Patents

Literature

37results about How to "Magnetic influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

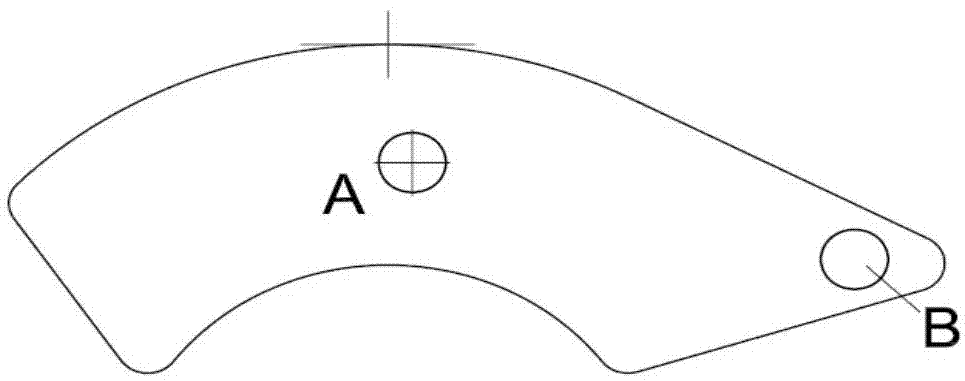

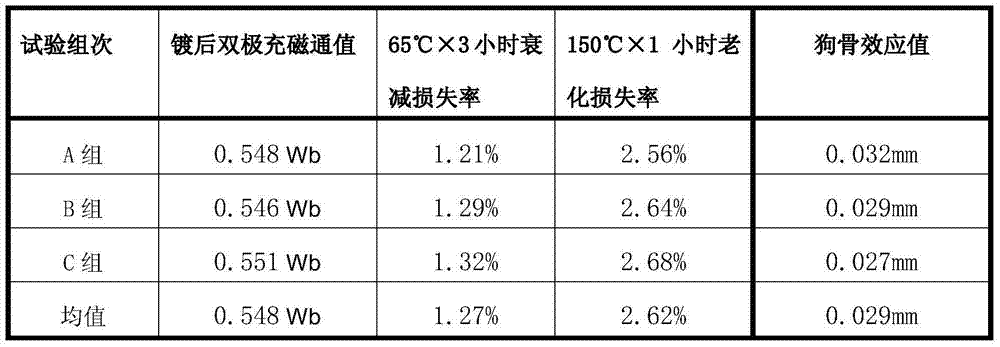

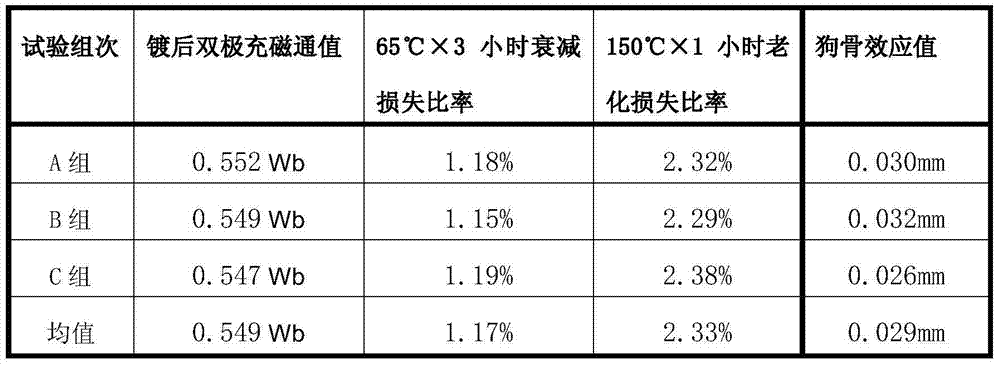

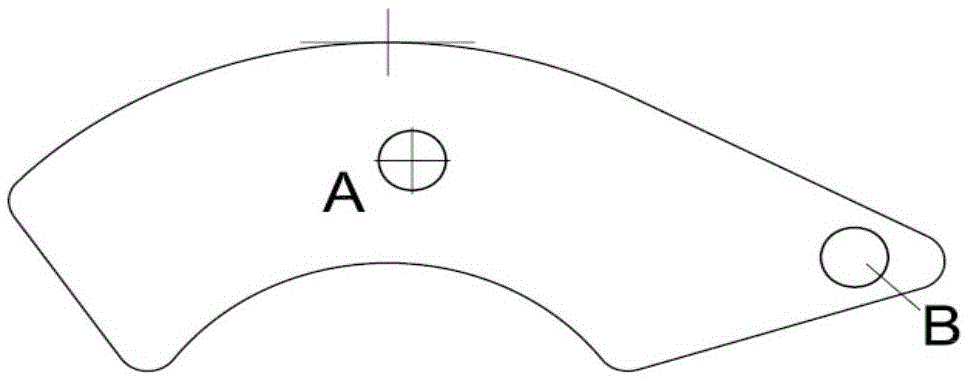

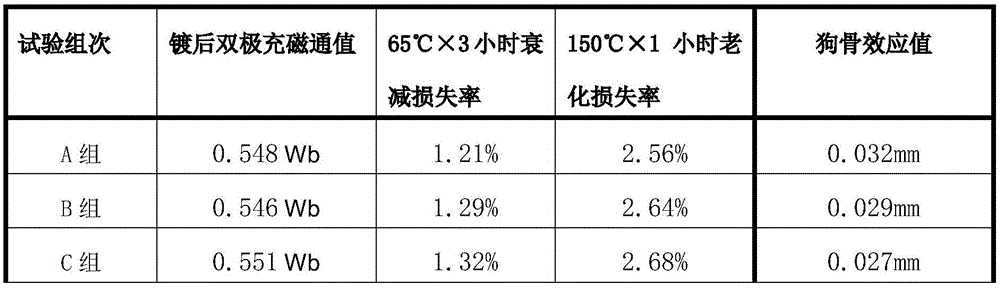

Method for carrying out electronickelling on neodymium-iron-boron magnet

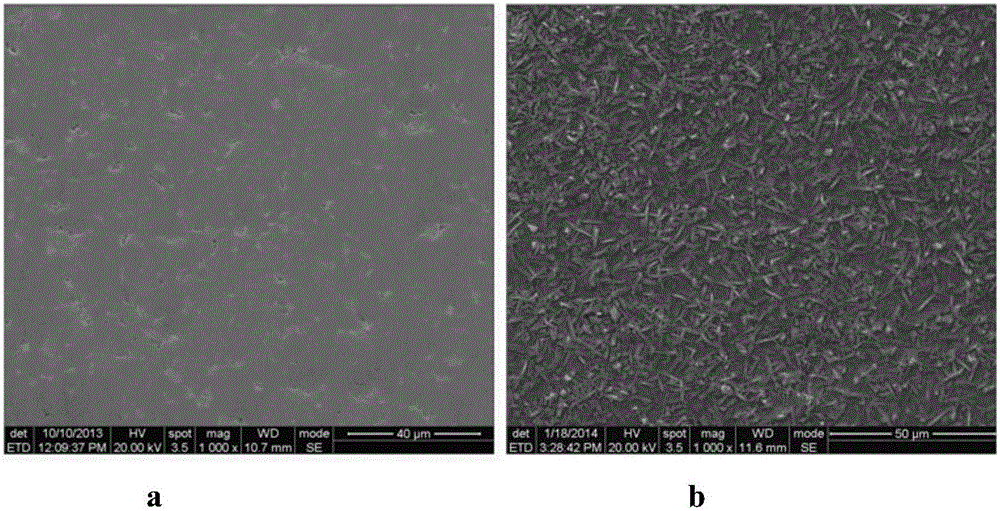

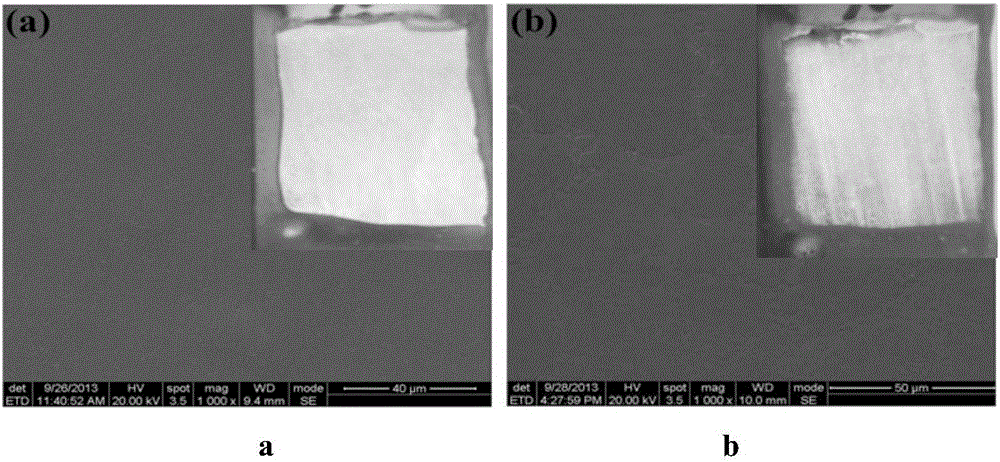

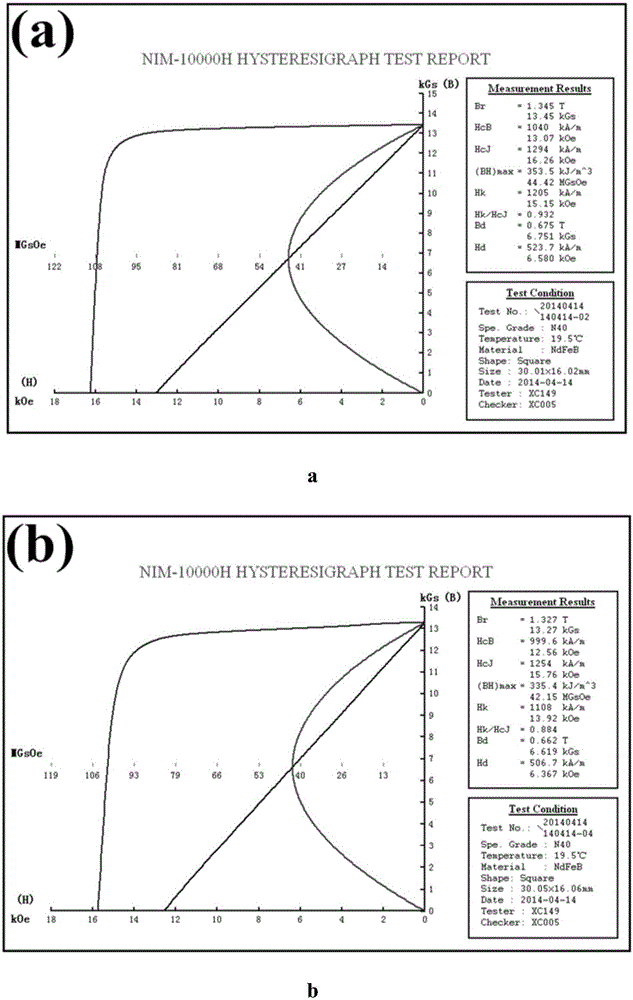

The invention discloses a method for carrying out electronickelling on a neodymium-iron-boron magnet. The method particularly comprises the following steps of: carrying out a pretreatment process, a nickel preplating process, a water washing process, a semi-bright nickel plating process, the washing process, a bright nickel plating process and a water washing process on the neodymium-iron-boron magnet, wherein a first electronickelling solution which comprises nickel sulfate, boric acid, sodium succinate, sodium carboxyethyl sulfonate and water is adopted for the nickel preplating process; a second electronickelling solution which comprises nickel sulfate, diammonium hydrogen citrate, the boric acid, ammonia water and water is adopted for the semi-bright nickel plating process; the first electronickelling solution is free of chloride ions, and the first electronickelling solution contains the sodium succinate and the sodium carboxyethyl sulfonate; the second electronickelling solution contains a proper amount of diammonium hydrogen citrate. The method disclosed by the invention can ensure that the neodymium-iron-boron magnet has better magnetic property by reducing the influence of an electroplating process on the magnetic property of the neodymium-iron-boron magnet and achieves uniform distribution of coating thickness when a product with a smaller end part angle is electroplated.

Owner:NINGBO YUNSHENG +4

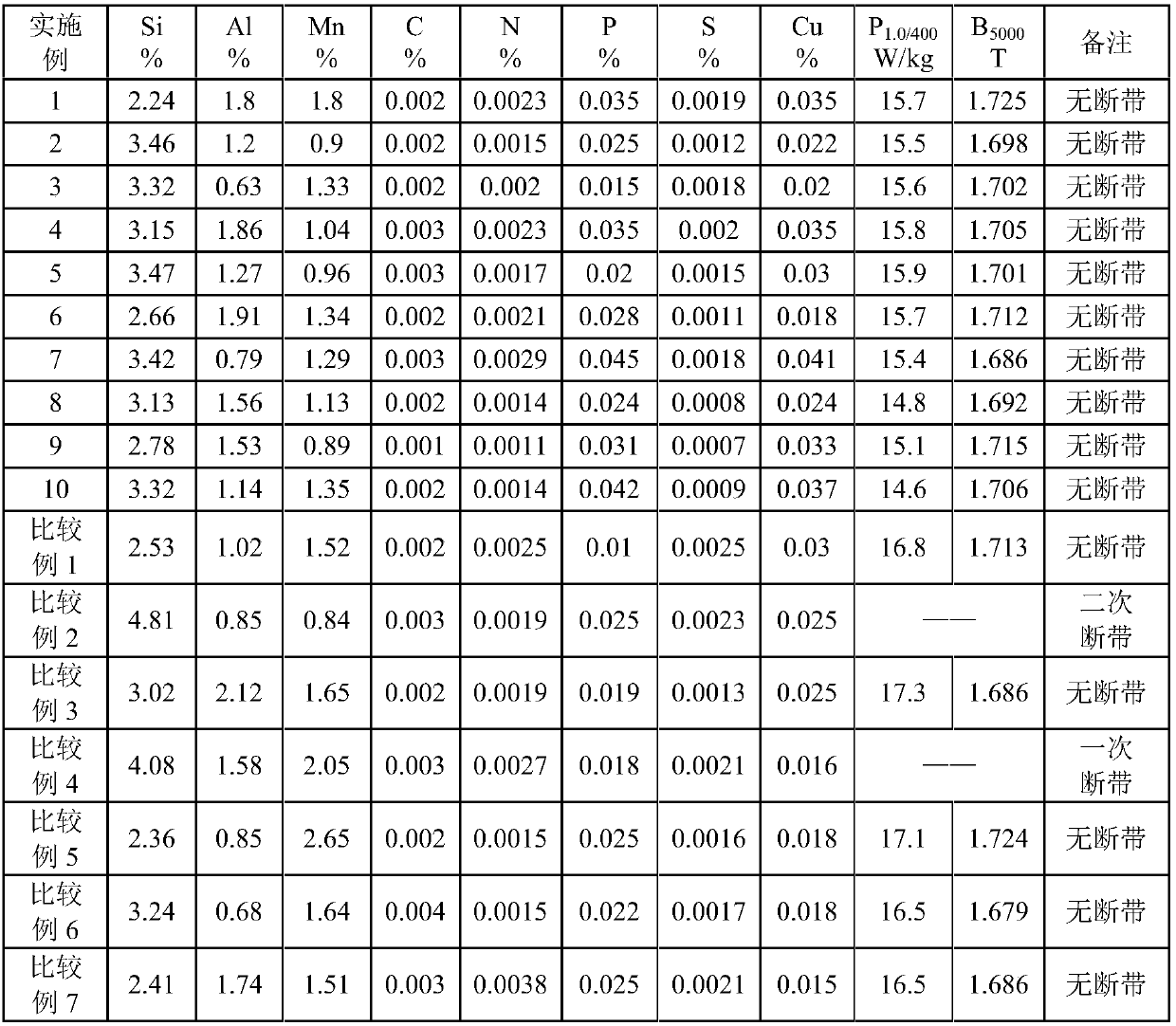

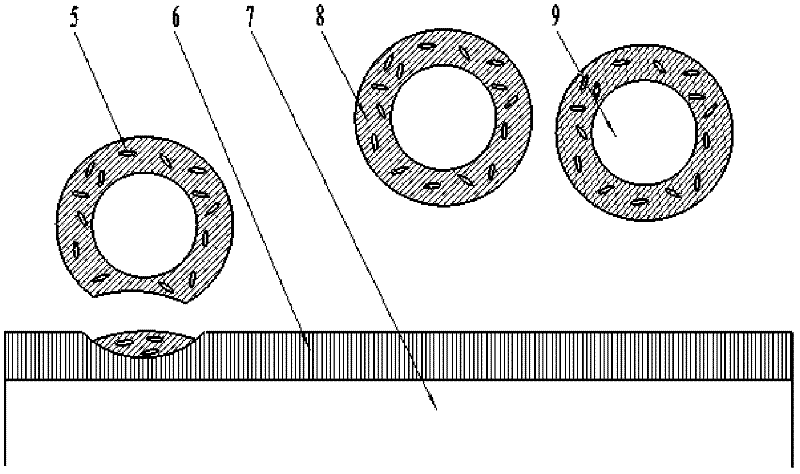

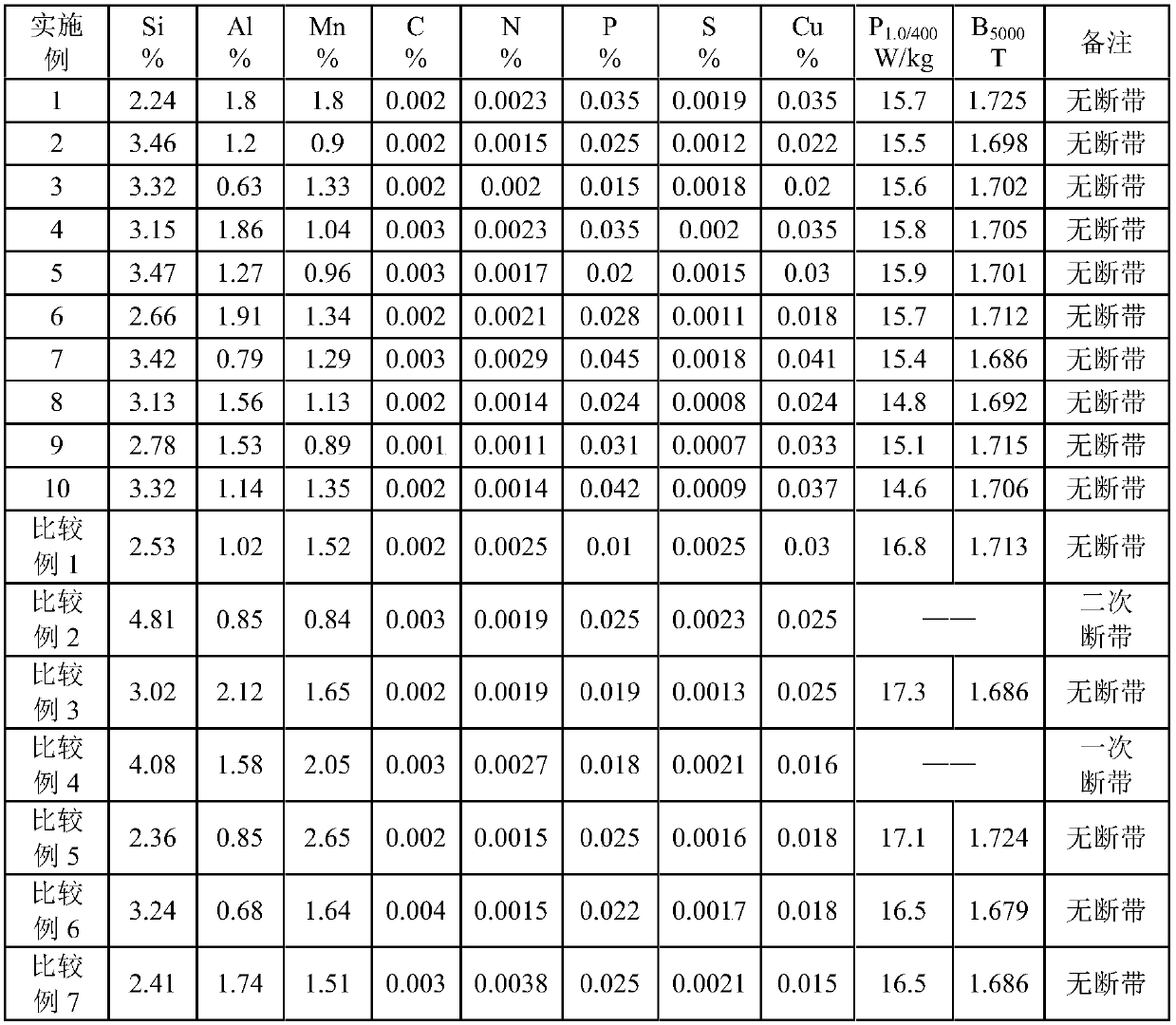

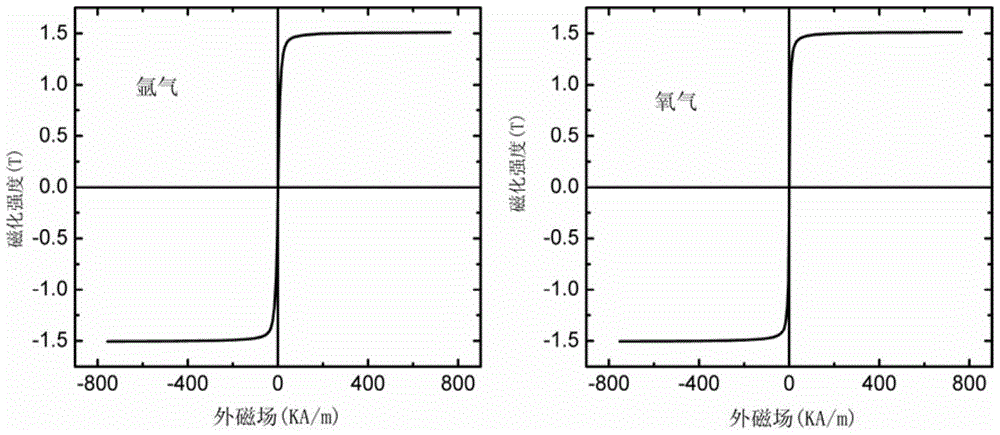

Non-oriented silicon steel with excellent magnetism and for drive motor of electric car, and production method thereof

The invention provides non-oriented silicon steel with excellent magnetism and for a drive motor of an electric car. The non-oriented silicon steel comprises, by weight, 1.0 to 3.5% of Si, 0.5 to 2.0%of Al, 0.5 to 2.0% of Mn, no more than 0.003% of N, no more than 0.002% of S, no more than 0.003% of C, no more than 0.05% of P and no more than 0.05% of Cu. The production method for the non-oriented silicon steel comprises the following steps: smelting and casting; heating of continuously cast billet; rough rolling; finish rolling; reeling; normalizing; pickling; single-stage cold rolling; annealing; segmental speed-variable cooling; and natural cooling to room temperature for subsequent usage. With the method in the invention, the total number of AlN, MnS and Cu<x>S precipitates is no morethan 200 * 10<6> / mm<3>, the average size of the precipitates is no less than 0.50 [mu]m, and residual stress after annealing and cooling is no more than 70 MPa, so unfavorable influence of the AlN, MnS and Cu<x>S precipitates and residual stress on magnetism is effectively inhibited, and the produced non-oriented silicon steel for the drive motor of the electric car has a thickness of 0.27 to 0.35 mm, P<1.0 / 400> of no more than 16.0 W / kg and B<5000> of no less than 1.65 T.

Owner:武汉钢铁有限公司

Method for forming aluminum coating on surface of neodymium iron boron magnet

ActiveCN102389871ASimple processShorten the timePretreated surfacesCoatingsCorrosionAluminum coating

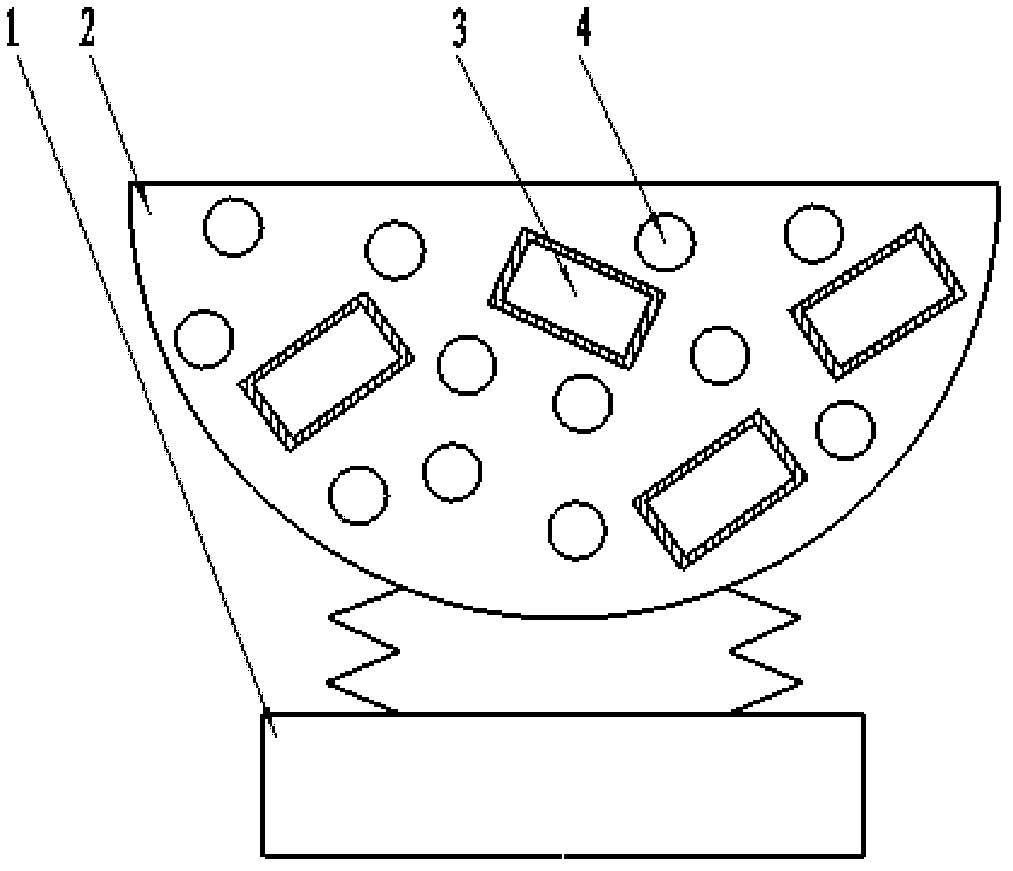

The invention relates to a method for forming an aluminum coating on the surface of a neodymium iron boron magnet and belongs to the technical field of magnet surface treatment. An adopted mechanical aluminum-plating process comprises the following steps of: colliding an impacting medium having aluminum coating powder on the surface thereof with the surface of a plated piece under an action of external mechanical vibration, thereby transferring the aluminum coating powder from the surface of the impacting medium to the surface of the plated piece; heating and solidifying the plated piece; and finally, forming a corrosion-resistance coating on the surface of the plated piece. The method provided by the invention has the advantages that the process is simpler and has a shorter time, the consumption of resources such as water, electricity and the like is low, and the raw materials used in the method, such as aluminum, epoxy resins and the like are low in costs, so that the total cost is greatly lowered.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

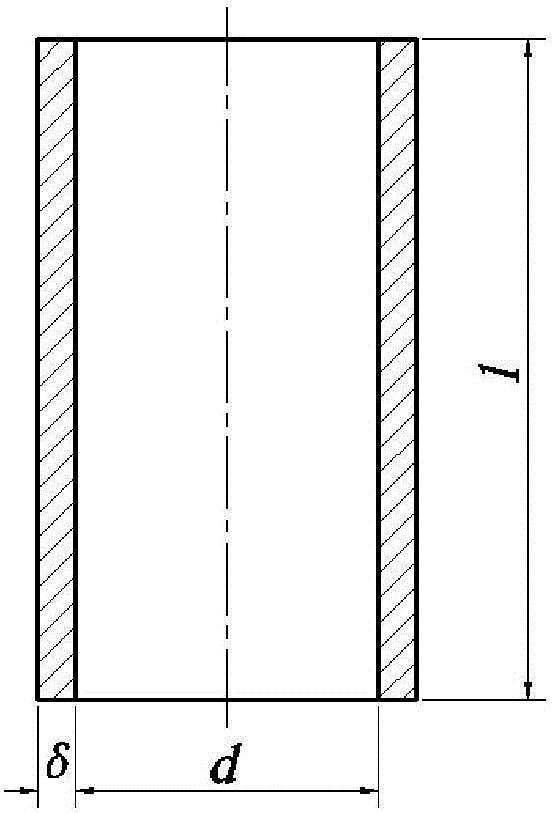

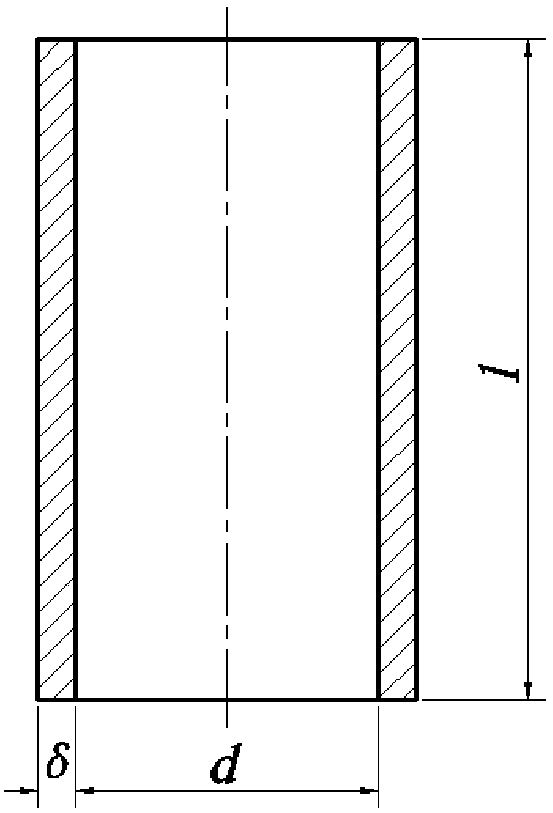

Spinning forming method for manufacturing magnetically soft alloy cylindrical part

ActiveCN106391810AIncrease profitImprove processing efficiencyFurnace typesHeat treatment furnacesReduction rateAlloy

The invention discloses a spinning forming method for manufacturing a magnetically soft alloy cylindrical part. The method includes the steps that the geometric dimensions of a cylindrical blank are determined according to the principle that the material size is not changed in the plastic deformation process, the actual wall thickness of the thin-wall cylindrical part, the requirement for trimming after forming and the design principle that the wall thickness reduction rate is 40%-80%; the pipe blank is heated to 700 DEG C, and preheating is carried out after 0.5h of heat preservation; multi-pass staggered spinning forming is carried out on the cylindrical blank to enable the wall thickness to be reduced to a predetermined value; a workpiece subjected to spinning forming is heated to 1100-1180 DEG C in vacuum protection, heat preservation is conducted for 3-6h, then the workpiece is cooled to 600 DEG C at the speed which is not higher than 200 DEG C / h and continues to be cooled to 200 DEG C at the speed not smaller than 400 DEG C / h, and the workpiece is discharged out of a furnace and subjected to final heat treatment to improve the magnetic performance of the material; and excess materials at the two ends of the workpiece are cut off, so that a final product is obtained. By means of the spinning forming method for manufacturing the magnetically soft alloy cylindrical part, the cylindrical part with high forming quality and good soft magnetism performance can be obtained, and the defects that a traditional machining method is low in material utilization rate, poor in forming quality, prone to flux leakage and the like are overcome.

Owner:SOUTH CHINA UNIV OF TECH

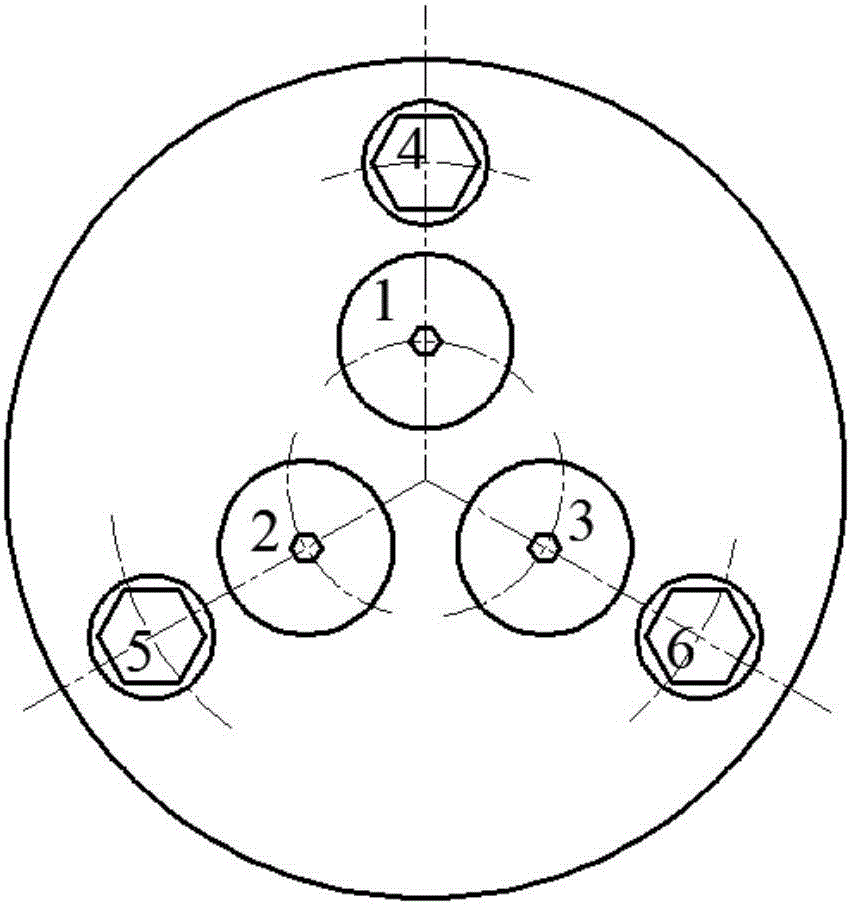

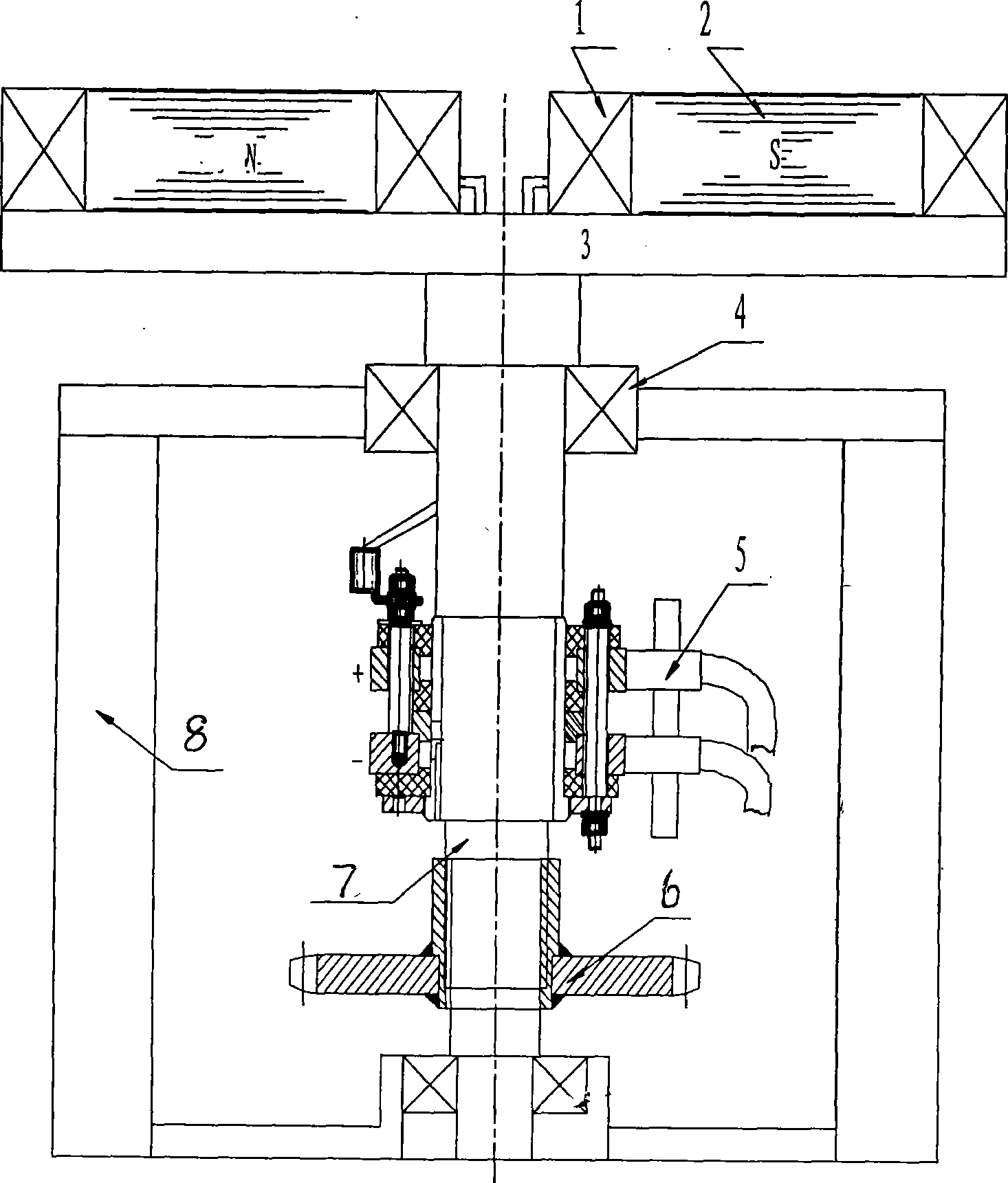

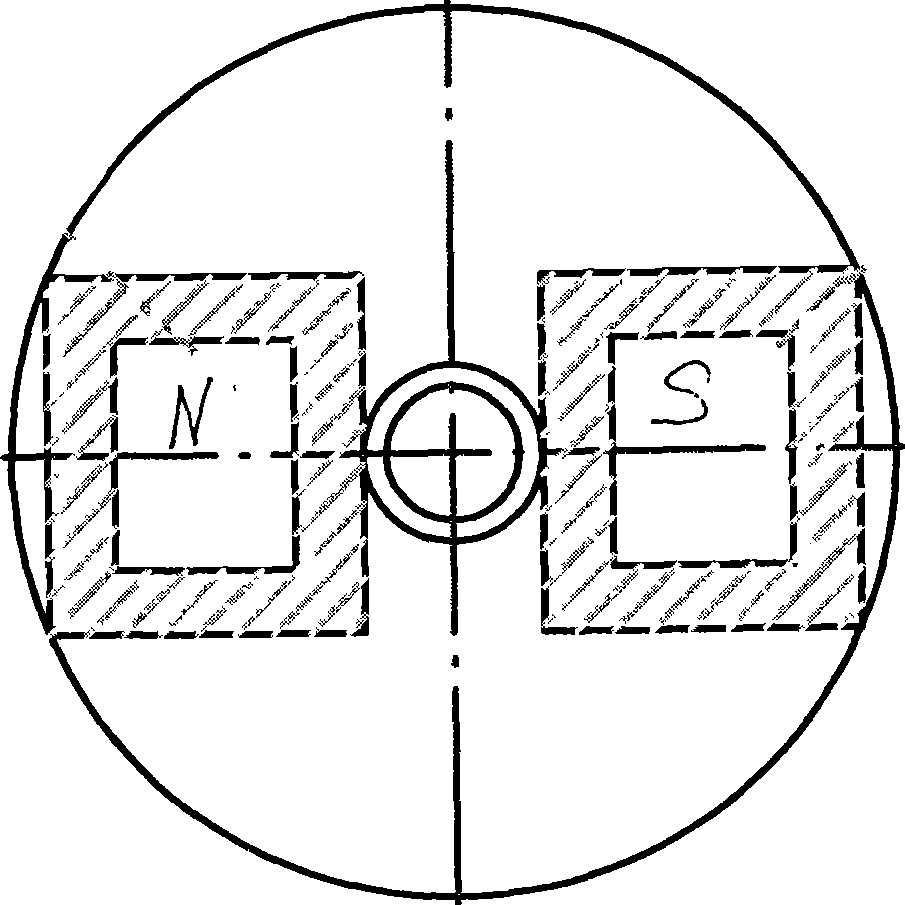

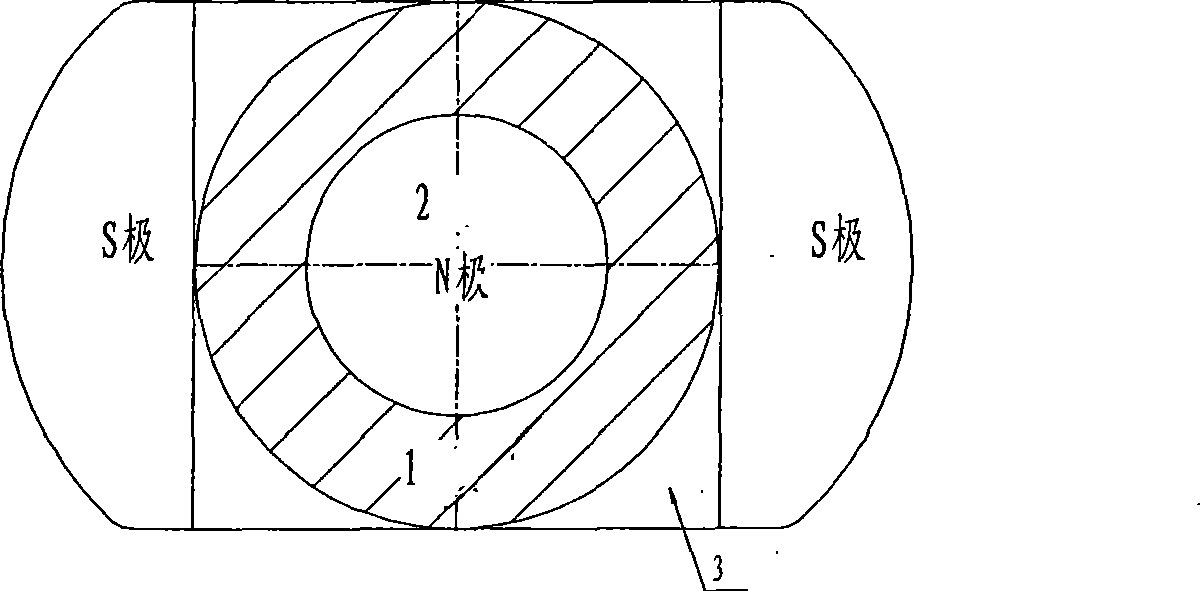

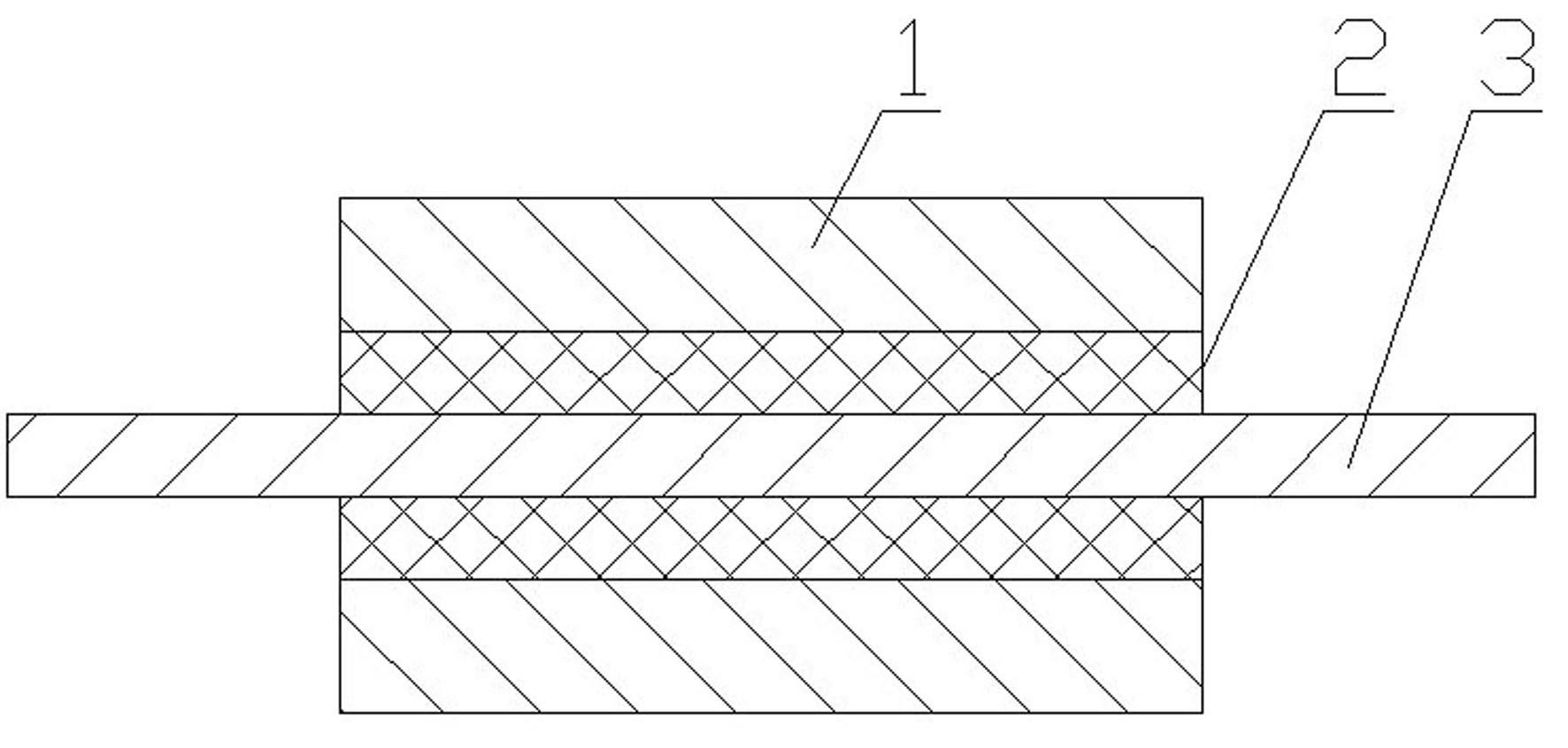

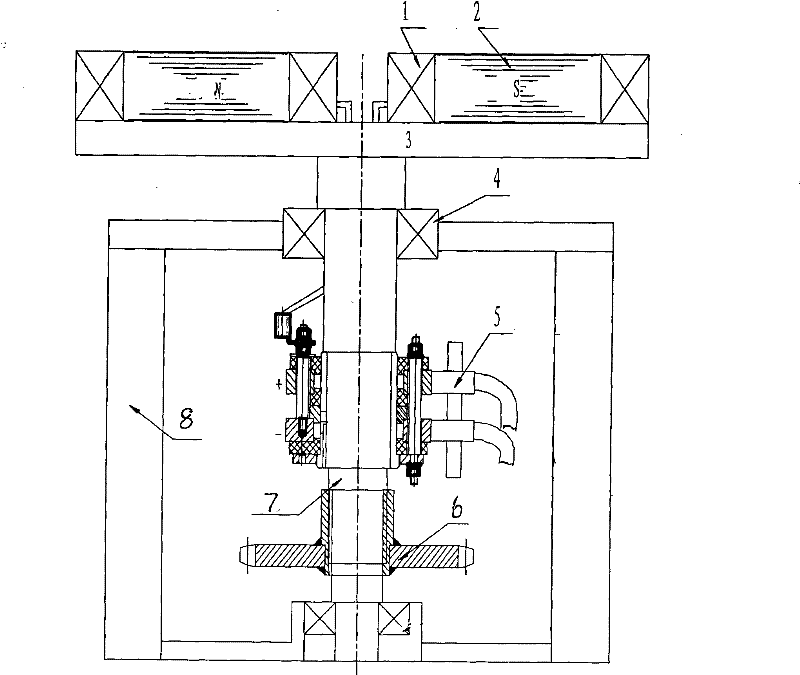

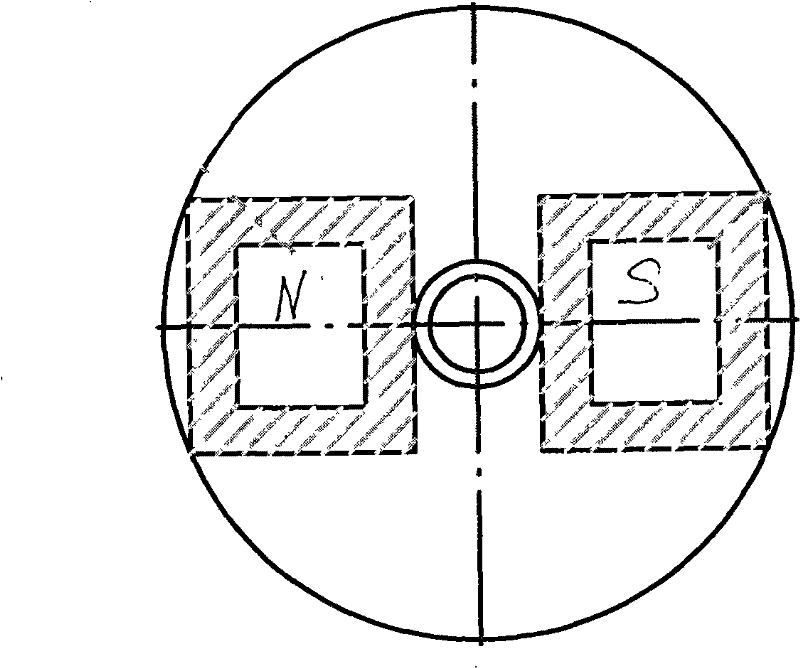

Bottom assembling electromagnetic agitator for direct current excitation smelting furnace

InactiveCN101509730ALow priceInexpensive materialsMechanical apparatusStirring devicesEngineeringSmelting

The invention discloses a bottom-mounted electromagnetic stirrer used for a direct current (DC) electric-excitation melting furnace, consisting of an exciter coil, an iron core, a yoke iron, a collector ring, a mainshaft, a bracket, a rectifier system and a trailing system. The electromagnetic mixer is mainly characterized in that a DC power supply supplies the power to the exciter coil, namely, the magnetic field source of the stirrer is provided by a DC electromagnet consisting of a magnetic pole which consists of the iron core and the coil with DC. The stirrer has low material cost, the magnetism is not affected by the environmental temperature, the coil can be replaced during the malfunction, and therefore, the mixer has more advantages than an electromagnetic stirrer working at low frequency and a permanent magnetic mixer which uses the permanent magnets.

Owner:张森林

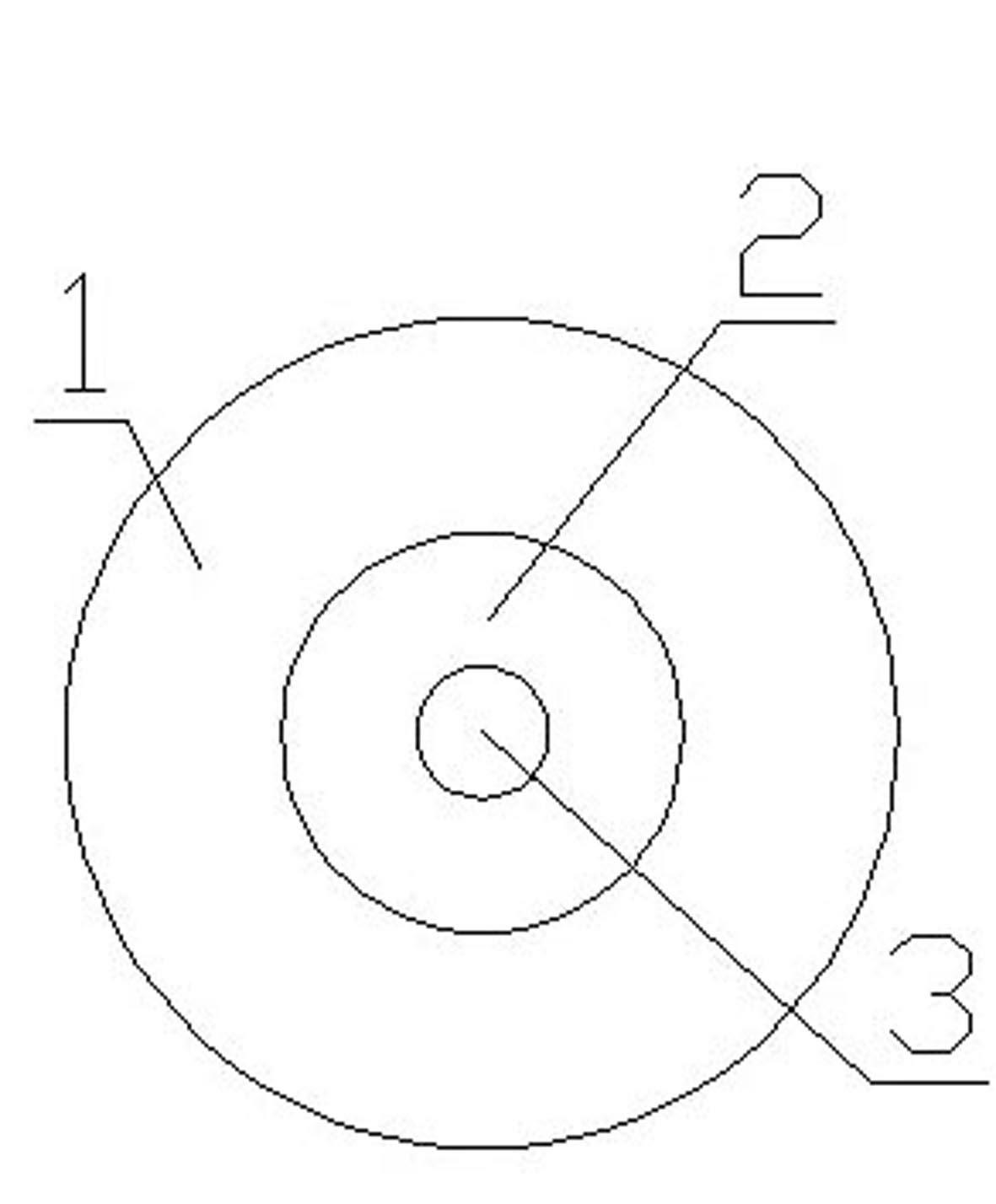

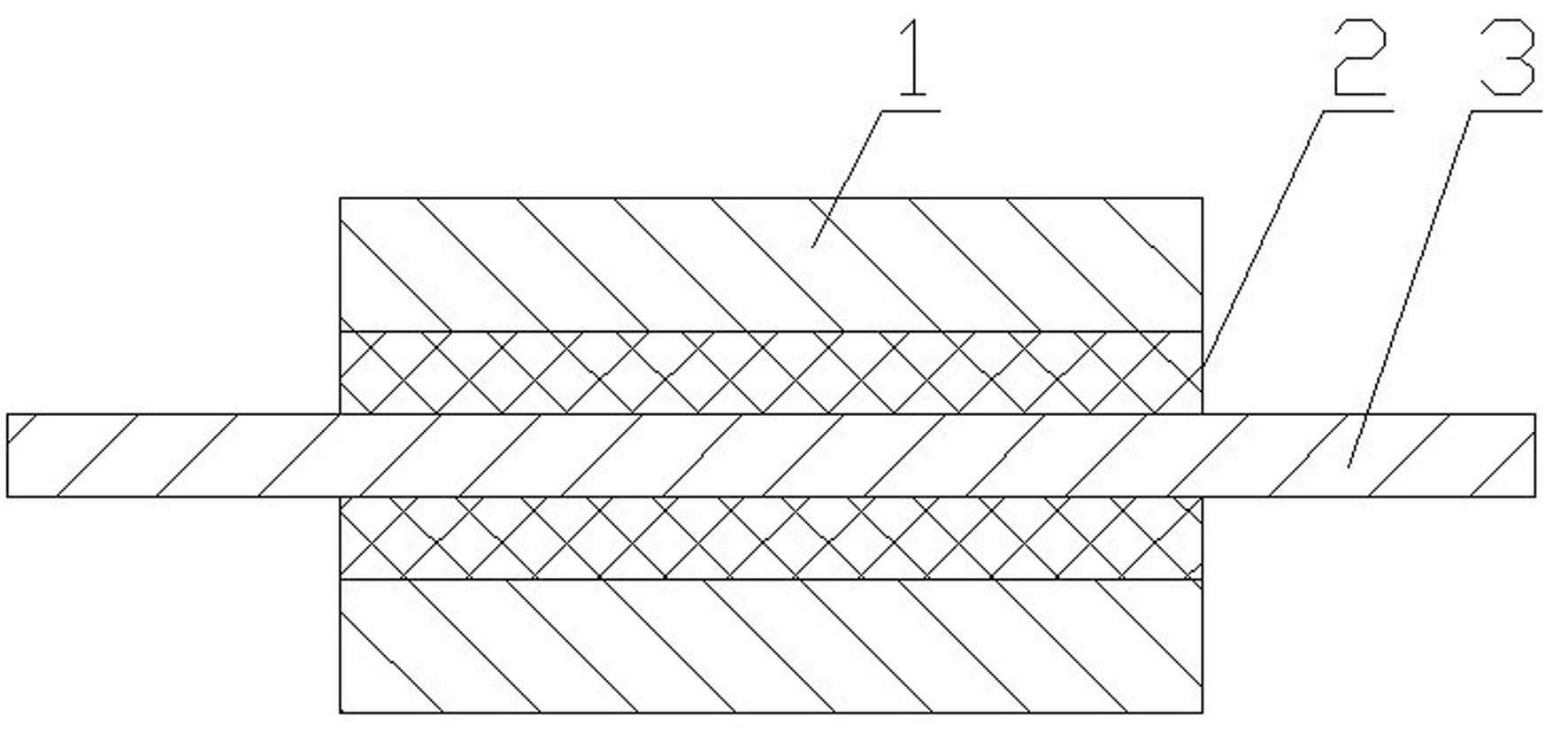

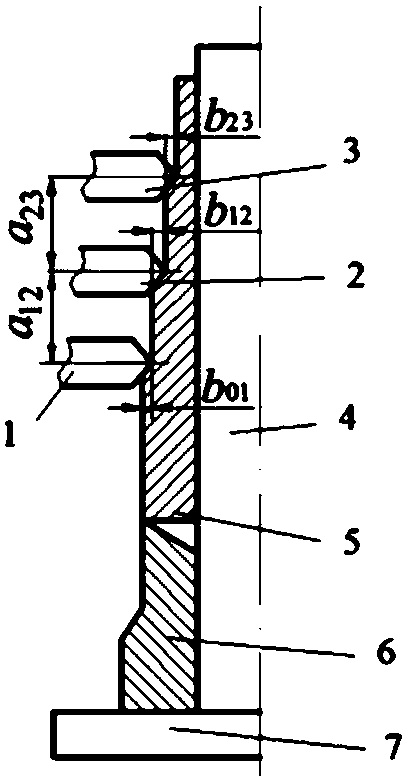

Method for manufacturing plastic bonded permanent magnet rotor with buffering layer

ActiveCN102324812AAvoid crackingCrack improvement or avoidanceManufacturing stator/rotor bodiesPermanent magnet rotorEngineering

The invention discloses a method for manufacturing a plastic bonded permanent magnet rotor with a buffering layer, belonging to the field of permanent magnet rotors. The technical scheme is that: the plastic bonded permanent magnet rotor comprises a metal shaft and a bonded permanent magnet; and the buffering layer is formed between the metal shaft and the bonded permanent magnet. The manufacturing method comprises the following steps of: I, molding and processing the buffering layer onto the outer side of the metal shaft by adopting a die pressing or injection molding way to form a semi-finished product; and II, molding and processing the bonded permanent magnet onto the outer side of the buffering layer by adopting an injection molding way or die pressing way to form a finished product. The invention has the beneficial effects that: the plastic bonded permanent magnet rotor with the buffering layer designed by the invention can be produced without changing the conventional production process and production equipment in the manufacturing method, and industrialization is facilitated; in the manufactured plastic bonded permanent magnet rotor, a buffering layer structure is arranged, so that the plastic bonded permanent magnet rotor can be effectively prevented from cracking in the molding processing or using process; and simultaneously, the cost is lowered.

Owner:QINGDAO UNIV OF SCI & TECH

External rotor alternating current (AC) independent excitation permanent magnet reluctance motor

InactiveCN106100274AReduce dosageReduce adverse effects of magnetic propertiesMagnetic circuit rotating partsSynchronous machine detailsMagnetic polesPermanent magnet motor

The invention relates to an external rotor AC independent excitation permanent magnet reluctance motor. The external rotor alternating current (AC) independent excitation permanent magnet reluctance motor is characterized in that a rotor support is provided with permanent magnet units and magnetizer units, which have the same quantity, and are arranged in an alternate, annular, and radially equalized manner, and in addition, gaps are arranged between the magnetizer units and the adjacent permanent units; during the rotation of the rotor support, all of the permanent magnet magnetic pole end surfaces of the permanent magnet units and all of the magnetizer end surfaces of the magnetizer units are capable of whisking excitation magnetic pole end surfaces of all of excitation body units on a stator base sequentially, and are superposed with the excitation magnetic pole end surfaces sequentially to form a shortest closed magnetic loop. The external rotor AC independent excitation permanent magnet reluctance motor is advantageous in that bad influences on the performance of the permanent magnet caused by current commutation of the excitation coils of the excitation body units are reduced, and the consumption of the permanent magnet is reduced, and excitation power supply commutation frequency is reduced, and the integral torque of the motor is improved; a parallelogram permanent magnet and magnetizer technical scheme provided by the invention is used to further eliminate a setback phenomenon, and then the operation of the motor is smoother.

Owner:戴珊珊

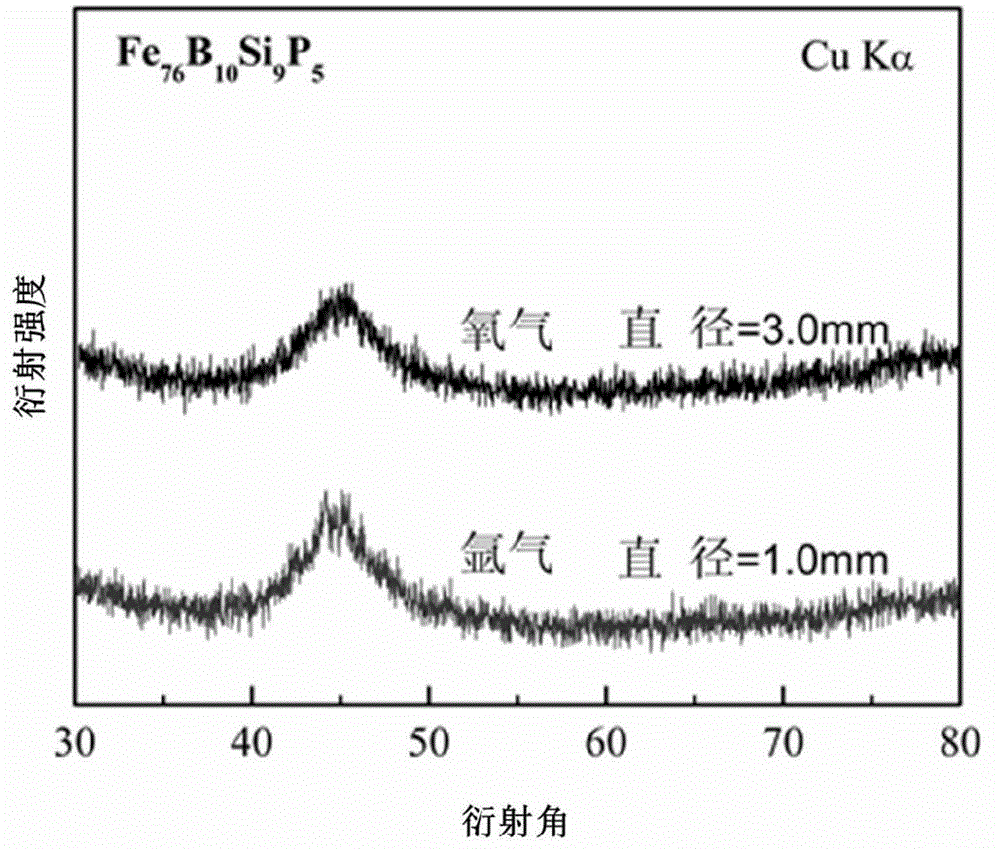

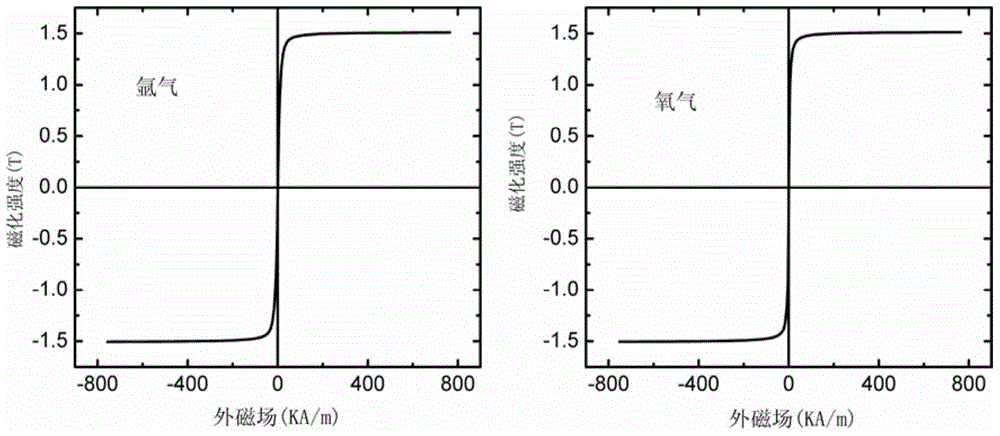

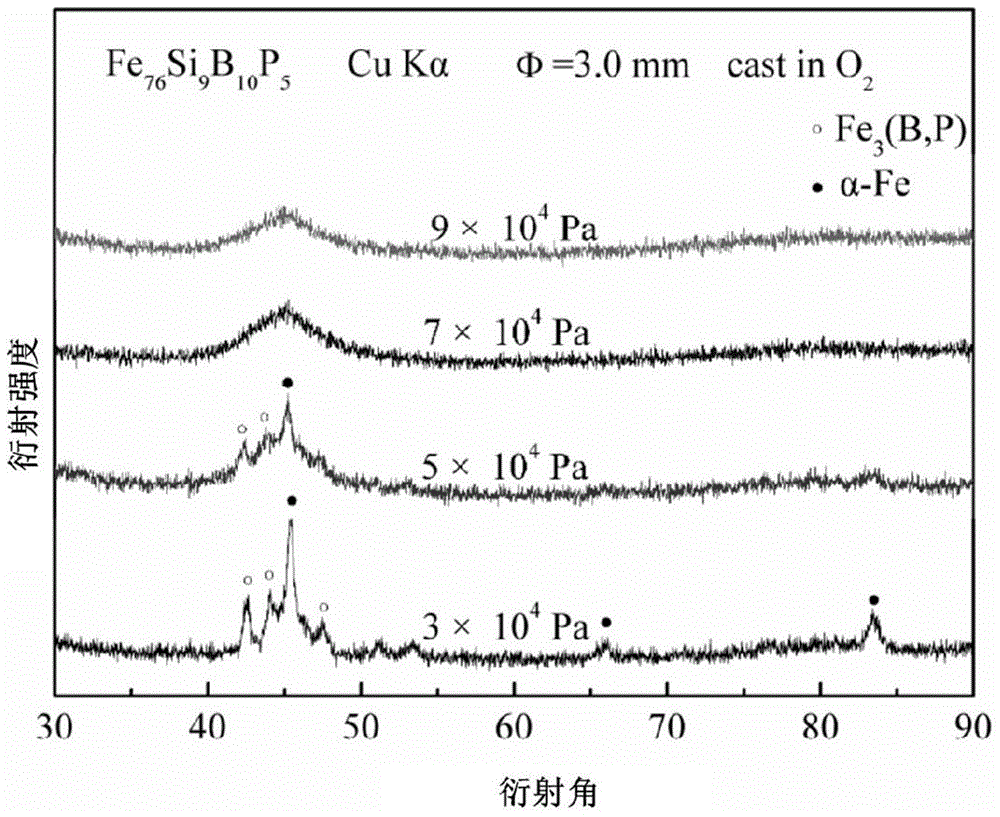

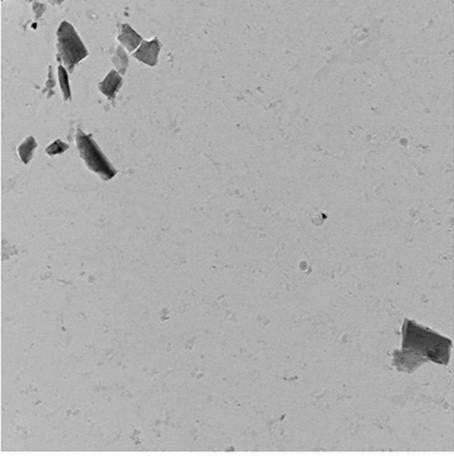

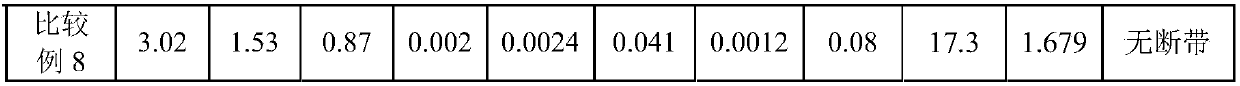

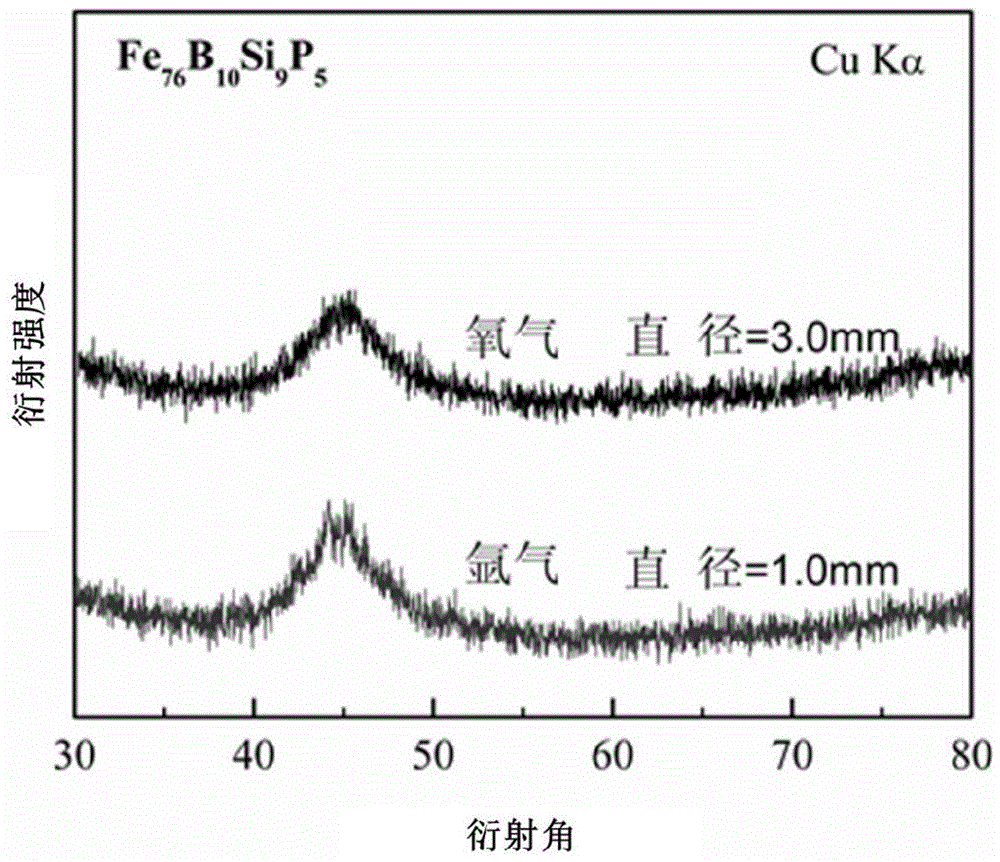

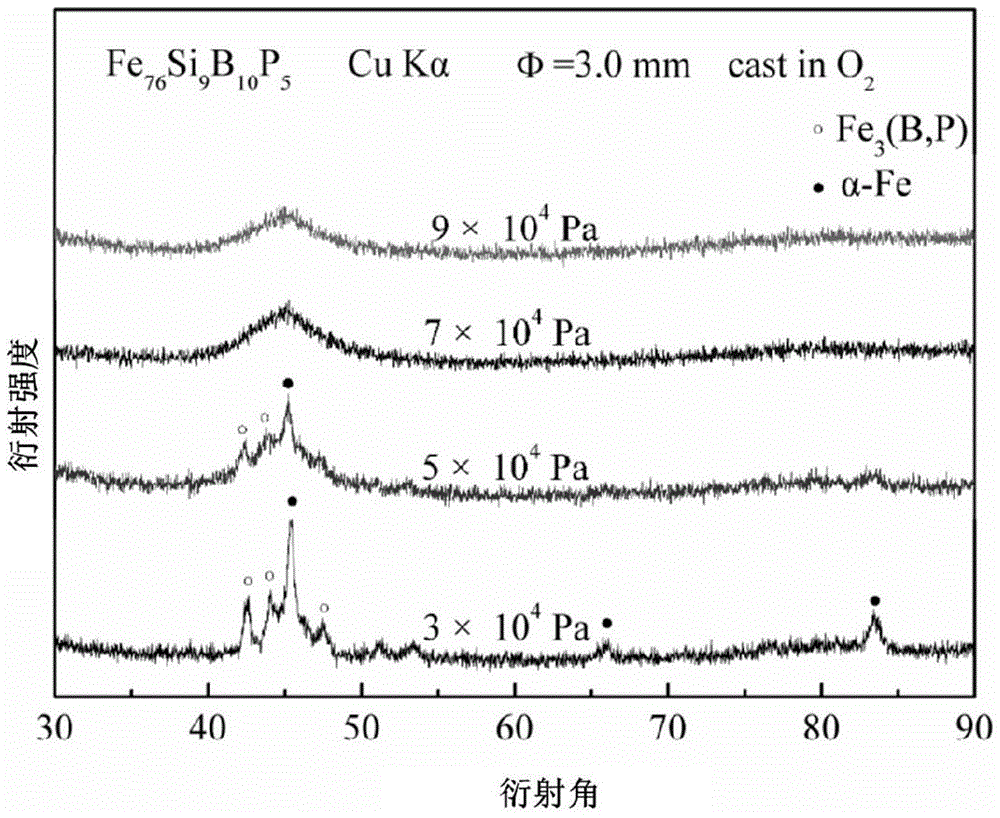

Method for improving glass forming ability of Fe-Si-B-P series block amorphous alloy

The invention provides method for improving the glass forming ability of Fe-Si-B-P series block amorphous alloy. The method is characterized in that when a molten mother alloy liquid is used to prepare a block alloy material through adopting a copper mold casting technology, the casting process is carried out in oxygen-containing atmosphere. Experiments confirm that the method can improve the glass forming ability of alloy, does not introduce too many other elements into amorphous alloy components, does not have great influences on the magnetic performance or other performances of the amorphous alloy, and allows conditions to be simply and easily controlled, so the method has good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

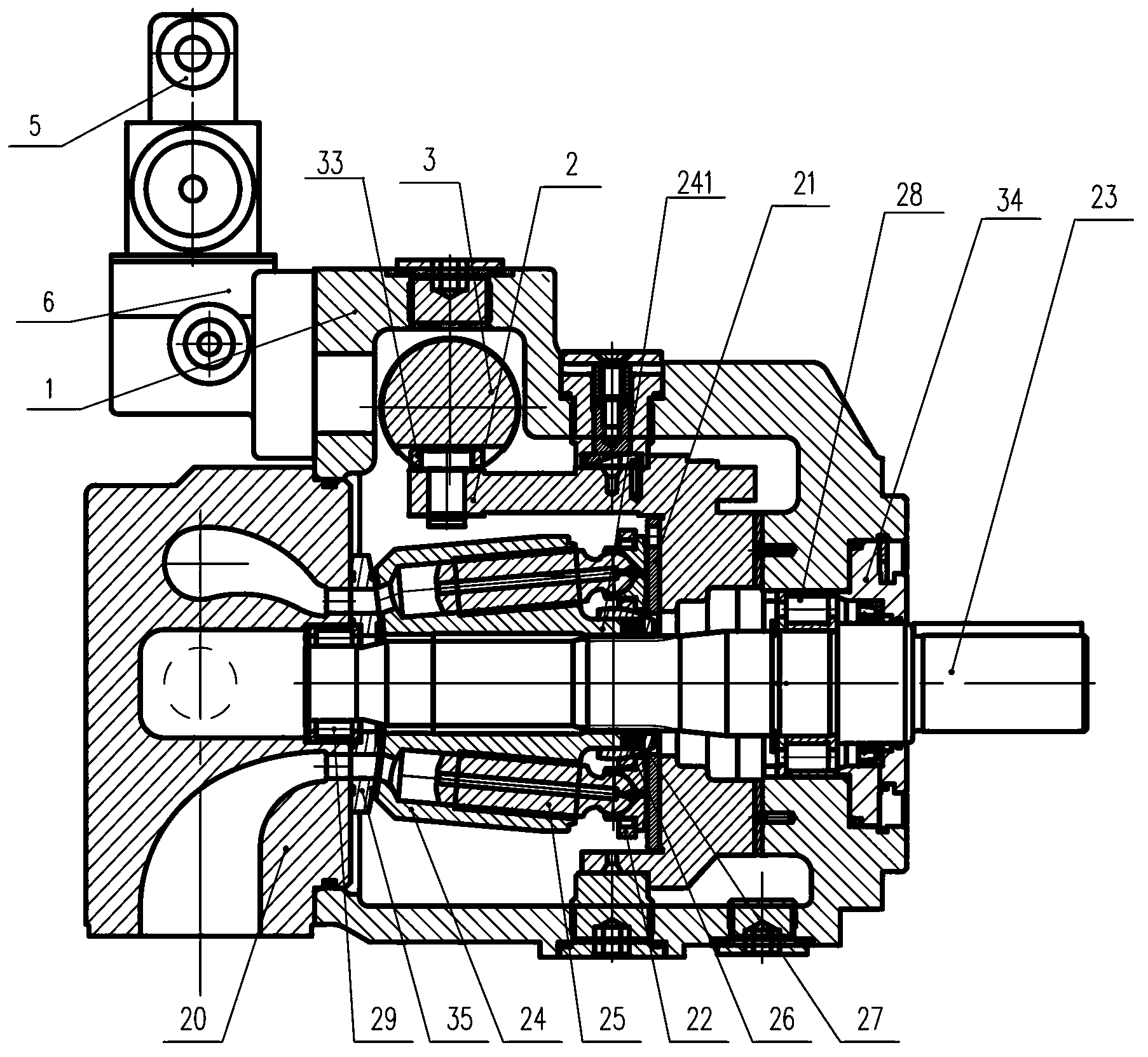

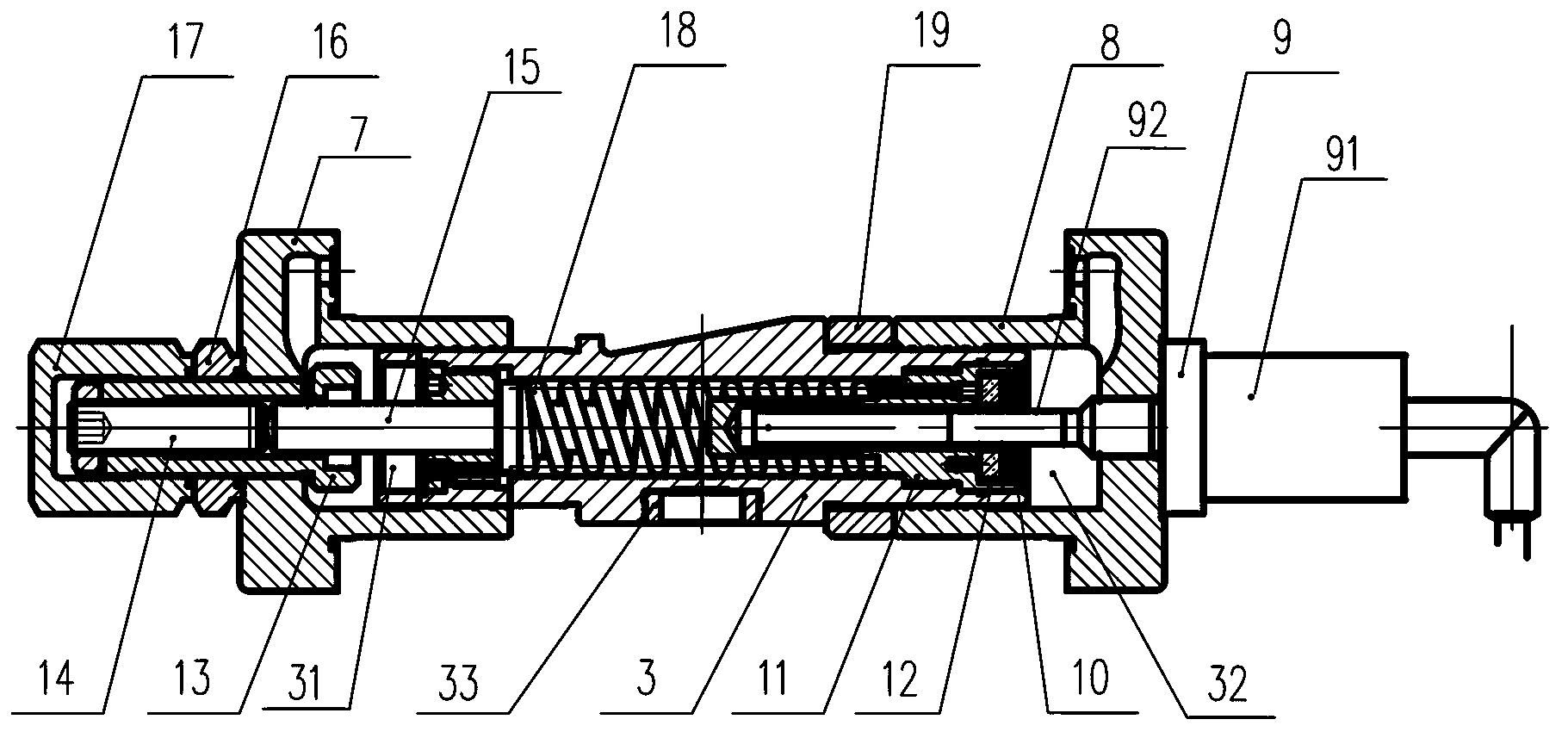

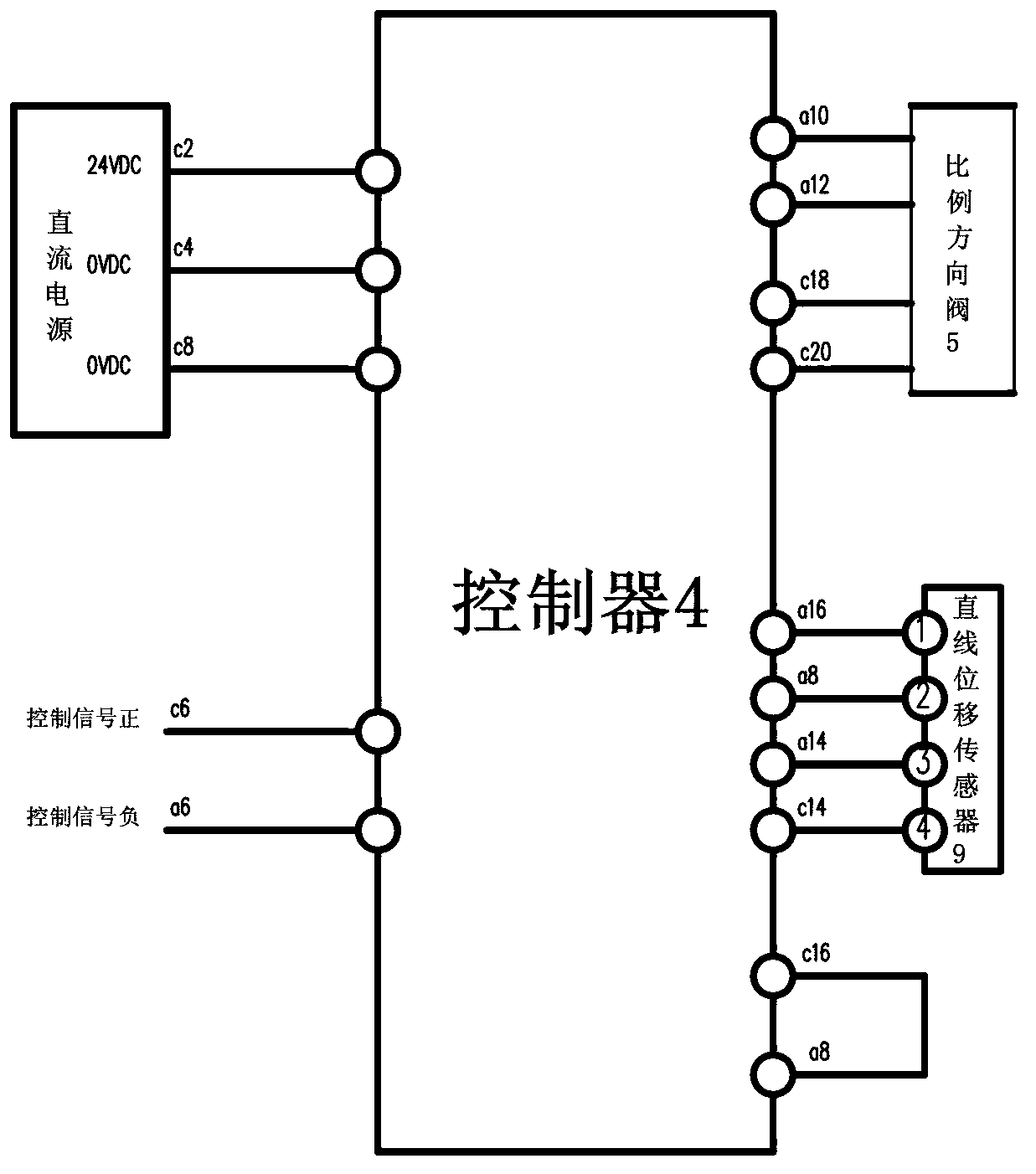

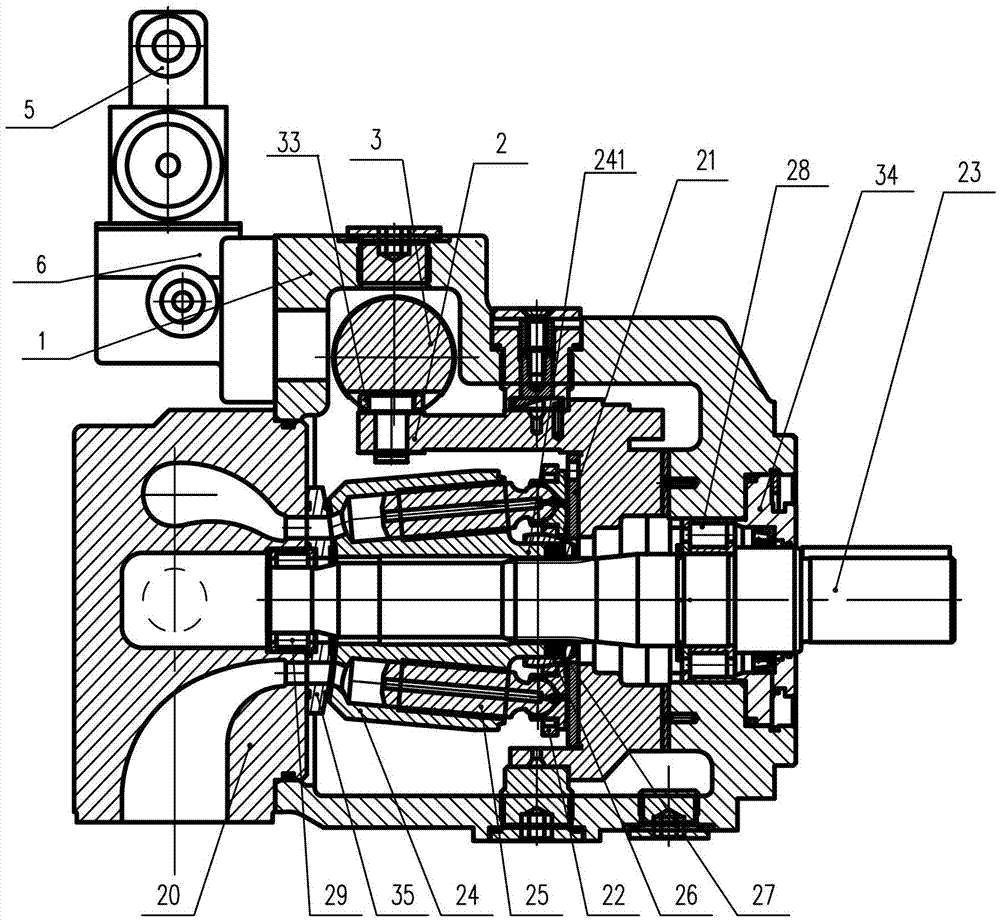

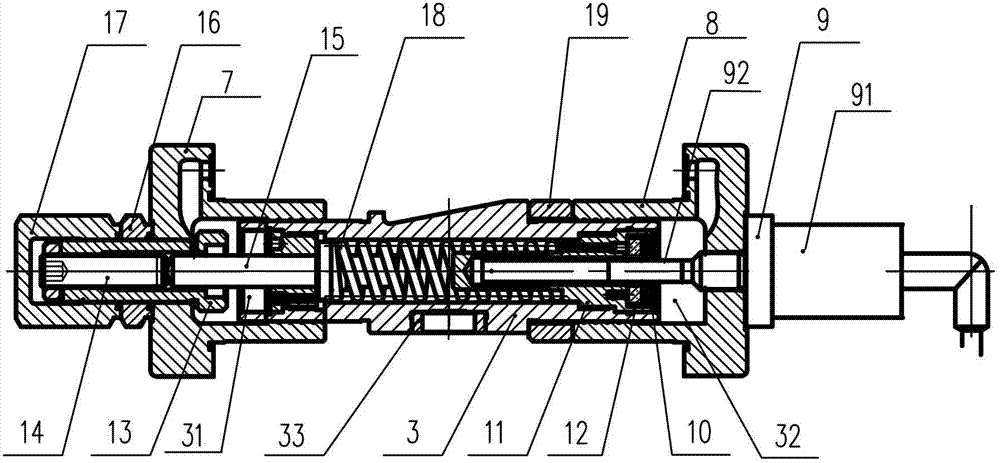

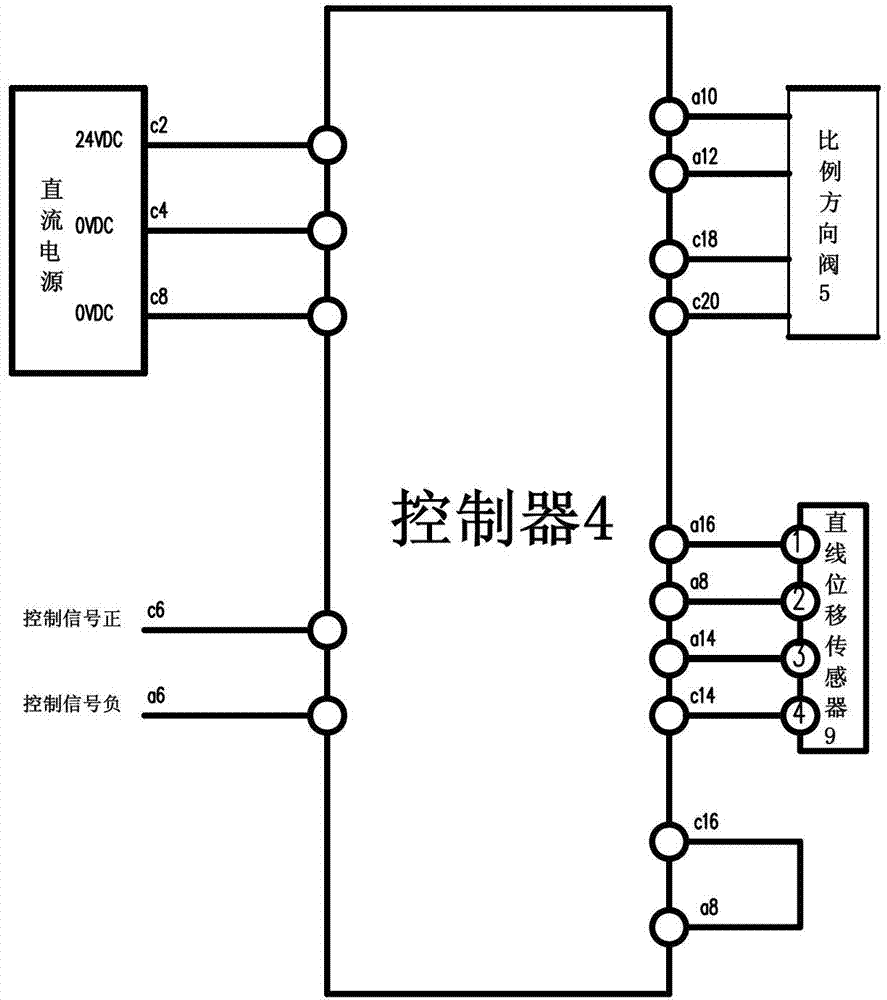

Electric proportional variable axial plunger pump

ActiveCN103291575AOutput displacement adjustmentImprove reliabilityPositive-displacement liquid enginesMulti-cylinder pumpsControl theoryPlunger pump

The invention discloses an electric proportional variable axial plunger pump comprising a plunger pump body and a variable mechanism arranged on one side of the plunger pump body. The plunger pump body comprises a pump body and a variable tray arranged inside the pump body. The variable mechanism comprises a variable piston connected with the variable tray and a first oil chamber and a second chamber which are formed at two ends of the variable plunger. A hydraulic control system is further arranged on the outer side of the pump body, and comprises a controller, a proportional direction value, a transition plate and a detection mechanism, wherein the proportional direction value is connected with the controller and used for controlling flow of oil, the detection mechanism is used for detecting the position of the variable piston, the transition plate provided with two oil outlets is mounted on the outer side of the pump body. The two oil outlets are communicated with the first and second oil chambers respectively, the proportional direction valve is mounted on the transition plate, and the detection mechanism is connected with the controller. The electric proportional variable axial plunger pump has the advantages of simplicity in control, high reliability and repeat accuracy, and emission can be regulated in real time during operation.

Owner:宁波恒力液压股份有限公司

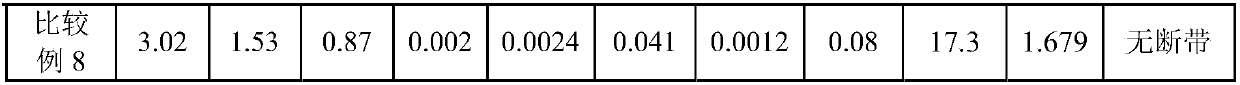

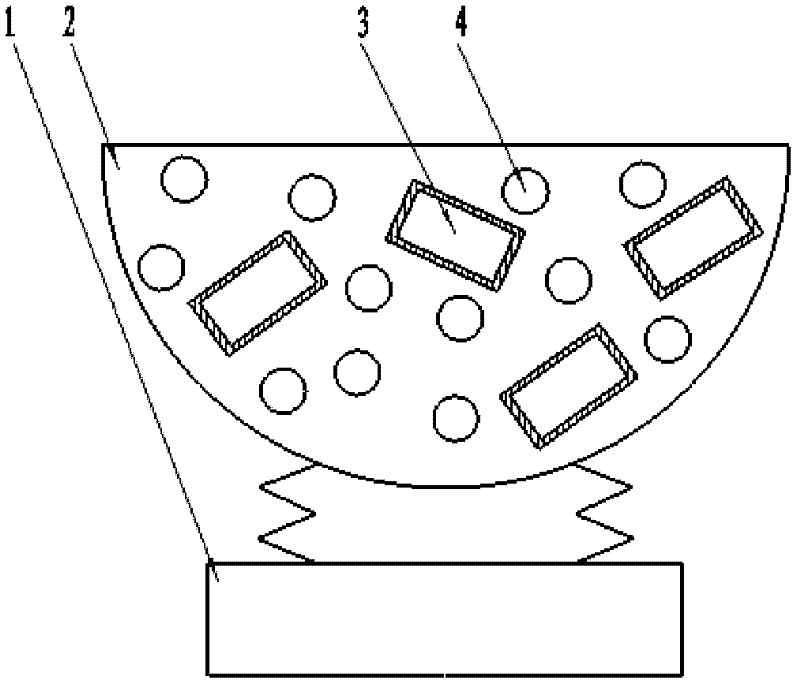

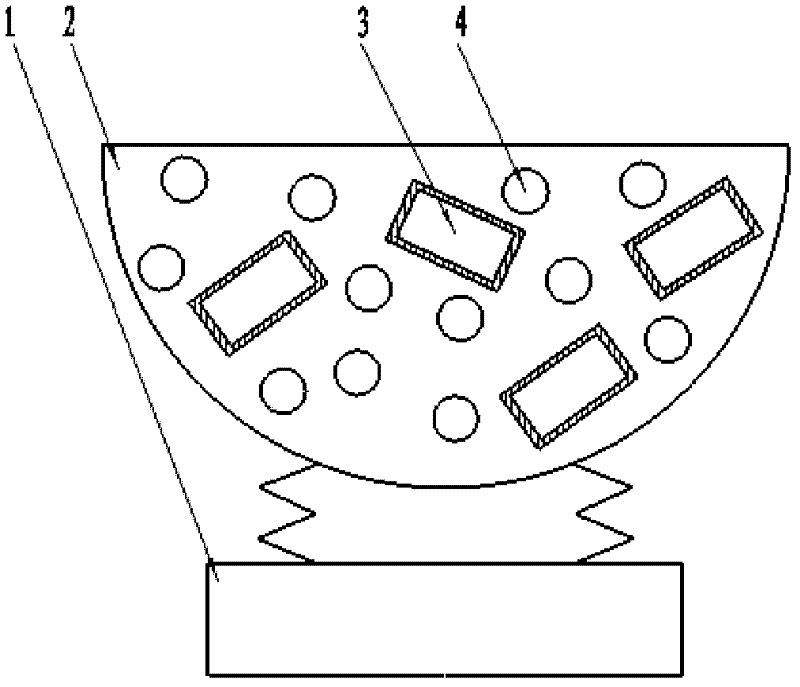

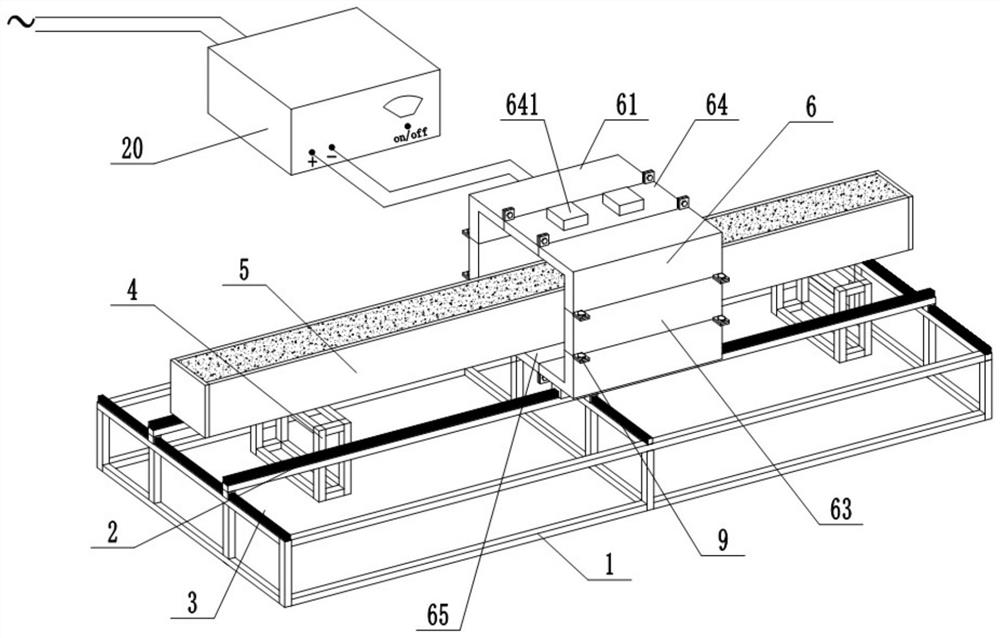

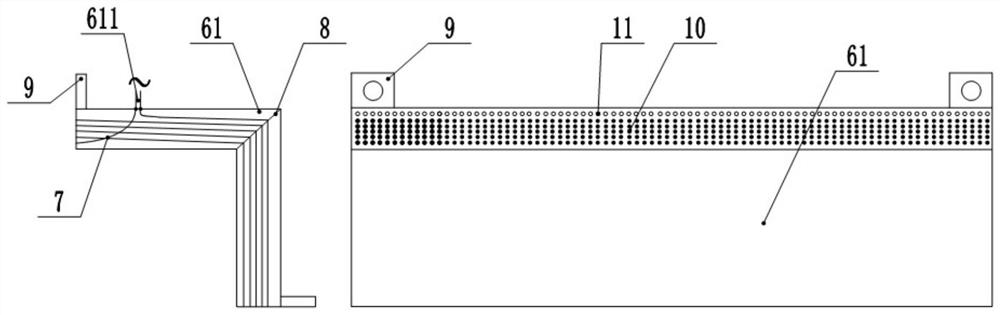

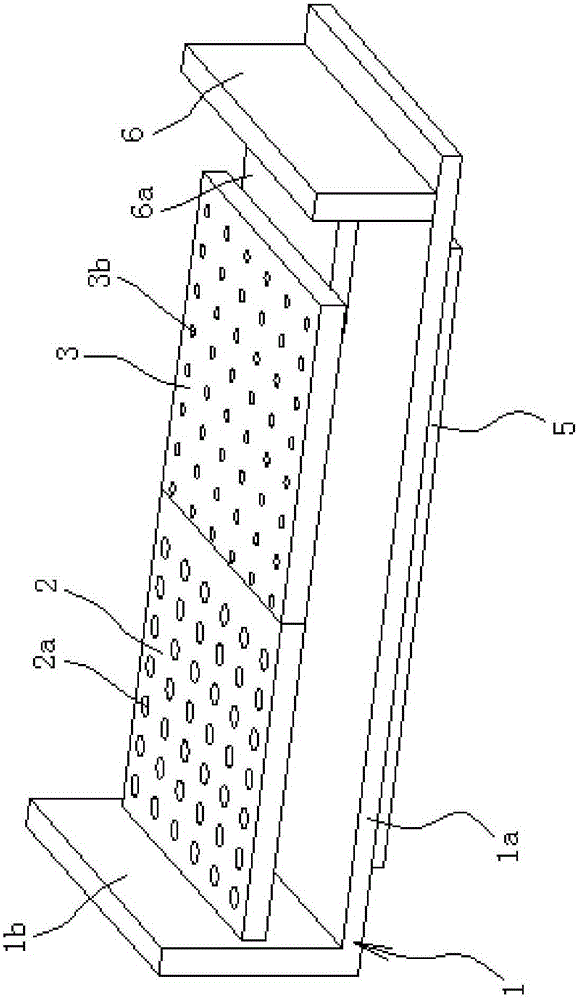

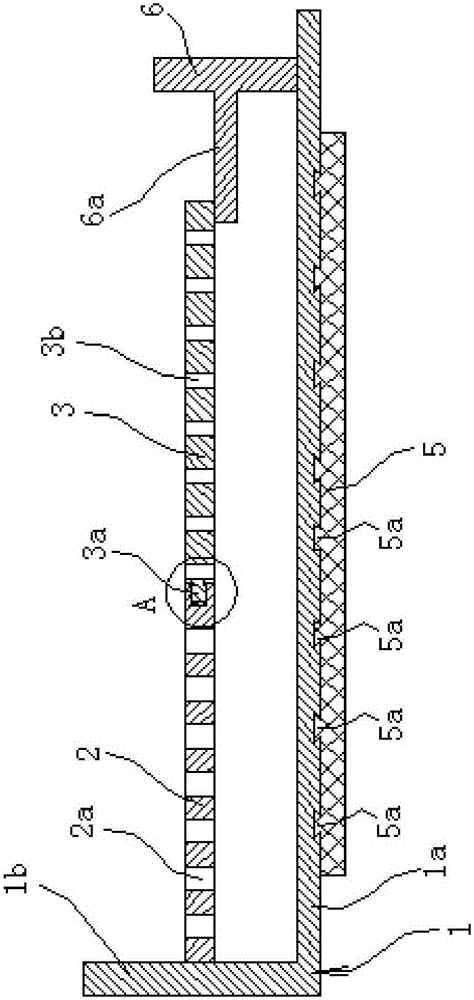

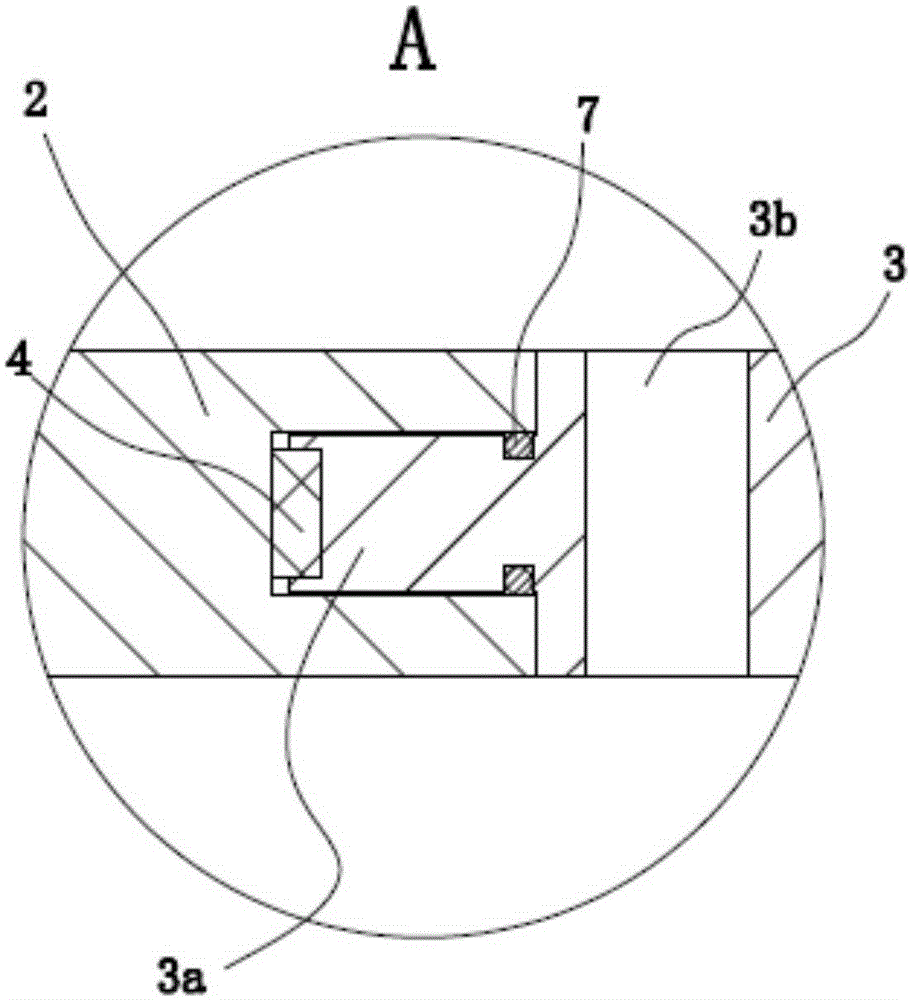

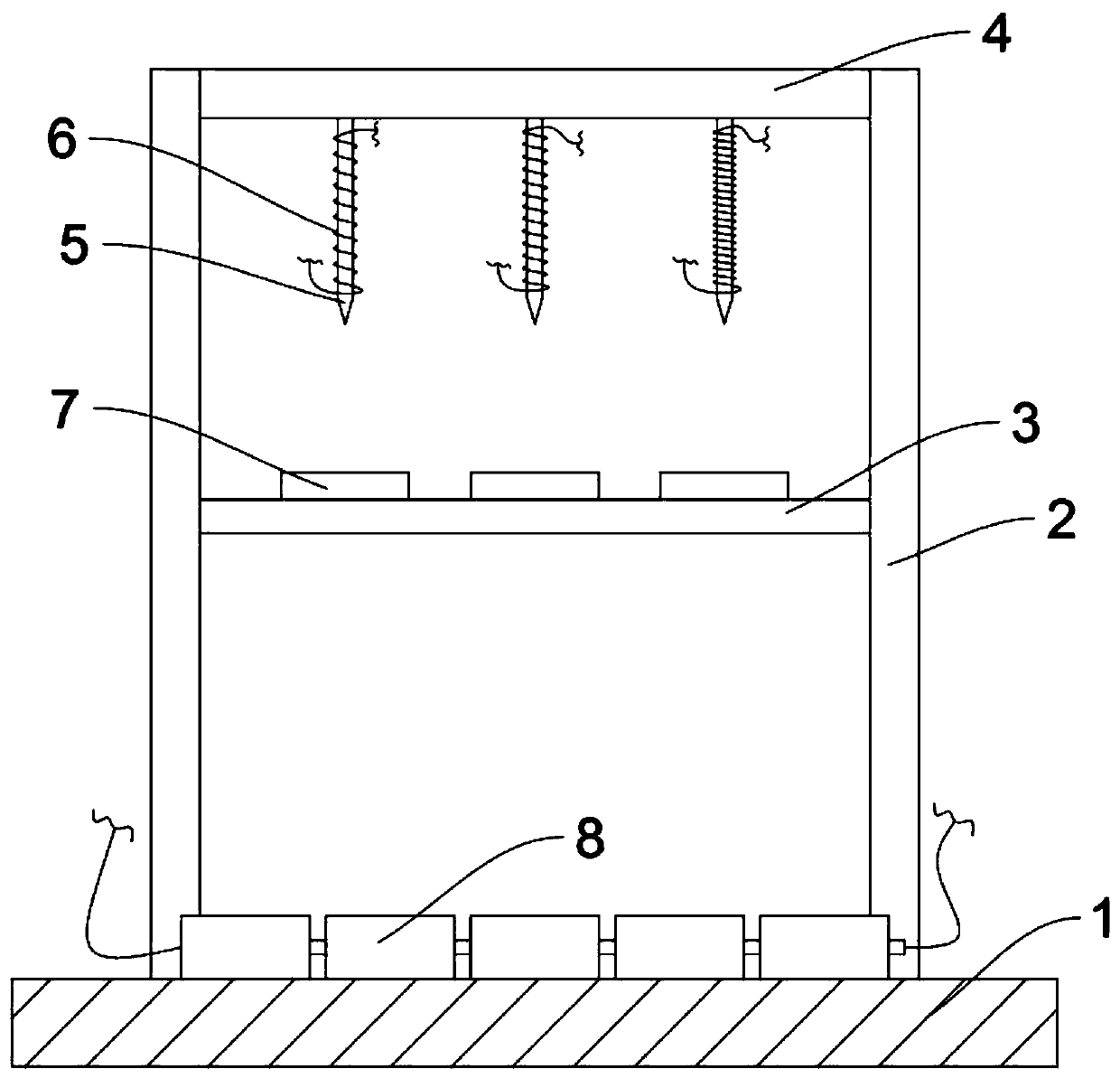

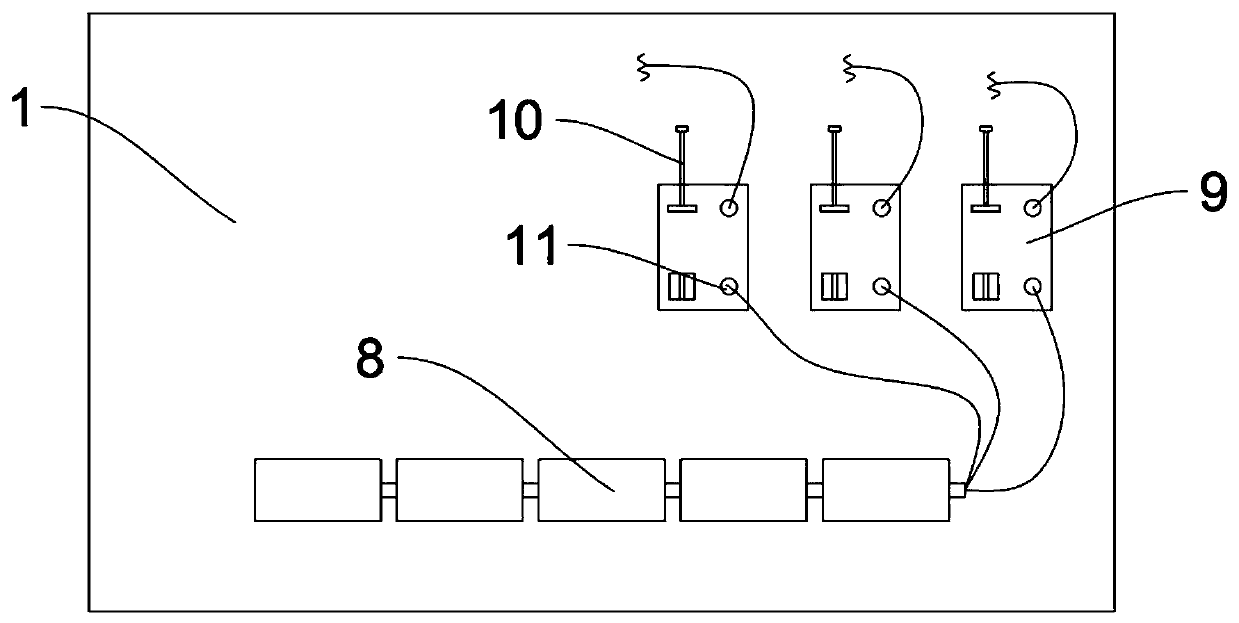

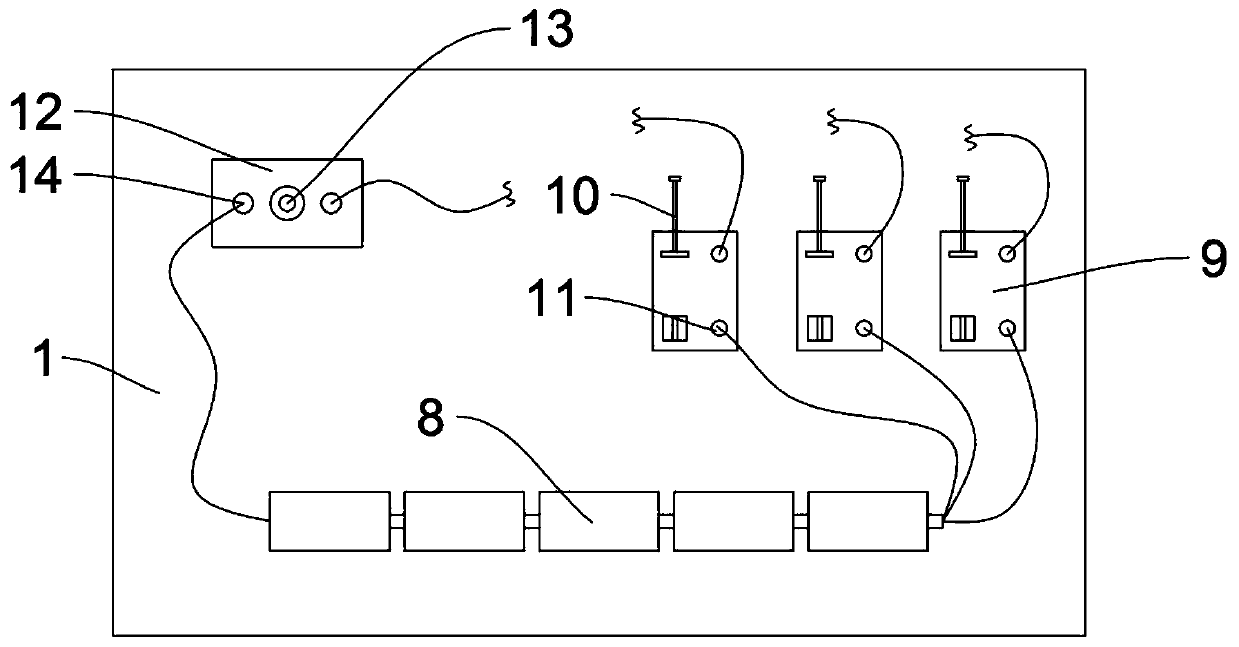

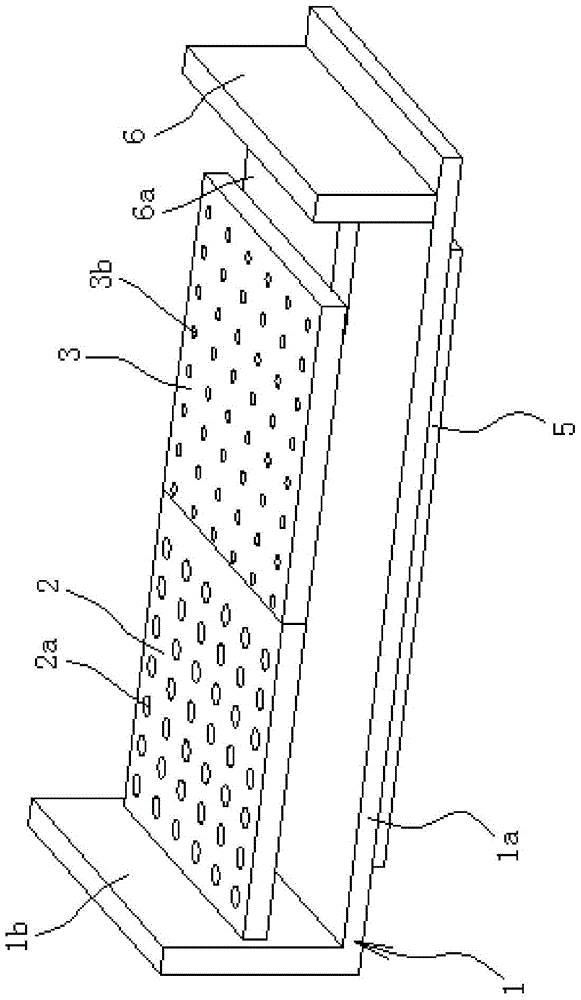

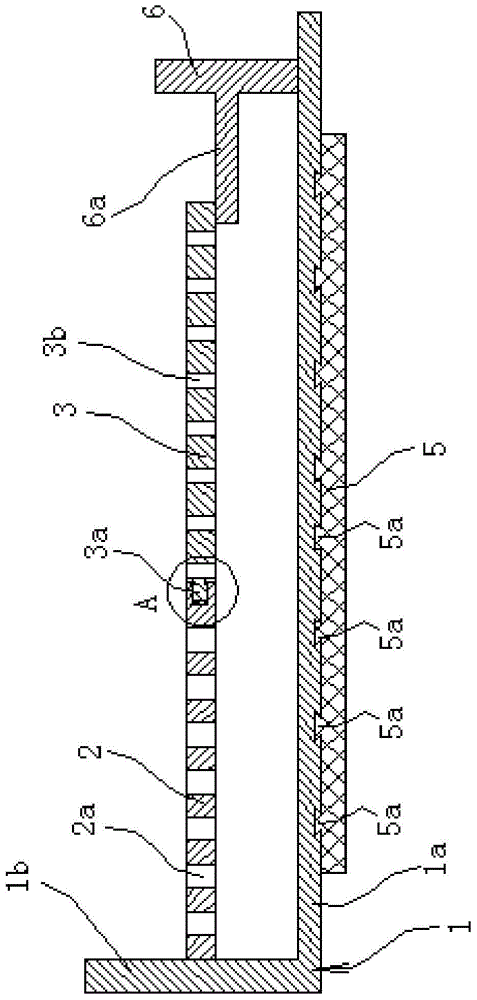

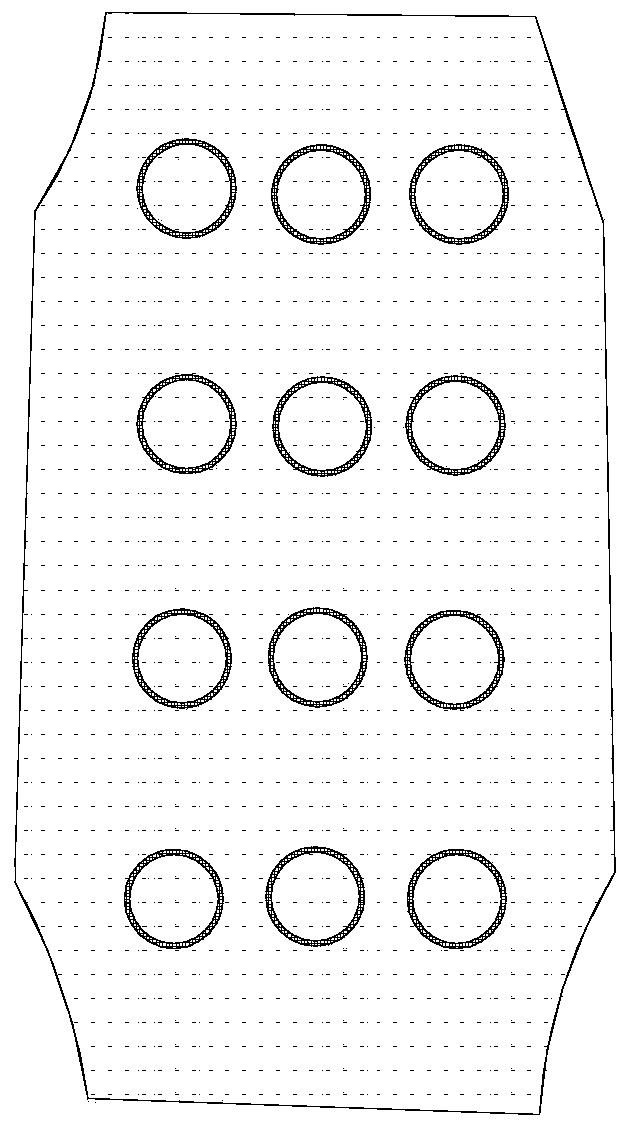

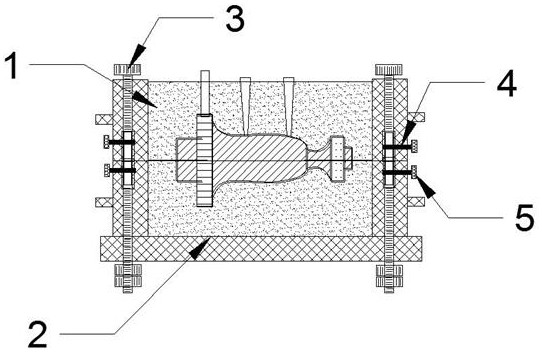

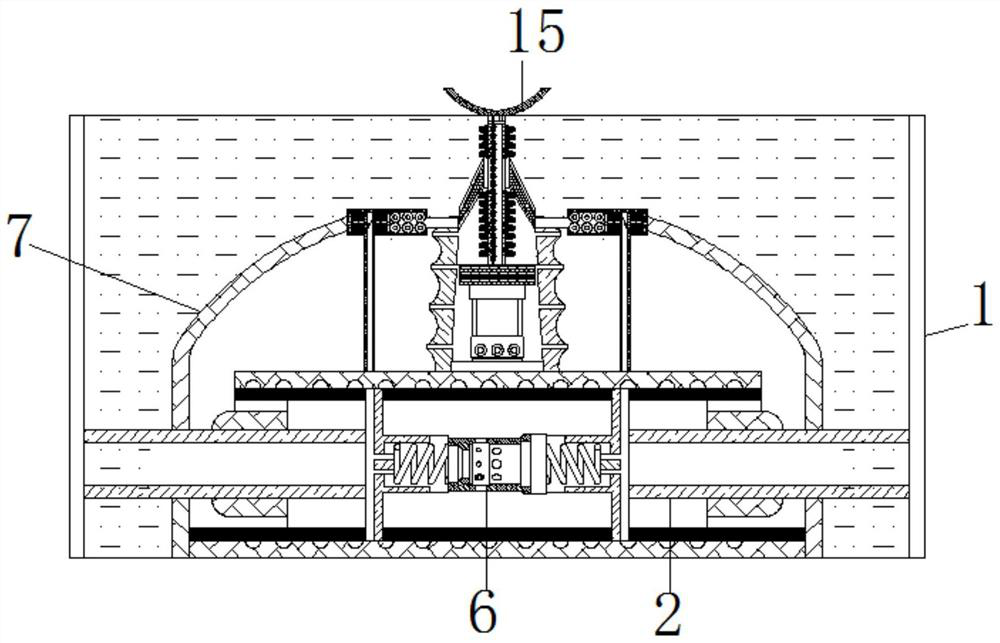

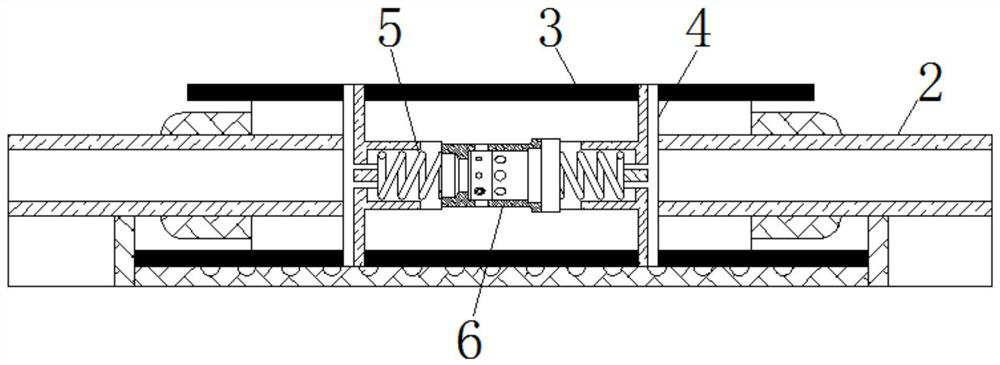

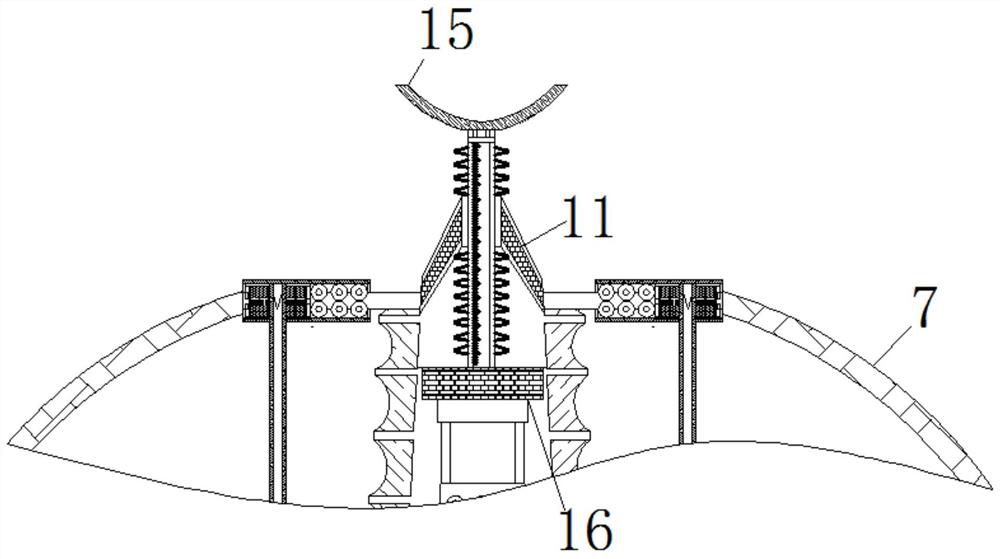

Preparation device and preparation method of directional steel fiber reinforced concrete prefabricated component

ActiveCN112025924AEliminate bending resistanceEliminate DirectionalityCeramic shaping apparatusFiber-reinforced concreteSteel fibre

The invention relates to the field of prefabricated type concrete structures, and particularly discloses a preparation device of a directional steel fiber reinforced concrete prefabricated component.The preparation device comprises a bottom supporting frame, the supporting frame is a rectangular metal frame, two first sliding rails in the horizontal direction are arranged on the upper surface ofthe supporting frame, and the two first sliding rails are symmetrically arranged; a coil is arranged on the first sliding rails, pulleys are fixed to the bottom of the coil, and the coil is slidably connected to the first sliding rails through the pulleys; two symmetrically-arranged steel supports are placed at the bottom of the supporting frame, the upper surfaces of the steel supports are located in the internal space of the coil, the steel supports are located between the two first sliding rails, a non-metal formwork is placed on the steel supports and penetrates through the coil, and vibrating rods are arranged on the coil; and a current exchanger is further arranged beside the supporting frame and electrically connected with the coil. The preparation device aims to solve the problem that tensile strength of a concrete matrix is insufficient due to steel fiber random distribution and low unidirectional reinforcement efficiency in an existing steel fiber concrete component.

Owner:TAIZHOU UNIV

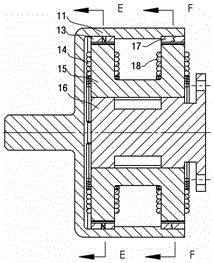

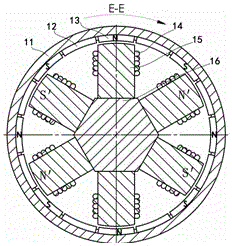

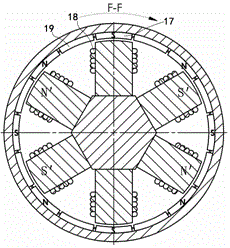

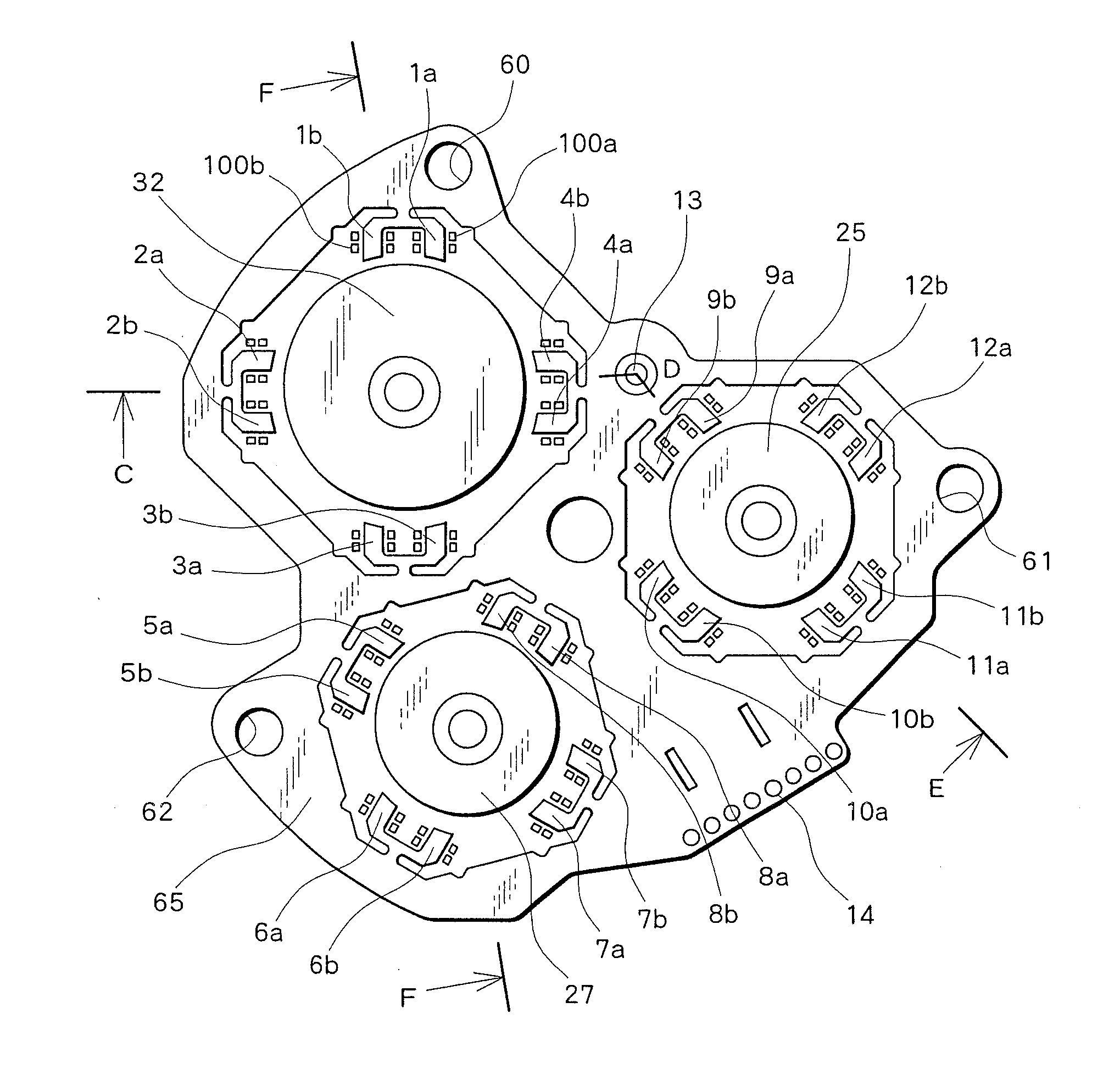

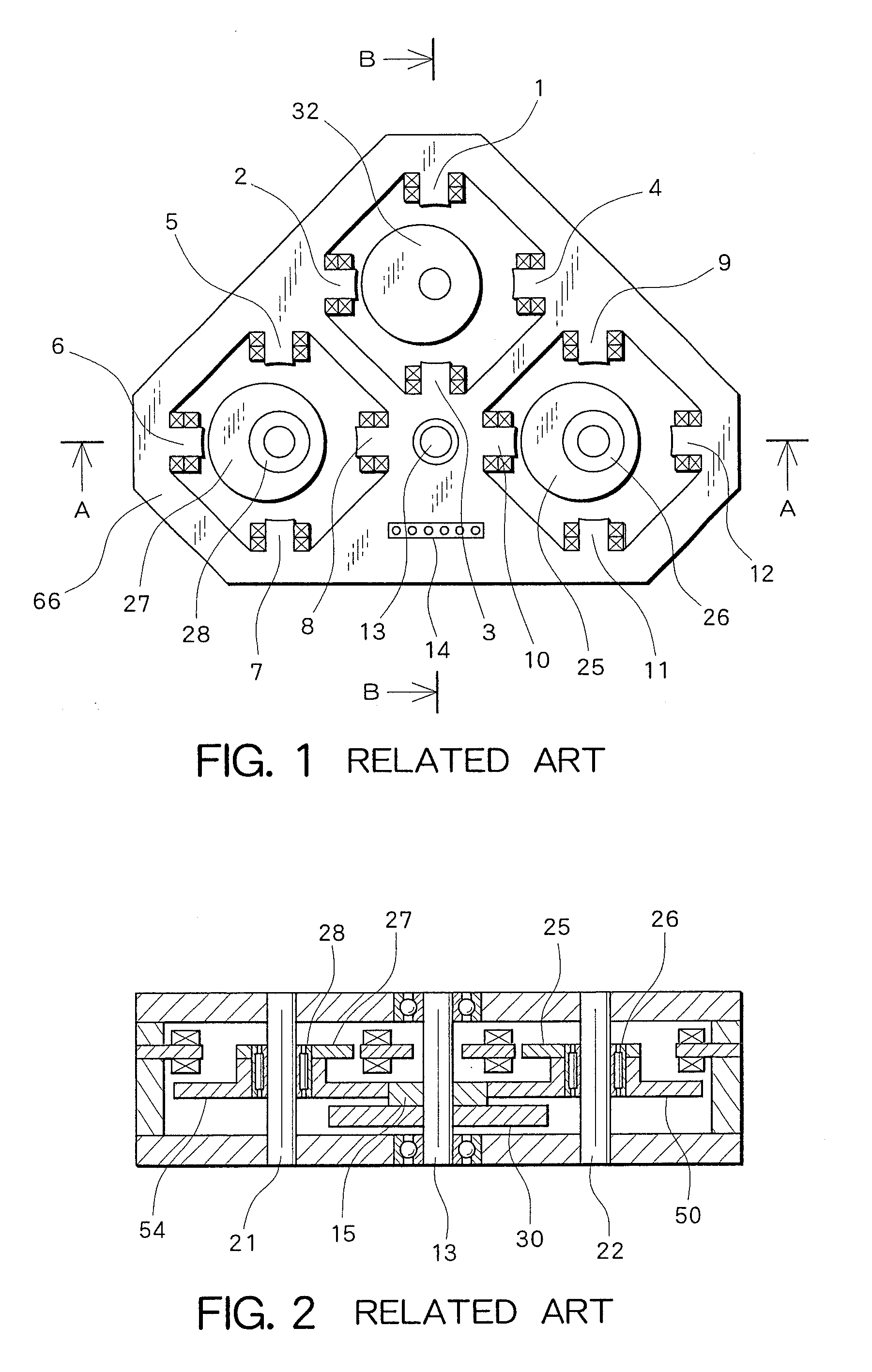

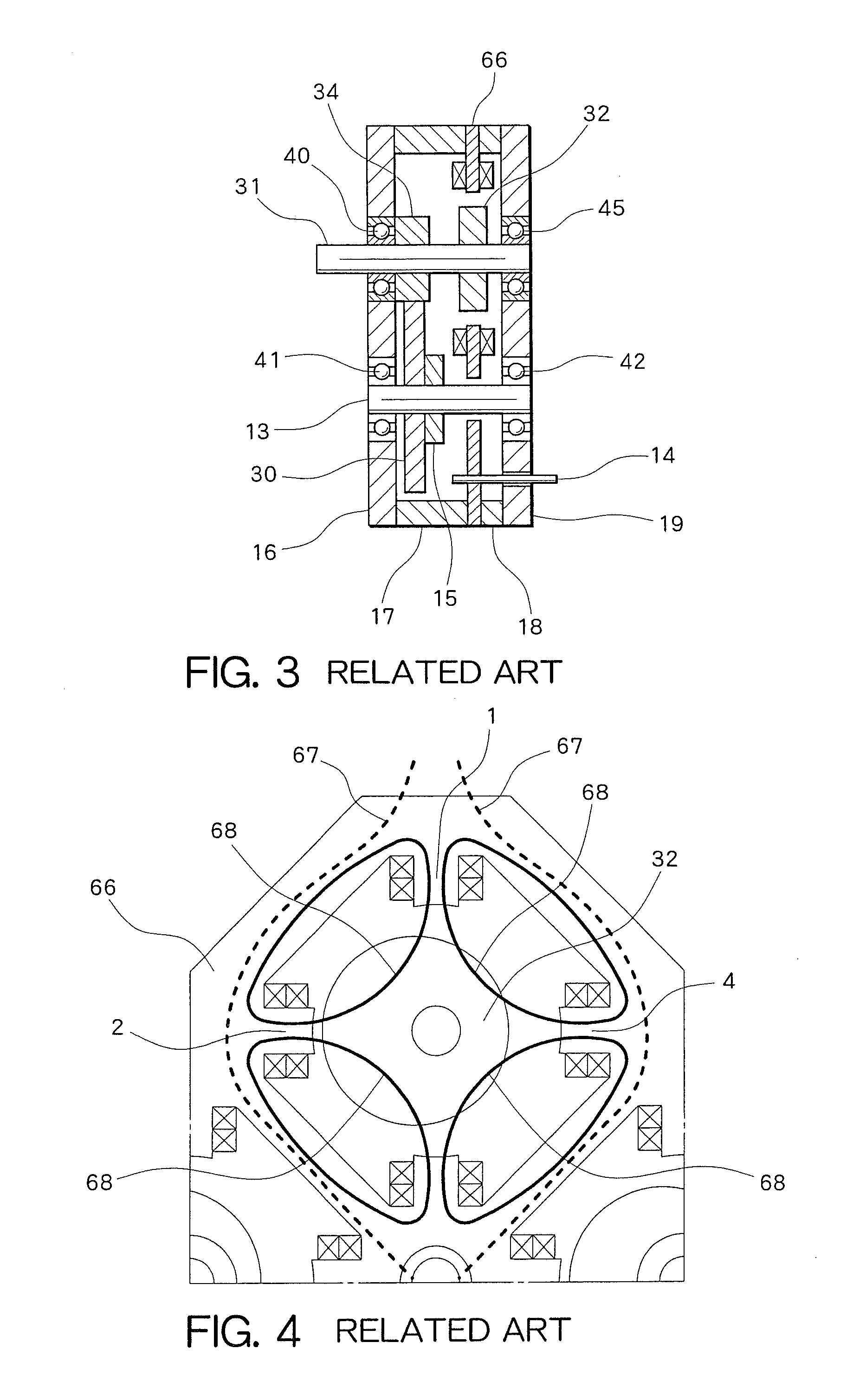

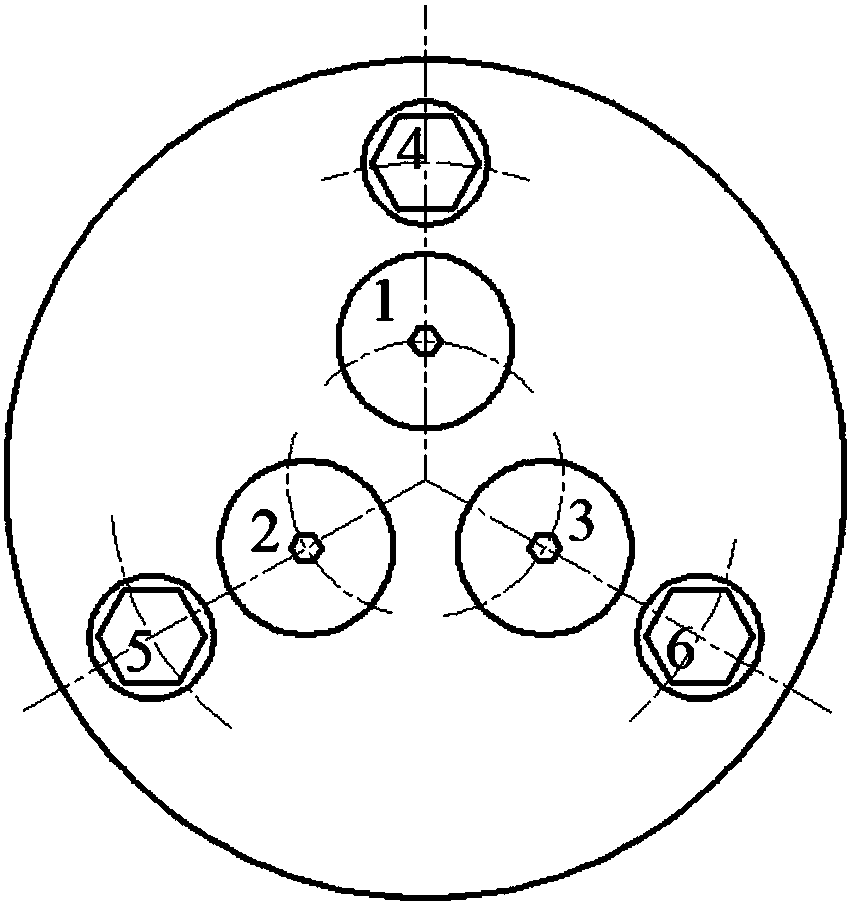

Resolver and multiple-rotation detector

InactiveUS20140002064A1Reduce the impactImprove noise immunityUsing electrical meansDynamo-electric machinesRotary transformerElectrical and Electronics engineering

A stator includes: a core formed by laminating magnetic steel sheets; and an excitation coil and a detection coil which are wound around teeth provided at the core. The core includes a peripheral section which is disposed to surround the rotor and a detection section which is disposed at the interior of the peripheral section and has the teeth. When the magnetic steel sheets are laminated, each of the magnetic steel sheets forming the core includes a portion which constitutes the peripheral section and a portion which constitutes the detection section. The detection section is substantially U-shaped, and both sides of the U-shape become a pair of teeth which form one phase. A base portion of the substantially U-shape of the detection section connects. with the peripheral section, and gaps are provided between the peripheral section and a part of the base portion which is the root of the teeth.

Owner:OKUMA CORP

Nickel electroplating method for NdFeB magnets

Owner:NINGBO YUNSHENG +4

Medical cleaning rack

The invention provides a medical cleaning rack, and belongs to the technical field of medical instruments. The problem that cost is higher when existing medical cleaning racks of different types are produced is solved. The medical cleaning rack comprises an L-shaped support. The support comprises a horizontal supporting part and a vertical fixed part. A first washing plate and a second washing plate are arranged in the support and are right opposite. One end of the first washing plate and the fixed part are fixed. A plurality of connecting parts protruding in a columnar shape are arranged on the end face of the second washing plate. Connecting holes with the number equal to that of the connecting parts are formed in the other end face of the first washing plate, and the connecting holes correspond to the connecting parts one to one in position. The connecting parts are inserted in the connecting holes. Magnets abutting against the inner walls of the connecting holes are arranged in the connecting holes and, and magnets and the connecting parts are fixed. Sealing pieces capable of sealing openings of the connecting holes are arranged on the connecting parts. First through holes and second through holes are formed in the first washing plate and the second washing plate respectively. The medical cleaning rack has the beneficial effect that cost is low when the cleaning racks of different types are produced.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

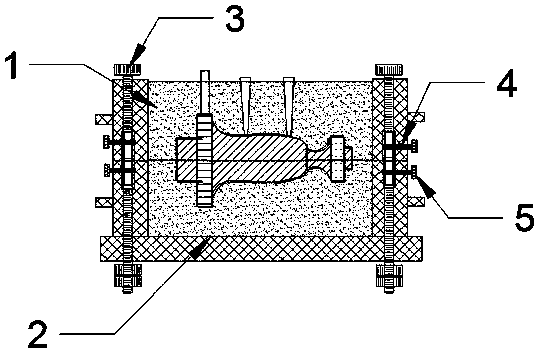

Dual box sand mould used for aluminum alloy component casting

ActiveCN110064738AStable structureStable structural strengthMoulding flasksUltimate tensile strengthMachining

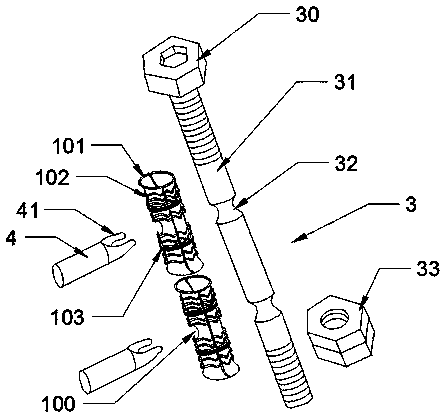

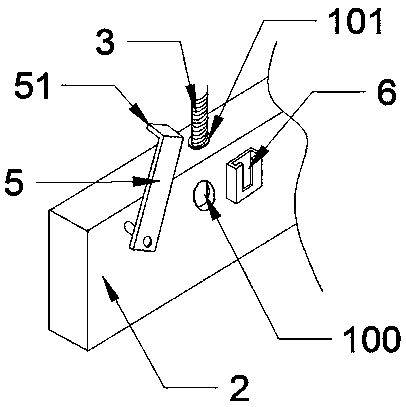

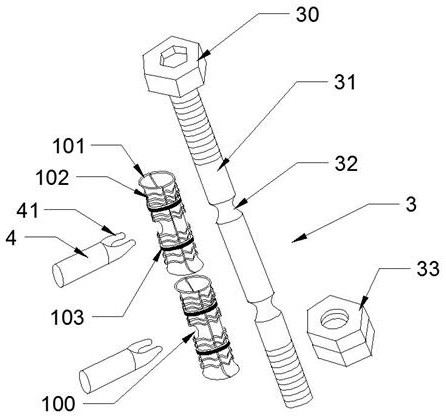

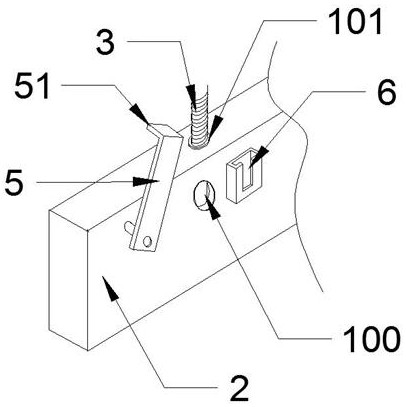

The invention belongs to the technical field of metal casting machining, and particularly relates to a dual box sand mould used for aluminum alloy component casting. The dual box sand mould comprisesan upper sand box and a lower sand box. The upper sand box and the lower sand box are fixed through bolts. Pin holes are formed in the outer walls of the sand boxes. Baffles are arranged on the outersides of the pin holes. Clamped connection grooves used for fixing the baffles are formed in the right sides of the baffles. Strong magnet lantern rings are arranged in screw holes. Cushion pipes arearranged in the strong magnet lantern rings, and corrugated springs are sleeved in gaps between the outer sides of the cushion pipes and the screw holes. External threads matched with internal threadsin the screw holes are arranged on the upper segments and the lower segments of screws of the bolts, the surface of the middle segment of each screw is free of a thread, and two contraction necks with the diameters gradually reduced are arranged in the middle segment of each screw. Limiting pins are arranged in the pin holes, and U-shaped grooves are formed in the front ends of the limiting pins.The sand mould is high in structural strength and strong in fastening function, the effects of vibration resistance and heat-resisting deformation prevention of the sand mould are relatively better,the screws cannot be locked in the casting process, and demolding is more convenient.

Owner:和县华顺铸造有限公司

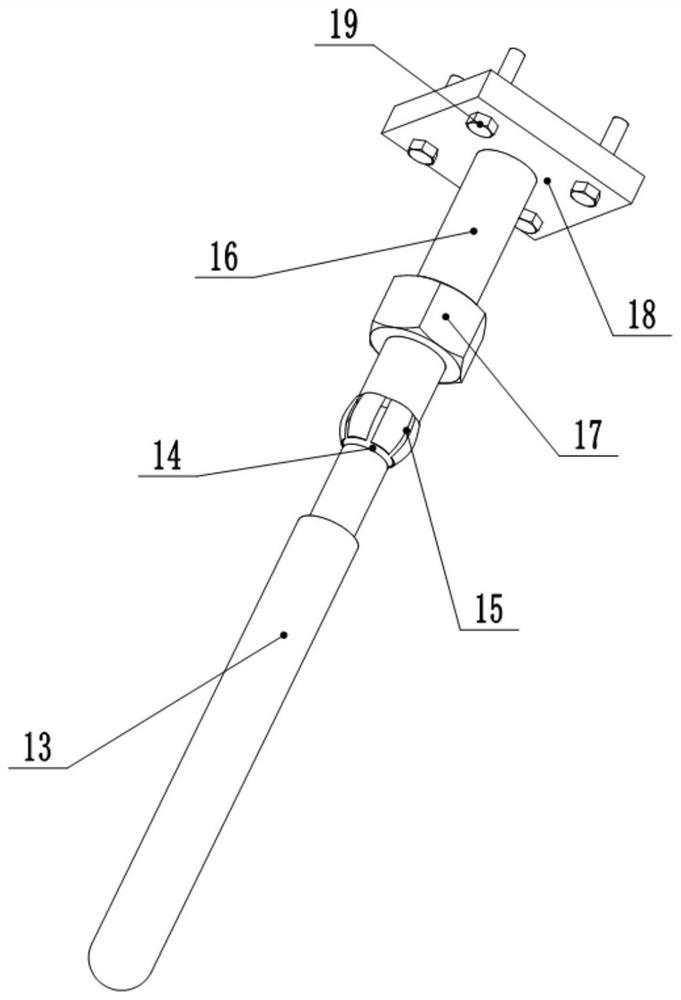

Experimental device for exploring factors influencing magnitude of electromagnetic force

InactiveCN109741668AReduce manufacturing costEasy to operateEducational modelsElectrical batteryElectromagnetic interference

Owner:金有芝

A Spinning Forming Method for Making Soft Magnetic Alloy Cylindrical Parts

ActiveCN106391810BImprove plasticityStrong magnetismFurnace typesHeat treatment furnacesMachiningMaterials science

The invention discloses a spinning forming method for manufacturing a magnetically soft alloy cylindrical part. The method includes the steps that the geometric dimensions of a cylindrical blank are determined according to the principle that the material size is not changed in the plastic deformation process, the actual wall thickness of the thin-wall cylindrical part, the requirement for trimming after forming and the design principle that the wall thickness reduction rate is 40%-80%; the pipe blank is heated to 700 DEG C, and preheating is carried out after 0.5h of heat preservation; multi-pass staggered spinning forming is carried out on the cylindrical blank to enable the wall thickness to be reduced to a predetermined value; a workpiece subjected to spinning forming is heated to 1100-1180 DEG C in vacuum protection, heat preservation is conducted for 3-6h, then the workpiece is cooled to 600 DEG C at the speed which is not higher than 200 DEG C / h and continues to be cooled to 200 DEG C at the speed not smaller than 400 DEG C / h, and the workpiece is discharged out of a furnace and subjected to final heat treatment to improve the magnetic performance of the material; and excess materials at the two ends of the workpiece are cut off, so that a final product is obtained. By means of the spinning forming method for manufacturing the magnetically soft alloy cylindrical part, the cylindrical part with high forming quality and good soft magnetism performance can be obtained, and the defects that a traditional machining method is low in material utilization rate, poor in forming quality, prone to flux leakage and the like are overcome.

Owner:SOUTH CHINA UNIV OF TECH

Electric proportional variable axial plunger pump

ActiveCN103291575BOutput displacement adjustmentImprove reliabilityPositive-displacement liquid enginesMulti-cylinder pumpsControl theoryPlunger pump

The invention discloses an electric proportional variable axial plunger pump comprising a plunger pump body and a variable mechanism arranged on one side of the plunger pump body. The plunger pump body comprises a pump body and a variable tray arranged inside the pump body. The variable mechanism comprises a variable piston connected with the variable tray and a first oil chamber and a second chamber which are formed at two ends of the variable plunger. A hydraulic control system is further arranged on the outer side of the pump body, and comprises a controller, a proportional direction value, a transition plate and a detection mechanism, wherein the proportional direction value is connected with the controller and used for controlling flow of oil, the detection mechanism is used for detecting the position of the variable piston, the transition plate provided with two oil outlets is mounted on the outer side of the pump body. The two oil outlets are communicated with the first and second oil chambers respectively, the proportional direction valve is mounted on the transition plate, and the detection mechanism is connected with the controller. The electric proportional variable axial plunger pump has the advantages of simplicity in control, high reliability and repeat accuracy, and emission can be regulated in real time during operation.

Owner:宁波恒力液压股份有限公司

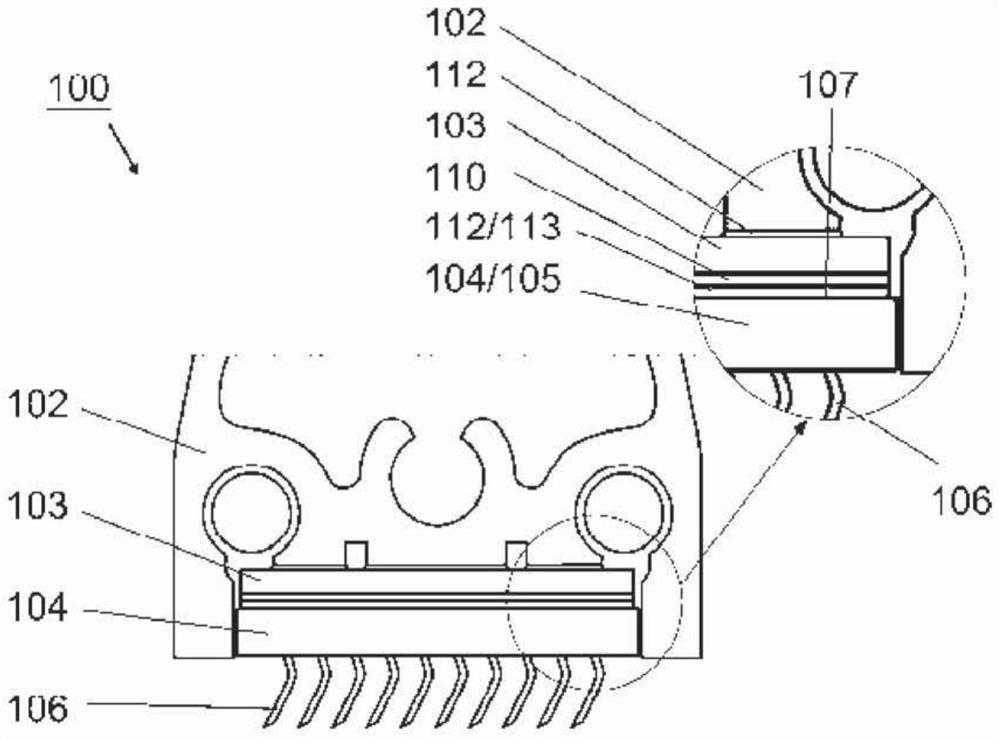

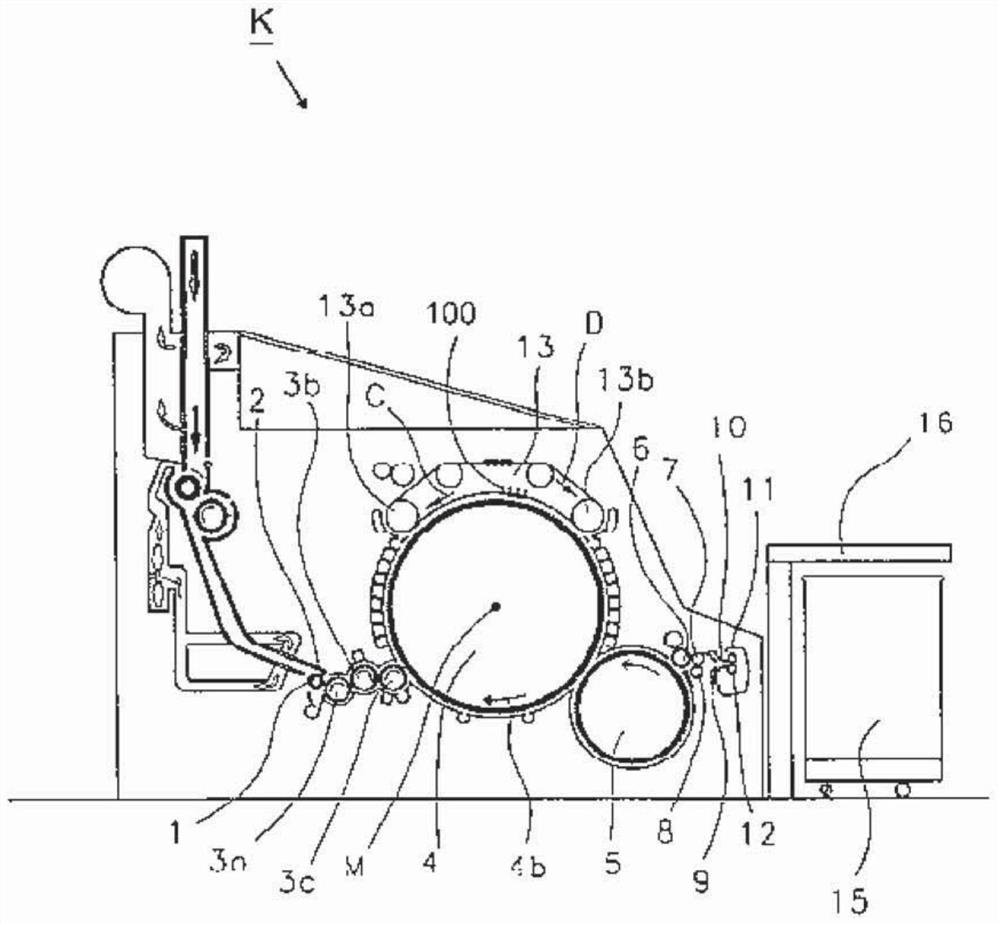

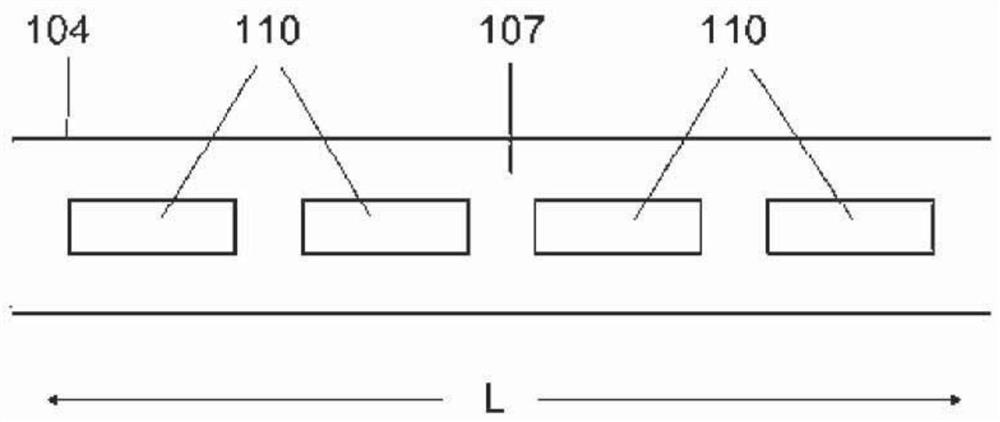

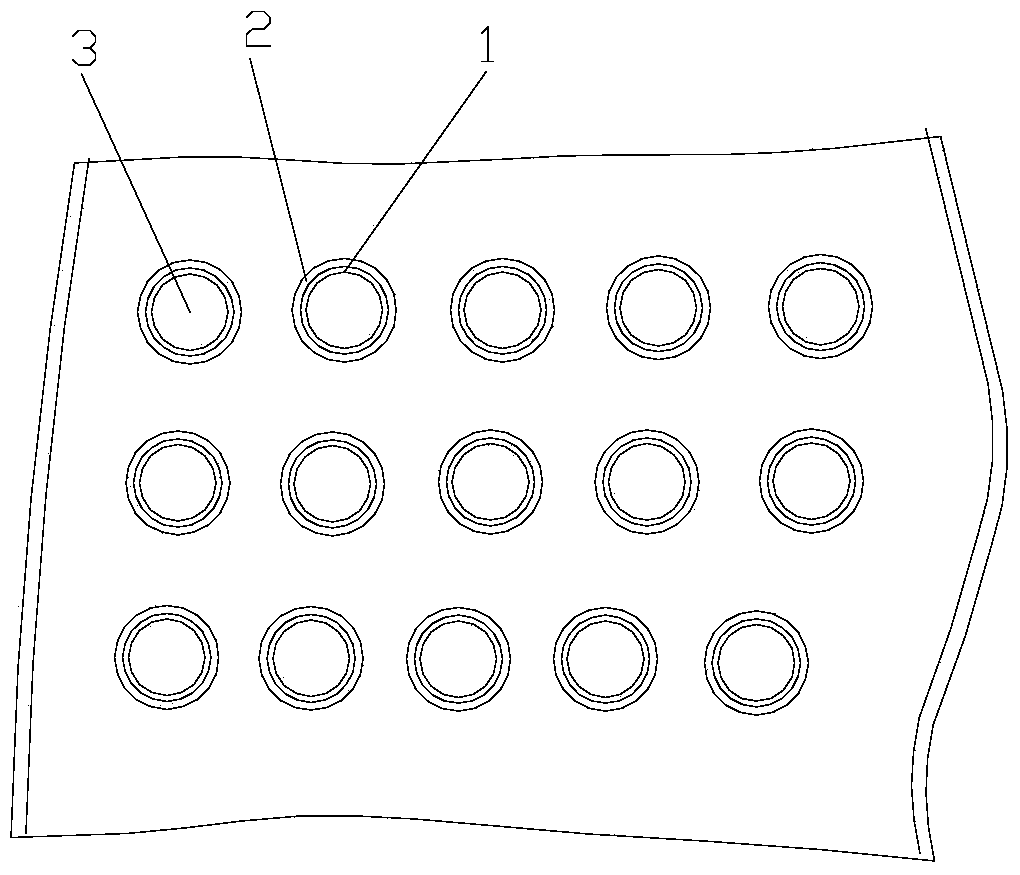

Cover strip system

The invention relates to a flat strip system (100) for use on a carding machine (K) for cotton, chemical fibers or the like, said flat strip system comprising an elongated flat strip (102) and a long shaped clothing strip (104) on which a magnetic element (103) is fastened, said clothing strip having a back side (107) facing the flat strip (102) of the clothing strip layer, the back layer contains ferrous metal material. Correspondingly, the clothing strip (104) can be detachably fastened magnetically to the magnetic element (103) of the flat strip (102) by means of the backing layer (108) of the clothing strip. The back layer (108) has a plurality of segments (110) which respectively contain ferrous metal material, wherein the segments (110) are arranged spaced apart from each other and in the longitudinal direction of the clothing strip (104) ( L) separated from each other.

Owner:TRUETZSCHLER GRP SE

A medical washing rack

The invention provides a medical cleaning rack, and belongs to the technical field of medical instruments. The problem that cost is higher when existing medical cleaning racks of different types are produced is solved. The medical cleaning rack comprises an L-shaped support. The support comprises a horizontal supporting part and a vertical fixed part. A first washing plate and a second washing plate are arranged in the support and are right opposite. One end of the first washing plate and the fixed part are fixed. A plurality of connecting parts protruding in a columnar shape are arranged on the end face of the second washing plate. Connecting holes with the number equal to that of the connecting parts are formed in the other end face of the first washing plate, and the connecting holes correspond to the connecting parts one to one in position. The connecting parts are inserted in the connecting holes. Magnets abutting against the inner walls of the connecting holes are arranged in the connecting holes and, and magnets and the connecting parts are fixed. Sealing pieces capable of sealing openings of the connecting holes are arranged on the connecting parts. First through holes and second through holes are formed in the first washing plate and the second washing plate respectively. The medical cleaning rack has the beneficial effect that cost is low when the cleaning racks of different types are produced.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

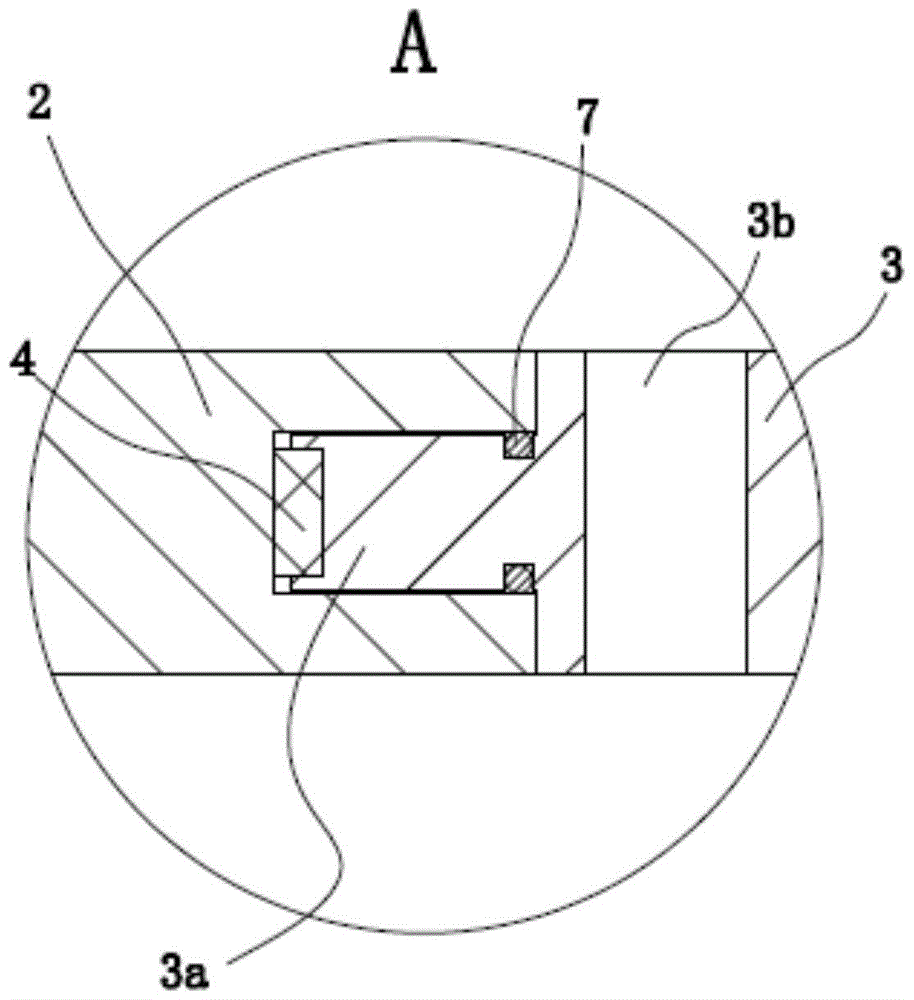

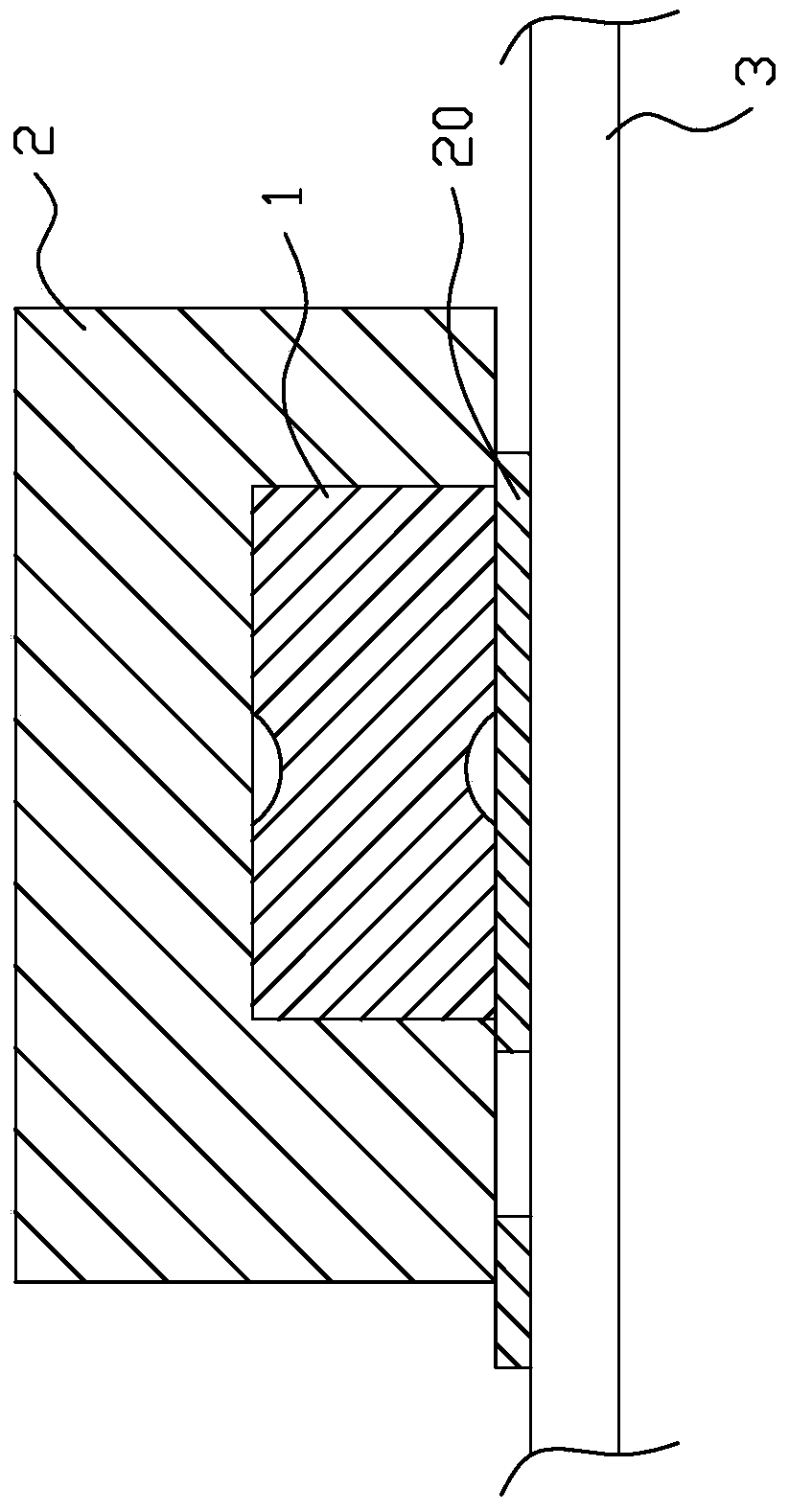

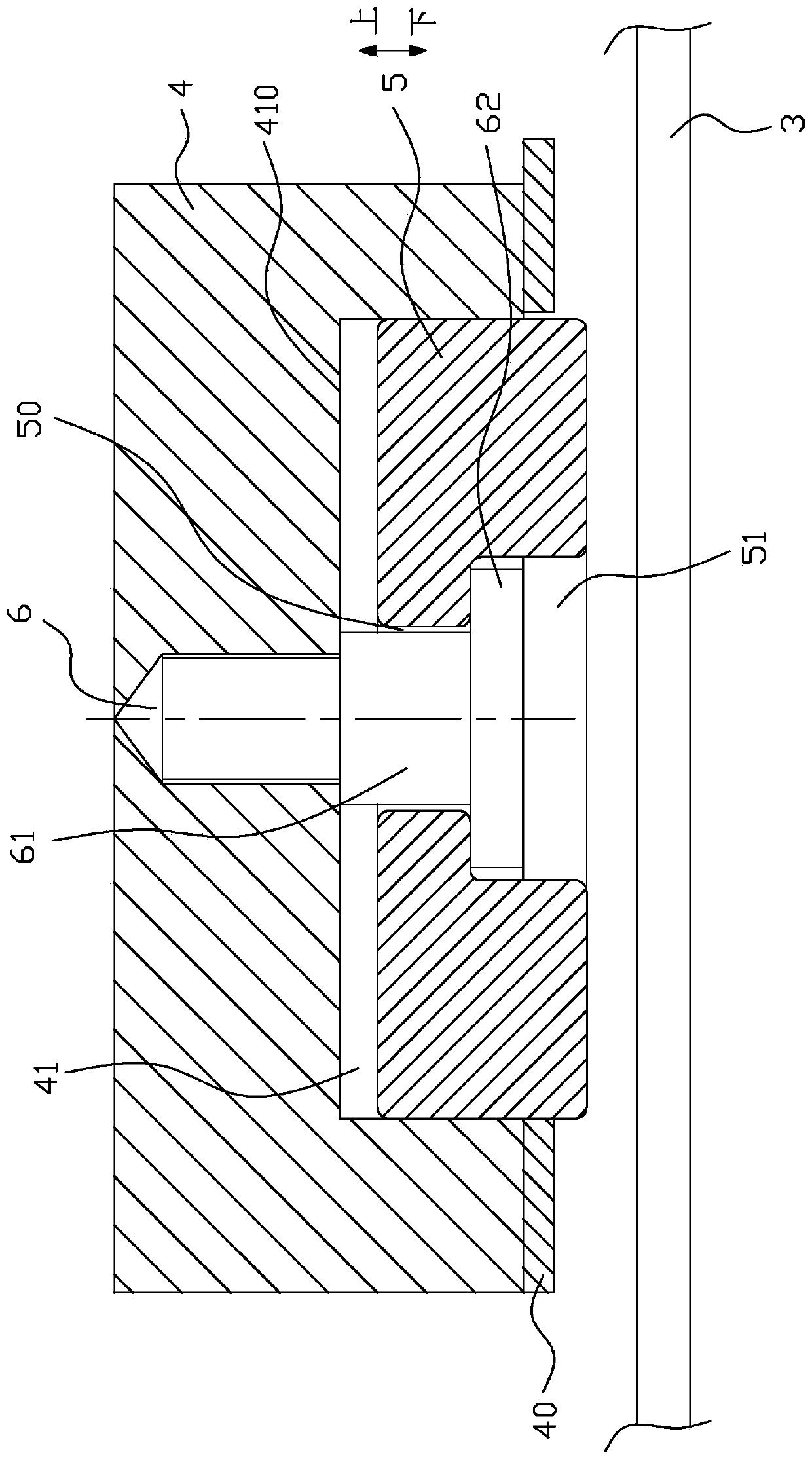

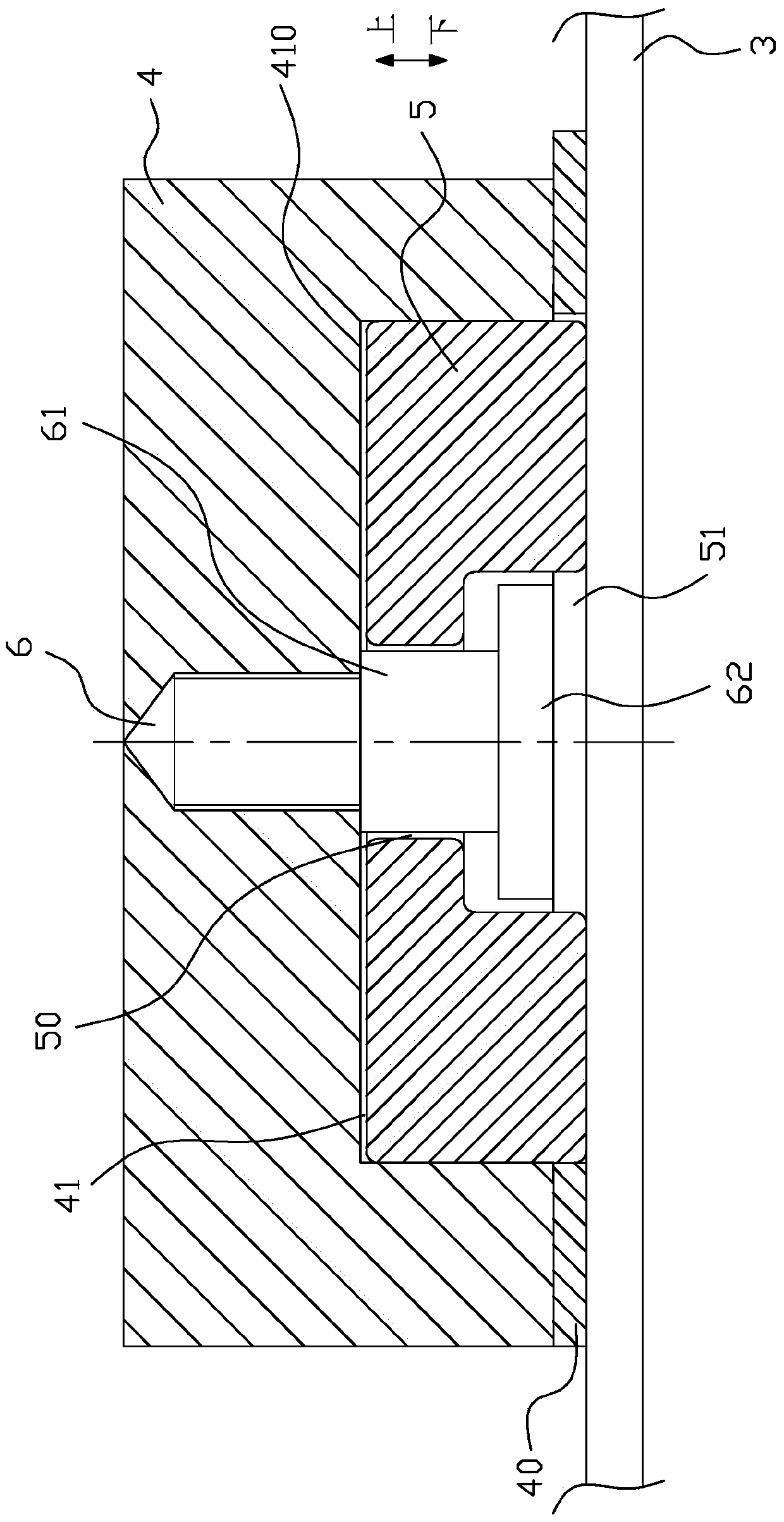

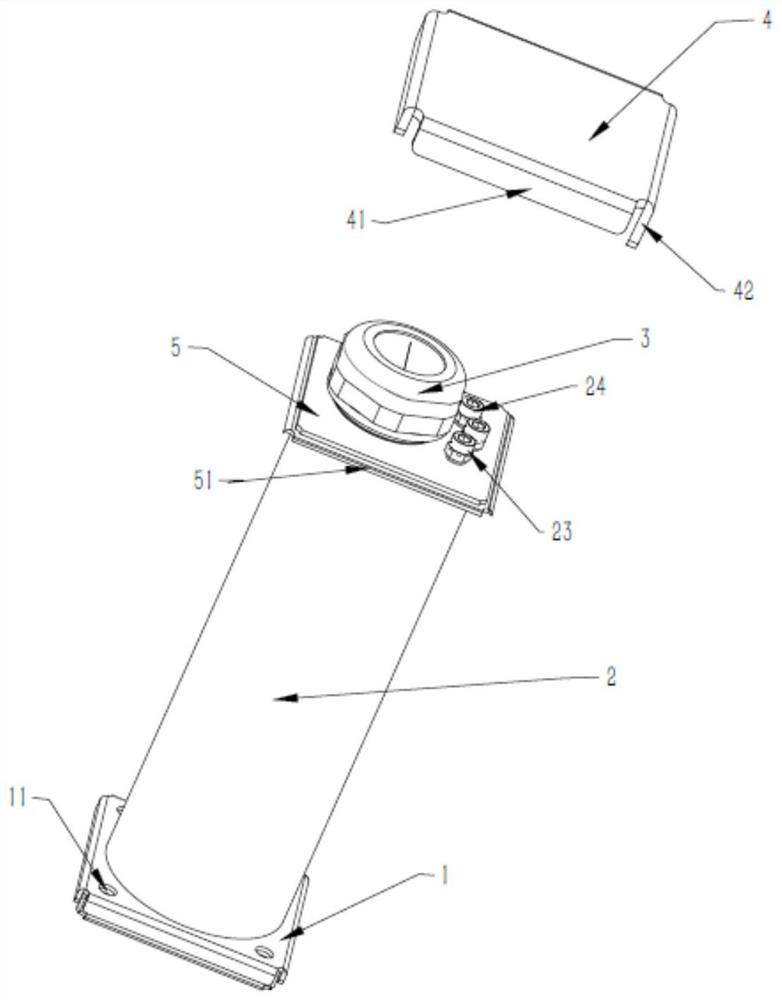

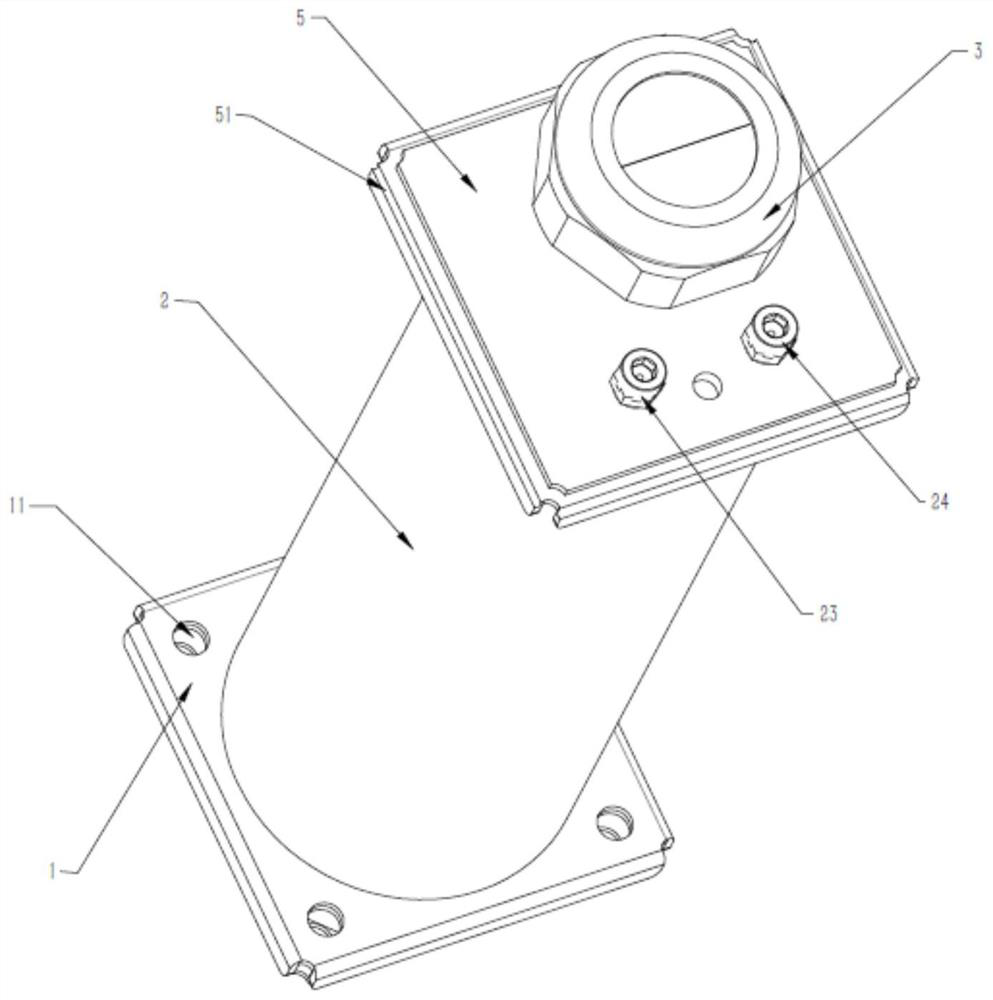

Magnetic fixed structure

The invention provides a magnetic type fixing structure adaptive to a desktop product and can absorb a pedestal of the desktop product onto a table surface. The magnetic type fixing structure comprises a magnet and a fixing member, wherein the magnet is slideably disposed in an accommodating groove formed in the bottom of a pedestal via the fixing member, so the magnet can project out of or recessed into the pedestal; and therefore, the magnetic type fixing structure can be directly adhered to a metal surface and effect on magnetism by distance can be reduced.

Owner:KUNDA COMP TECHKUSN +1

Method for forming aluminum coating on surface of neodymium iron boron magnet

ActiveCN102389871BImprove corrosion resistanceUniform thicknessPretreated surfacesCoatingsEpoxyElectricity

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

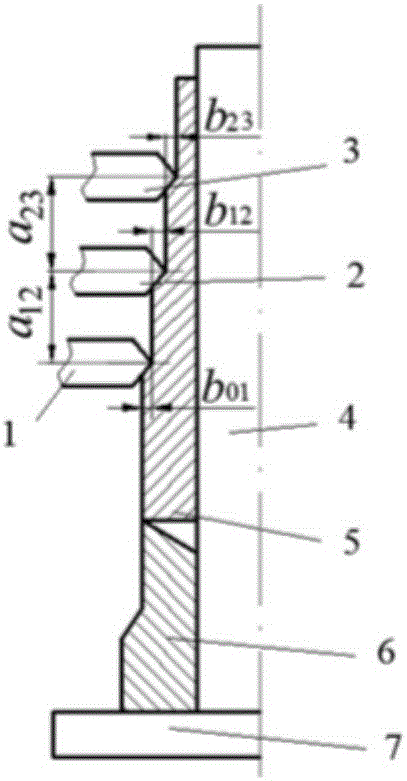

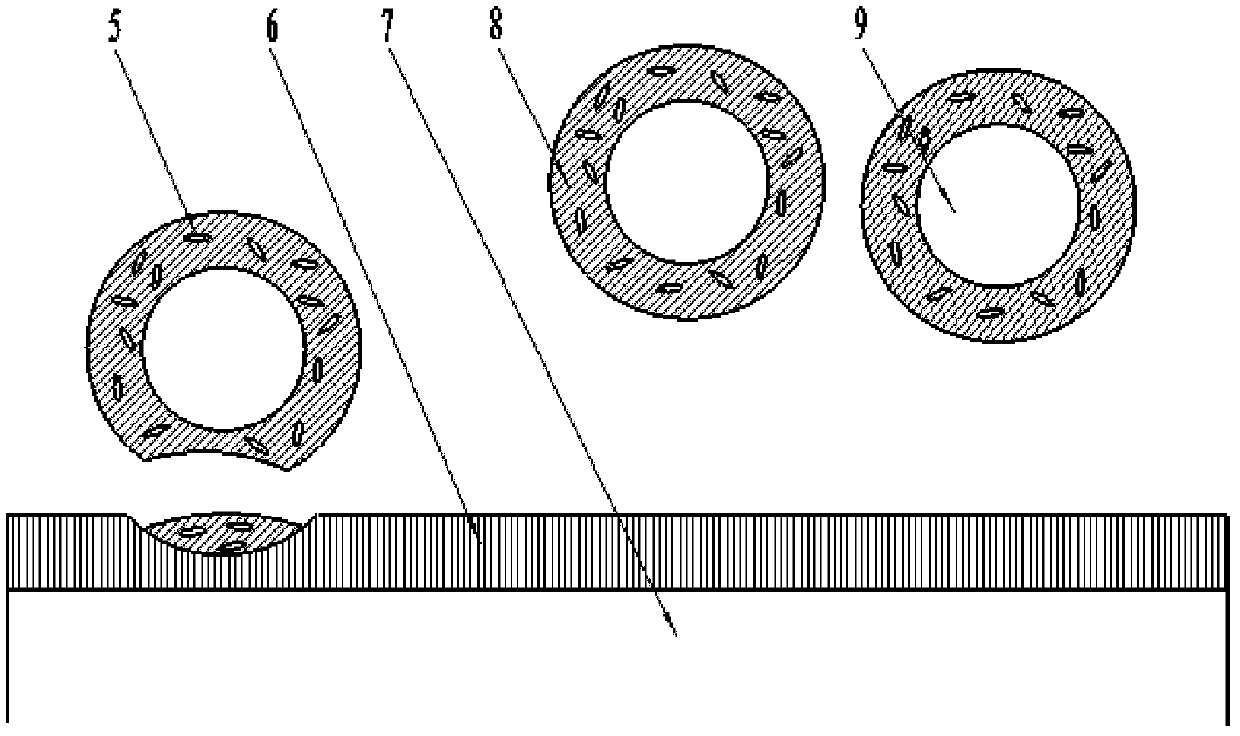

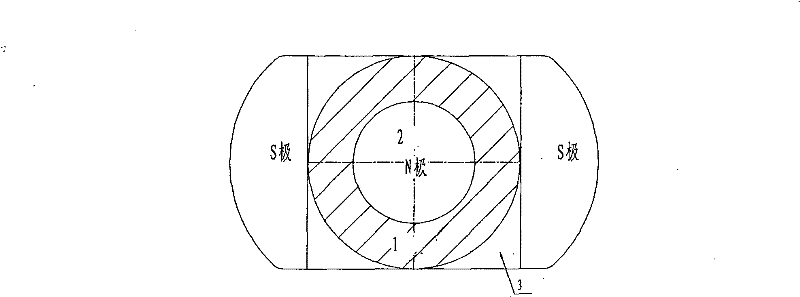

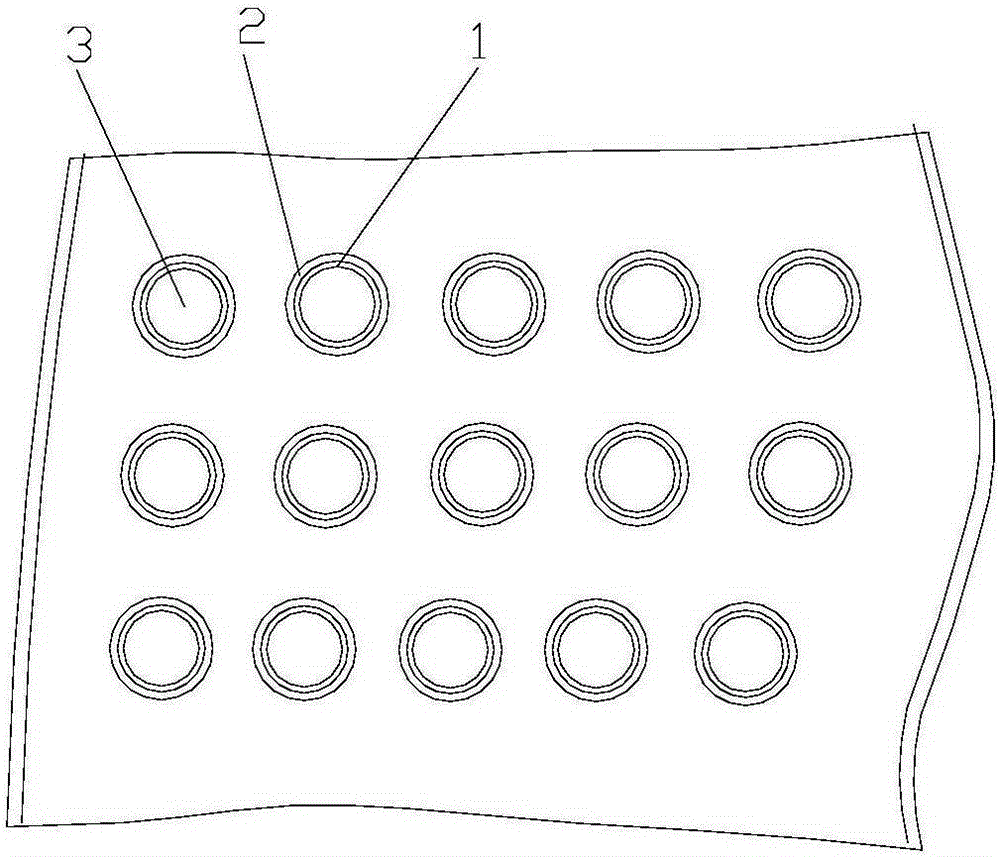

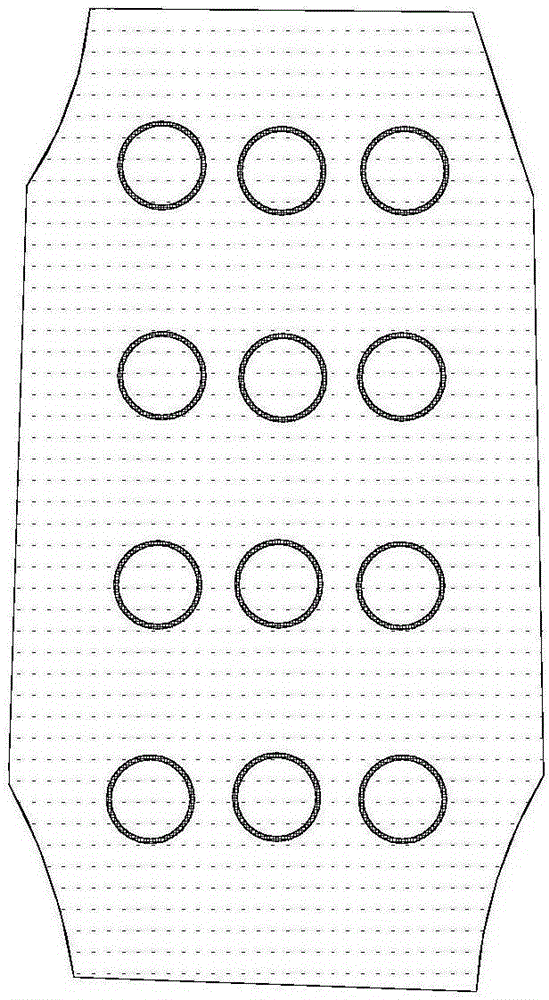

A method for fixing magnets on a magnetic therapy module

ActiveCN105153949BMagnetic influenceMagnetic lossAdhesive processesElectrotherapyUltrasound - actionUltrasonic welding

The invention discloses a method for fixing magnets on a magnetic therapy module. A special mold is designed according to the required shape of the magnetic therapy module. A groove for storing magnets is arranged at the corresponding position of the lower mold of the mold. Protruding ring-shaped bosses, positioning magnets are set at the bottom of the special mold groove; a layer of cloth with a film that can be welded to each other under the action of ultrasonic waves is laid on the lower die of the mold, and a magnet block is placed on the film of the cloth. Cover the magnet block with a layer of fabric with the same welding ability under the action of ultrasonic waves, place the upper mold of the mold on the upper fabric, press the ring-shaped boss of the lower mold with the plane of the upper mold, and start the mould. Ultrasonic device, through ultrasonic wave, two layers of cloth PVC film or PU film are welded at room temperature. The invention uses a special mold to place the required magnets according to their positions, and then uses ultrasonic vibration to fuse the film layers of the cloth. Due to the ultra-high-speed ultrasonic vibration, the film layers of the upper and lower layers of cloth are welded, so that the magnet block is fixed on the The ideal fixing effect is achieved between the upper and lower layers of the fabric, saving time and improving work efficiency.

Owner:JIANGSU REAK HEALTHY ARTICLES CO LTD

Bottom assembling electromagnetic agitator for direct current excitation smelting furnace

InactiveCN101509730BInexpensive materialsMagnetic influenceMechanical apparatusStirring devicesMagnetic polesEngineering

The invention discloses a bottom-mounted electromagnetic stirrer used for a direct current (DC) electric-excitation melting furnace, consisting of an exciter coil, an iron core, a yoke iron, a collector ring, a mainshaft, a bracket, a rectifier system and a trailing system. The electromagnetic mixer is mainly characterized in that a DC power supply supplies the power to the exciter coil, namely, the magnetic field source of the stirrer is provided by a DC electromagnet consisting of a magnetic pole which consists of the iron core and the coil with DC. The stirrer has low material cost, the magnetism is not affected by the environmental temperature, the coil can be replaced during the malfunction, and therefore, the mixer has more advantages than an electromagnetic stirrer working at low frequency and a permanent magnetic mixer which uses the permanent magnets.

Owner:张森林

Non-oriented silicon steel for electric vehicle drive motor with excellent magnetic properties and production method

The invention provides non-oriented silicon steel with excellent magnetism and for a drive motor of an electric car. The non-oriented silicon steel comprises, by weight, 1.0 to 3.5% of Si, 0.5 to 2.0%of Al, 0.5 to 2.0% of Mn, no more than 0.003% of N, no more than 0.002% of S, no more than 0.003% of C, no more than 0.05% of P and no more than 0.05% of Cu. The production method for the non-oriented silicon steel comprises the following steps: smelting and casting; heating of continuously cast billet; rough rolling; finish rolling; reeling; normalizing; pickling; single-stage cold rolling; annealing; segmental speed-variable cooling; and natural cooling to room temperature for subsequent usage. With the method in the invention, the total number of AlN, MnS and Cu<x>S precipitates is no morethan 200 * 10<6> / mm<3>, the average size of the precipitates is no less than 0.50 [mu]m, and residual stress after annealing and cooling is no more than 70 MPa, so unfavorable influence of the AlN, MnS and Cu<x>S precipitates and residual stress on magnetism is effectively inhibited, and the produced non-oriented silicon steel for the drive motor of the electric car has a thickness of 0.27 to 0.35 mm, P<1.0 / 400> of no more than 16.0 W / kg and B<5000> of no less than 1.65 T.

Owner:武汉钢铁有限公司

A method for improving the amorphous forming ability of fe‑si‑b‑p bulk amorphous alloys

The invention provides method for improving the glass forming ability of Fe-Si-B-P series block amorphous alloy. The method is characterized in that when a molten mother alloy liquid is used to prepare a block alloy material through adopting a copper mold casting technology, the casting process is carried out in oxygen-containing atmosphere. Experiments confirm that the method can improve the glass forming ability of alloy, does not introduce too many other elements into amorphous alloy components, does not have great influences on the magnetic performance or other performances of the amorphous alloy, and allows conditions to be simply and easily controlled, so the method has good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

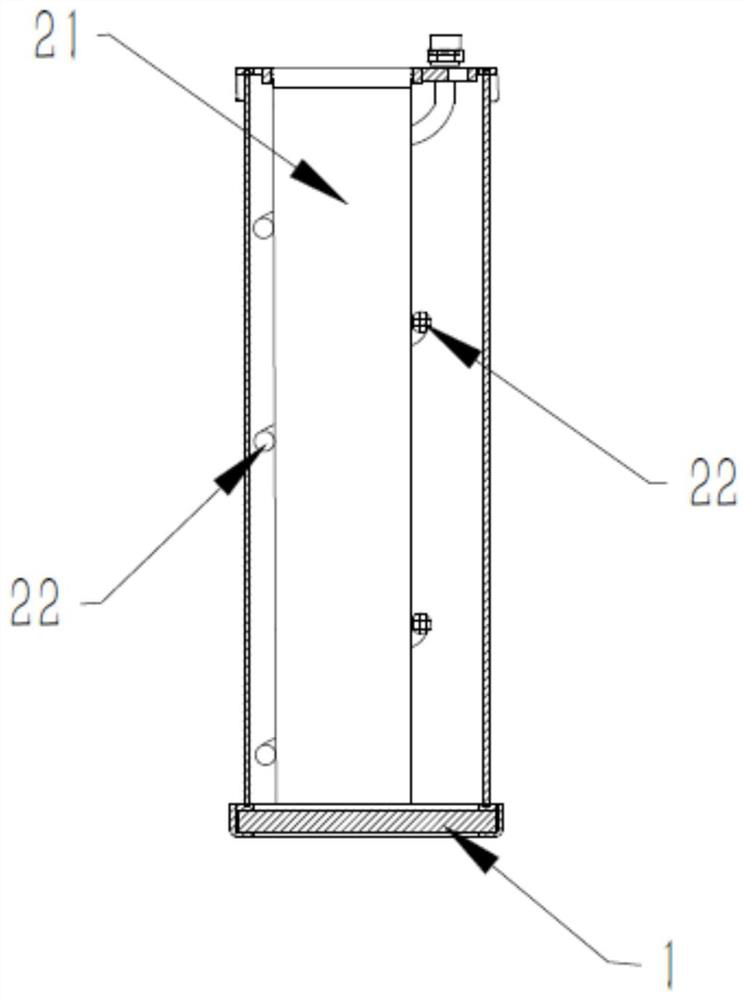

Magnetic material storage device and use method thereof

PendingCN113715641AMagnetic influenceEasy to fixCharging stationsShock-sensitive articlesStructural engineeringMaterial storage

The invention discloses a magnetic material storage device and a use method thereof. The magnetic material storage device comprises a base, a protective sleeve and a protective head, one end of the protective sleeve is fixedly connected with the base, the other end of the protective sleeve is provided with threads matching the protective head, the protective sleeve is of a hollow interlayer structure and comprises a first interlayer and a second interlayer, the second interlayer annularly sleeves the first interlayer, a baffle is arranged on the side, facing the protective head, of the protective sleeve and fixedly connected with the protective sleeve, and through holes matching the first interlayer and the second interlayer are formed in the baffle. A permanent magnet is protected through a special structure, so that after the permanent magnet is buried underground, the permanent magnet can be effectively protected, the permanent magnet is prevented from rusting or being in an environment with large temperature difference, and the maximum charging effect is achieved through a special burying mode.

Owner:深圳市贝贝特科技实业有限公司

A process for electroplating nickel-tungsten-phosphorus on the surface of sintered NdFeB magnets

ActiveCN104073849BAvoid corrosionImprove corrosion resistanceElectroless nickelBiological activation

The invention discloses a process for electroplating nickel-tungsten phosphorus on the surface of a sintered NdFeB magnet. In the process, the surface of the sintered NdFeB magnet is polished, alkaline degreased, and hot water washed successively, and then placed in an oxalic acid solution , soaking or ultrasonic activation treatment, electroplating nickel-tungsten phosphorus alloy coating on the surface of the sintered NdFeB magnet after activation treatment; The surface of the iron-boron magnet is homogenized, the bonding force between the surface of the NdFeB magnet and the nickel-tungsten-phosphorus alloy coating is enhanced, and the corrosion resistance of the NdFeB magnet is improved. The process is simple, the production cost is low, and it can be applied industrially.

Owner:湖南纳菲尔新材料科技股份有限公司

A double box sand mold for casting aluminum alloy parts

ActiveCN110064738BImprove yield rateImprove structural stabilityMoulding flasksScrew threadUltimate tensile strength

The invention belongs to the technical field of metal casting machining, and particularly relates to a dual box sand mould used for aluminum alloy component casting. The dual box sand mould comprisesan upper sand box and a lower sand box. The upper sand box and the lower sand box are fixed through bolts. Pin holes are formed in the outer walls of the sand boxes. Baffles are arranged on the outersides of the pin holes. Clamped connection grooves used for fixing the baffles are formed in the right sides of the baffles. Strong magnet lantern rings are arranged in screw holes. Cushion pipes arearranged in the strong magnet lantern rings, and corrugated springs are sleeved in gaps between the outer sides of the cushion pipes and the screw holes. External threads matched with internal threadsin the screw holes are arranged on the upper segments and the lower segments of screws of the bolts, the surface of the middle segment of each screw is free of a thread, and two contraction necks with the diameters gradually reduced are arranged in the middle segment of each screw. Limiting pins are arranged in the pin holes, and U-shaped grooves are formed in the front ends of the limiting pins.The sand mould is high in structural strength and strong in fastening function, the effects of vibration resistance and heat-resisting deformation prevention of the sand mould are relatively better,the screws cannot be locked in the casting process, and demolding is more convenient.

Owner:和县华顺铸造有限公司

Industrial high-temperature boiler steam water quantity detection equipment

ActiveCN111721378AReduce the impactReduce impactLevel indicators by physical variable measurementMagnetic effectLiquid water

The invention relates to the technical field of industrial boiler steam water quantity position measurement, and discloses industrial high-temperature boiler steam water quantity detection equipment comprising a shell, a liquid inlet pipe is fixedly connected to the interior of the shell; a sliding rail is arranged in the liquid inlet pipe; a sliding plate is movably connected to the surface of the sliding rail; a buffer spring is movably connected to the surface of the sliding plate; the surface of the buffer spring is movably connected with a guide shaft; the surface of the liquid inlet pipeis movably connected with a supporting rod; a magnetic plate is fixedly connected to the end, away from the liquid inlet pipe, of the supporting rod, a roller is movably connected to the surface of the magnetic plate, a push rod is movably connected to the surface of the roller, a movable rod is movably connected to the end, away from the roller, of the push rod, a location pipe is movably connected to the surface of the movable rod, and a pulse pipe is movably connected to the surface of the location rod. According to the magnetic effect of the current, the pulse current generates a pulse magnetic field, and the rear pulse pipe deforms under the influence of pulse magnetism so that the effect of detecting the water quantity in the furnace body by utilizing the intermittent adding characteristic of the liquid water is achieved.

Owner:山东林耀生物科技有限公司

Magnet fixing method used on magnetic therapy module

ActiveCN105153949AShorten the timeImprove work efficiencyAdhesive processesElectrotherapyPhysicsEngineering

The invention discloses a magnet fixing method used on a magnetic therapy module. A special die is designed according to a required shape of the magnetic therapy module, a groove for storing a magnet is formed in a corresponding position of a lower die of the die, an annular boss protruding outwards is arranged at the inside of the groove, and a positioning magnet is arranged at the bottom of the groove of the special die; a layer of cloth capable of being subjected to butt fusion under the action of ultrasonic waves is arranged on the lower die of the die, a magnetic block is placed on the membrane of the cloth, a layer of same cloth capable of being subjected to butt fusion under the action of ultrasonic waves is arranged again on the magnetic block, an upper die of the die is placed on the cloth at the upper layer, the annular boss of the lower die and the plane of the upper die are compressed, an ultrasonic wave device of the die is started, and PVC or PU membranes of the two layers of cloth are subjected to butt fusion at normal temperature by the ultrasonic waves. The special die is adopted to place the magnet in the required position, the membrane layers of the cloth are subjected butt fusion by vibrating through the ultrasonic waves, and since the membrane layers of the upper and lower layers of cloth are subjected to butt fusion by the vibration of the ultrahigh-speed ultrasonic waves, the magnetic block is fixed between the upper and lower layers of cloth, an ideal fixing effect is achieved, time is saved and work efficiency is improved.

Owner:JIANGSU REAK HEALTHY ARTICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com