Method for improving glass forming ability of Fe-Si-B-P series block amorphous alloy

A fe-si-b-p, amorphous alloy technology, applied in the field of amorphous alloy preparation, can solve the problem of unsatisfactory improvement of the amorphous formation ability of the alloy, achieve simple and easy control conditions, easy popularization and application, and improve amorphous alloys. Effect of crystal forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

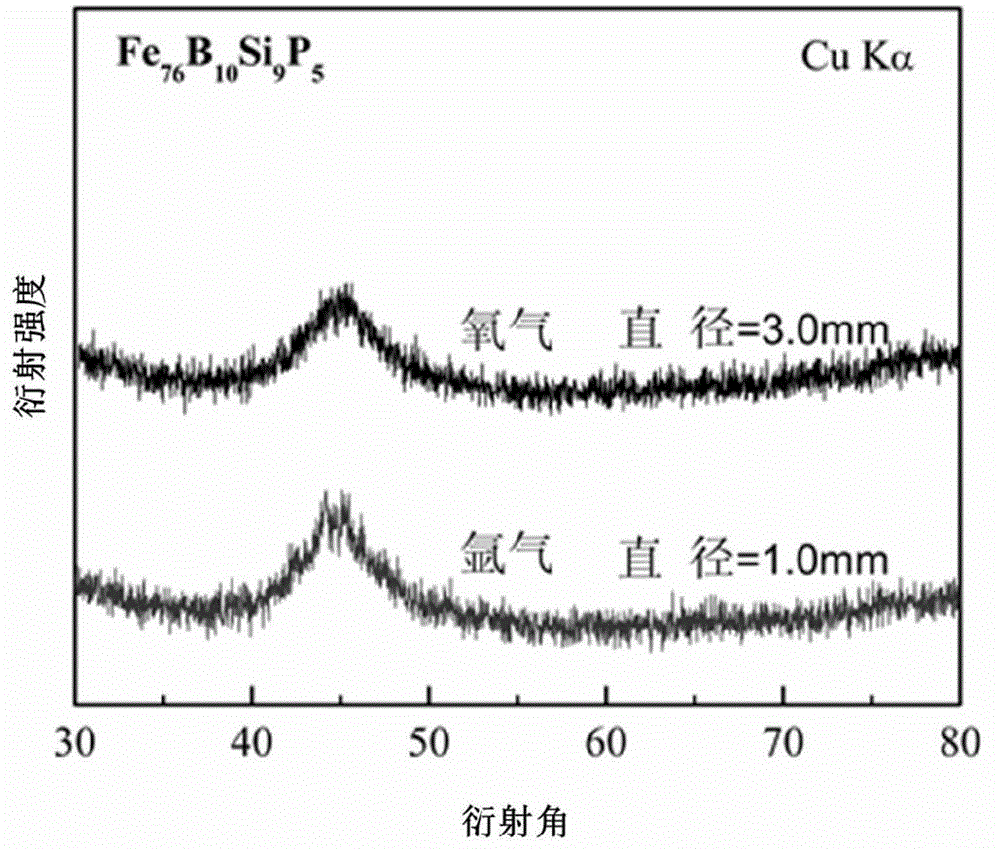

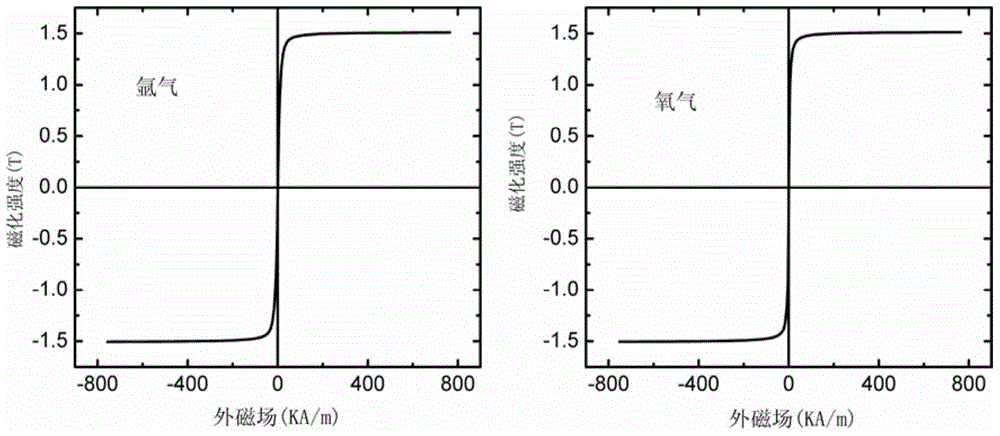

[0033] In this embodiment, the molecular formula of the amorphous alloy material is Fe 76 Si 9 B 10 P 5 .

[0034] The preparation method of the amorphous alloy material comprises the following steps:

[0035] (1) select the raw material whose purity is more than 99.5%, and make ingredients according to the molecular formula of the amorphous alloy;

[0036] (2) Put the raw materials prepared in step 1 into the induction melting furnace for melting, and vacuumize to -5×10 -3 Below Pa, fill with nitrogen or argon atmosphere protection, keep warm for 20 to 30 minutes after melting, so that the alloy raw material is melted into a uniform molten steel, and then cooled with the furnace or injected into the mold to obtain the master alloy ingot;

[0037](3) After crushing the master alloy ingot obtained in step (2), put it into an open quartz glass tube, place it in the induction coil of the liquid quenching device, and evacuate it to -5×10 -3 Below Pa, it is filled with air or...

Embodiment 2

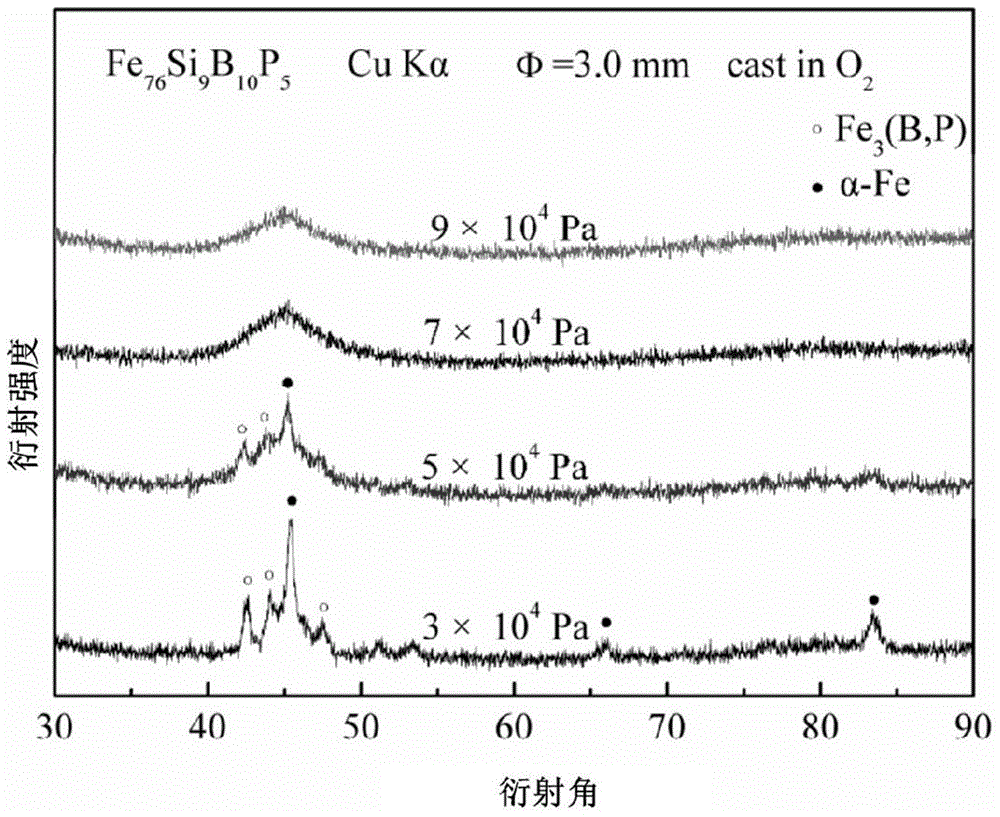

[0058] In Example 2, the molecular formula of the amorphous alloy material is exactly the same as that of the above-mentioned Example 1, both of which are Fe 76 Si 9 B 10 P 5 .

[0059] In Example 2, the preparation method of the amorphous alloy material is basically the same as that of the above-mentioned Example 1, except that in order to observe the influence of the pressure of the oxygen atmosphere on the amorphous forming ability of the alloy, a pressure of 3×10 4 Pa, 5×10 4 Pa, 7×10 4 The oxygen atmosphere of Pa is hydraulically poured the molten master alloy into Cu molds with different diameters, including Cu molds with diameters of 1mm, 2mm, 3mm, 4mm, etc., to obtain bulk amorphous alloy rod samples by copper mold casting method. Rod samples with a diameter of 3 mm were analyzed.

[0060] image 3 It shows the XRD patterns of the amorphous alloy rods with a diameter of 3 mm cast in the above-mentioned oxygen atmosphere at different pressures. From image 3 It...

Embodiment 3

[0062] In this embodiment, the molecular formula of the amorphous alloy material is Fe 76 P 5 (B 0.5 Si 0.3 C 0.2 ) 19

[0063] The preparation method of the amorphous alloy material comprises the following steps:

[0064] (1) select the raw material whose purity is more than 99.5%, and make ingredients according to the molecular formula of the amorphous alloy;

[0065] (2) Put the raw materials prepared in step 1 into the induction melting furnace for melting, and vacuumize to -5×10 -3 Below Pa, fill with nitrogen or argon atmosphere protection, keep warm for 20 to 30 minutes after melting, so that the alloy raw material is melted into a uniform molten steel, and then cooled with the furnace or injected into the mold to obtain the master alloy ingot;

[0066] (3) After crushing the master alloy ingot obtained in step (2), put it into an open quartz glass tube, place it in the induction coil of the liquid quenching device, and evacuate it to -5×10 -3 Below Pa, it is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical dimension | aaaaa | aaaaa |

| Critical dimension | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com