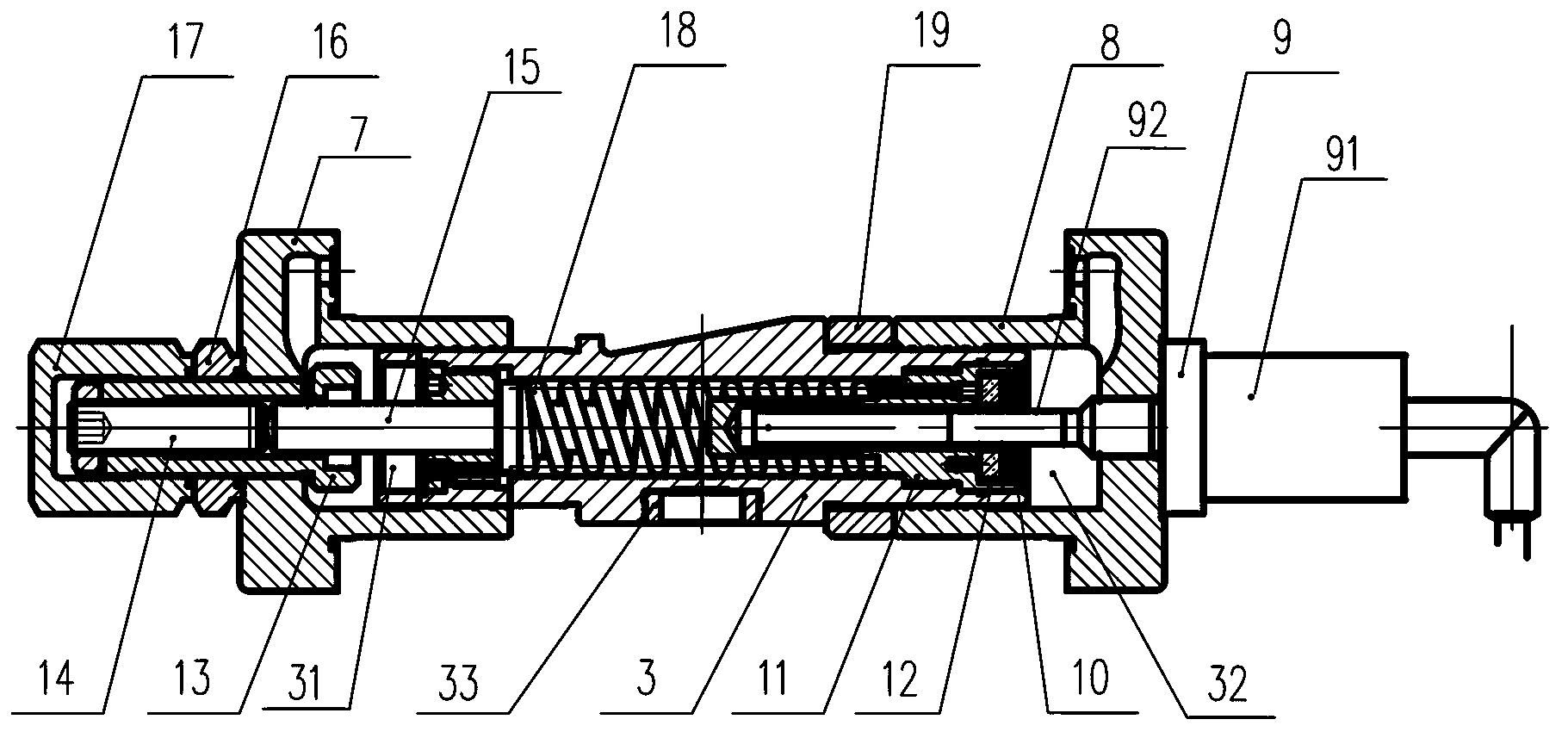

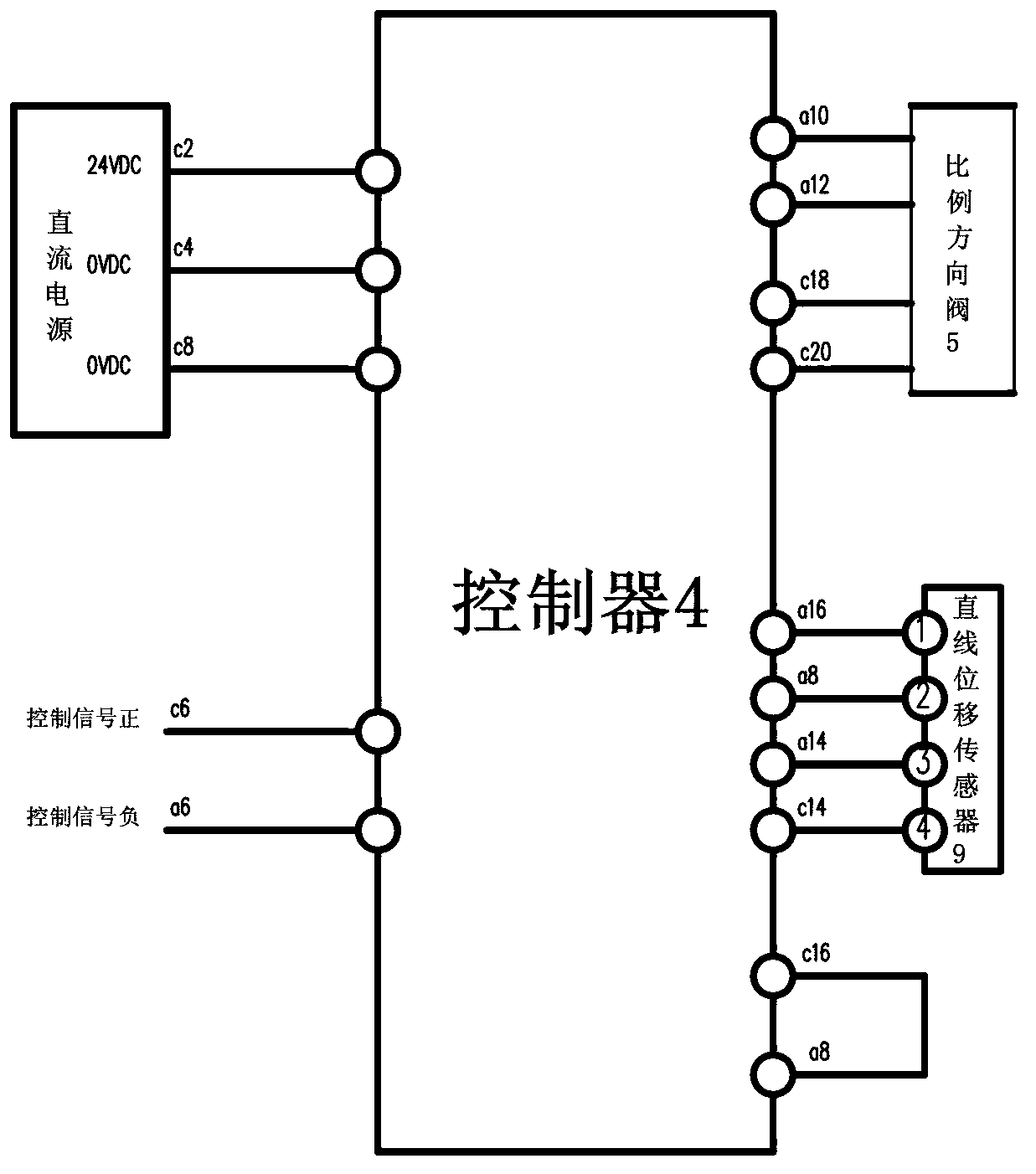

[0020] Embodiment: As shown in the figure, an electronically controlled proportional variable axial plunger pump includes a plunger pump body and a variable mechanism arranged on one side of the plunger pump body. The plunger pump body includes a pump body 1 and a pump body 1 The variable plate 2 in the body 1, the variable mechanism includes the variable piston 3 connected with the variable plate 2 and the first oil chamber 31 and the second oil chamber 32 formed at both ends of the variable piston 3, the variable piston 3 acts through the variable slider 33 On the variable plate 2, a hydraulic control system is also provided outside the pump body 1. The hydraulic control system includes a controller 4, a proportional directional valve 5 connected to the controller 4 and used to control the flow of oil, a transition plate 6 and a valve for monitoring the variable. The detection mechanism for the position of the piston 3, the transition plate 6 is installed outside the pump bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com