A method for fixing magnets on a magnetic therapy module

A magnet fixation and magnet technology, applied in magnetic therapy, electrotherapy, bonding methods, etc., can solve the problems of affecting the overall appearance, poor product consistency, poor fixing effect, etc., and achieve the effect of improving work efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for fixing magnets on a magnetic therapy module, including the following steps:

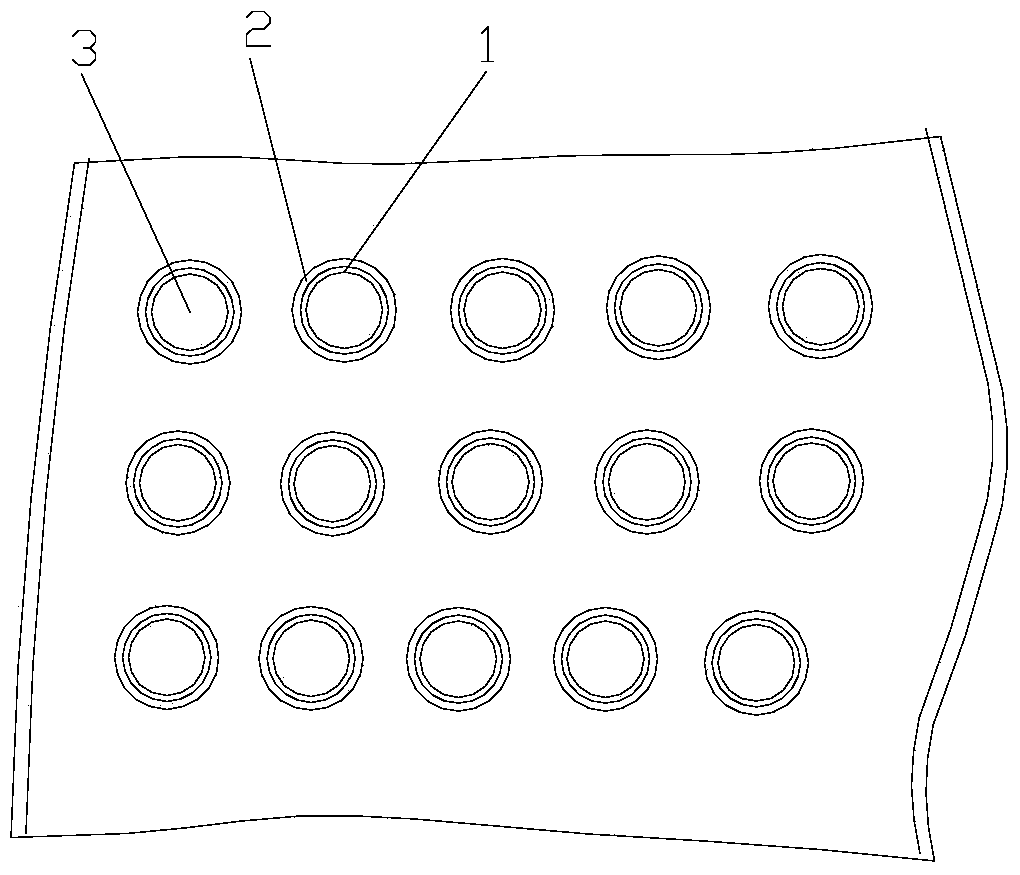

[0023] (1) Design a special mold according to the required shape of the magnetic therapy module, the structure is as follows figure 1 As shown, a groove 1 for storing magnets is provided at the corresponding position of the lower mold of the mold, an outwardly protruding annular boss 2 is arranged on the inner side of the groove, and a positioning magnet 3 is arranged at the bottom of the special mold groove;

[0024] (2) Lay a layer of cloth that can be welded to each other under the action of ultrasonic waves on the lower mold of the mold. A welding film is provided on one side of the cloth. The welding film of the cloth is set upwards. The thickness of the film is 1.0mm. contact with the lower die of the mould;

[0025] (3) Place a magnet block on the welding film of the fabric, and select the corresponding magnetic field strength of the magnet accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com