Patents

Literature

111results about How to "Stable structural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

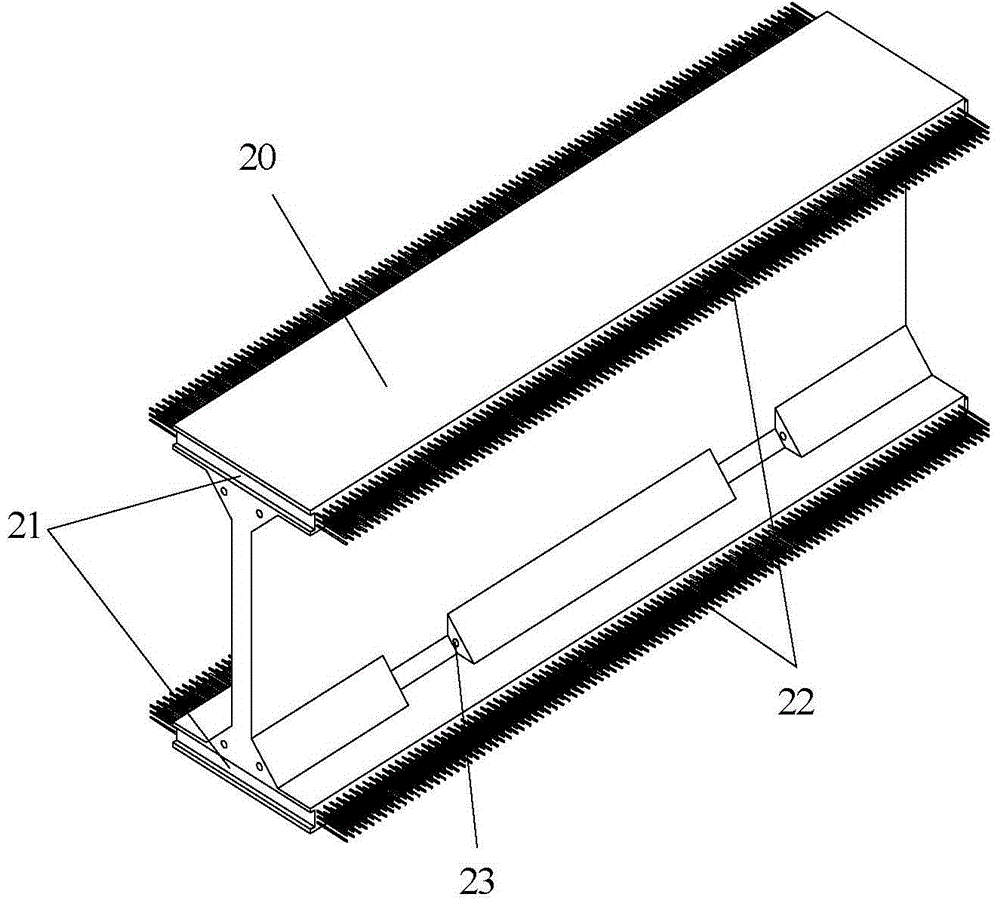

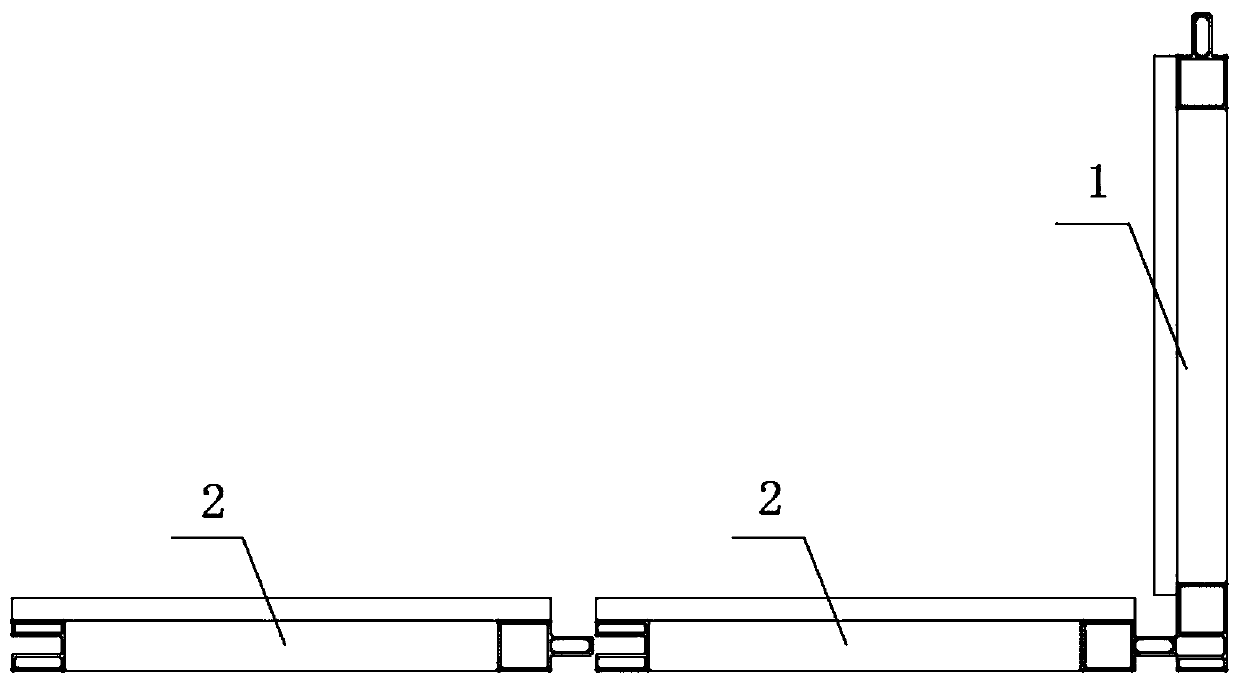

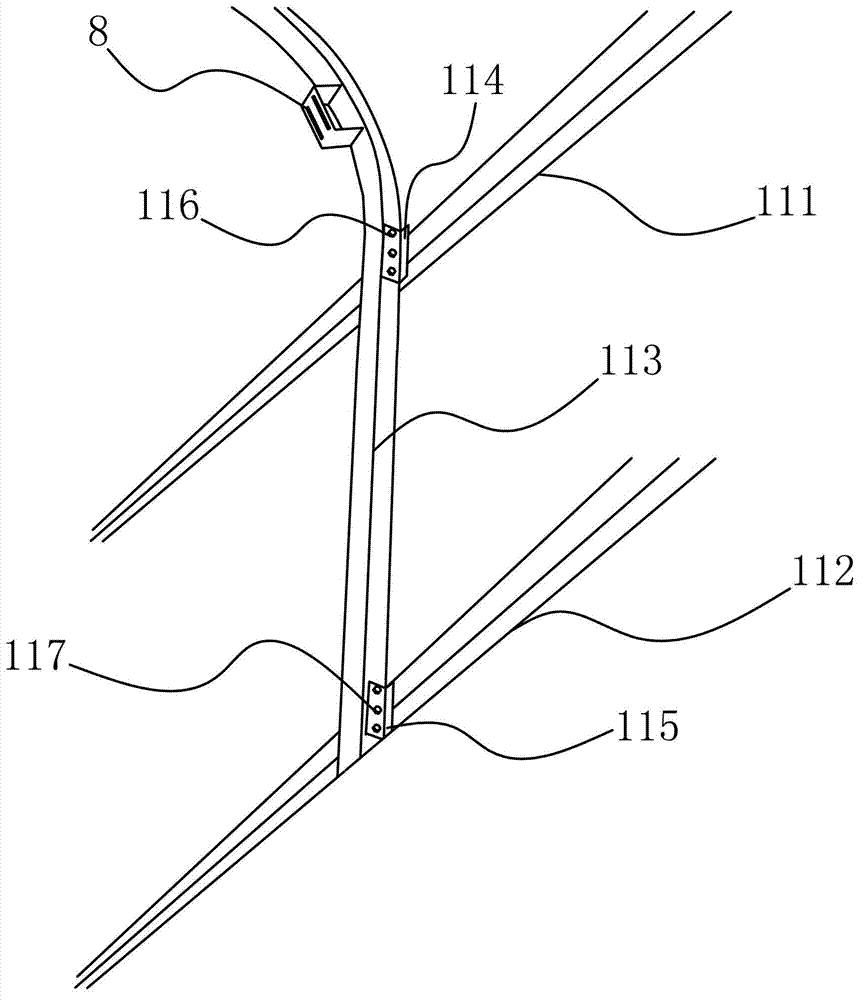

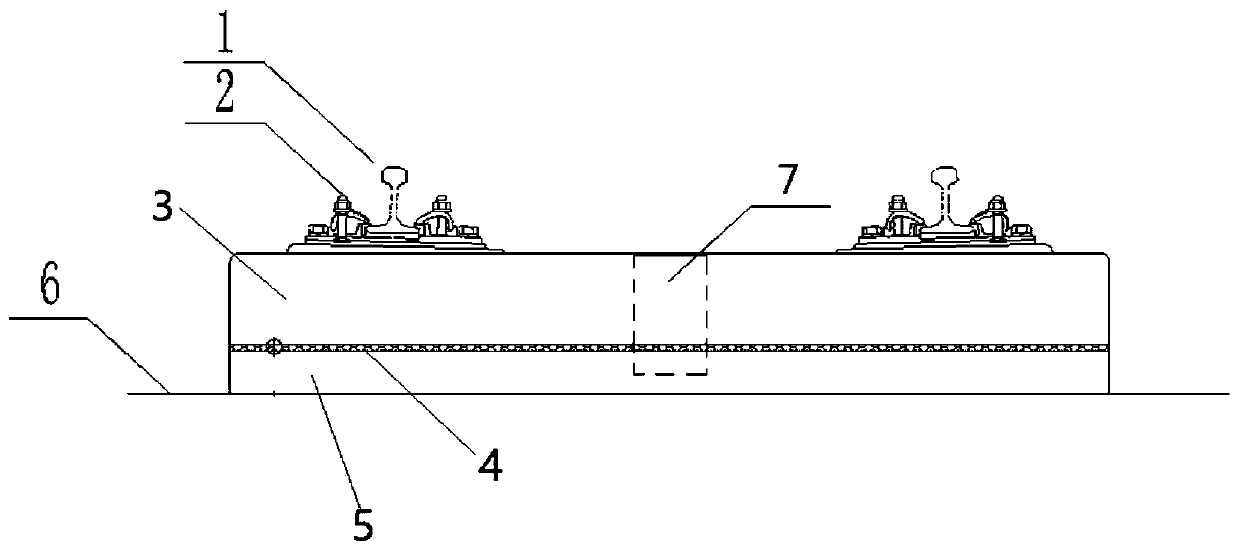

Concrete hollow slab bridge reinforced by transverse steel beams

InactiveCN102635060AStable structural strengthImprove structural strengthBridge structural detailsSingle plateBridge deck

The invention discloses a concrete hollow slab bridge reinforced by transverse steel beams. The concrete hollow slab bridge comprises a bridge deck beam constituted by arranging a plurality of hollow plate beams in parallel and at least one stiffening cross beam which is arranged on the bottom surface of the bridge deck beam and is used for transversely reinforcing the bridge deck beam so as to enable all the hollow plate beams to transversely transfer loads on the hollow plate beams, wherein the stiffening cross beam is fixedly connected with the hollow plate beams. According to the concrete hollow slab bridge reinforced by the transverse steel beams, disclosed by the invention, the overall structural strength is high, the bearing capacity of the bridge is strong, the single-plate stress can be avoided by reinforcing through the transverse steel beams, the service life of the bridge is prolonged, and the concrete hollow slab bridge has the advantages of simple structure construction, easiness in ensuring engineering construction quality, good stress performance, obvious reinforcing effect, convenience and quickness in construction, lower requirements for machines, tools and equipment required for construction and significant economic benefits, and is further conductive to popularization.

Owner:茅桥交通科技(东莞)有限公司 +1

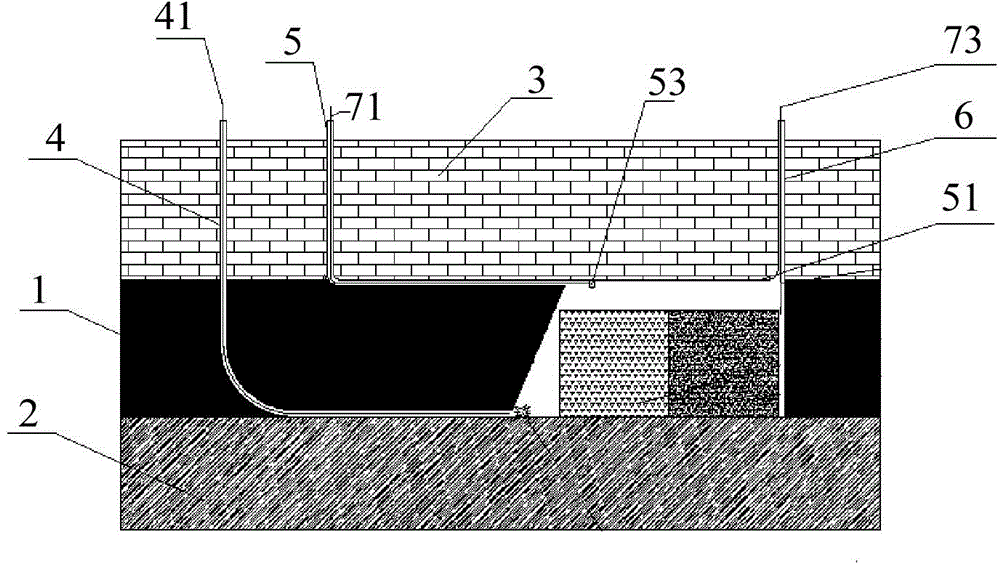

Coal underground gasification system and control method

ActiveCN104563992AStable structural strengthAvoid fluctuations or even shortfallsConstructionsFluid removalCoalEngineering

The invention relates to a coal underground gasification system and a control method. The coal underground gasification system comprises a bottom plate, a top plate, a first directional drill, a second directional drill and a vertical well, wherein the first directional drill penetrates through the top plate and a target coal layer, is bent, extends into a combustion area, and is communicated with the combustion area; the vertical well is communicated with the communication area; the second directional drill penetrates through the top plate, is bent, and is communicated with the communication area; an air inlet passage is arranged in the first directional drill and is communicated with the combustion area; a first filling material conveying pipeline is arranged in the second directional drill, a second filling material conveying pipeline is arranged in the vertical well, and the first filling material conveying pipeline and the second filling material conveying pipeline are communicated with the combustion area. The coal underground gasification system has the advantages that by filling the combustion area, the size of the combustion area is in a dynamic balance state, the fluctuating and insufficiency of a gasification agent caused by the expansion of the combustion space area are avoided, and the stability of combustion strength and the combustion quality are improved; the defects of movement, cracking damage and surface sinking of a coal rock layer above the combustion space area are avoided, and the production safety of a gasification furnace is improved.

Owner:ENN SCI & TECH DEV

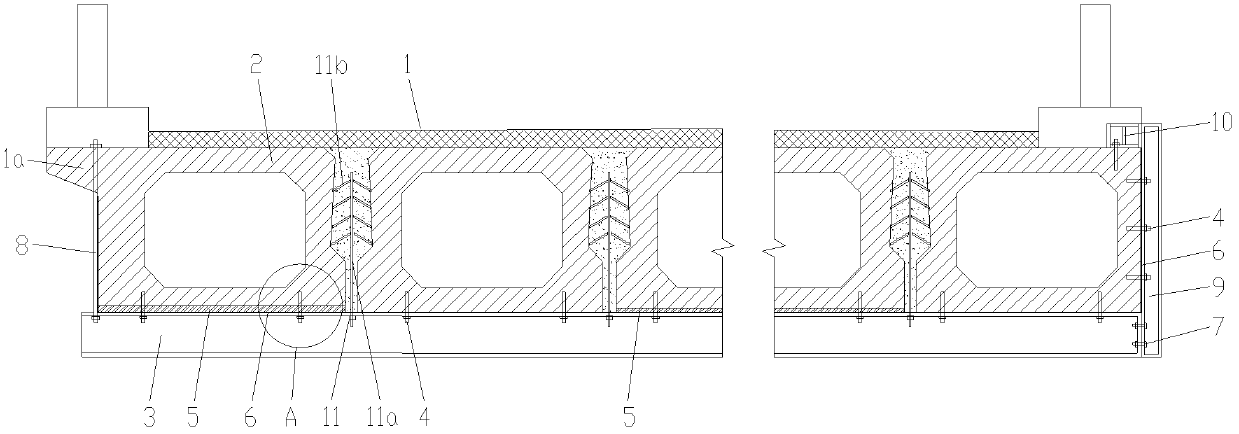

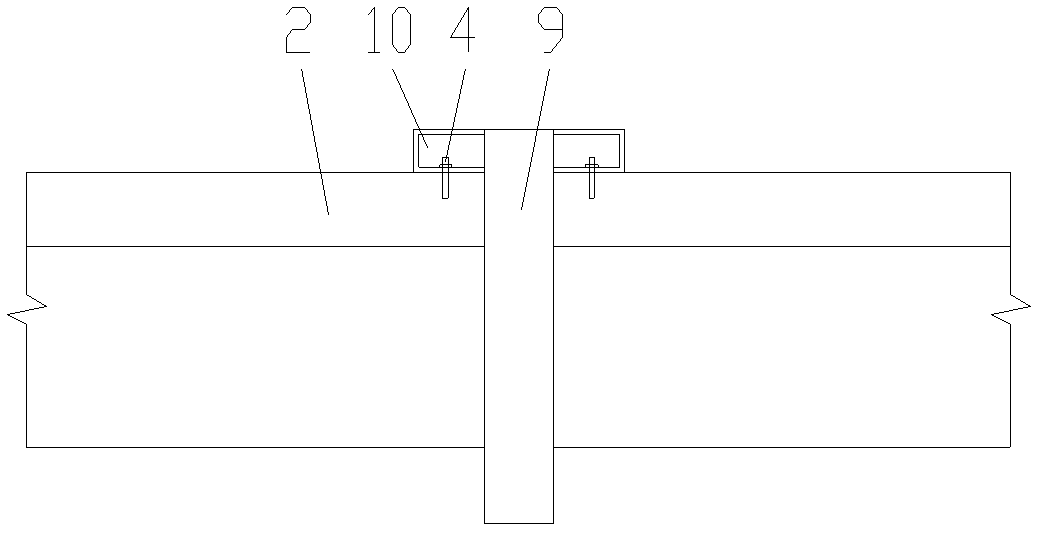

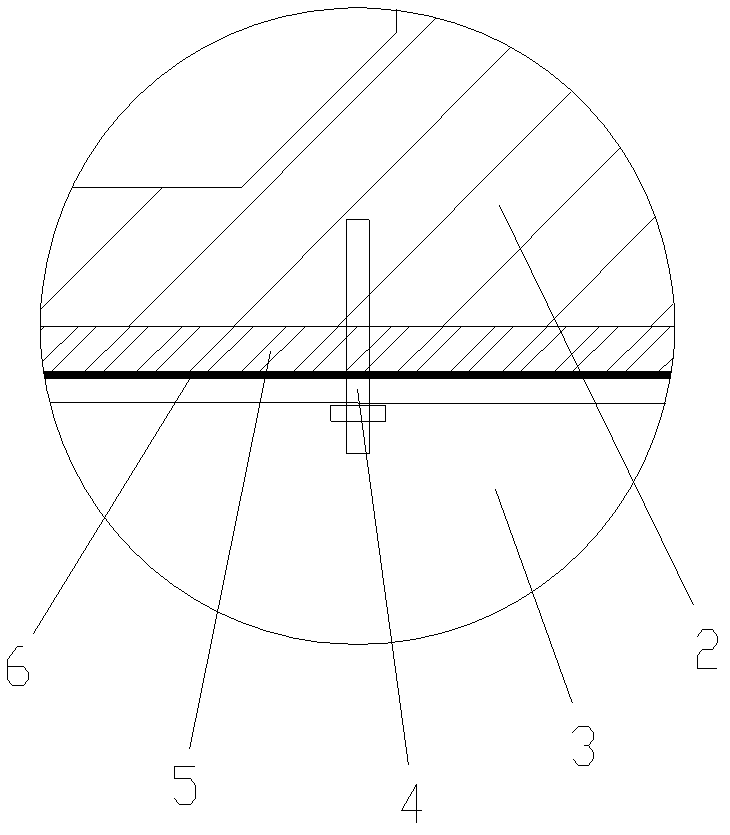

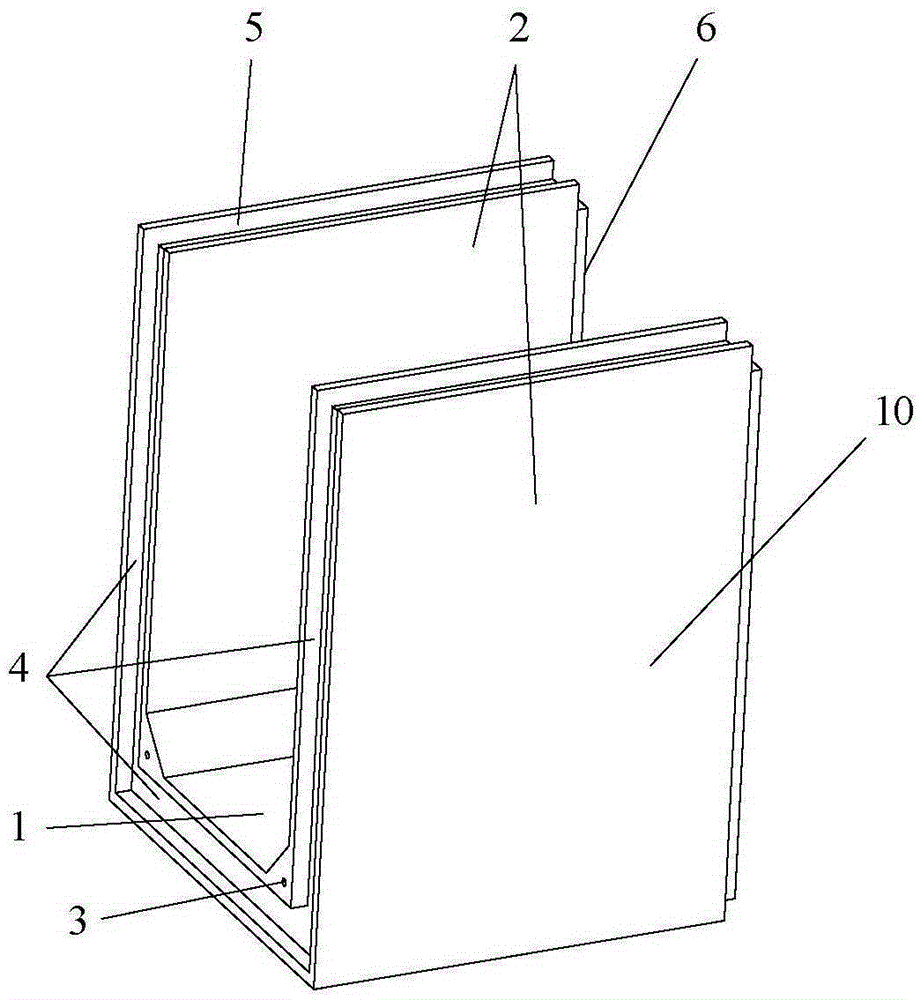

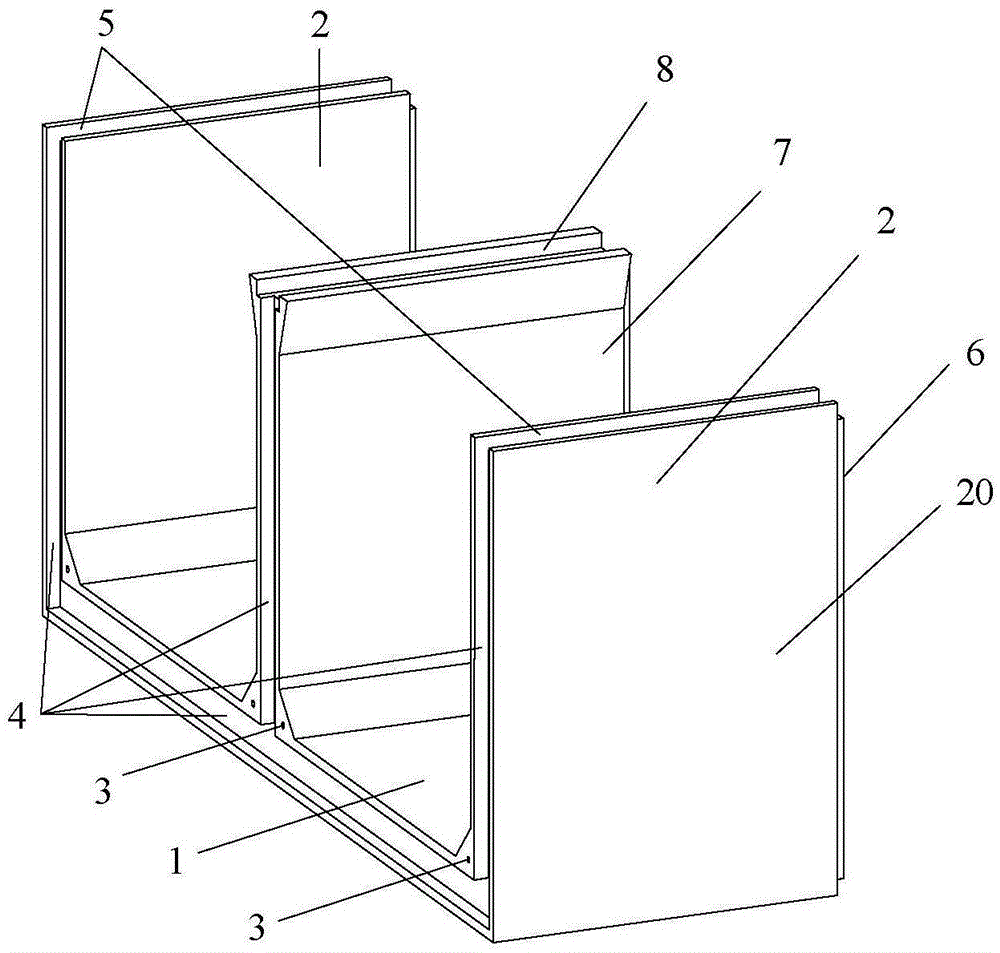

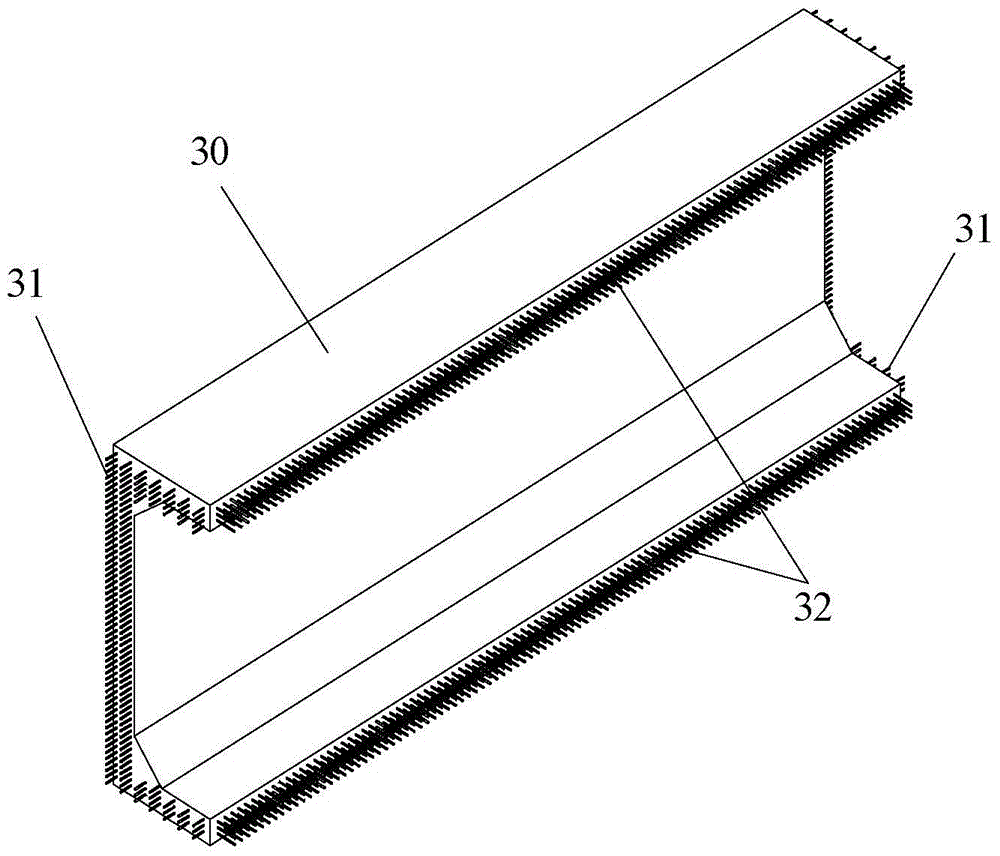

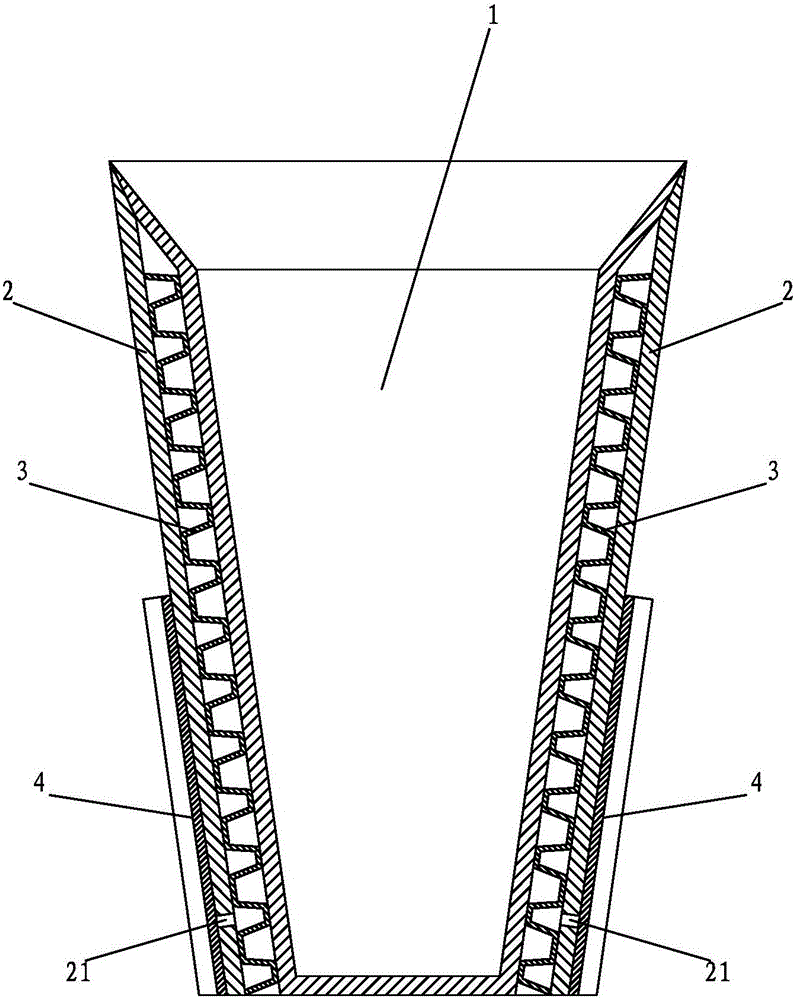

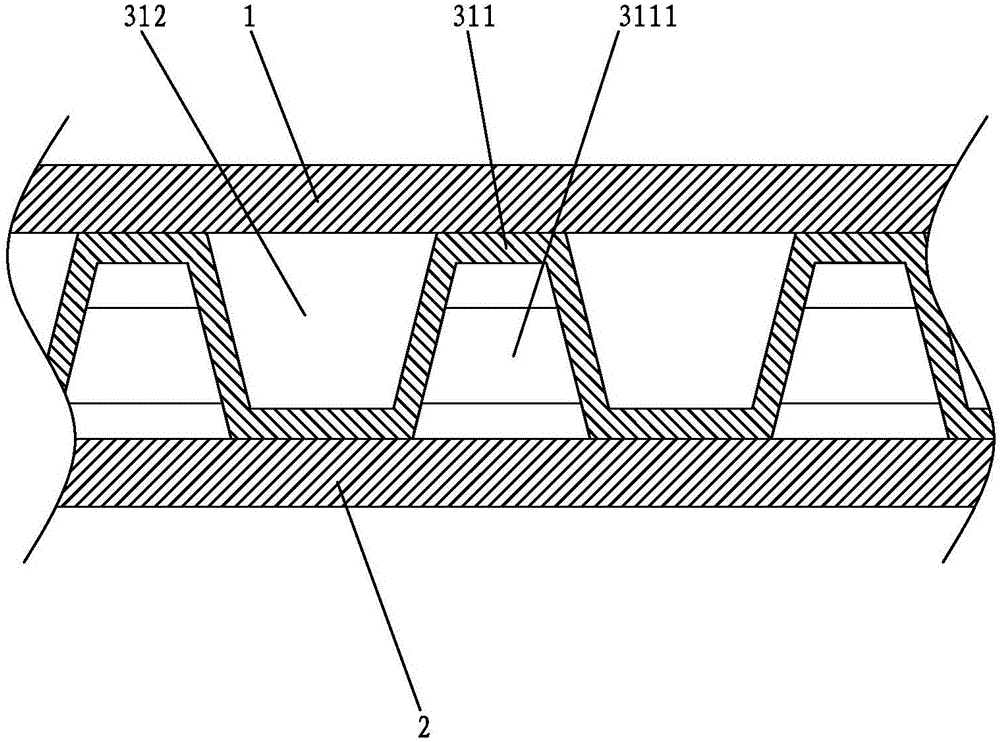

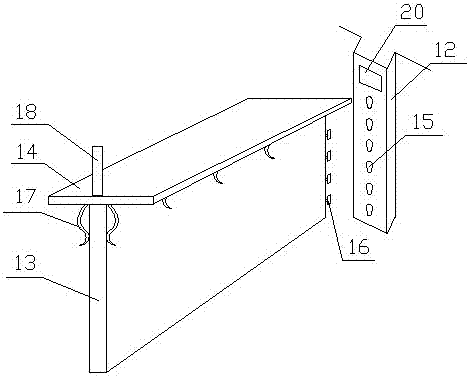

Pipe gallery prefabricated member and assembled comprehensive pipe gallery

InactiveCN105256837AEasy to transportStable structural strengthArtificial islandsUnderwater structuresUtility tunnelEngineering

The invention provides a pipe gallery prefabricated member and an assembled comprehensive pipe gallery. The pipe gallery prefabricated member comprises a bottom frame prefabricated member and a cover board prefabricated member. The bottom frame prefabricated member comprises a bottom board, vertical boards, internal reinforcing pieces of the bottom board and the vertical boards and prestress steel cable holes formed in the inside corners connected with the bottom board and the vertical boards. A U-shaped bin groove is formed by every two adjacent vertical boards and the bottom board. The bottom frame prefabricated member at least comprises one U-shaped bin groove. Grooves A and protrusions A are arranged on the end faces of the portions, on the two sides of each U-shaped bin groove, of the bottom board and the end faces of the vertical boards respectively, wherein the protrusions A are inserted in the grooves A in a matched manner. Grooves B are formed in the upper end faces of the vertical boards of the U-shaped bin grooves. The cover board prefabricated member comprises protrusions B arranged on the bottom face and inserted in the grooves B in a matched manner, grooves C and protrusions C, wherein the two ends of the cover board prefabricated member are provided with the grooves C and the protrusions C, and the protrusions C are inserted in the grooves C in a matched manner. The pipe gallery comprises sealing pads, prestress steel cables, the bottom frame prefabricated member and the cover board prefabricated member. The needed pipe gallery is formed by assembling the bottom frame prefabricated member and the cover board prefabricated member. By the adoption of the pipe gallery prefabricated member and the assembled comprehensive pipe gallery, the site assembling construction load is low, transport and installation cost is low, assembling operation is flexible, and various use requirements are met.

Owner:SHENZHEN HUAHAN GUANLANG PROPERTY SERVICES CO LTD

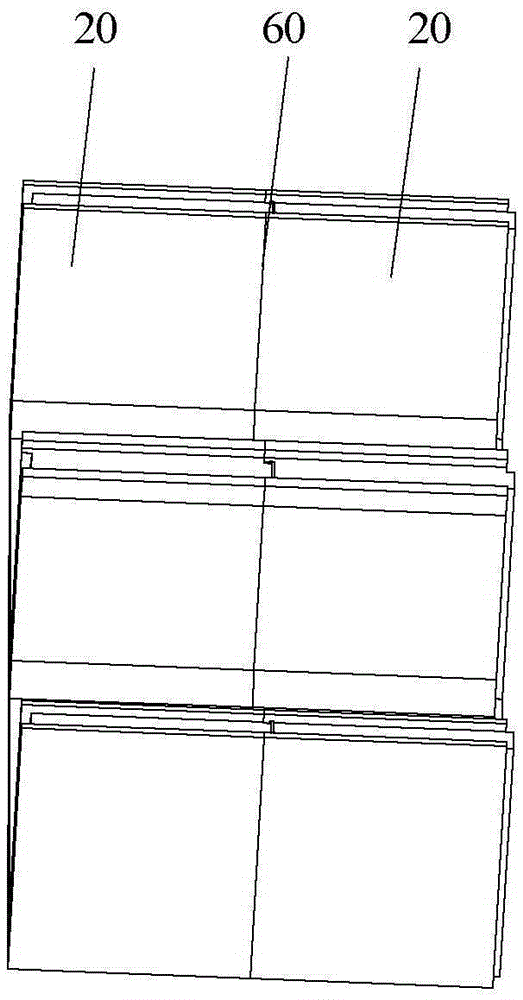

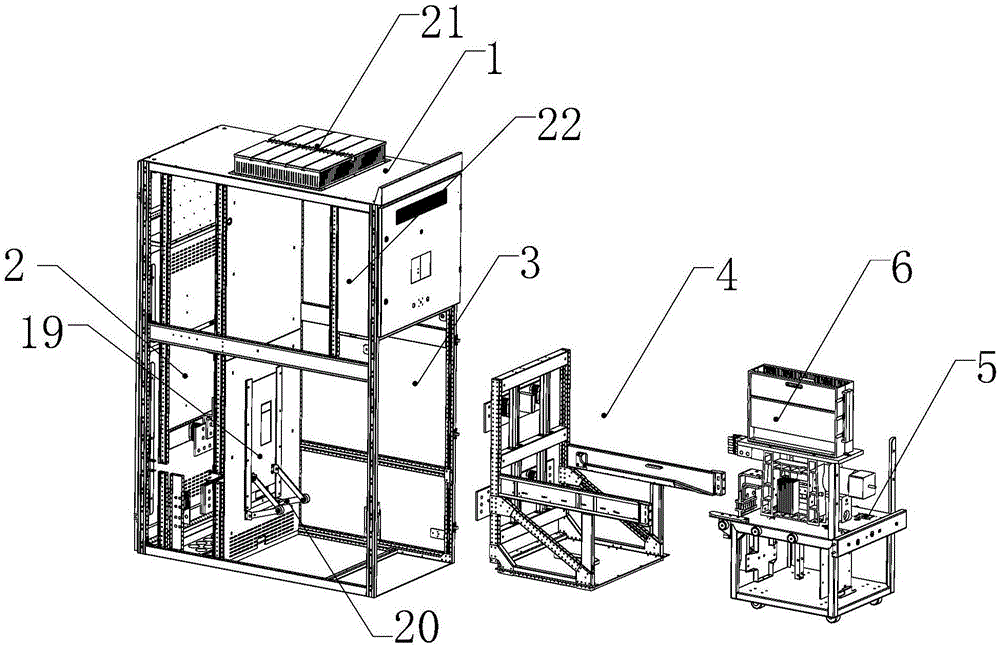

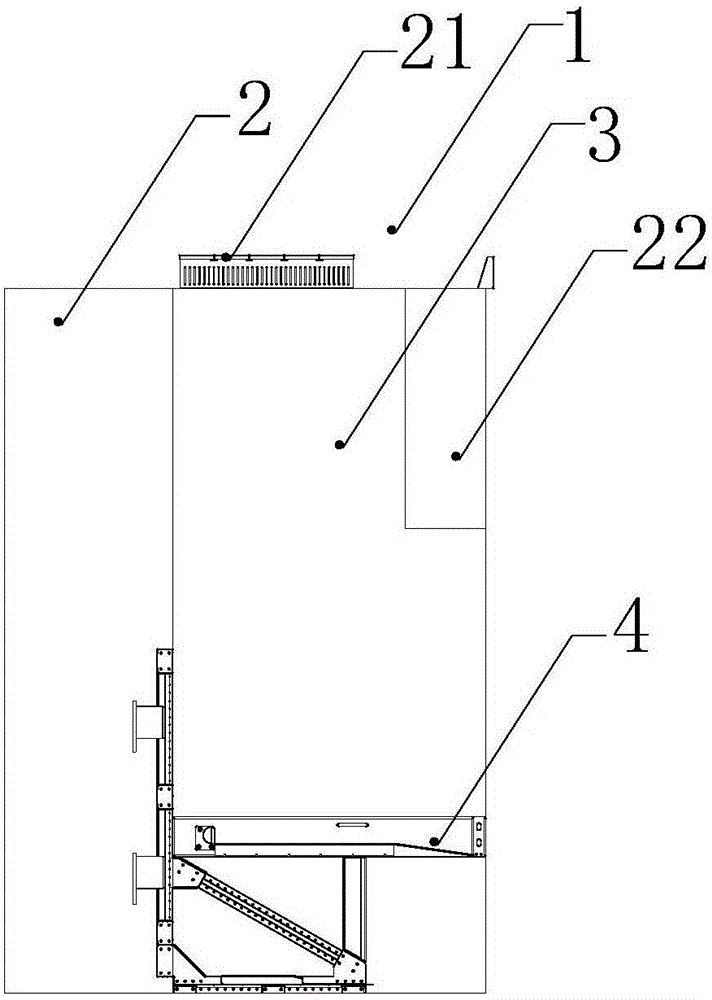

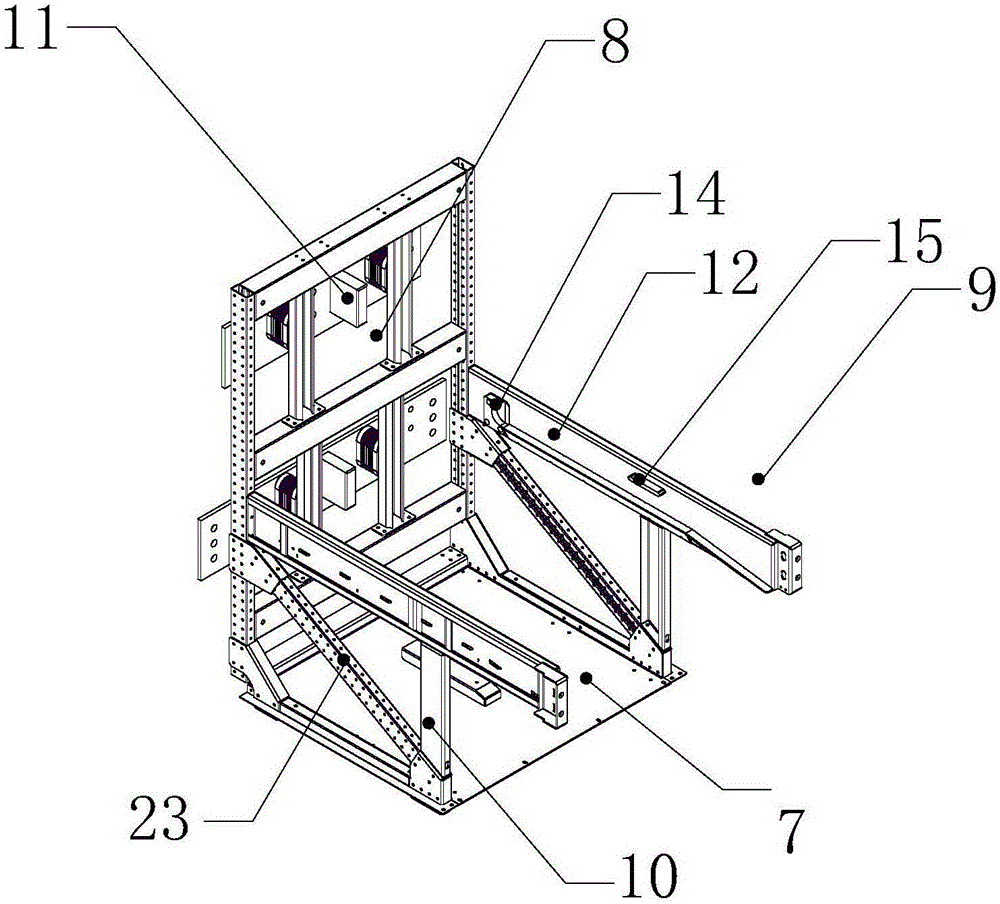

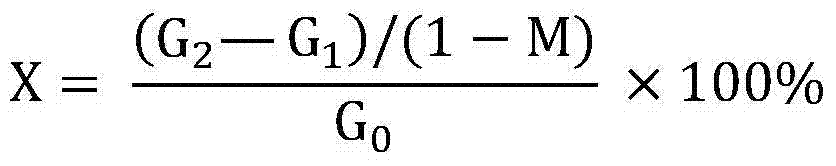

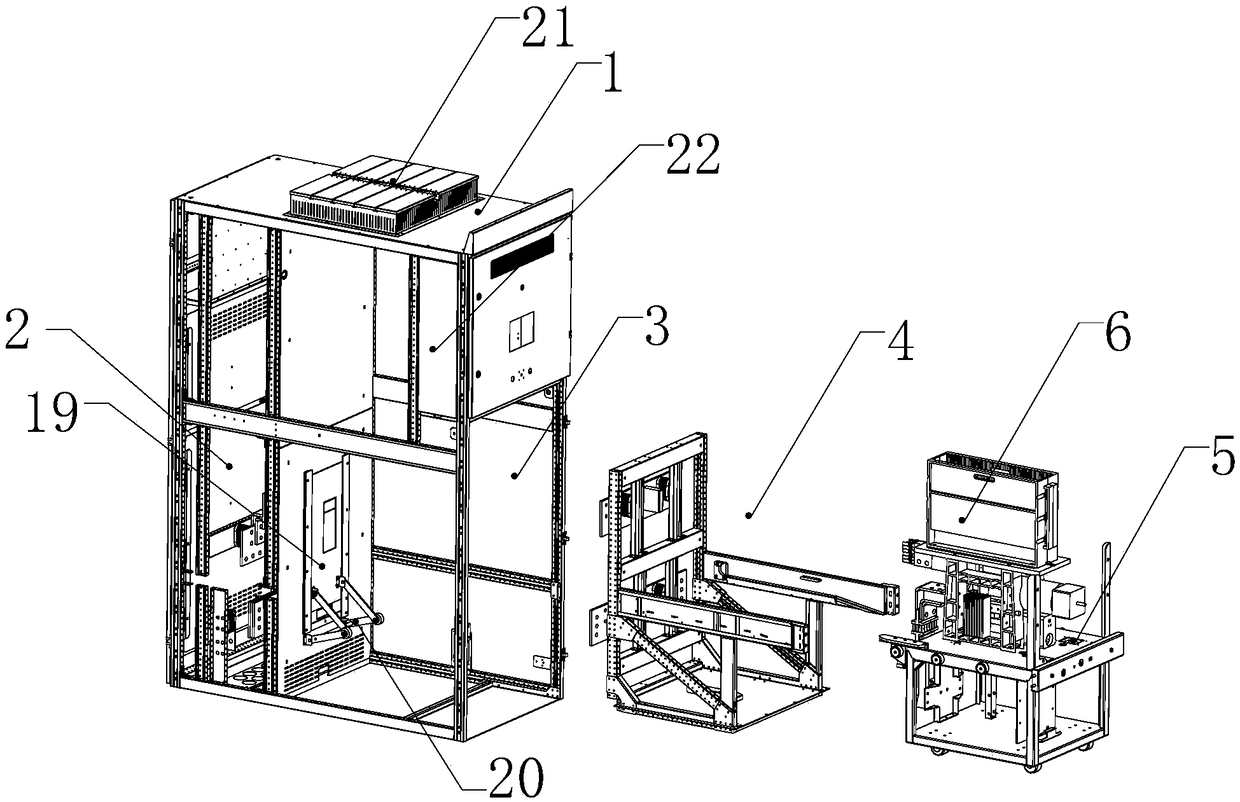

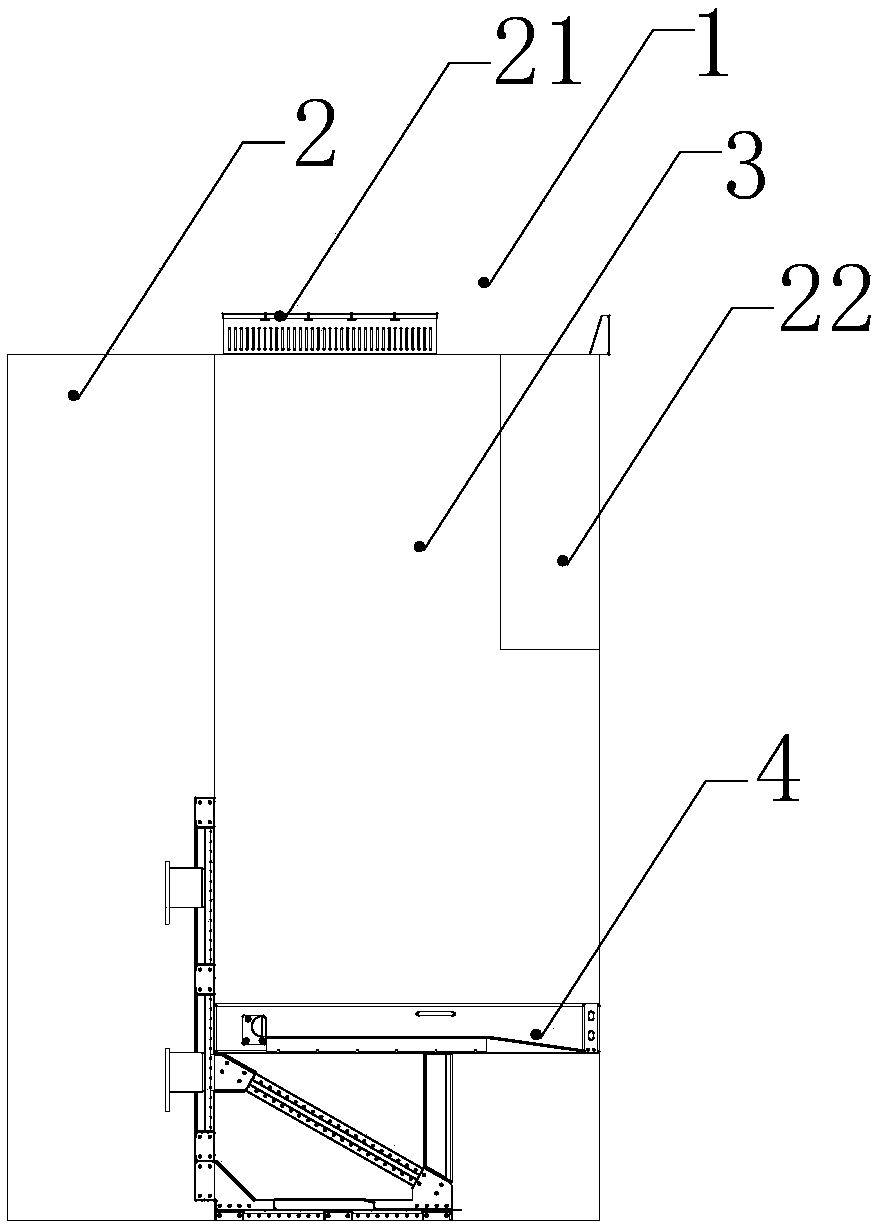

Modularization direct current traction feeder cabinet

ActiveCN106558849ASimple structureOvercome stabilitySwitchgear detailsSubstation/switching arrangement casingsElectrical stabilityBusbar

The present invention relates to a modularization direct current traction feeder cabinet. The cabinet comprises a cabinet body, the front side of the cabinet body is provided with a cabinet door capable of opening or closing, the interior of the cabinet body is divided into a busbar chamber and a breaker chamber, the breaker chamber is located at the front side of the busbar chamber, the breaker chamber is internally provided with a breaker distribution cabinet unit and a breaker handcart, the breaker distribution cabinet unit is fixedly arranged at the inner bottom surface of the breaker chamber, the breaker handcart is arranged in the breaker distribution cabinet unit, and when the cabinet door is opened, the breaker handcart can be pulled out or pushed into the breaker distribution cabinet unit from the opening of the cabinet door; and the upper portion of the breaker handcart is provided with the breaker, when the breaker handcart is pushed into the breaker distribution cabinet unit, the breaker is contacted with and electrically connected with the copper bar in the busbar chamber. The structure is concise, and the breaker unit portion with high matching requirement is subjected to modularization design to improve the matching precision of the breaker contact so as to greatly improve the electrical stability performances of products and realize the complete interchangeability of the breaker distribution cabinet.

Owner:WUHAN ZHONGZHI ELECTRIC

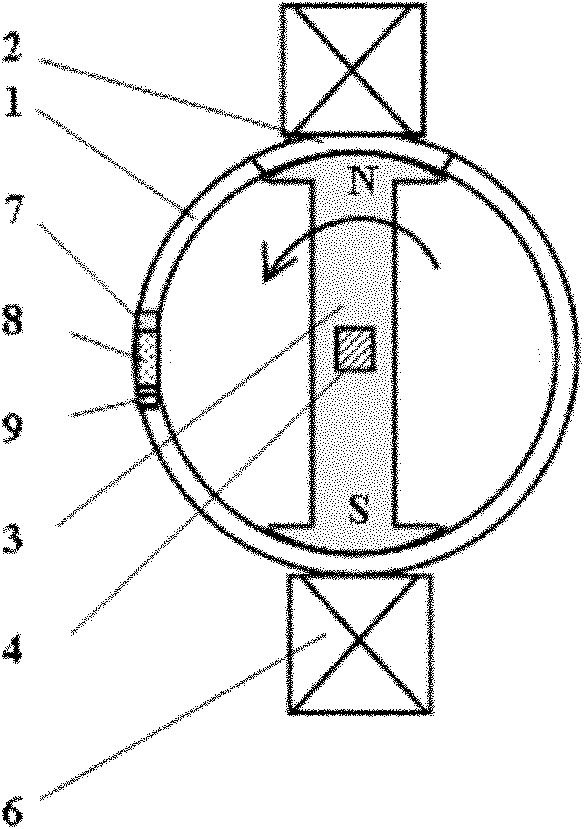

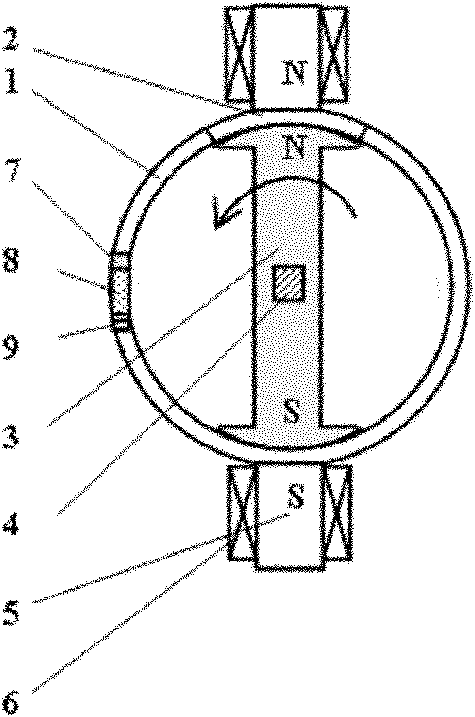

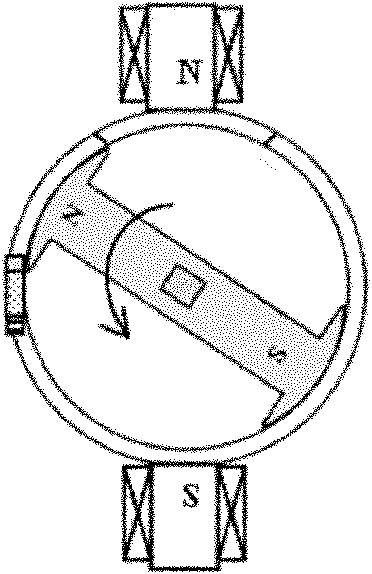

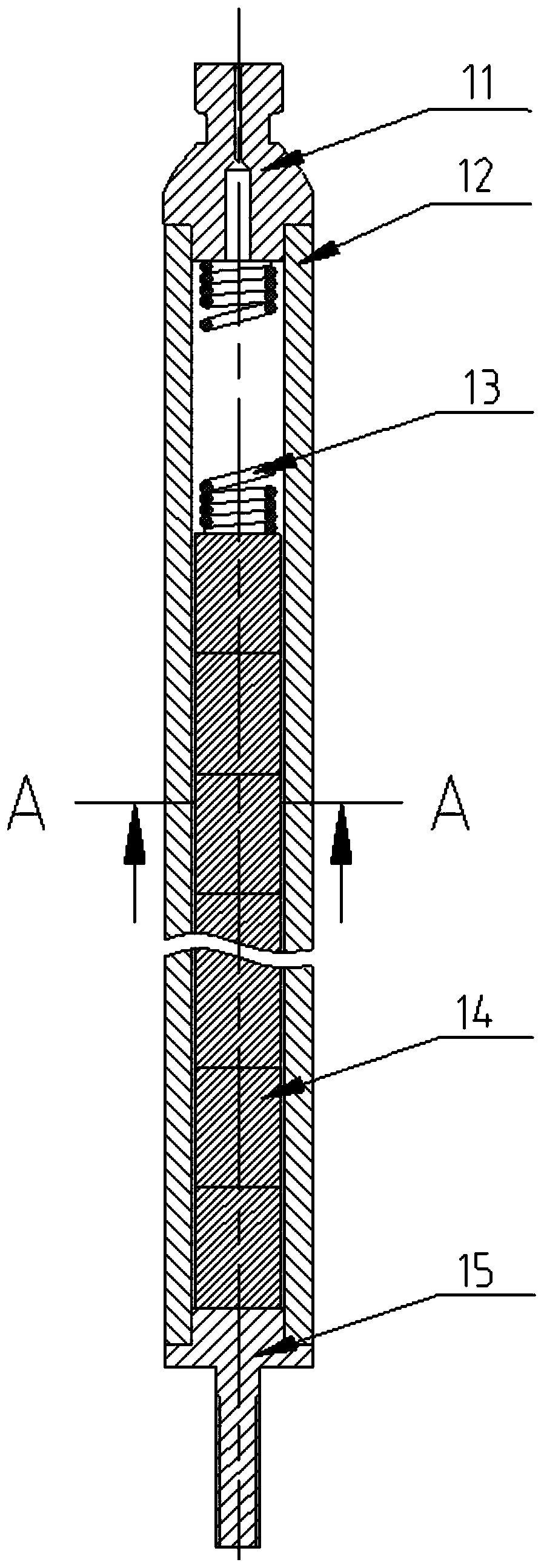

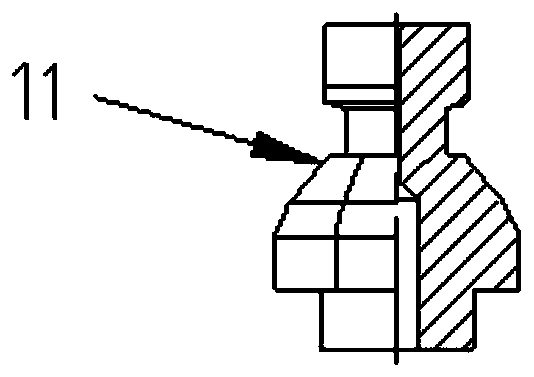

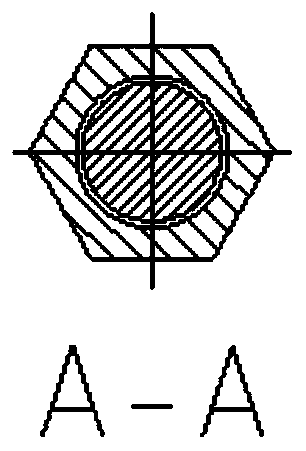

Self-driven joint

ActiveCN101956891ASimple joint structureLess componentsStands/trestlesStructural associationElectrical polaritySelf driven

The invention discloses a self-driven joint, which belongs to the technical field of driving sensing control. The self-driven joint comprises a sleeve, a structural permanent magnet and a magnetic field generating device. The structural permanent magnet is arranged in the sleeve in a way of rotating around the axis of the sleeve. The magnetic field generating device is fixedly arranged outside the sleeve and comprises a magnetostrictive piezoelectric sensor and corresponding electromagnetic coils, wherein the plurality of pairs of corresponding electromagnetic coils with opposite polarities are oppositely arranged on the outer wall of the sleeve; and the magnetostrictive piezoelectric sensor is arranged on the side wall of the sleeve. The self-driven joint has a compact structure and high structural strength and can acquire sensor electric signal conveniently without being driven by any power supply.

Owner:伶机(上海)驱动技术中心(有限合伙)

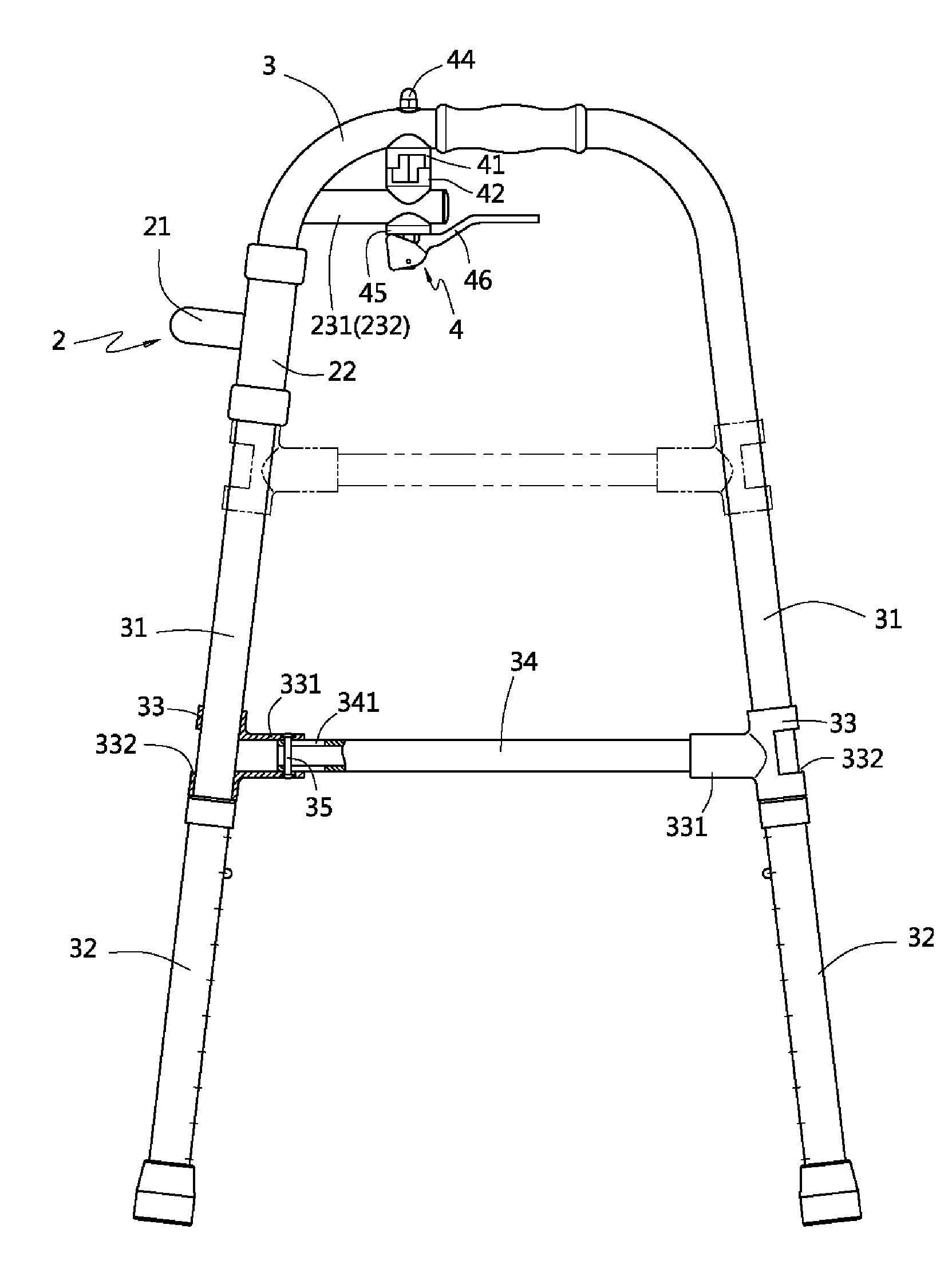

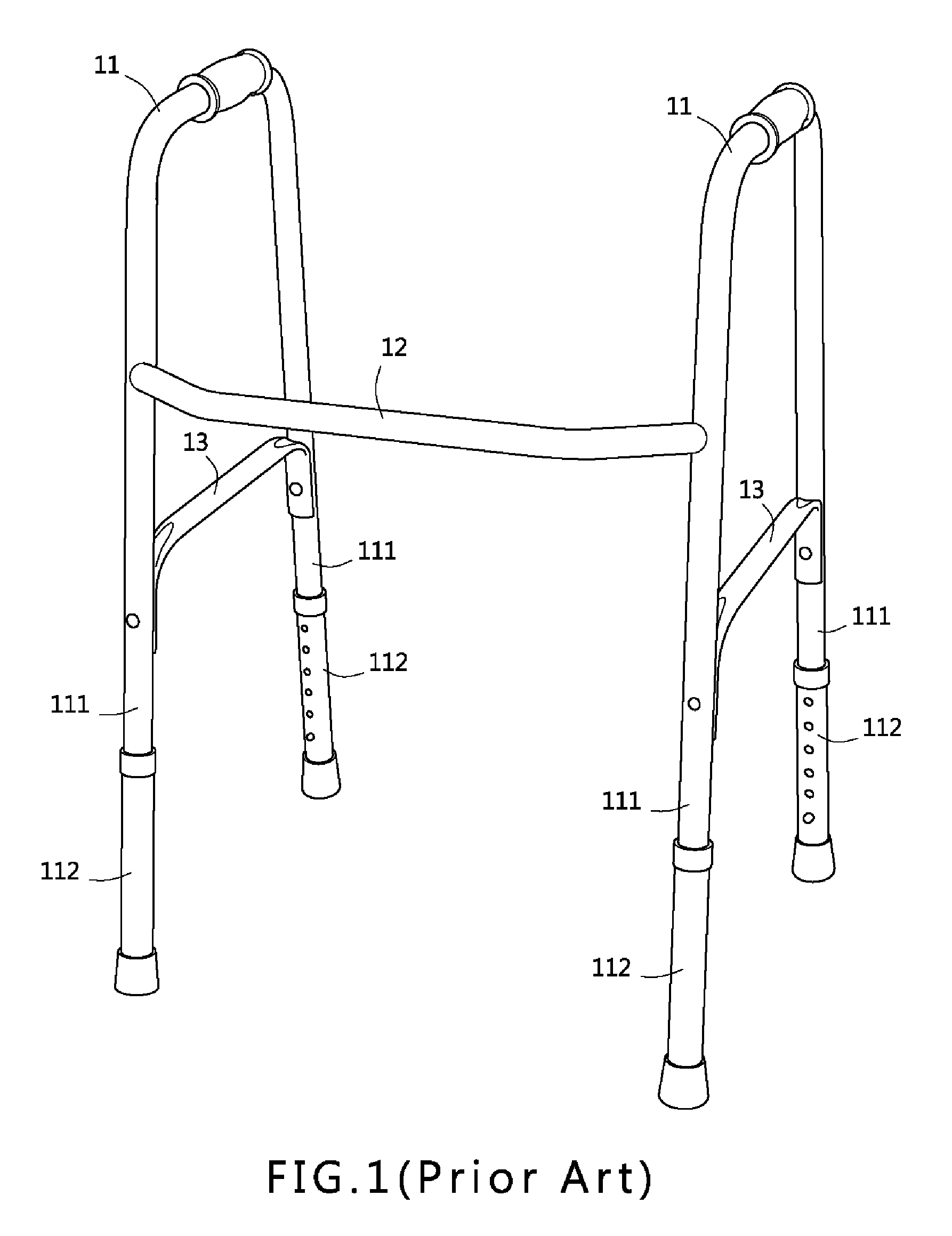

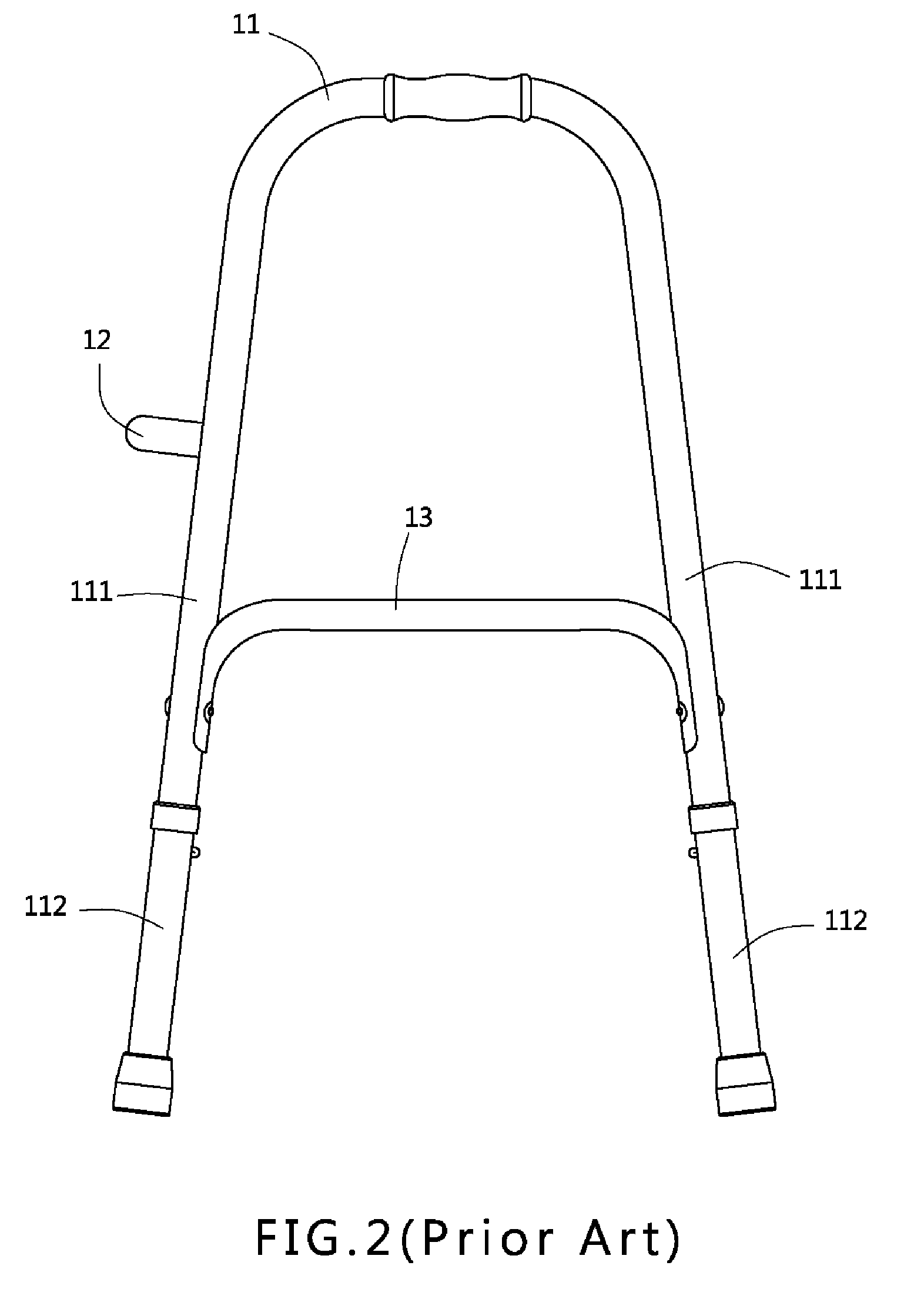

Walker for children and adults

InactiveUS20080163913A1Maintain relatively stableStable structural strengthWalking sticksWalking aidsEngineeringClutch

The present invention is to claim a walker for both child and adult users, which comprises two supporting units and a connecting unit transversely connecting the two supporting units at the front sides thereof wherein a horizontal rod is provided between two leg portions of each said supporting unit. Therein, each said horizontal rod has two slots at the opposite ends and two sliding joints are mounted on the supporting units in the manner that the ends of the horizontal rod can be received by the sliding joints and two pin members can be respectively pierced through one of the sliding joint and the corresponding slot. Further, two sets of clutch members each having a toothed portion for being detachably engaged with each other are provided between the ends of the telescopic members of the connecting unit and the adjacent supporting units. Thereby, the horizontal rods can freely shift vertically corresponding to the variation of the height of the walker and through operating the clutch members of the positioning units to become engaged or disengaged mutually, the opposite supporting units can be easily or can be stably fixed after being unfolded, or alternatively, can be operated in a reciprocal manner.

Owner:HSIAO FANG JUNG

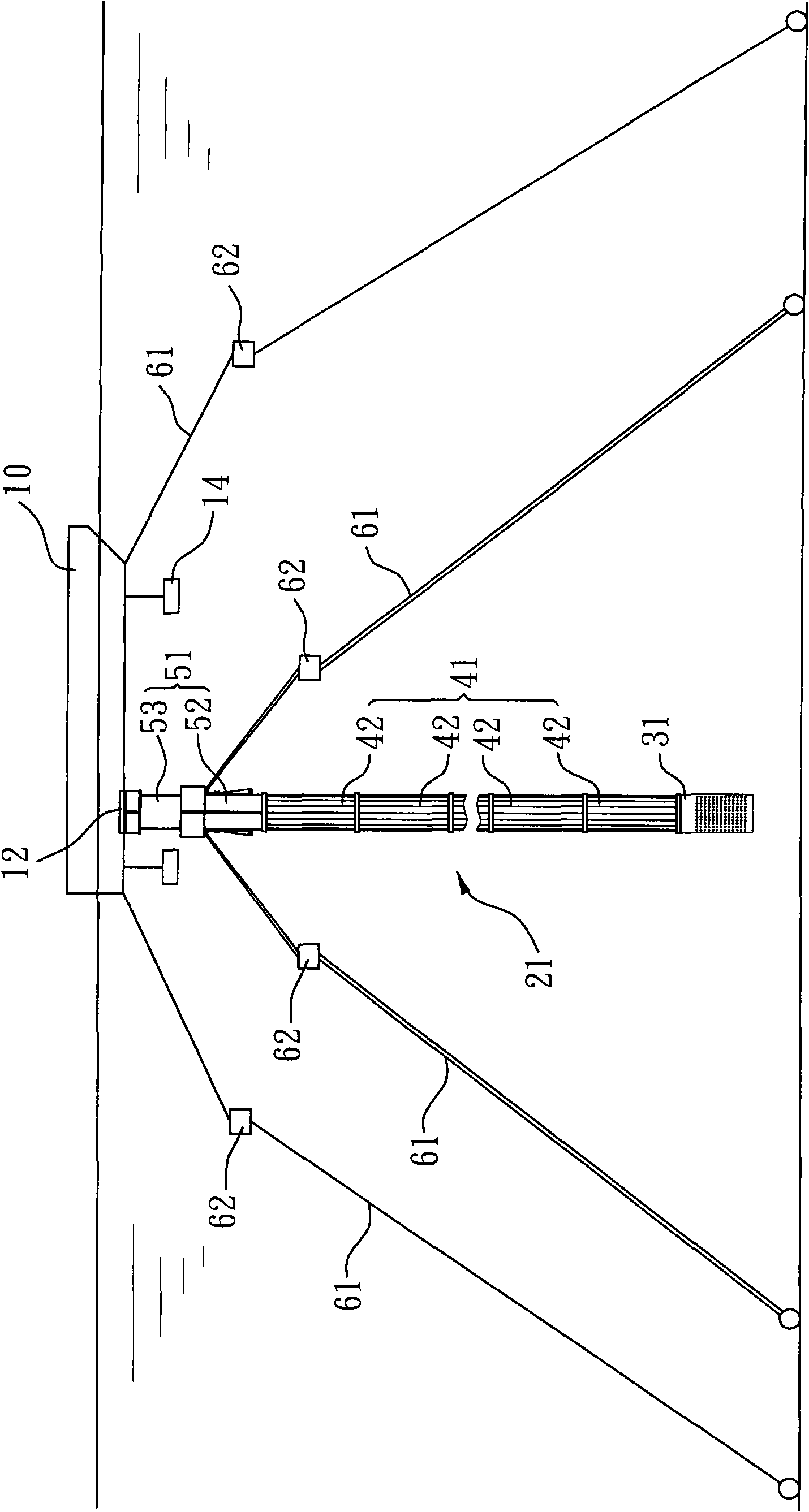

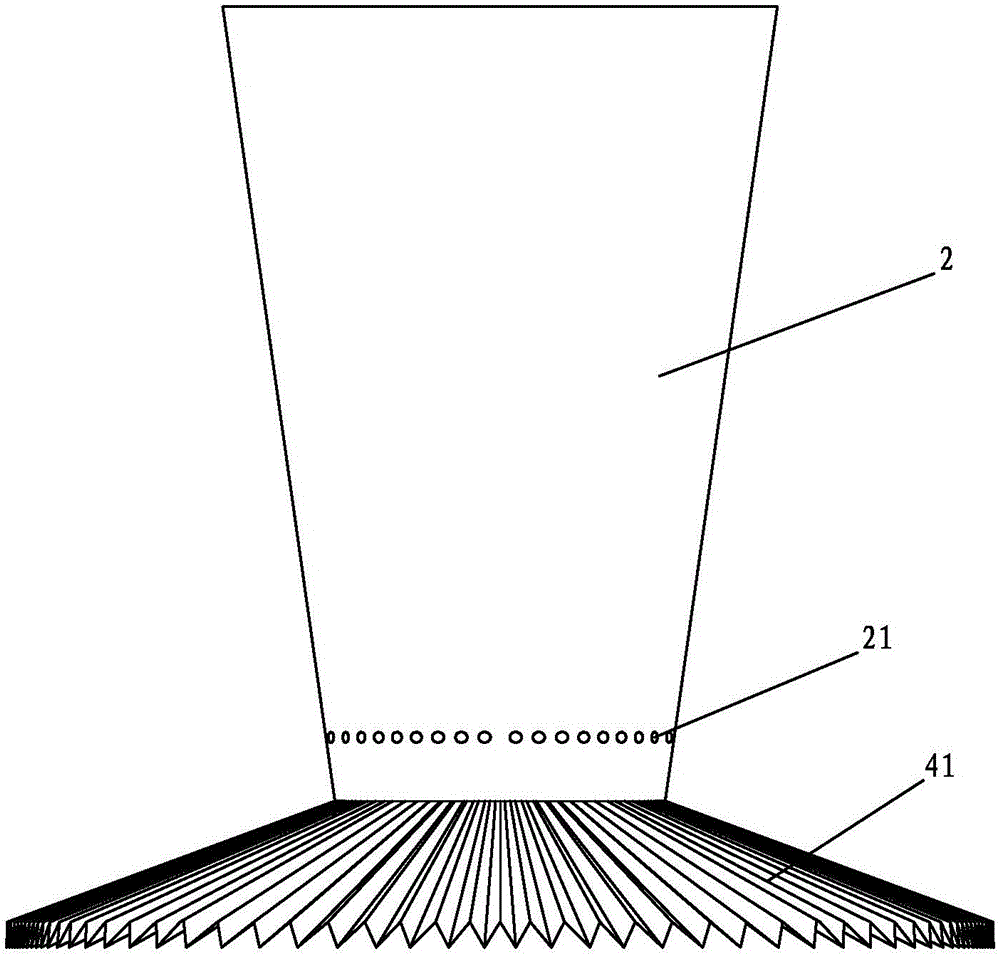

Seafloor cold-water-pipe water taking system for ocean thermal energy conversion power plants

InactiveCN101539347AStable structural strengthNot easy to damageOther heat production devicesSea energy generationSurface oceanOcean bottom

The invention provides a seafloor cold-water-pipe water taking system for ocean thermal energy conversion power plants. A cold water inlet is arranged on a generating ship. A cold water pipe comprises a water taking head, a water taking pipe and a connecting pipe, wherein the water taking pipe is formed by serially connecting a plurality of composite pipes; each composite pipe is in a tubular shape formed by a plurality of wavy inner pipes in sequential arrangement; the connecting pipe consists of an outer casing pipe and an inner casing pipe in mutual socket joint; the connecting pipe is connected with the cold water inlet of the generating ship through the inner casing pipe thereof; and the tail end of the outer casing pipe of the connecting pipe is connected with a connecting part of the water taking pipe. The system has the advantages that the system can transmit a large amount of low-temperature seawater on deep seafloor for the commercial operation of the power plants, has firm structure strength, can bear the intrusion of seawater and ocean currents, and is not easy to damage.

Owner:郭芳声

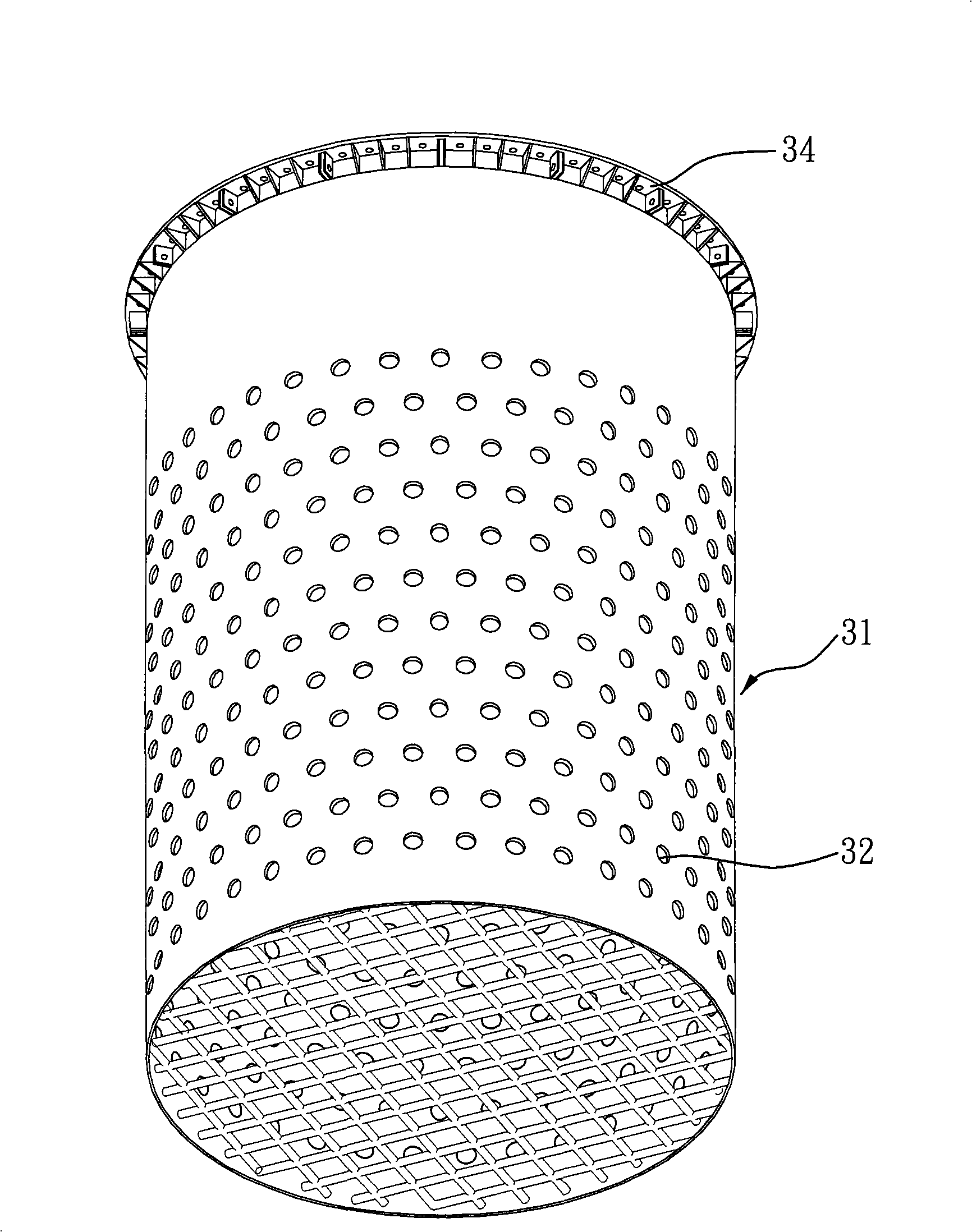

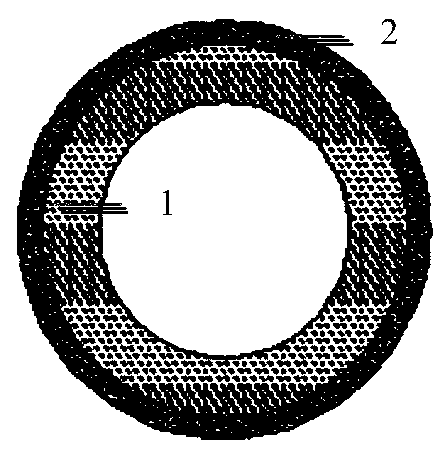

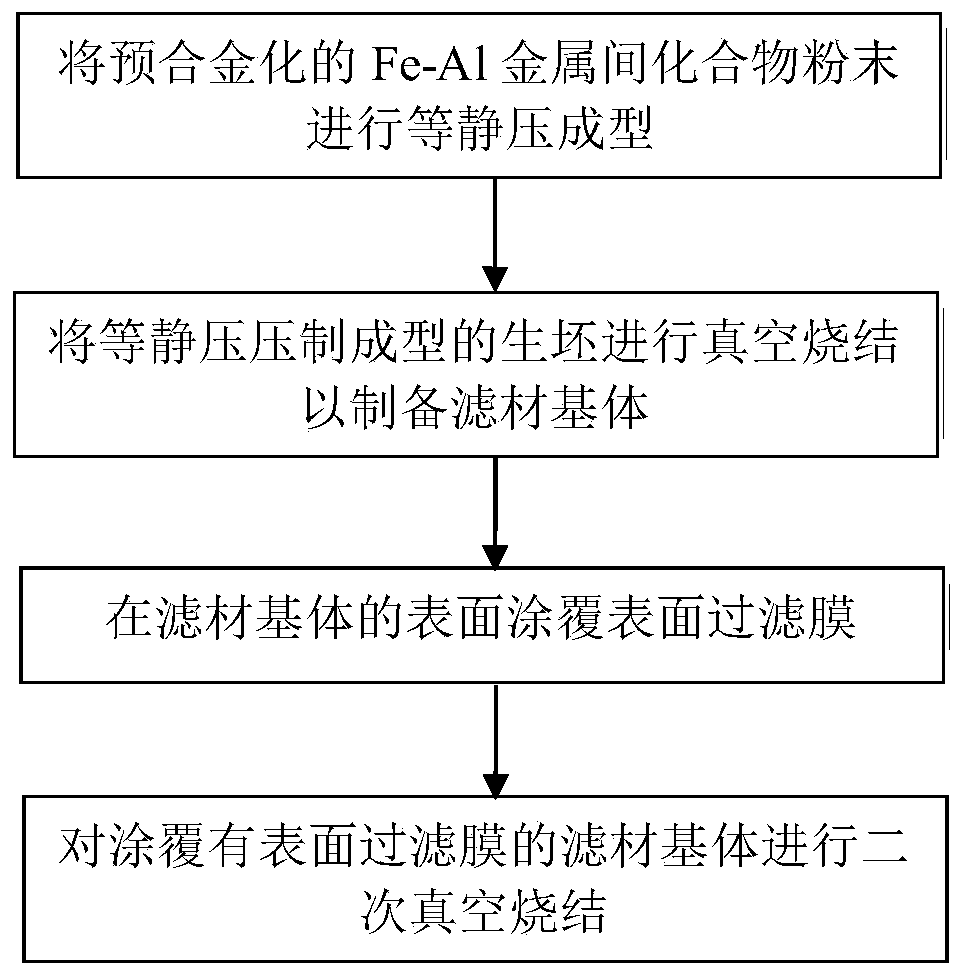

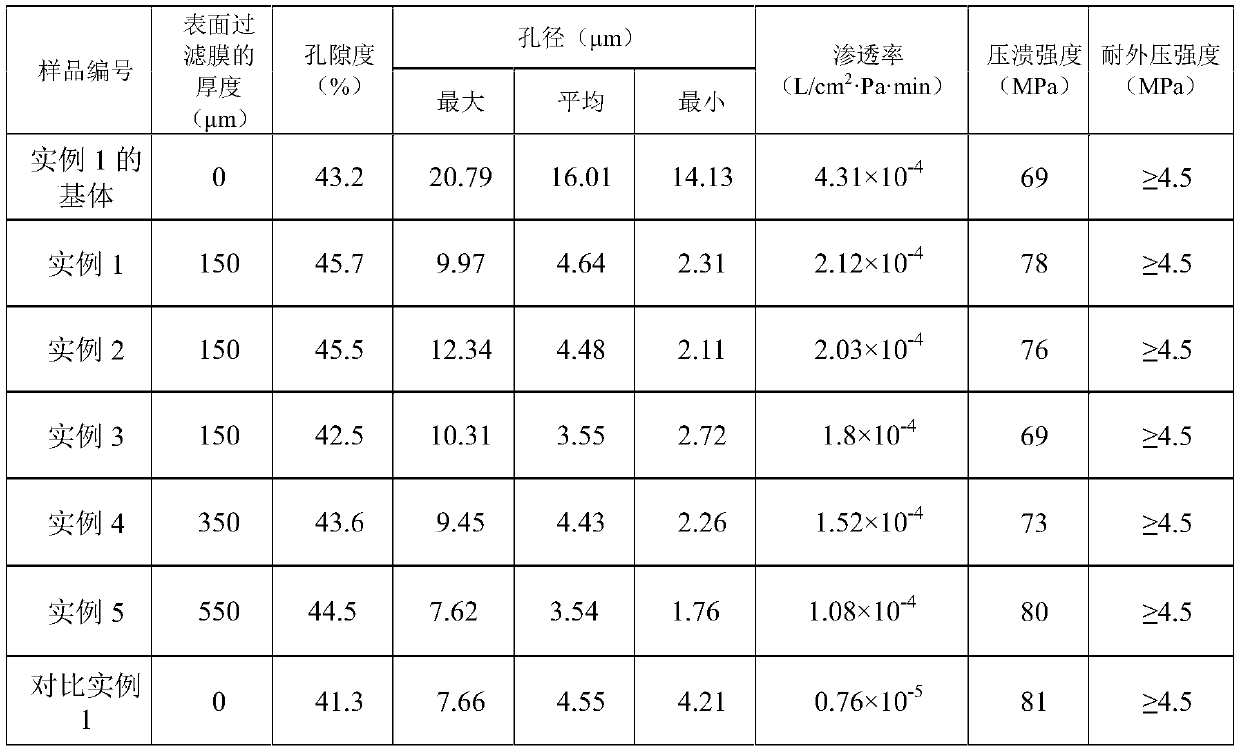

Gradient composite Fe-Al intermetallic compound microporous filter material and preparation method thereof

PendingCN111069590AHigh strengthImprove toughnessSemi-permeable membranesMembranesIntermetallicHigh-temperature corrosion

The invention discloses a gradient composite Fe-Al intermetallic compound microporous filter material and a preparation method thereof, and relates to the field of powder metallurgy preparation. Aiming at the problem that a Fe-Al filter material with high temperature corrosion resistance is difficult to prepare due to process limitation in the prior art, the invention provides the gradient composite Fe-Al intermetallic compound microporous filter material. The gradient composite Fe-Al intermetallic compound microporous filter material is characterized by comprising a matrix framework and a surface filter membrane outside the matrix framework, wherein the matrix framework is pressed and sintered prealloyed Fe-Al intermetallic compound powder; and the surface filter membrane is a mixture ofa binder, water and the prealloyed Fe-Al intermetallic compound powder which are coated on the outer surface of the matrix framework and then sintered for the second time. Therefore, the gradient composite Fe-Al intermetallic compound microporous filter material with high precision, large flux, low resistance drop, good back flushing regeneration characteristic, high strength and high temperaturecorrosion resistance is realized.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

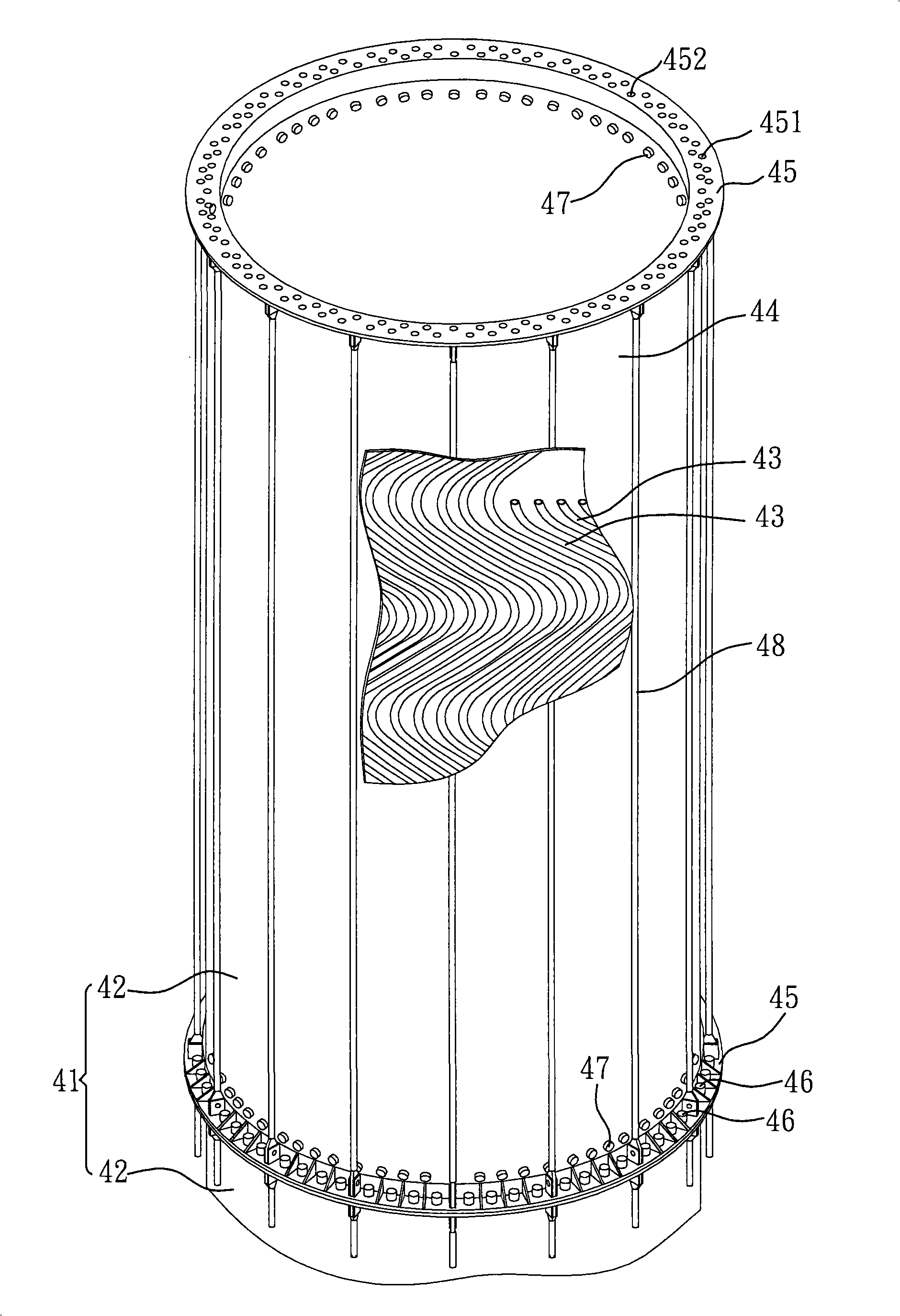

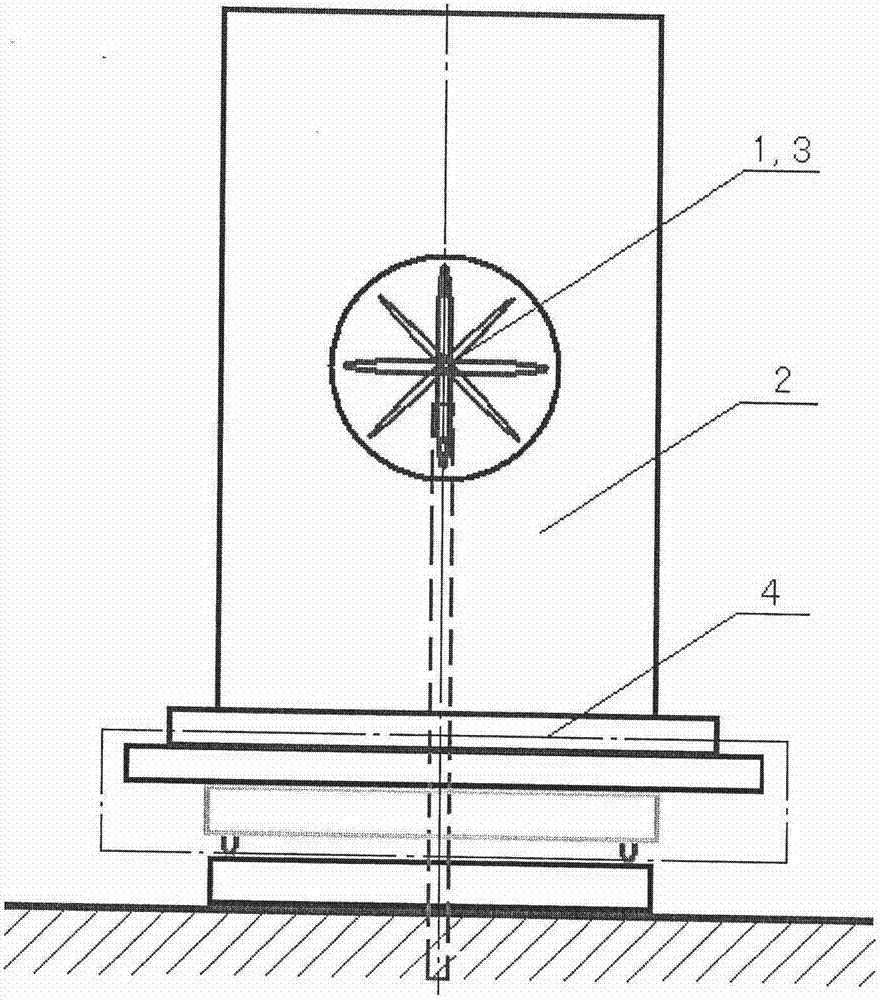

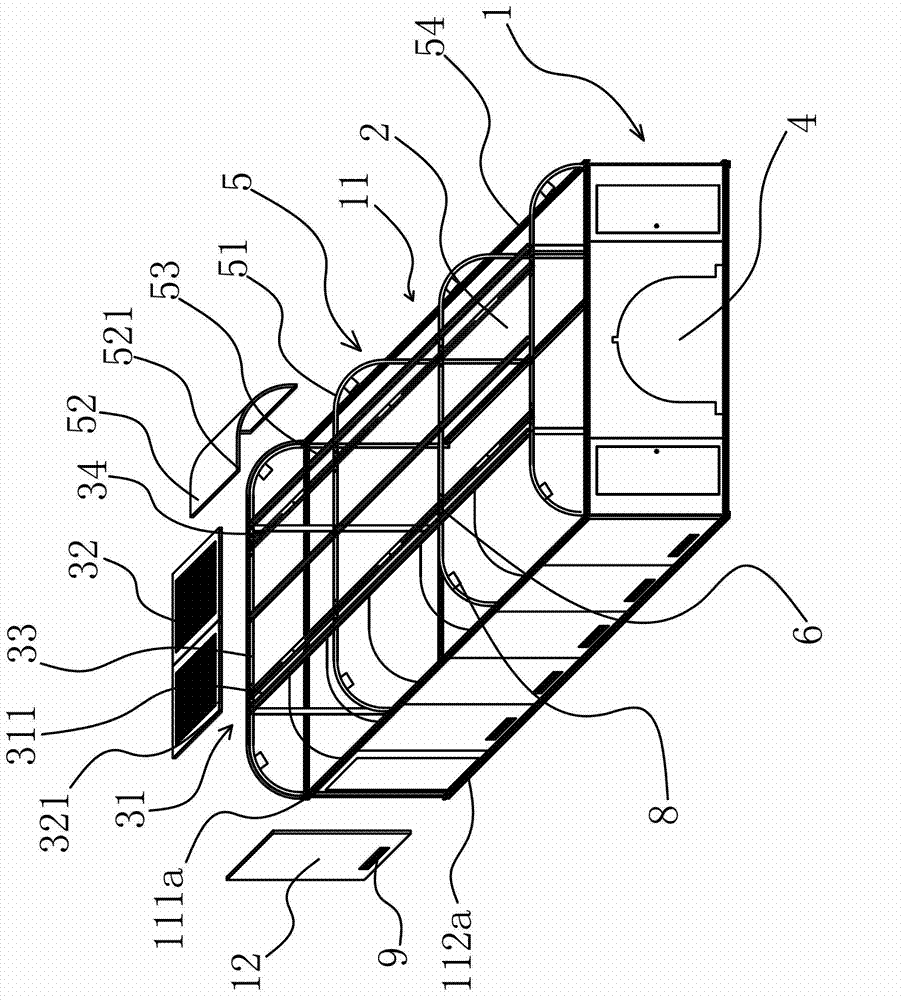

10MW-rank seat stand type wind guider turbine power generator system

InactiveCN103047087AIncrease wind speedHigh densityMachines/enginesWind motor combinationsElectricityTower

A 10MW-rank seat stand type wind guider turbine power generator system is designed for industry requirement of upgrading a current wind power unit to that with higher single-machine capacity technology. By concentrating wind energy with a wind guide groove, increasing wind speed and adopting a medium and high-speed short-vane turbine to drive an alternating-current power generate to generate power, dependency on a gearbox is reduced, and more wind energy can be intercepted. Meanwhile, a tower and a variable-pitch blade device are omitted in a seat stand structure utilized as a groove carrier, power generation wind-speed range is enlarged, functions of the seat stand structure originally including a yawing function are increased to include yawing, wind regulating and auxiliary braking, and an implementing site is changed to the ground from overhead site, many technical difficulties caused by upsizing are solved by the new design, and power cost of unit loading is expected to reduce.

Owner:SHANGHAI WIND NEW ENERGY TECH

Pipe gallery prefabricated parts and prefabricated comprehensive pipe gallery

ActiveCN105256838BEasy to transportStable structural strengthArtificial islandsUnderwater structuresPre stressEngineering

Owner:SHENZHEN HUAHAN GUANLANG PROPERTY SERVICES CO LTD

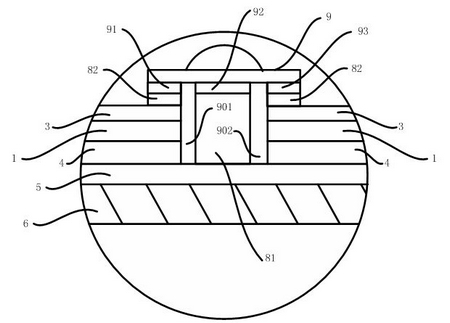

Highly efficient heat radiation LED (Light Emitting Diode) lamp

InactiveCN102155666AImprove thermal conductivityStable structural strengthPoint-like light sourceElectric circuit arrangementsHeat conductingCopper foil

The invention provides a highly efficient heat radiation LED (Light Emitting Diode) lamp, which comprises a lamp bead and a heat conducting substrate. The highly efficient heat radiation LED lamp is characterized in that a conductive welding material layer, a copper foil layer, an insulating layer and a heat conducting plating layer are arranged between the lamp bead and the heat conducting substrate in turn. In the invention, an electrode pad of the lamp bead is connected to the copper foil layer by the conductive welding material layer; a heat conducting pad of the lamp bead is connected to the heat conducting plating layer by the conductive welding material layer; and the heat conducting performance is largely increased and the structural strength is stabilized by using a non-mechanical connecting mode. Furthermore, atoms between the plating layer and the heat radiation substrate can be exchanged actively by using a silver-tin composite plating layer so that the heat conducting effect can be obviously increased.

Owner:黄晓华

Corrugated paper cup

ActiveCN105775300AAvoid bending deformationWill not bendVenting meansRigid containersAir cyclePaper based

The invention discloses a corrugated paper cup. An isolation cavity is formed by a corrugated paper layer, so that the fact that the hand of a user is scalded by a hot beverage in a paper cup main body; longitudinal corrugated structures are laterally supported and restrained by horizontal corrugated structures; the horizontal corrugated structures are laterally supported and restrained by the longitudinal corrugated structures; and the sidewalls of the longitudinal corrugated structures and the sidewalls of the horizontal corrugated structures do not easily curve laterally. The longitudinal corrugated structures and the horizontal corrugated structures can perform bending resistance supporting, so that the defect of a traditional corrugated paper cup that a crease is formed along a corrugated structure extension direction, so that bending deformation is formed in the direction vertical to corrugated structures is overcome. The upper surfaces and the lower surfaces of the longitudinal corrugated structures and the horizontal corrugated structures all form planar surfaces, so that the contact area of the paper cup main body and an outer paper layer is enlarged, and the longitudinal corrugated structures and the horizontal corrugated structures are favorably glued onto the paper cup main body and the outer paper layer. A communication ventilation web is formed by the whole corrugated paper layer, and the corrugated paper layer communicates with the outside to perform cold and hot air circulation; and the hot beverage in the paper cup main body is subjected to rapid and natural heat dissipation and cooling. An annular corrugated paper base can be overturned up and down to perform stable and stretched support or to be folded.

Owner:FUJIAN WENSONG COLOR PRINTING

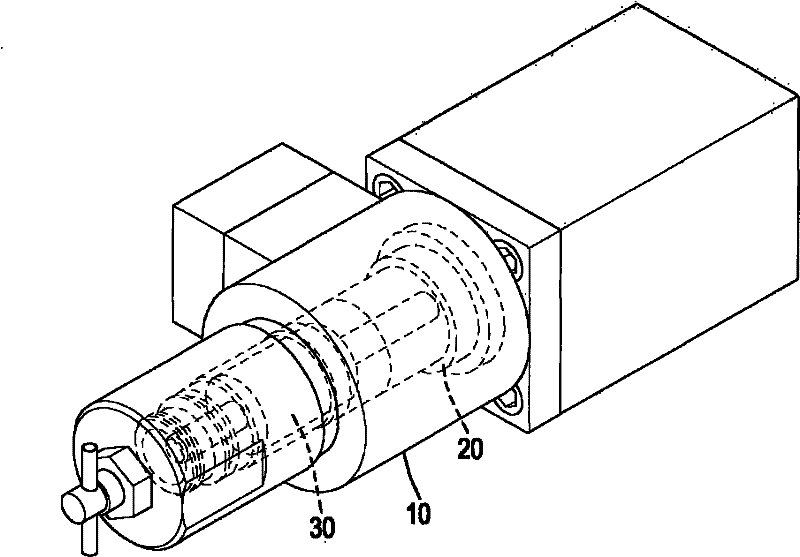

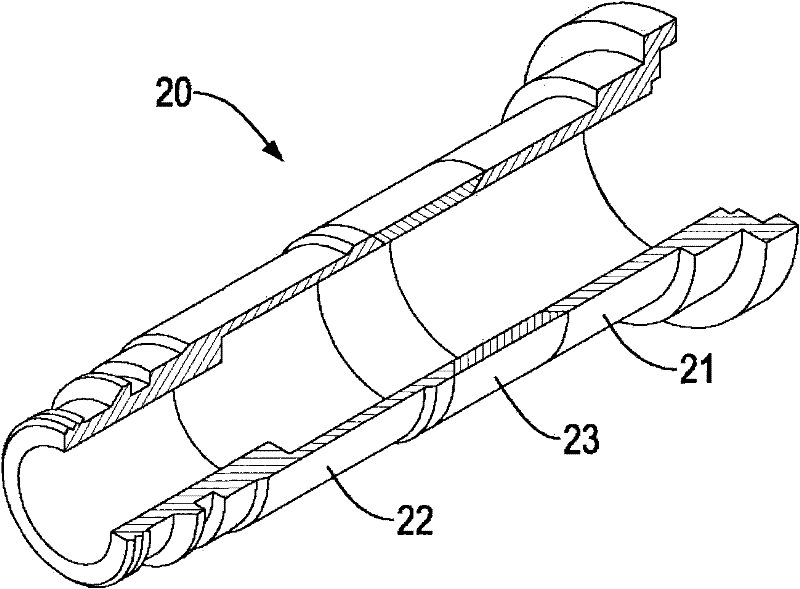

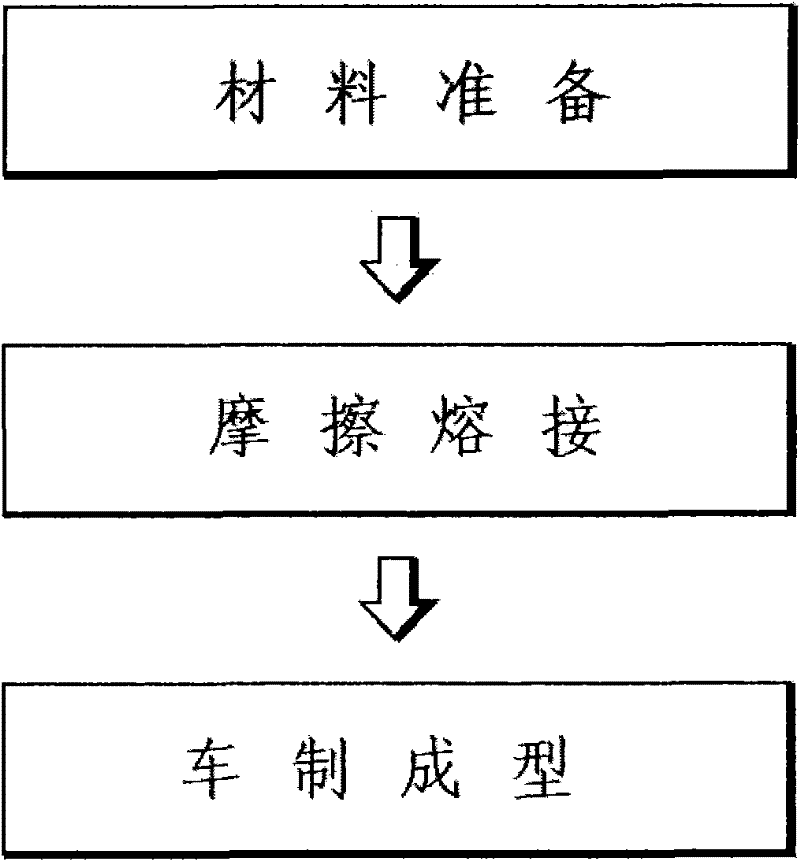

Method for manufacturing electromagnetic pipe of proportional electromagnetic valve

InactiveCN102233507AStable structural strengthIncrease joint areaNon-electric welding apparatusMagnetic tension forceEngineering

The invention relates to a method for manufacturing an electromagnetic pipe of a proportional electromagnetic pipe. The method comprises the following steps of: correspondingly jointing a first joint surface of a first exciting pipe body onto a first fusion welding surface of a non-magnetic pipe body; and correspondingly jointing a second joint surface of a second exciting pipe body onto a second fusion welding surface of the non-magnetic pipe body, wherein at least one group of corresponding surfaces are mutually folded in an oblique state. Therefore, according to current size, the aims of controlling the magnitude of magnetic force, increasing the jointing surface between each exciting pipe body and the non-magnetic pipe body on the electromagnetic pipe, intensifying a jointing structure and improving high-pressure resistance can be fulfilled.

Owner:蔡承宏 +2

Quick splicing ceramic tiles

PendingCN111335570AIntegrity guaranteedAvoid it happening againCovering/liningsStructural engineeringMechanical engineering

The invention discloses quick splicing ceramic tiles. The ceramic tiles comprise first base plates, second base plates, connecting insert blocks, right-angle connecting blocks and connecting insert grooves, wherein each connecting insert block comprises an insert block body and a third fixing portion, and the insert block body is fixedly connected to one end of the third fixing portion; each right-angle connecting block comprises a first fixing portion and a connecting portion, the connecting portion is fixedly connected to one end of the first fixing portion, and a first insert groove is formed in one end of the connecting portion; and each connecting insert groove comprises a second fixing portion, and a second insert groove is formed in the surface of one end of the second fixing portion. According to the quick splicing ceramic tiles, through the arranged connecting insert blocks, the right-angle connecting blocks and the connecting insert grooves, mounting is convenient and fast, building block type splicing is adopted, the paving integrity of the ceramic tiles can be guaranteed, in addition, no professional craftsman is needed for paving, the construction cost is greatly lowered, seamless joint is adopted, the waterproof effect is good, meanwhile, pollution caused by residual water stains due to seams is avoided, and the overall attractiveness can also be improved.

Owner:合肥高丽今生实业有限公司

Assembling type steam turbine casing

ActiveCN103195511AEasy maintenanceImprove flatnessMachines/enginesEngine componentsTorsional strengthUltimate tensile strength

The invention belongs to the technical field of machinery and particularly relates to an assembling type steam turbine casing which solves the problem that an existing steam turbine casing is inconvenient to disassemble and assemble, low in structural strength and the like. The assembling type steam turbine casing comprises a frame body formed by assembling frame body section bars in detachable mode, an opening for a steam turbine to pass in and out is arranged at the top of the frame body, a top frame formed by assembling top frame section bars in detachable mode is connected at the position of the opening in detachable mode, a plurality of side plates capable of sealing the periphery of the frame body is assembled on the periphery of the frame body in detachable mode, a plurality of hollow cover plates capable of covering the opening are assembled on the top frame in detachable mode, and a power outlet for outputting power of the steam turbine is arranged at one end of the frame body. Compared with the prior art, the assembling type steam turbine casing has the advantages of being reasonable in design, compact in structure, convenient to disassemble and assemble, capable of facilitating steam turbine overhaul, good in radiating, high in overall structural strength, good in top evenness, strong in stability and high in torsional strength and bending strength.

Owner:杭州天桥电器有限公司

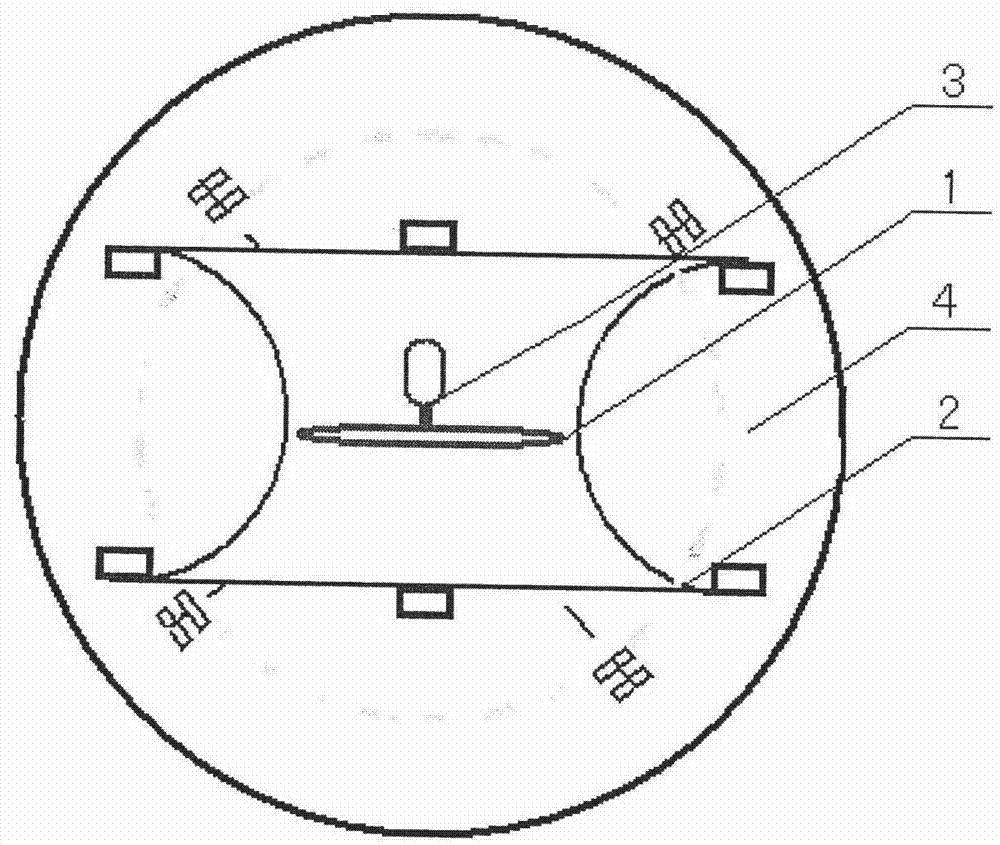

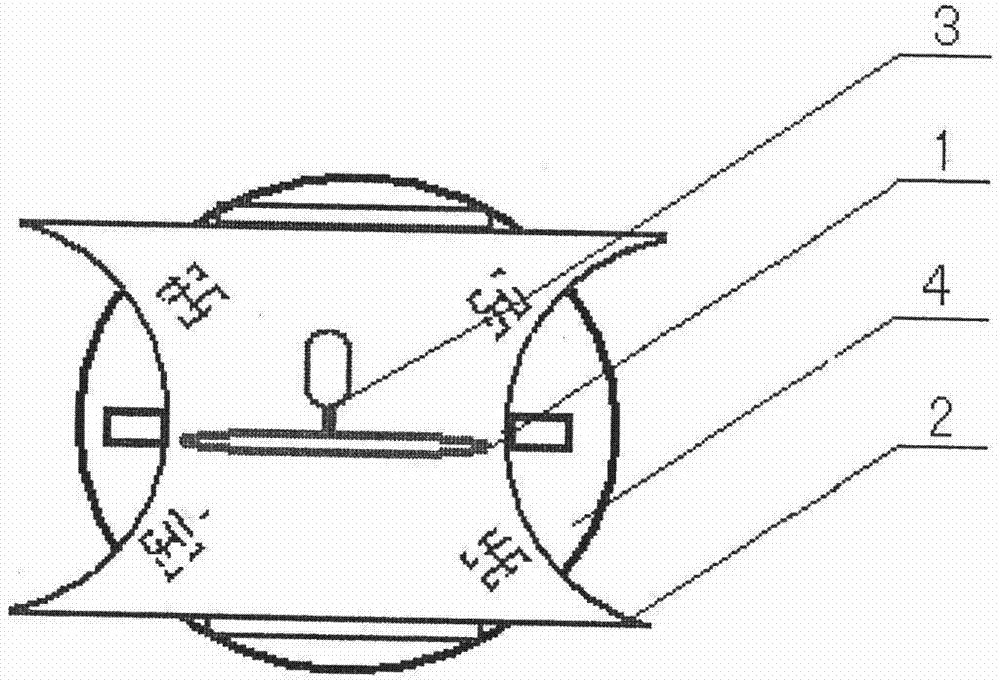

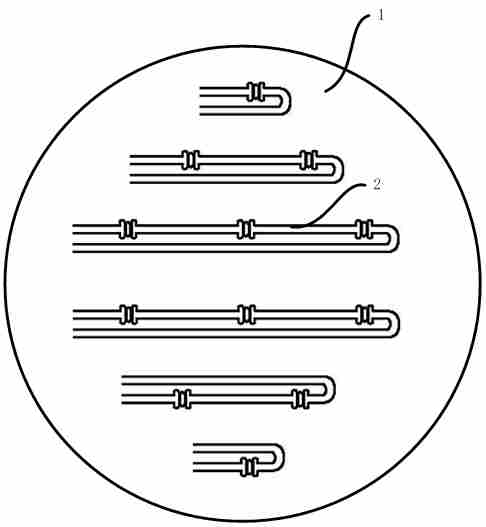

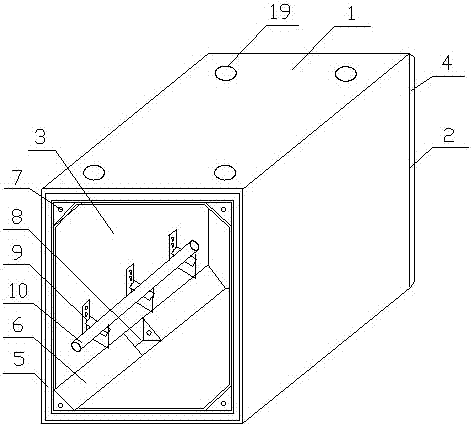

Reactor core structure of heat pipe reactor fuel element adopting hexagonal prism cladding

ActiveCN111081391AFlexible layoutHigh strengthFuel elementsNuclear energy generationRadiochemistryAtomic physics

The invention belongs to the technical field of nuclear fuel elements, and particularly relates to a reactor core structure of a heat pipe reactor fuel element adopting hexagonal prism cladding. The reactor core structure comprises fuel elements 1, heat pipes 2, a limiting base body 3, a cylinder container 4 and a reactor core upper grid plate 5, wherein the fuel elements 1 and the heat pipes 2 are arranged in the cylinder container 4 in a honeycomb shape, the limiting base body 3 is arranged between the arrangement of the fuel elements 1 and the heat pipes 2 and the inner wall of the cylindercontainer 4, and the reactor core upper grid plate 5 is arranged on the cylinder container 4.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

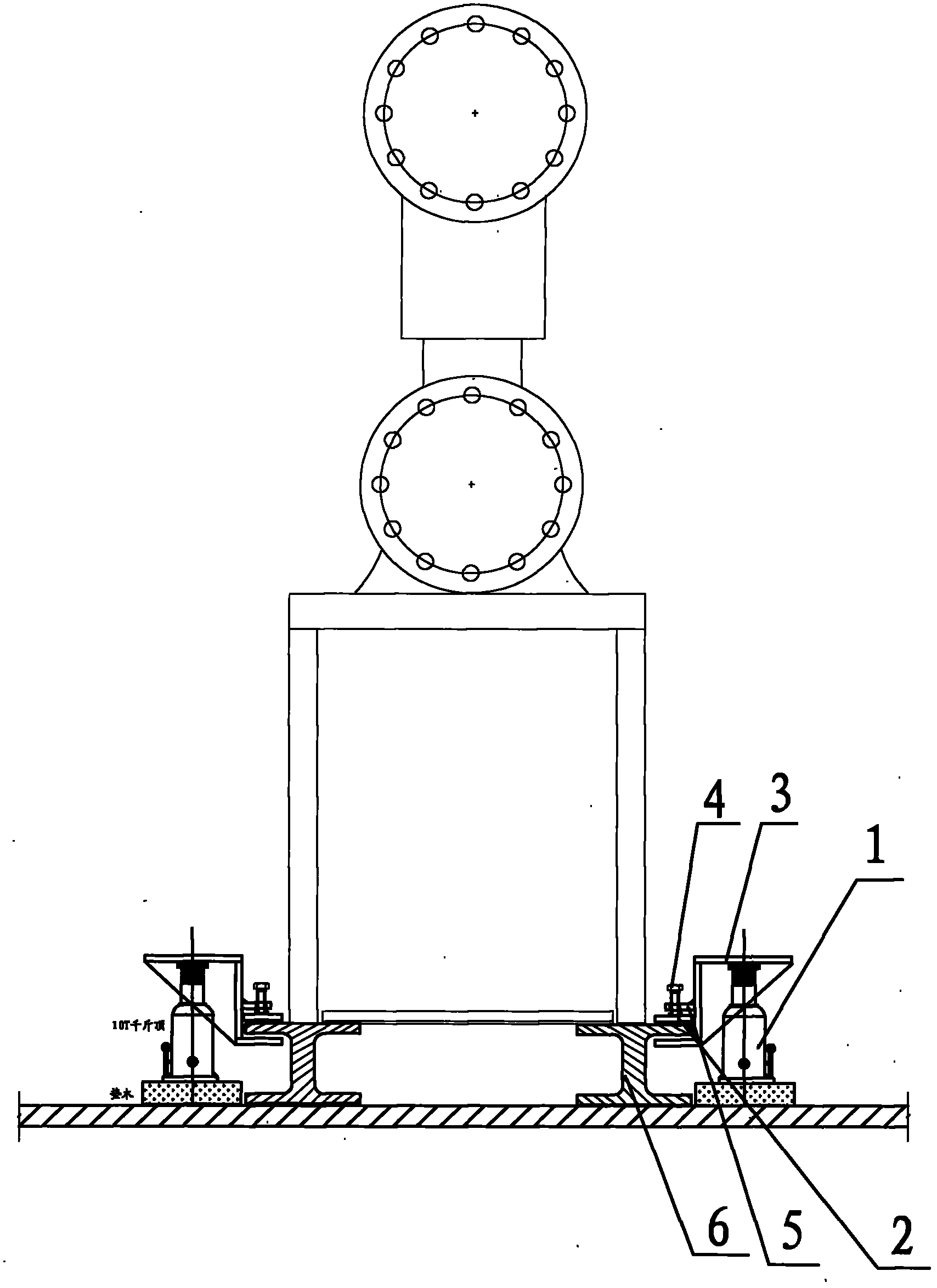

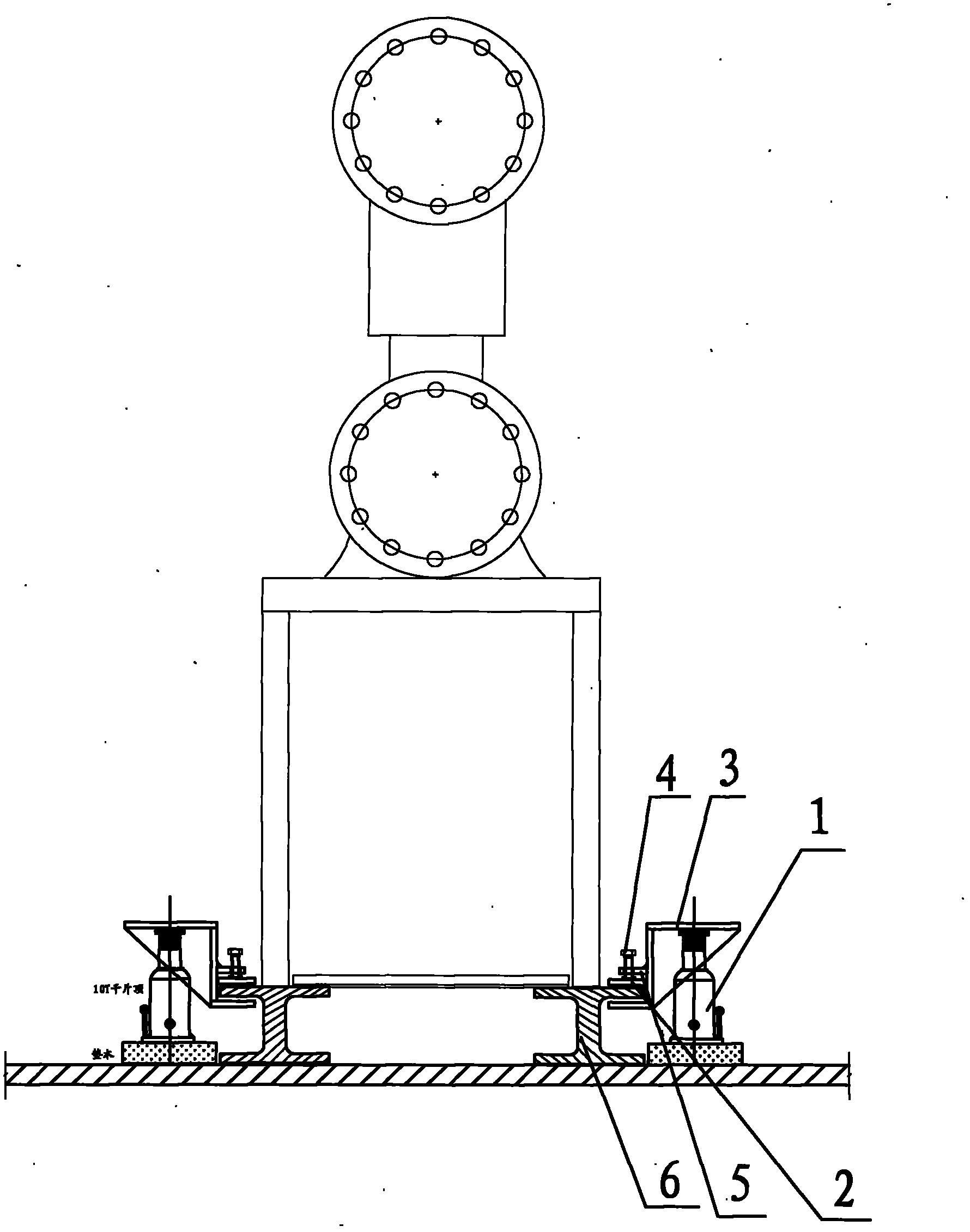

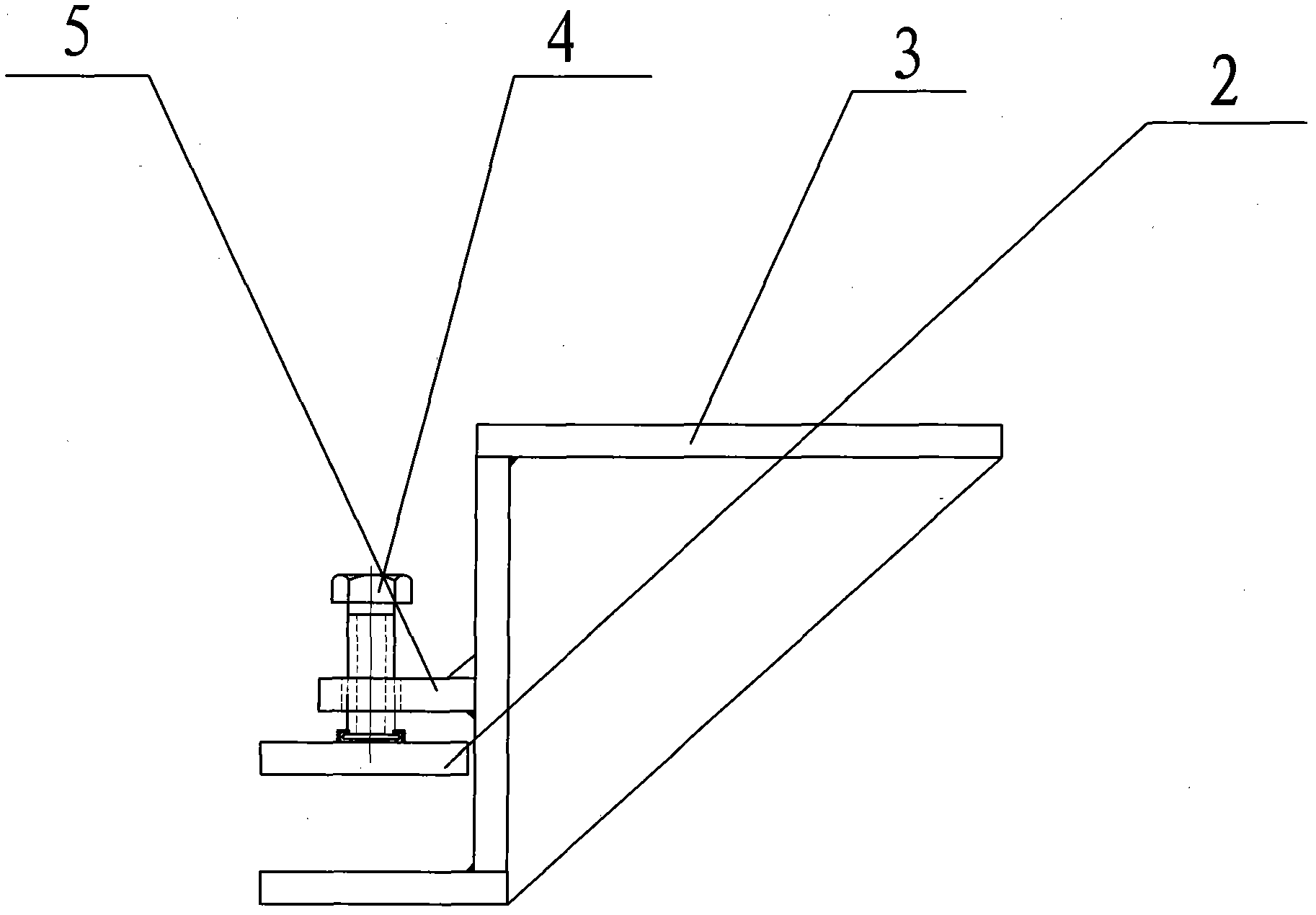

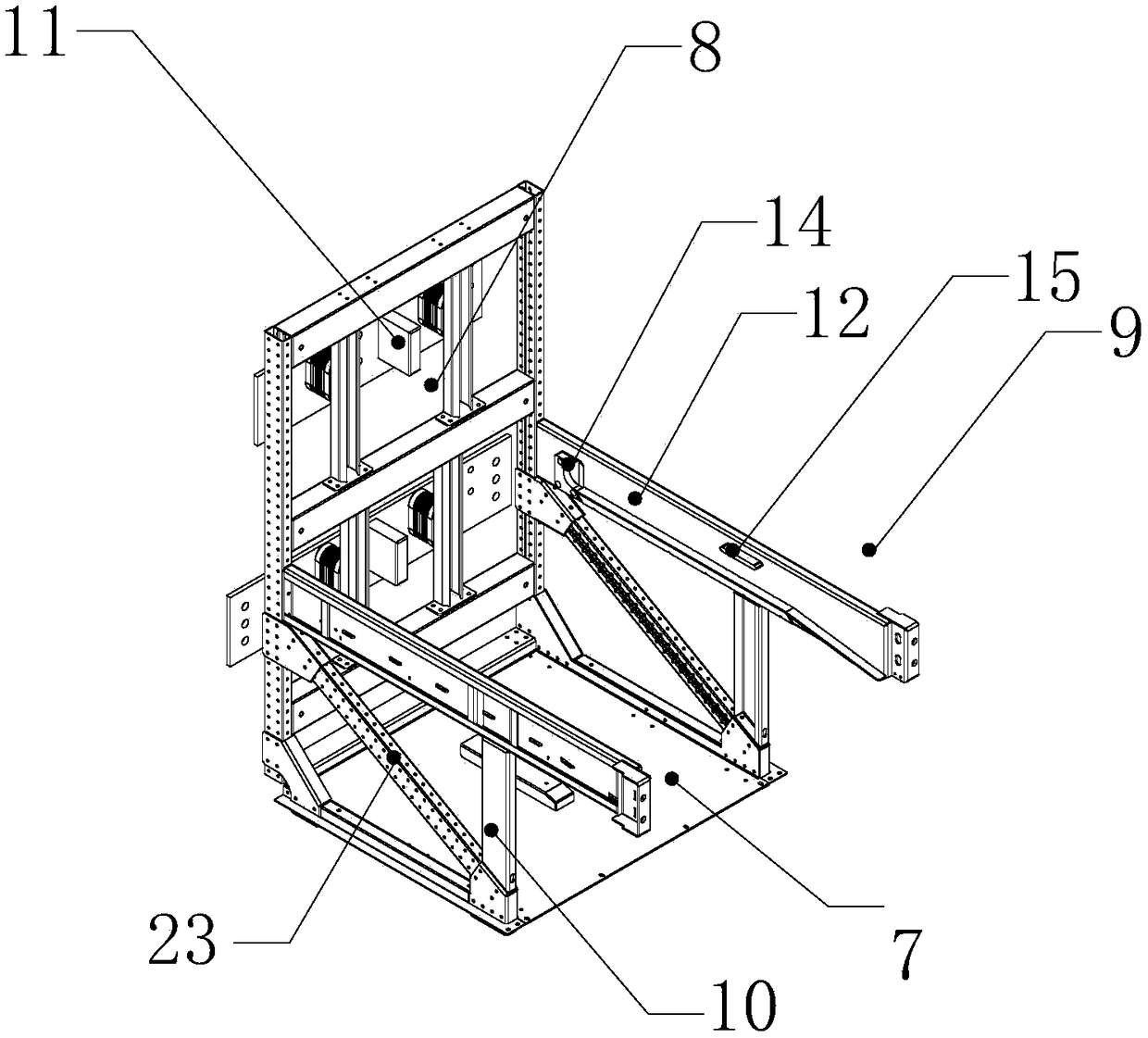

Combined electric geographic information system (GIS) equipment base lifter

InactiveCN102092656AReduce labor intensityReduce incidenceLifting devicesHigh intensityUltimate tensile strength

The invention discloses a combined electric geographic information system (GIS) equipment base lifter, which relates to the field of accurate in-place arrangement of large-scale equipment. The combined electric GIS equipment base lifter comprises jacks (1), operating handles (2) and triangular strong-strength channel steel plates (3), wherein the triangular strong-strength channel steel plates (3) are fixed on equipment supporting channel steels (6); the jacks (1) are arranged below and contacts with the corresponding triangular strong-strength channel steel plates (3); and the operating handles (2) are arranged on the right-angled lateral surfaces of the corresponding triangular strong-strength channel steel plates (3). The combined electric GIS equipment base lifter is simply manufactured and convenient to arrange, regulate and maintain, has low cost, strong structural strength, high adaptability, need of fewer operators and high working efficiency, ensures low labor intensity, greatly improves a safety coefficient in an operating process and reduces the probability of occurrence of accidents.

Owner:TAIAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

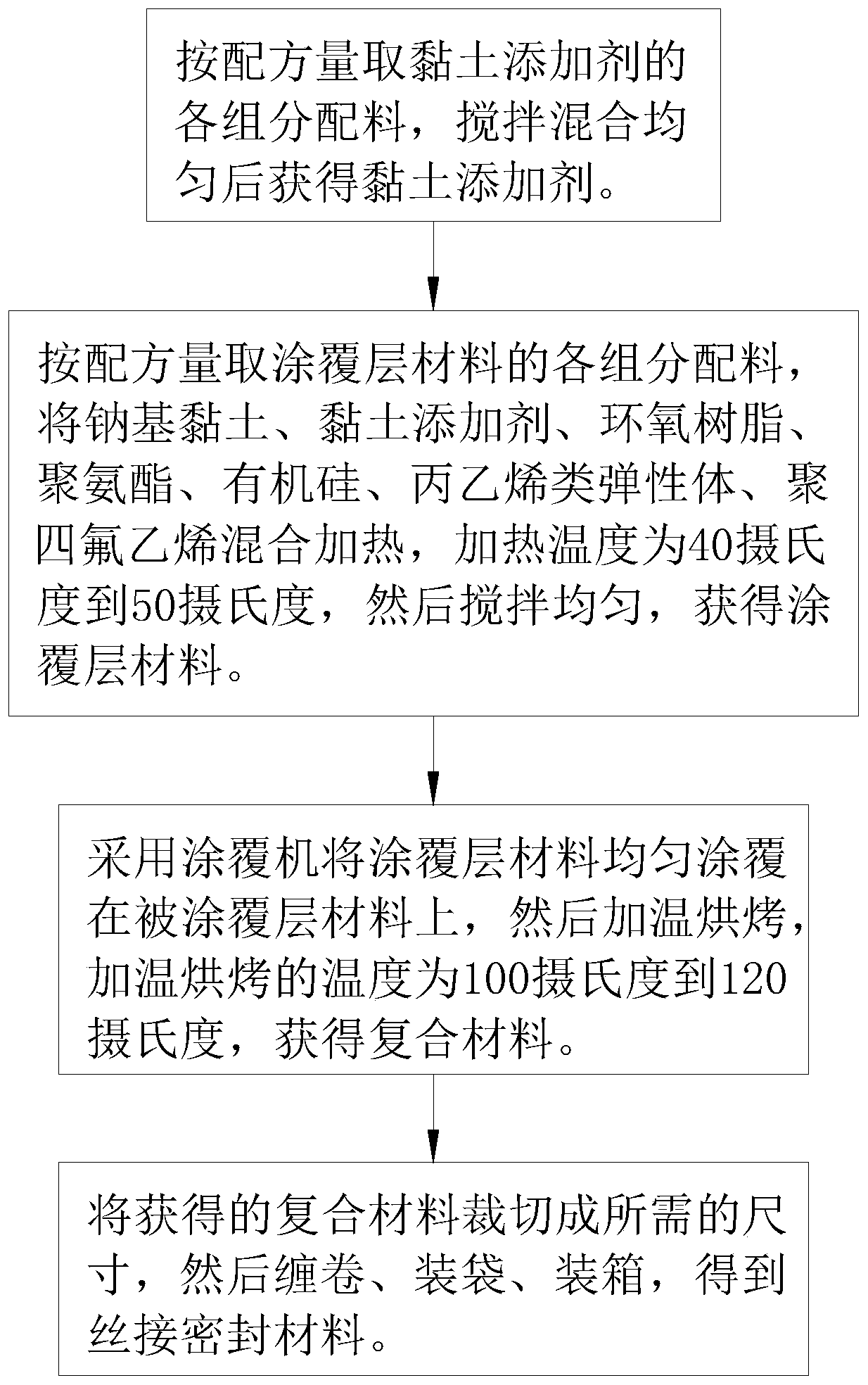

Novel threaded joint sealing material

PendingCN110924176AStable structural strengthStrong tear resistanceOther chemical processesTextiles and paperWoven fabricPolytetrafluoroethylene

The invention is applicable to the technical field of sealing materials for threaded joints of pipes, and provides a novel threaded joint sealing material. The novel threaded joint sealing material comprises a coating layer material and a coated layer material which are compounded with each other, wherein the coating layer material comprises the following components in parts by weight: 40-60 partsof sodium-based clay, 2-5 parts of a clay additive, 10-20 parts of epoxy resin, 5-10 parts of polyurethane, 5-10 parts of organic silicon, 5-8 parts of a vinyl-propylene elastomer, and 12-15 parts ofpolytetrafluoroethylene, wherein the sodium-based clay enables the coating layer material to have the characteristic of water swelling, so that secondary sealing can be carried out, and then the sealing effect is better, the epoxy resin, polyurethane, organic silicon, vinyl-propylene elastomer and polytetrafluoroethylene which are used as ingredients are added into the coating layer material, sothat the coating layer material is better in elasticity and higher in viscosity, the coated layer material is made of non-woven fabric, thus the sealing material has more stable overall structural strength and higher tearing resistance, and then the service life is longer.

Owner:涿州长兴新材料科技有限公司

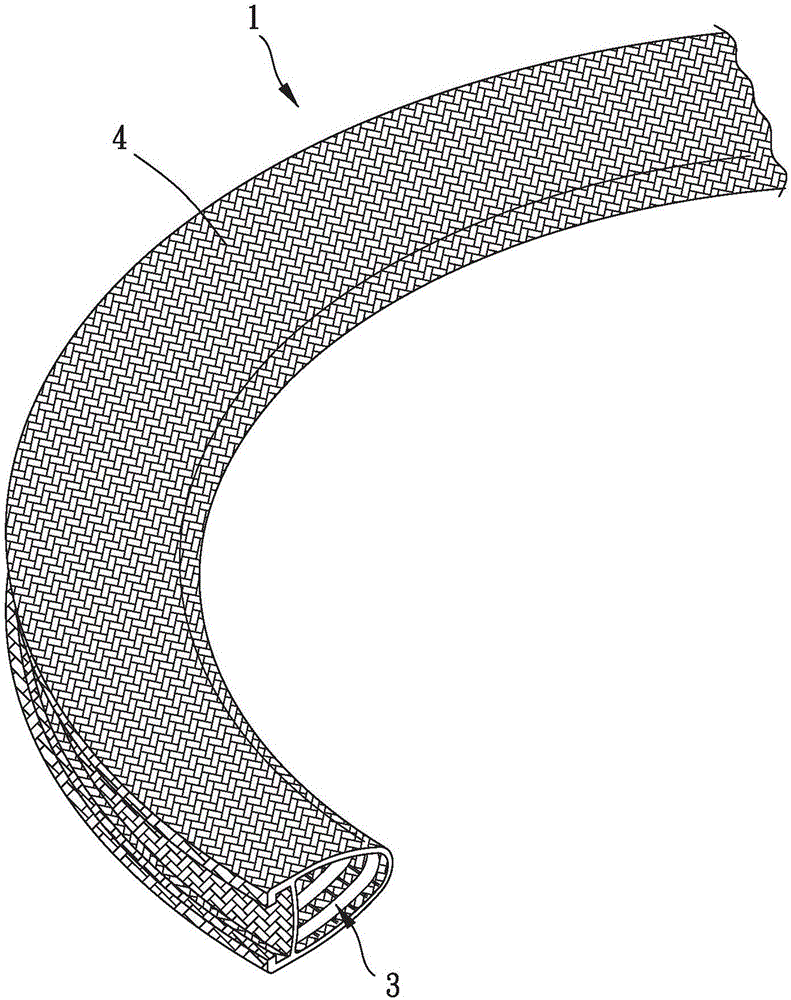

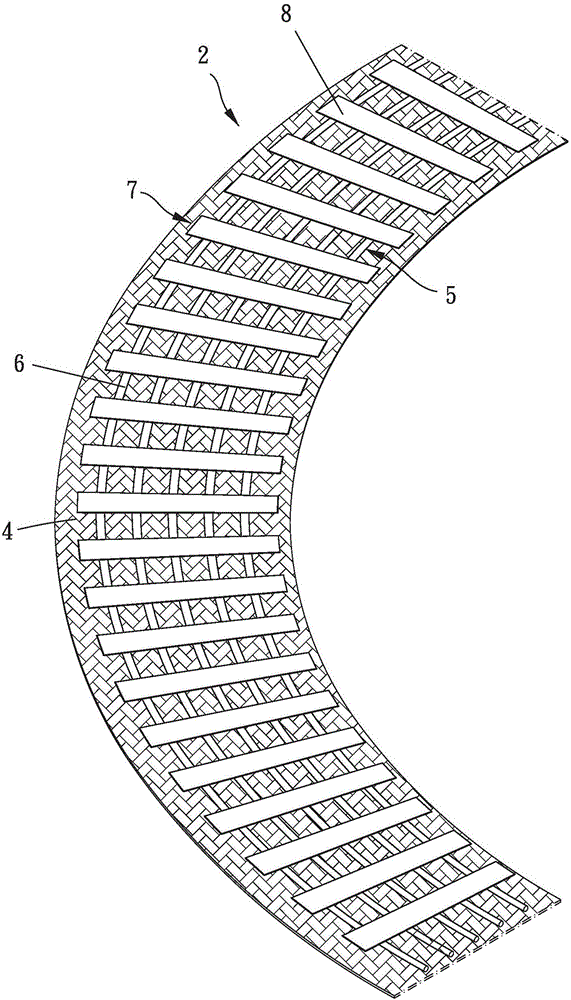

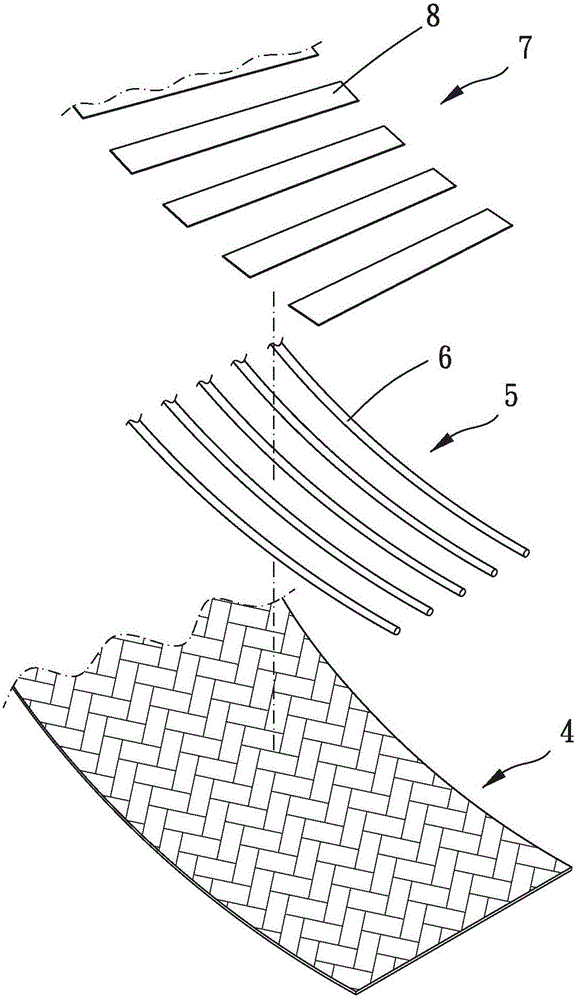

Carbon fiber wheel rim

InactiveCN105922814AReduce weightStable structural strengthNon-metallic wheel bodyCarbon fibersFiber layer

The invention relates to a carbon fiber wheel rim. The carbon fiber wheel rim comprises a body, the body is in a tubular shape and is winded in an annular shape, and the center of the circle is defined. The body defines a tubular space. The body is formed at least by overlaying a first carbon fiber layer and a second carbon fiber layer. The first carbon fiber layer is on the outer surface of the body and is a woven carbon fiber cloth. The second carbon fiber layer is between the first carbon fiber layer and the tubular space. The second carbon fiber layer comprises at least a carbon fiber cloth strip, and the at least a carbon fiber cloth strip is arranged around the center of the body.

Owner:CARBOTEC IND

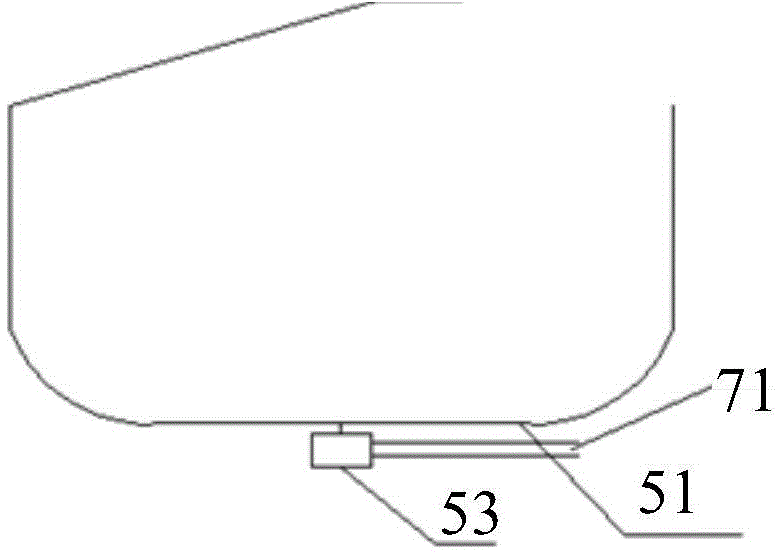

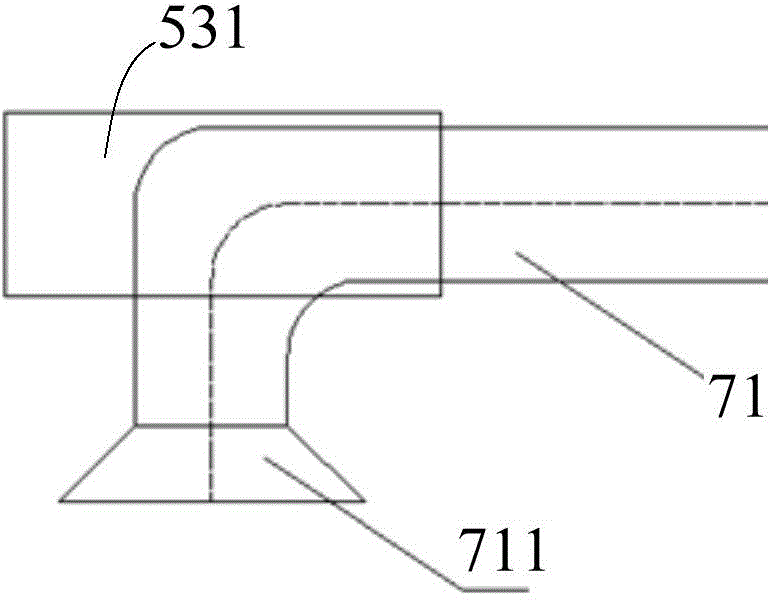

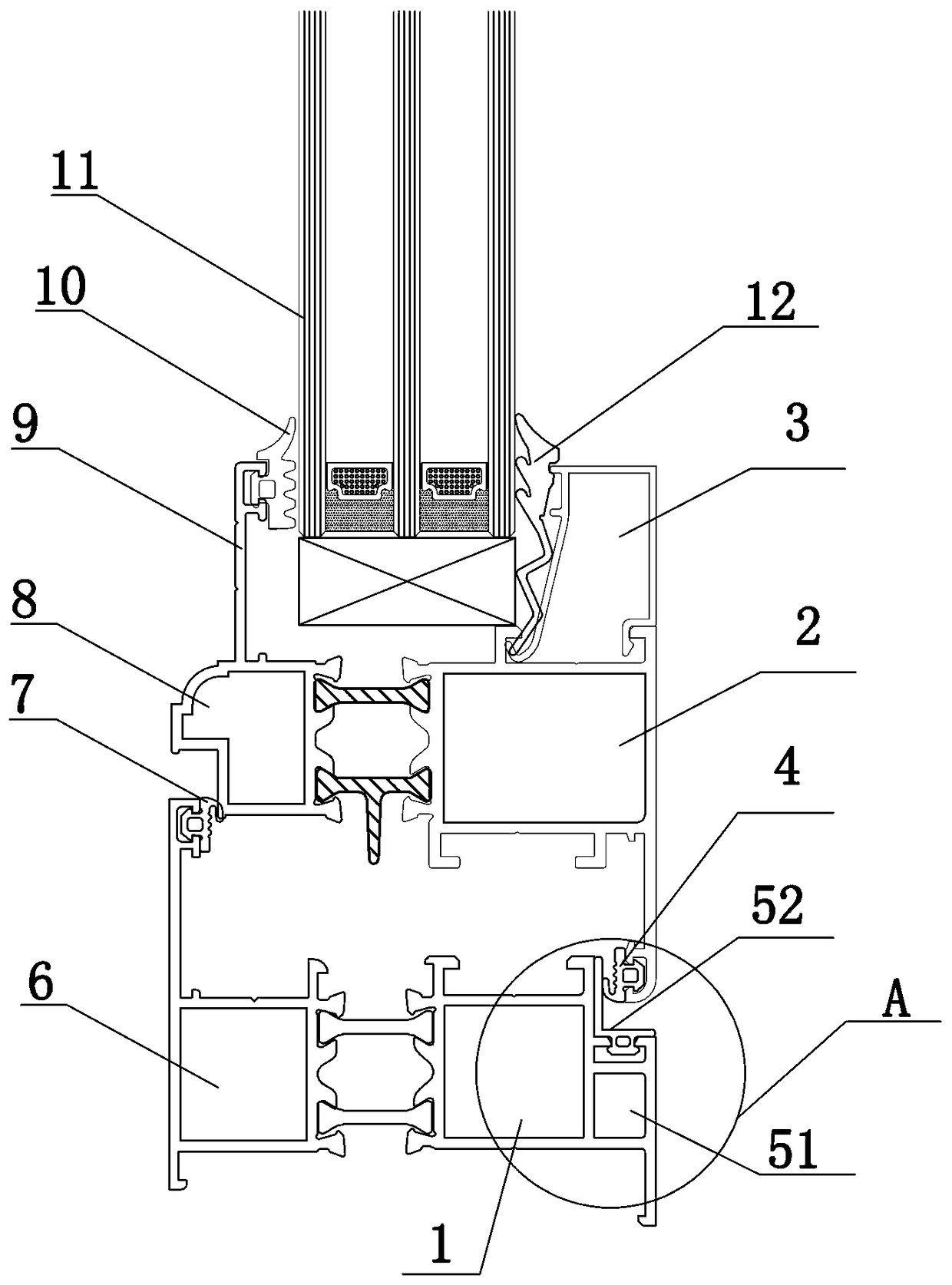

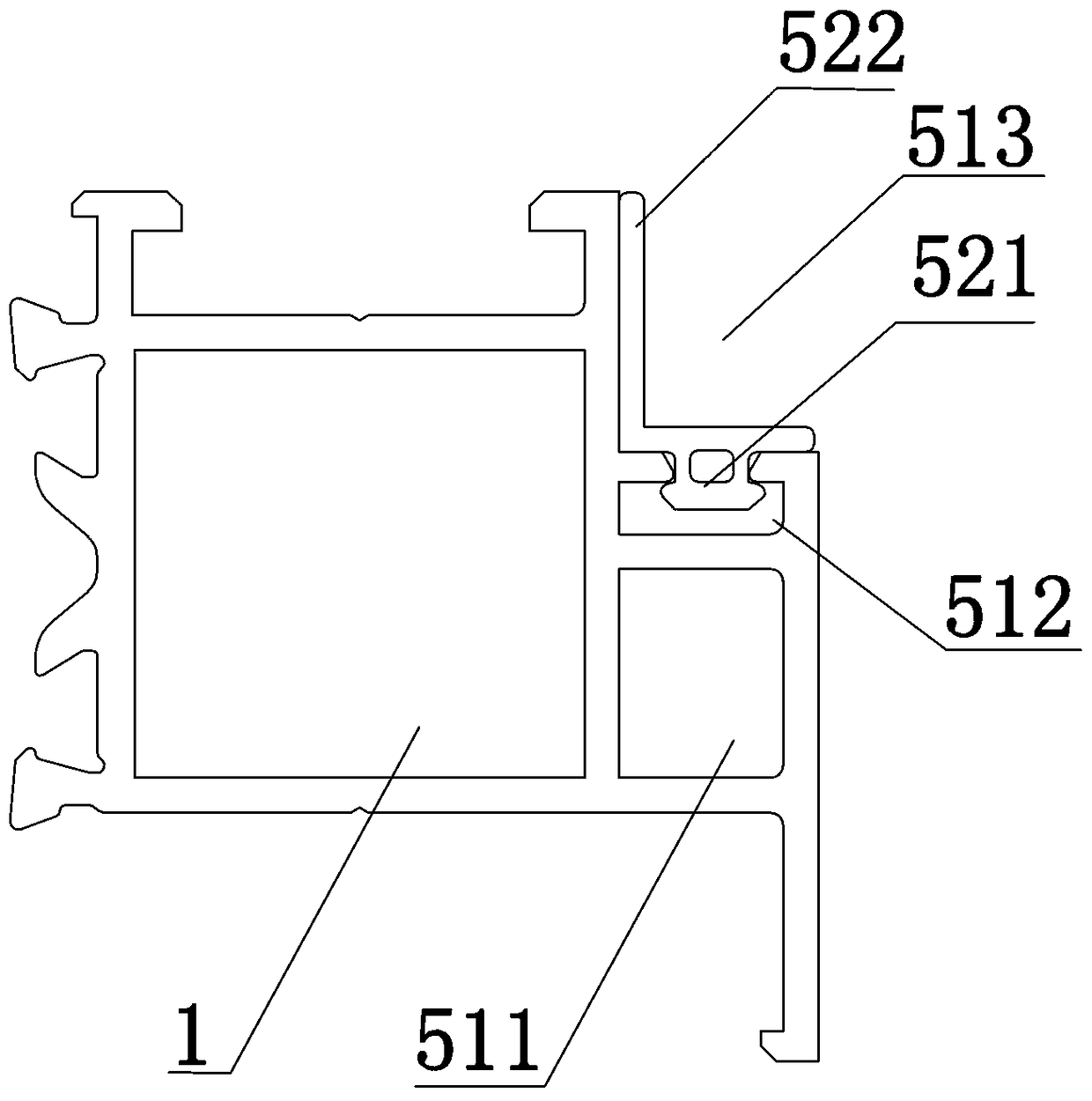

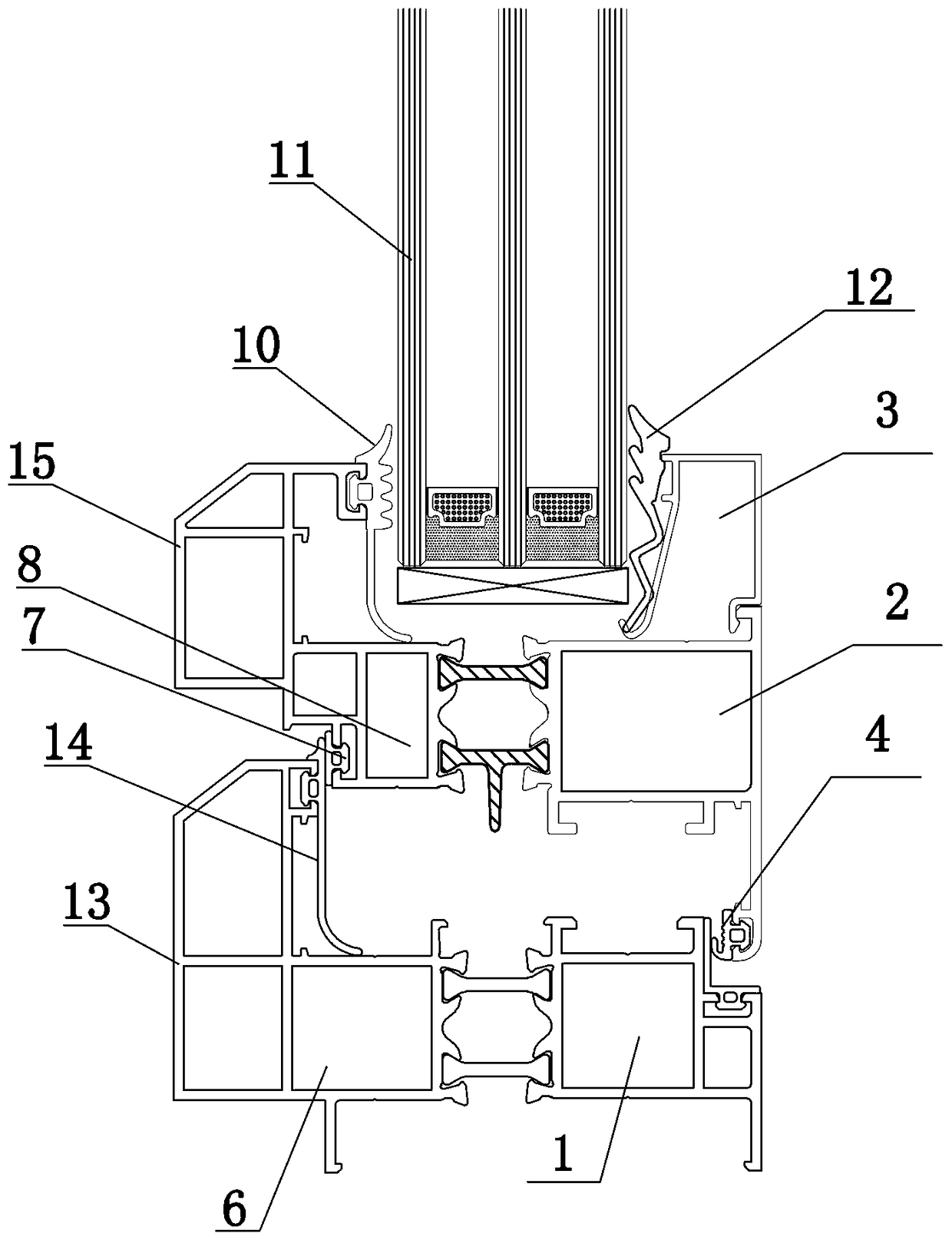

Casement window sash embedded structure

ActiveCN108999523AStable structural strengthImprove insulation effectClimate change adaptationWindows/door improvementButt jointEngineering

The invention relates to a casement window sash embedded structure. The casement window sash embedded structure comprises an inner window frame, an outer window frame, hollow glass, an inner glass fastening strip, an outer glass fastening strip, an inner glass sealing strip, an outer glass sealing strip, an inner sash, an outer sash, and sealing rubber strips; a heat insulating member for being embedded in the inner sash and lower than the inner window frame and an inner window frame side sealing rubber strip are additionally disposed on the right side of the inner window frame; the heat insulating member is a hollow square frame; an inserting groove for placing the window frame side sealing rubber strip is formed in the top of the hollow square frame; the hollow square frame and a side wall of the inner window frame form an L-shaped sash embedding groove matching an inner sash lower connection block; a lower part of the inner sash is embedded in the window frame embedding groove; theinner sash side sealing rubber strip is butt-jointed with the longitudinal length of the L-shaped sealing strip to form flexible connection sealing between the rubber strips. The advantages of the invention are that since the cavity structures of the window frame and the sash are of multi-cavity structures, the energy-saving effect, the heat insulating effect, the dustproof effect, the noise reduction effect, the wind pressure resistance, the appearance, and the safety are significantly improved.

Owner:高扬

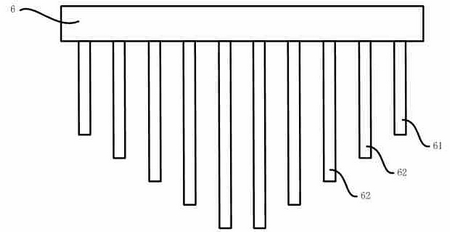

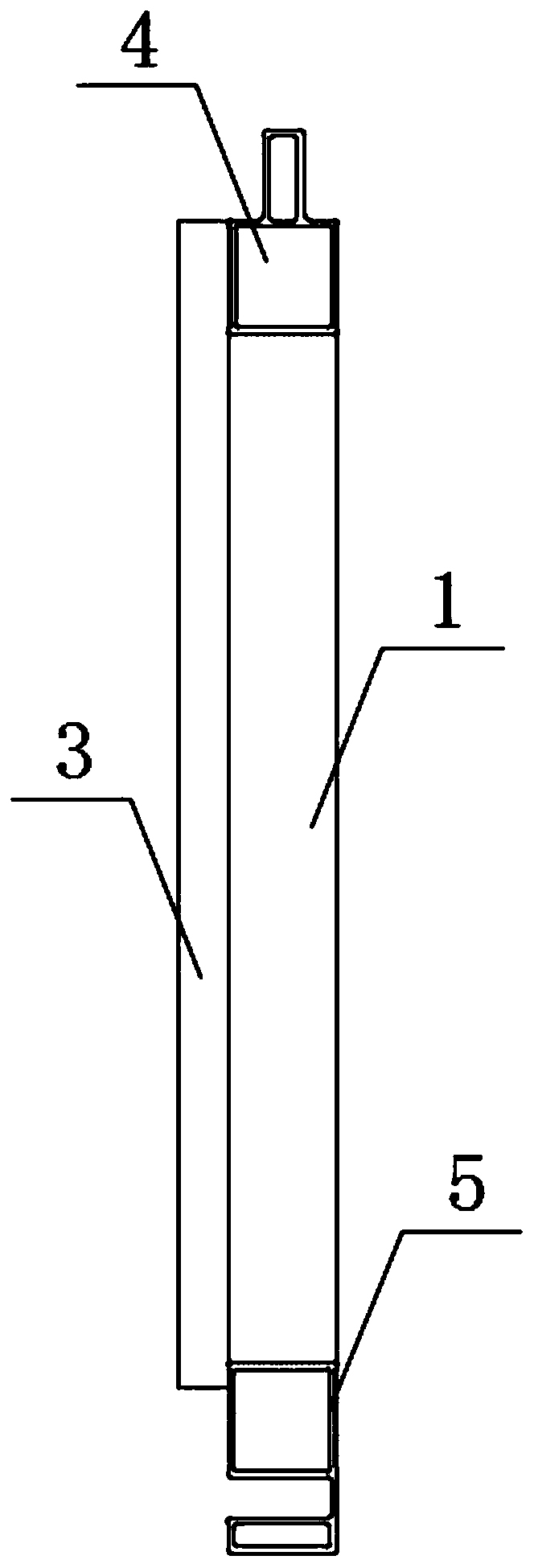

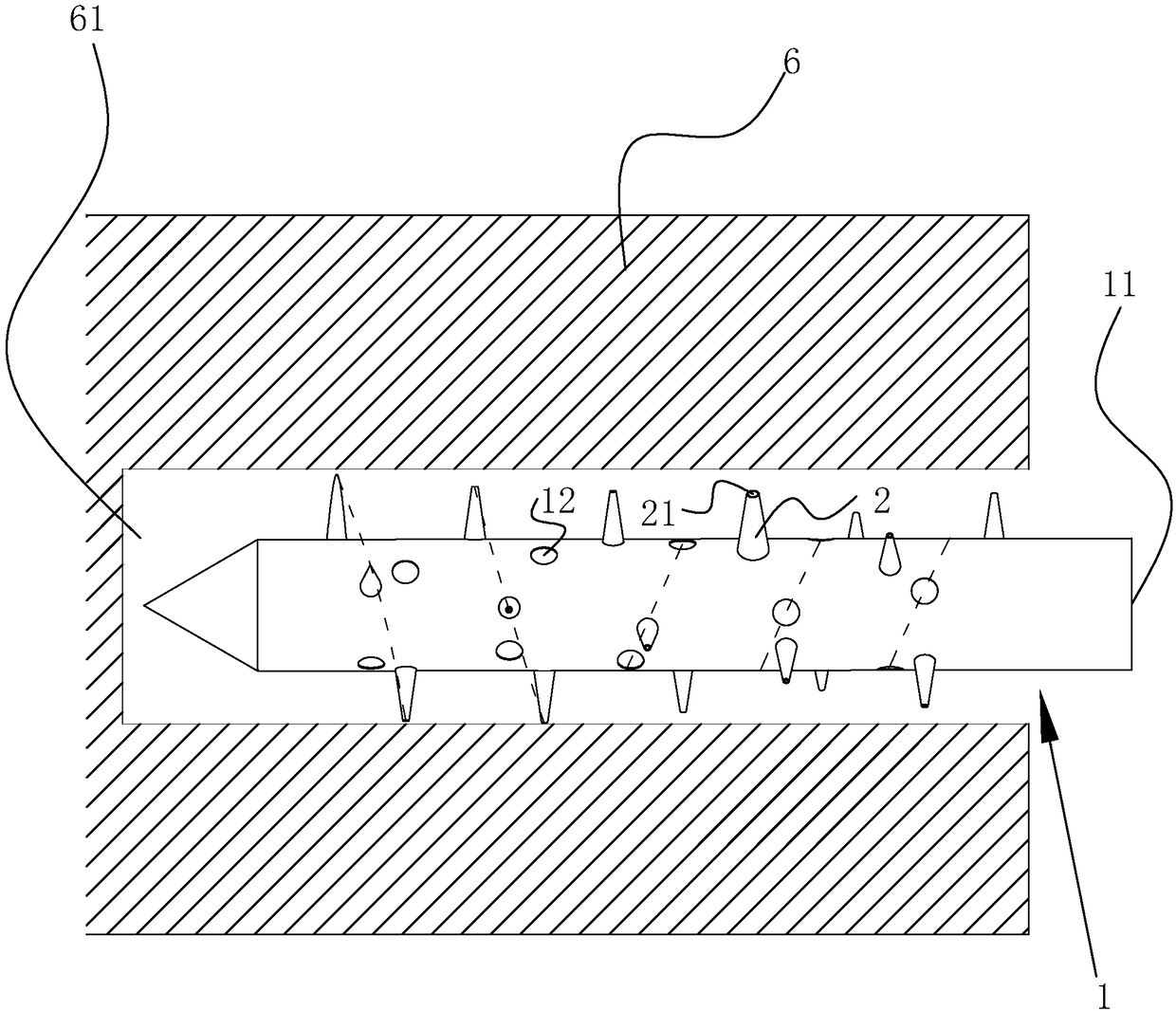

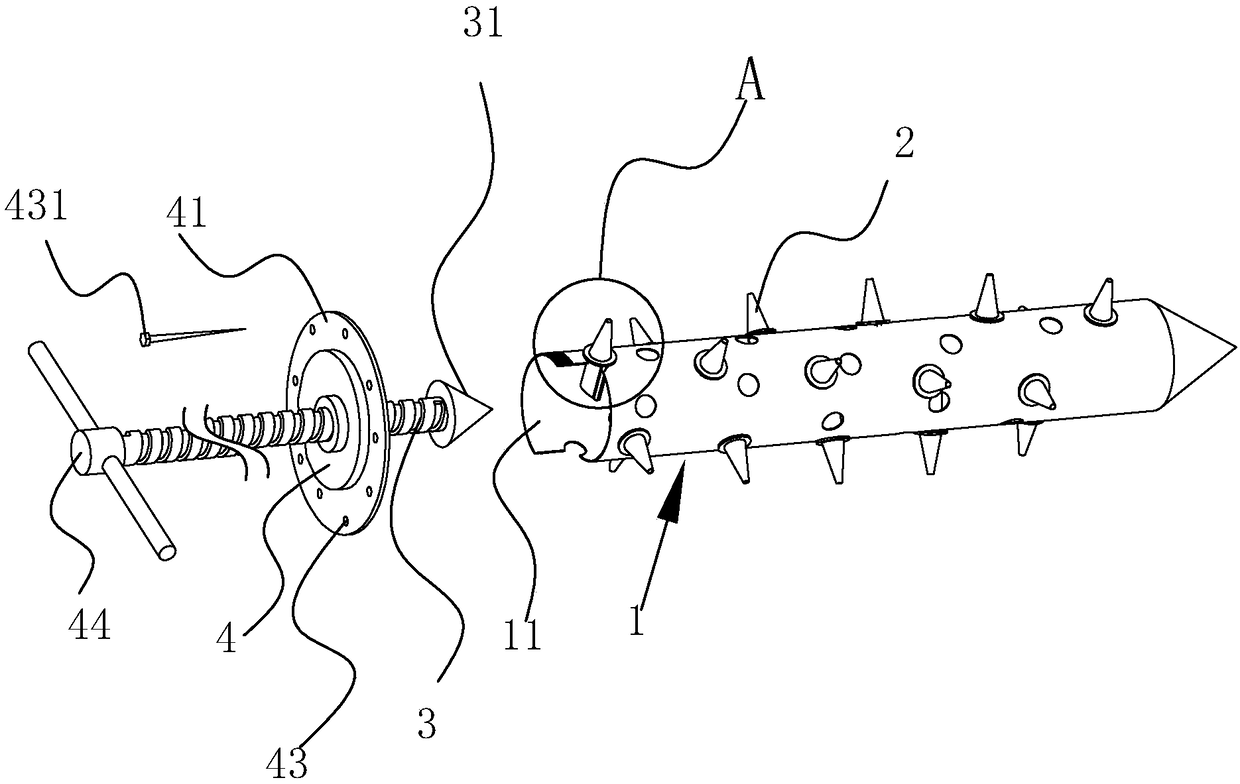

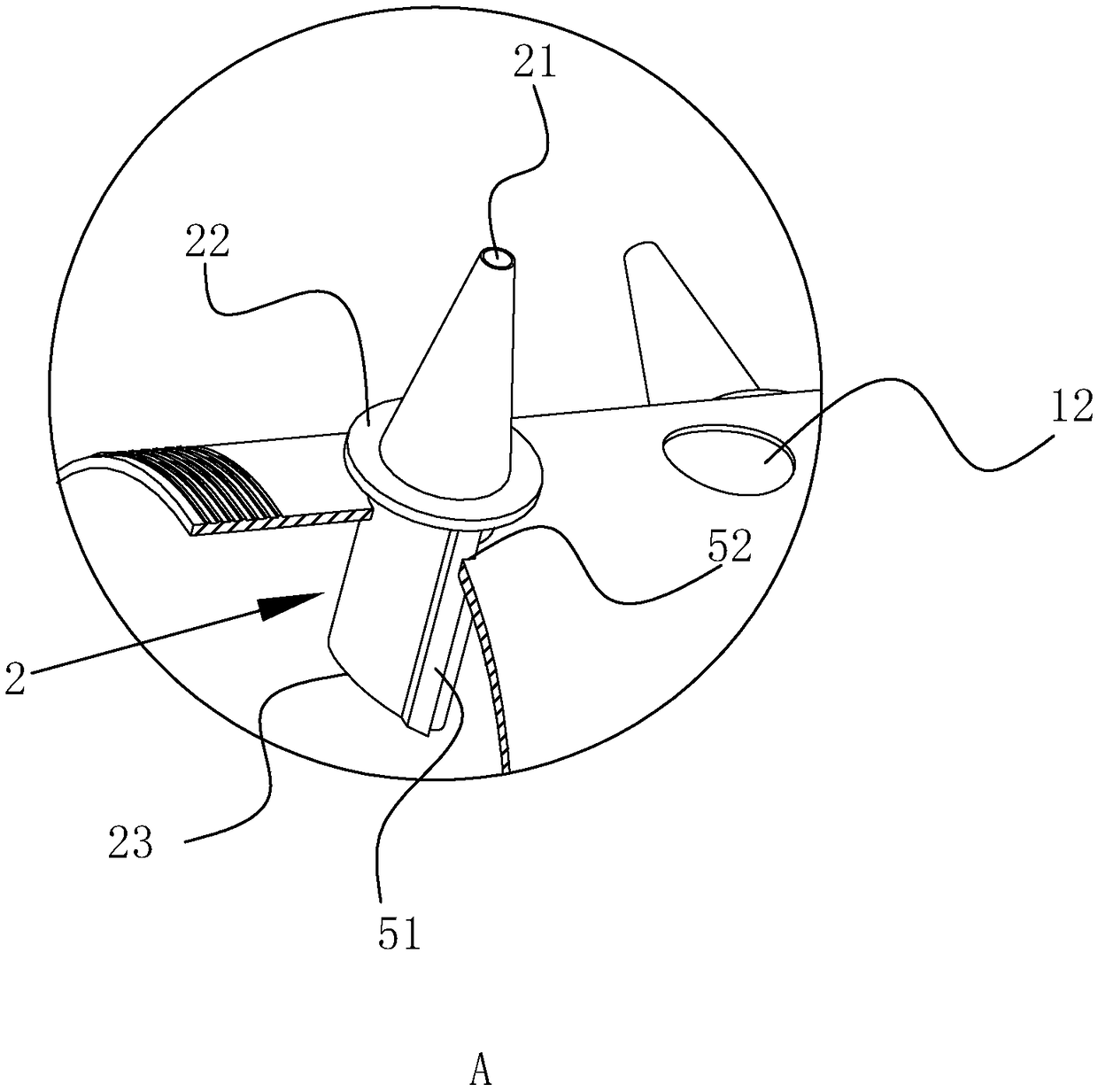

Tunnel supporting pipe

ActiveCN108979665AStable structural strengthHigh strengthUnderground chambersTunnel liningArchitectural engineeringGuide tube

The invention discloses a tunnel supporting pipe. The technical scheme is characterized in that the tunnel supporting pipe comprises a hollow pipe body, one end of the pipe body is provided with a grouting port, protruding support rods are arranged on the outer wall of the pipe body, each support rod is provided with a first grouting hole communicated with the interior of the pipe body, the support rods are helically arranged along the length direction of the pipe body, and one end, facing a geological stratum, of each support rod is conical. The outer wall of the pipe body is provided with second grouting holes communicated with the interior of the pipe body, the first grouting holes and the second grouting holes are distributed in a double-helix form on the outer wall of the pipe body, and the support rods are slidably inserted into the pipe body. Retaining blocks which are abutted against the outer wall of the pipe body to limit retraction of the support rods are fixed to the support rods, and one end, extending into the pipe body, of each support rod is provided with a slope facing the grouting port. The end, extending into the pipe, of a push rod is provided with a conical face which takes the slopes as fitting faces to push the support rods to extend out. By the support rods protruding the outer wall of a small guide pipe, the small guide pipe can be supported at the center of a geological hole, and a sufficient paste flowing space is reserved between the outer wall of the small guide pipe and the wall of the geological hole.

Owner:深圳市第一建筑工程有限公司

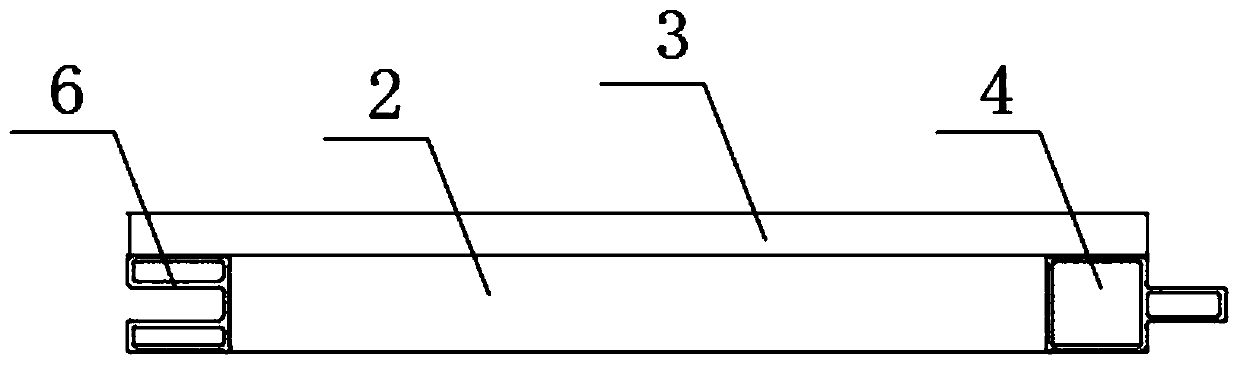

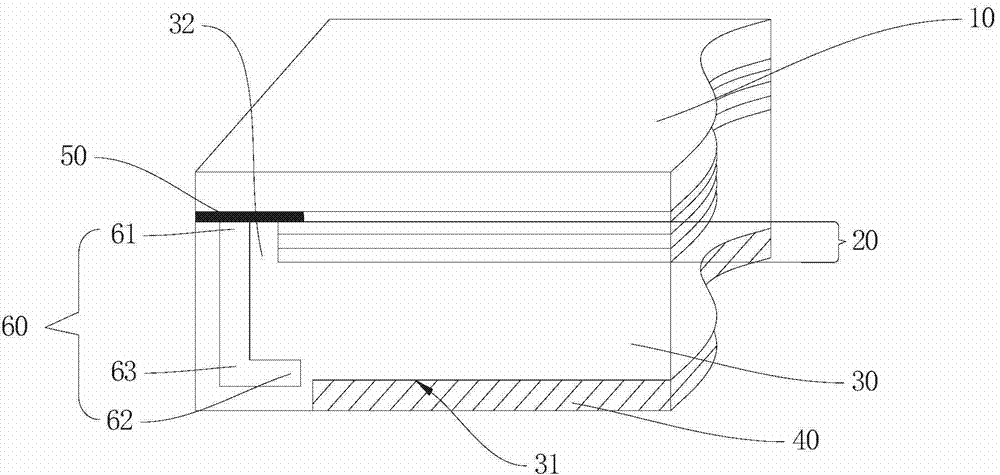

Backlight module structure

ActiveCN104501047ANarrow structureThin structurePlanar/plate-like light guidesLighting device detailsLight guideDisplay device

The invention relates to the technical field of display devices, in particular to a backlight module structure. The backlight module structure comprises a display panel, an optical film, a light guide plate and a reflector plate which are stacked in the vertical direction, as well as shading glue arranged at the bottom side of the display panel, wherein the side part of the light guide plate extends upwards through the optical film and is connected with the display panel by virtue of the shading glue; the bottom of the light guide plate is provided with a groove for assembling the reflector plate; the backlight module structure also comprises an iron frame provided with a first end part and a second end part; the first end part is connected with the display panel by virtue of the shading glue; the second end part extends into the light guide plate. According to the backlight module structure provided by the invention, a scheme that the iron frame and the light guide plate are integrated is adopted, the structure with the glue frame at the side part and the iron frame at the bottom in a backlight module is omitted, and a reflecting film is arranged at the groove formed in the bottom of the light guide plate, so that the backlight module structure is relatively narrow and thin.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

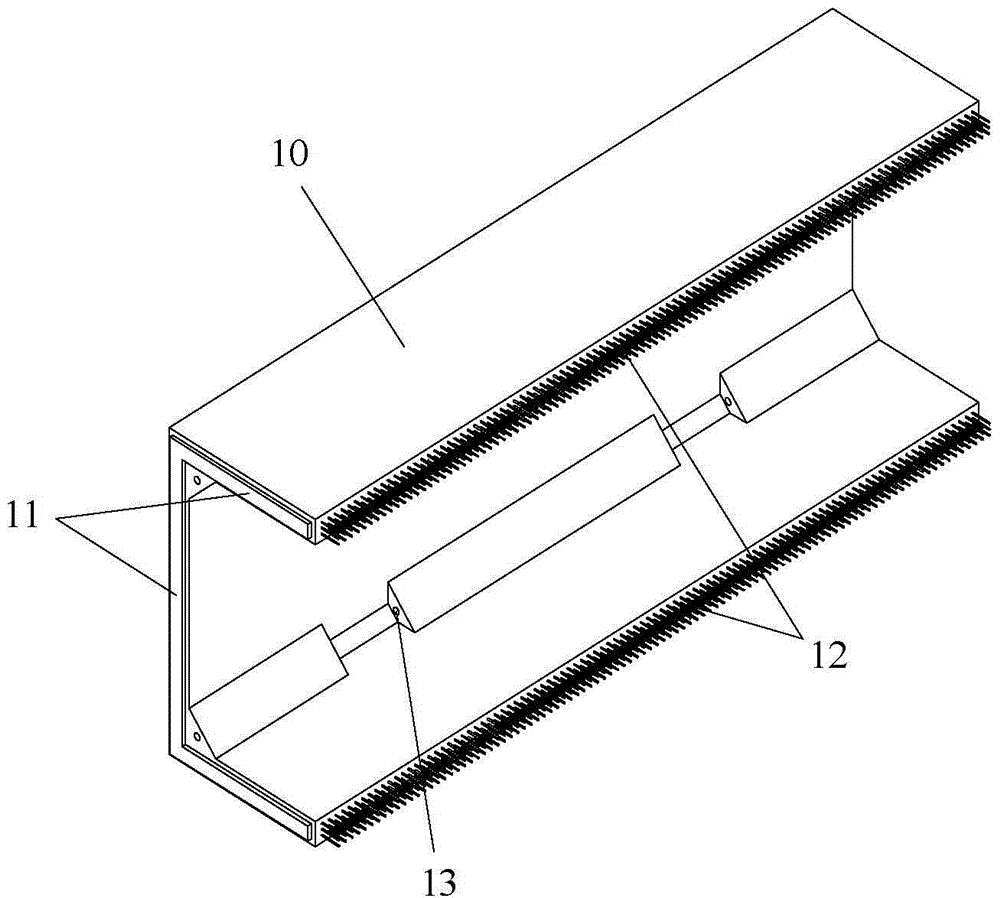

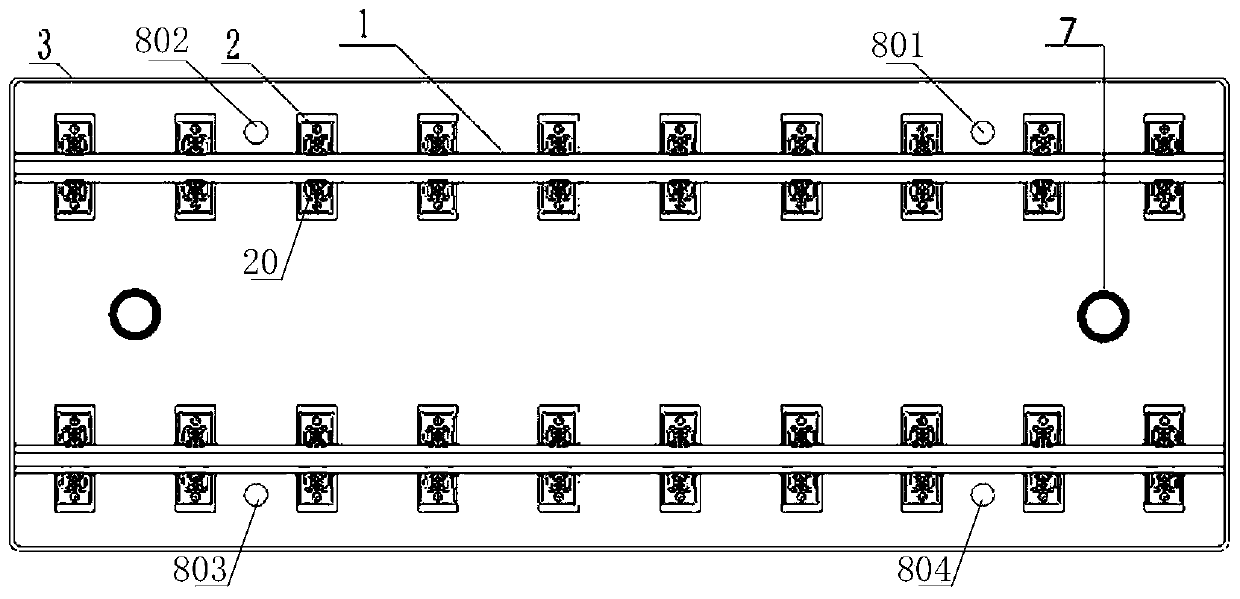

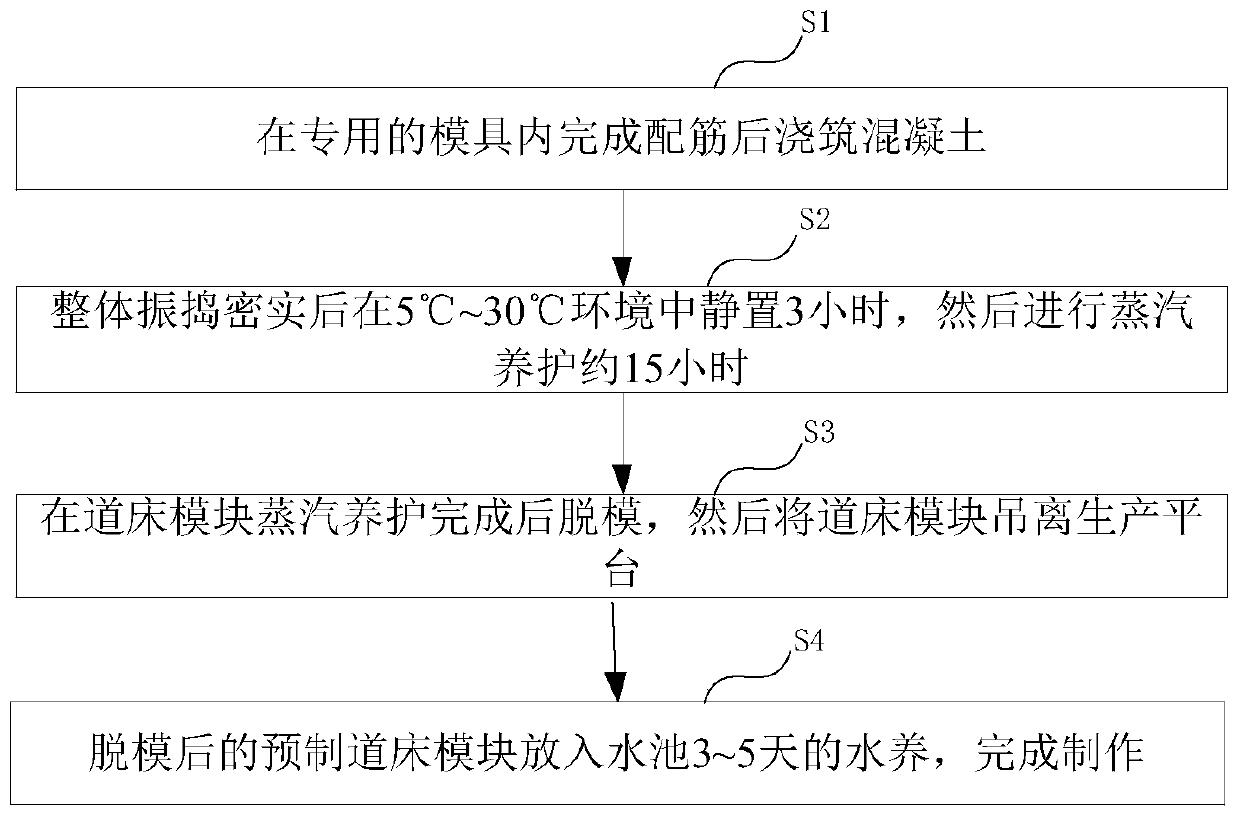

Assembled digitalized prefabricated ballast bed module, production method thereof and rail

InactiveCN110485214AEasy constructionEasy maintenanceBallastwayCeramic shaping apparatusEngineeringBallast

The embodiment of the invention provides an assembled digitalized prefabricated ballast bed module, a production method thereof and a rail. The ballast bed module comprises rail plates, rail bearing tables and steel rail fasteners, the rail bearing tables are arranged on the upper surfaces of the rail plates and are used for fixing the steel rail fasteners, and the steel rail fasteners are used for fixing steel rails; and each rail plate is integrally in a strip shape. The rail bearing tables are arranged to be perpendicular to the length directions of the rail plates. The rail plates are provided with limiting structures used for limiting plane movement of the rail plates. The N track plates are connected end to end on a preset railway line to form a detachable track monolithic ballast bed, wherein N is a positive integer greater than 1. The assembled digital prefabricated ballast bed module provided by the embodiment of the invention has a detachable property, can be laid on a railway line to form a track for a train to run, can be prefabricated in a factory, can be assembled on site on the railway line, and is convenient to construct, stable in structural strength and convenientto maintain and recycle.

Owner:吴永芳

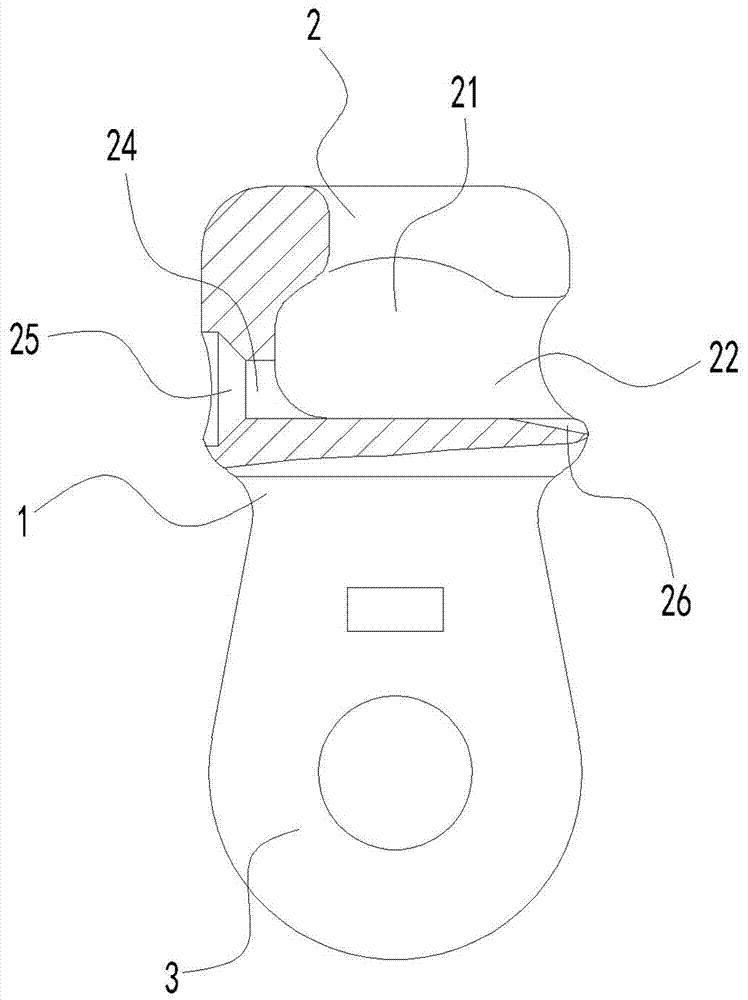

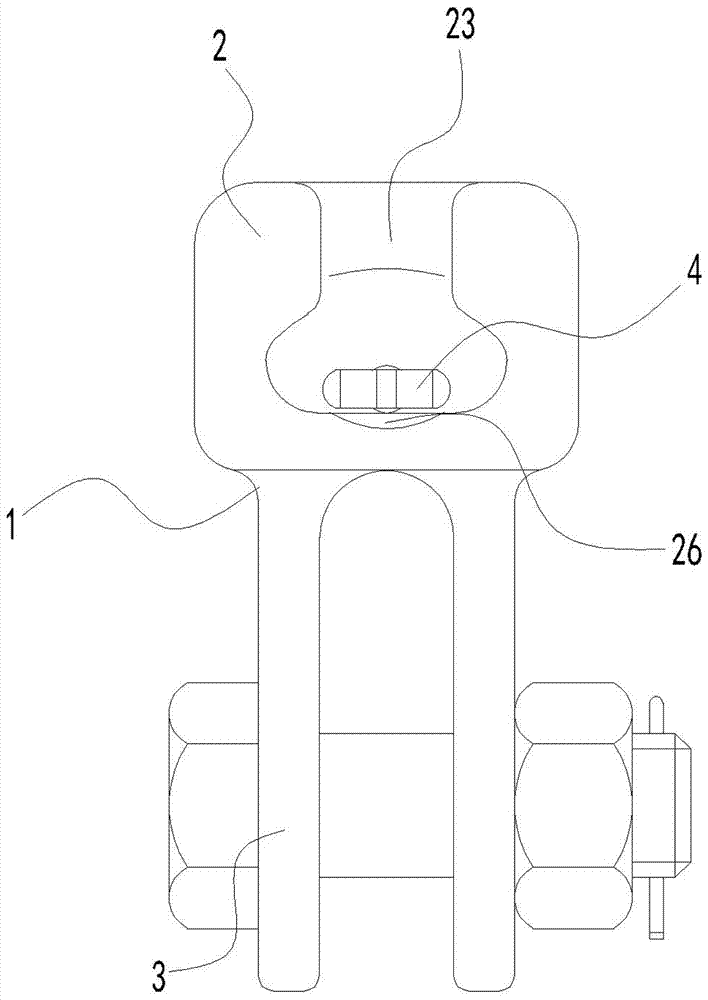

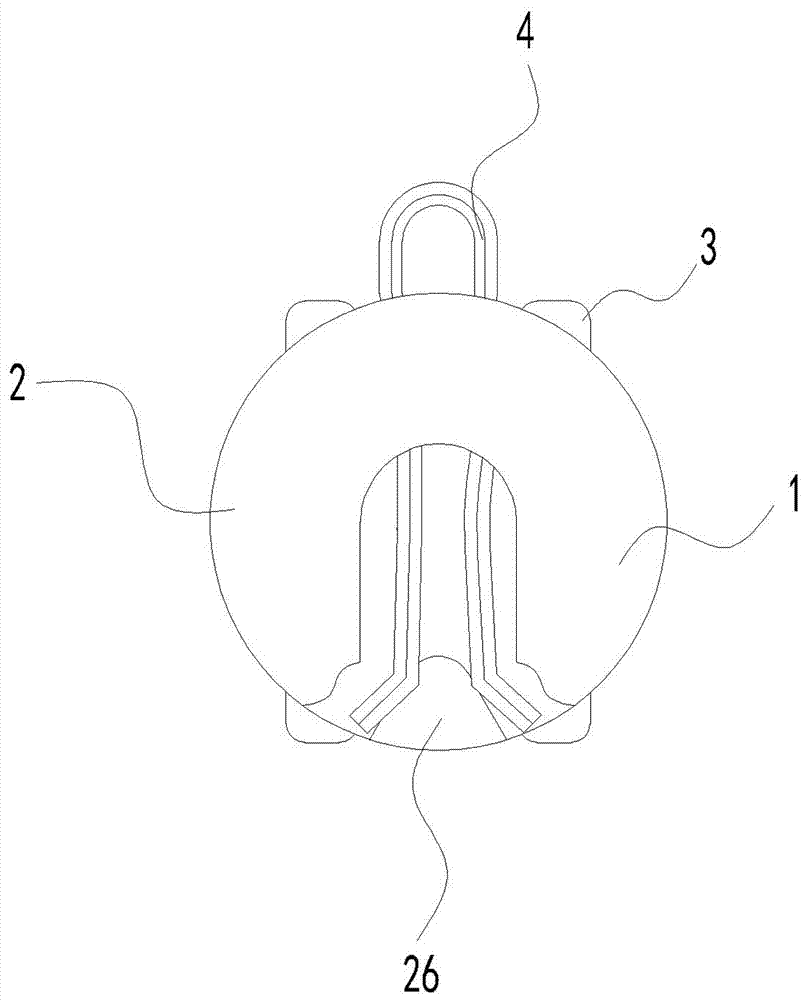

Ball socket fixing structure

PendingCN107979052AGuaranteed stabilityFit closelySuspension arrangements for electric cablesMechanical engineeringTransmission line

The invention discloses a ball socket fixing structure, and relates to the technical field of overhead transmission lines. The structure comprises a socket clevis base body, and the socket clevis basebody is provided with a socket placement part located at an end part, and a clevis body located at the tail end, wherein the socket placement part is cylindrical. The clevis body has parallel clevisplates, wherein the length of the clevis plates in the horizontal direction is equal to the diameter of the socket placement part, and the clevis plates are located at two sides of the central axis ofthe socket placement part. Two ends of the clevis plates respectively stretch out of the bottom of the clevis body. Through the increasing of the length of the clevis plates, the strength of the ballsocket fixing structure is improved.

Owner:浙江飞英电力器材有限公司

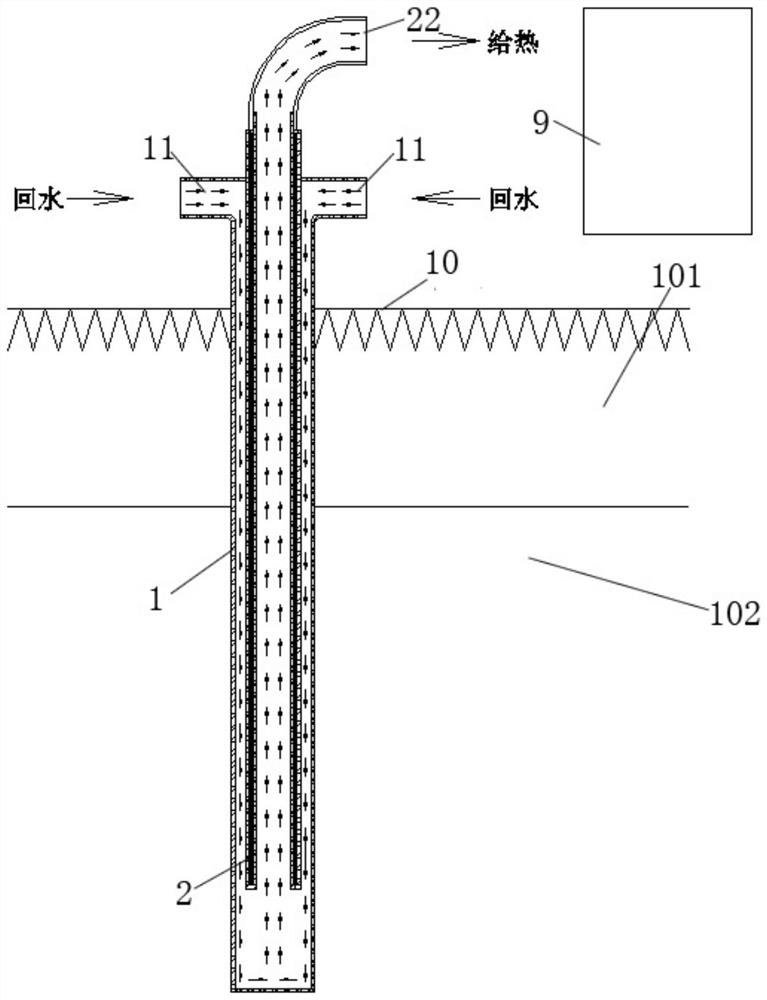

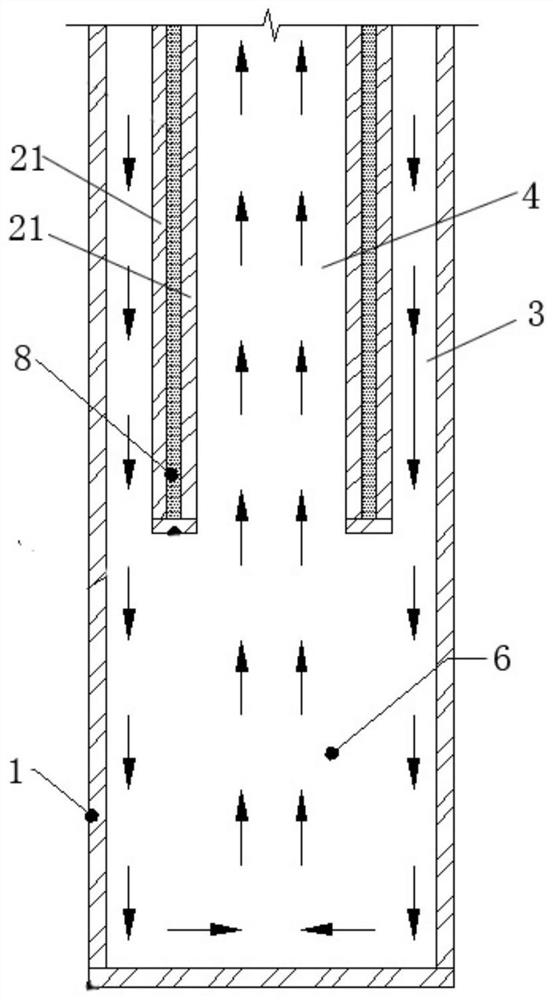

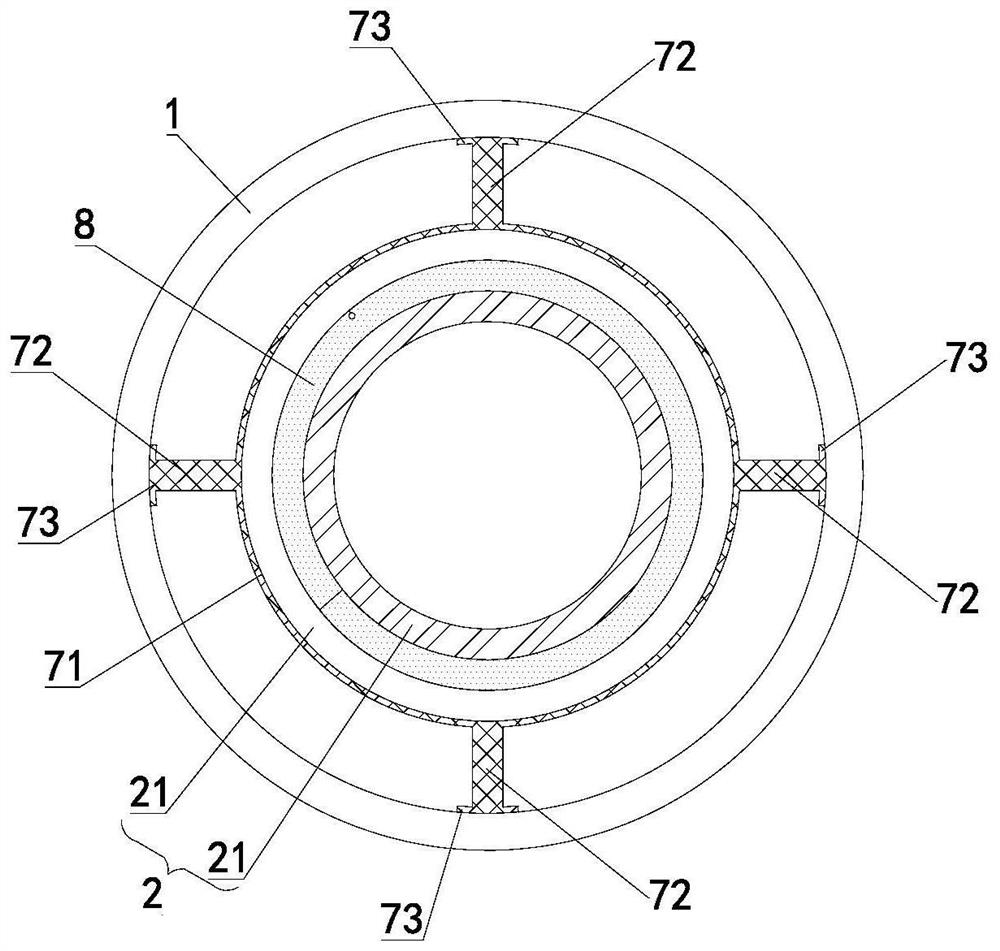

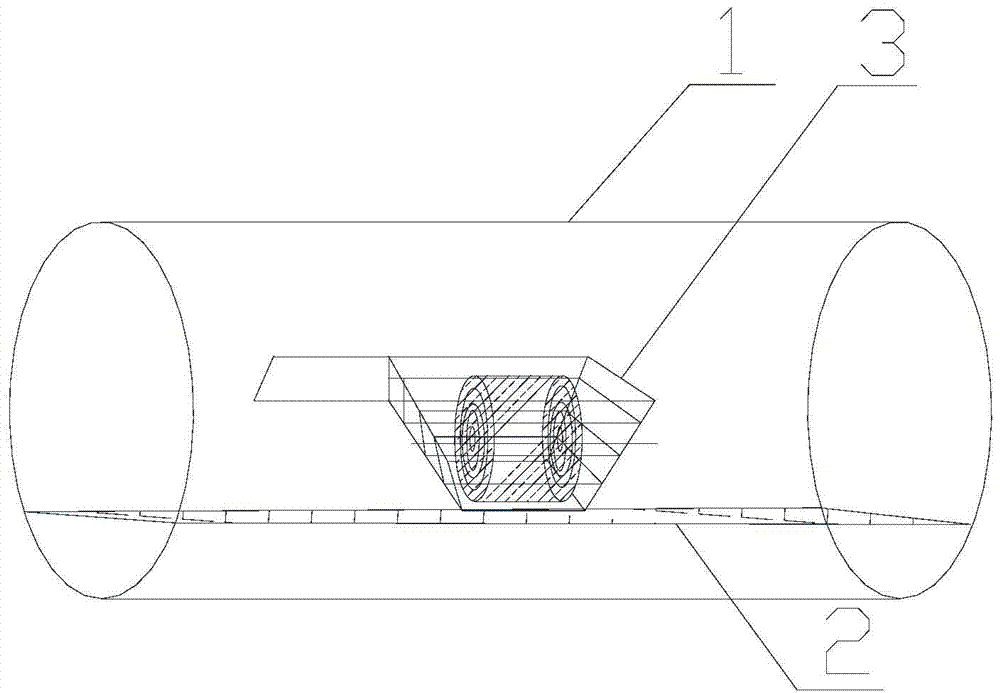

Multi-cavity heat insulation flow guide pipe with heat insulation structure and preparation method thereof

InactiveCN113790316AImprove utilization efficiencyHeating needs are highThermal insulationGeothermal energy generationEcological environmentEngineering

The invention relates to a multi-cavity heat insulation flow guide pipe with a heat insulation structure and a preparation method thereof, and belongs to the related technical field of heat insulation flow guide. The multi-cavity heat insulation flow guide pipe comprises an outer pipe and an inner pipe, the bottom of the outer pipe is of a sealed structure, and the top and the bottom of the inner pipe are of open structures; a first cavity is formed between the inner pipe and the outer pipe, the middle of the inner pipe is provided with an axially-through second cavity, the inner pipe is arranged in the outer pipe in a sleeved mode, a communication area is reserved between the bottom of the inner pipe and the bottom of the outer pipe, and the first cavity is communicated with the second cavity through the communication area; and a third cavity is formed between the inner side wall and the outer side wall of the inner pipe, the third cavity is a vacuum cavity, and a heat preservation material is sealed in the third cavity. The multi-cavity heat insulation flow guide pipe can be used for a medium-deep geothermal energy utilization system, the comprehensive utilization effects of small occupied area, low geothermal energy loss and zero influence on the ecological environment are achieved, the heating requirements of buildings and agriculture can be met without using high-grade energy for heat compensation, and the maximum utilization efficiency of geothermal energy is achieved.

Owner:北京千城集成房屋有限公司

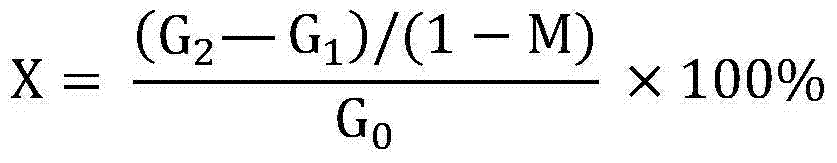

Method for rapidly determining ash content of paper filled with porous calcium silicate

ActiveCN104729954AGuaranteed accuracyAvoid fly ashWeighing by removing componentCombustionContent determination

The invention discloses a method for rapidly determining the ash content of paper filled with porous calcium silicate. The method comprises the following steps: firstly cutting the paper filled with porous calcium silicate into a plurality of paper slips in the same size and then enabling the paper slips to overlap each other and then rolling the paper slips into a cylindrical paper pattern along the length direction; then weighing the cylindrical paper pattern and a combustion apparatus used for placing the cylindrical paper pattern; then putting the cylindrical paper pattern in the combustion apparatus, igniting the cylindrical paper pattern by adopting a butane spray gun and combusting the cylindrical paper pattern, then putting the combustion apparatus in a dryer to be cooled after cooling the combustion apparatus in the air for a certain time and weighing the combustion apparatus after cooling; finally computing the ash content of the paper filled with porous calcium silicate via a formula. The method is high in ash content determination speed and accurate in data and can absolutely meet the requirement of rapid determination of the ash content of the paper in production and scientific research.

Owner:SHAANXI UNIV OF SCI & TECH

A modular DC traction feeder cabinet

ActiveCN106558849BAffect contact stabilityPrecise positioningSwitchgear detailsSubstation/switching arrangement casingsElectricityElectrical stability

The present invention relates to a modularization direct current traction feeder cabinet. The cabinet comprises a cabinet body, the front side of the cabinet body is provided with a cabinet door capable of opening or closing, the interior of the cabinet body is divided into a busbar chamber and a breaker chamber, the breaker chamber is located at the front side of the busbar chamber, the breaker chamber is internally provided with a breaker distribution cabinet unit and a breaker handcart, the breaker distribution cabinet unit is fixedly arranged at the inner bottom surface of the breaker chamber, the breaker handcart is arranged in the breaker distribution cabinet unit, and when the cabinet door is opened, the breaker handcart can be pulled out or pushed into the breaker distribution cabinet unit from the opening of the cabinet door; and the upper portion of the breaker handcart is provided with the breaker, when the breaker handcart is pushed into the breaker distribution cabinet unit, the breaker is contacted with and electrically connected with the copper bar in the busbar chamber. The structure is concise, and the breaker unit portion with high matching requirement is subjected to modularization design to improve the matching precision of the breaker contact so as to greatly improve the electrical stability performances of products and realize the complete interchangeability of the breaker distribution cabinet.

Owner:WUHAN ZHONGZHI ELECTRIC

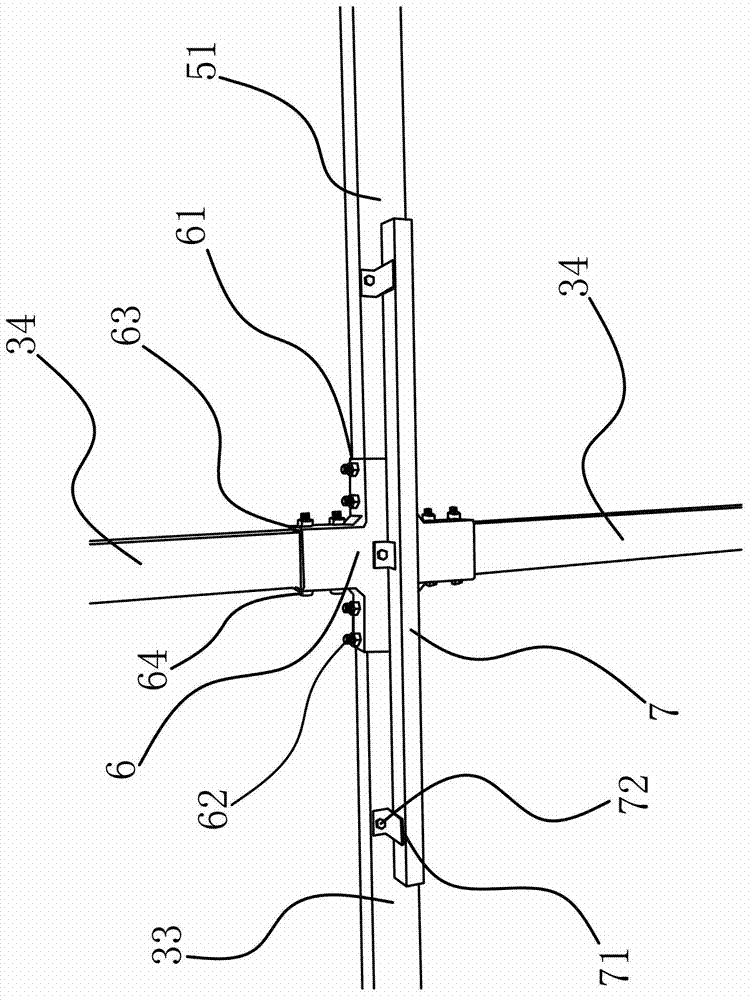

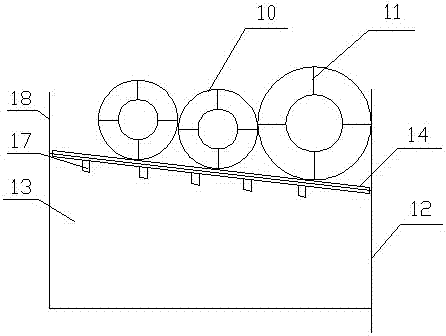

Assembly type prefabricated pipe gallery with protective cable covers

InactiveCN107237352AStable structural strengthEasy to installArtificial islandsCable installations in tunnelsSupport planePetroleum engineering

The invention discloses an assembled prefabricated pipe gallery with a protective cable cover, which includes a prefabricated pipe gallery. There are protruding blocks in the ring of the end ports, and the protruding blocks correspond to the corresponding annular grooves at the output end. Reinforcing ribs are provided at the corners of both ends, connecting holes are provided inside the reinforcing ribs, and anchoring holes are provided in the middle of the reinforcing ribs. There are 1‑3 rows of cable support frames inside the prefabricated part of the pipe gallery, and each row of cable support frames has 3 supporting devices arranged side by side. The separation plate and the front end of the support device are provided with a stopper. The present invention has stable structural strength, convenient and quick installation, high safety when the cable cover is installed, and the quality of the cable is shared by the uniform force plate, so the service life is long.

Owner:JIANGSU JINMAO TECH DEV

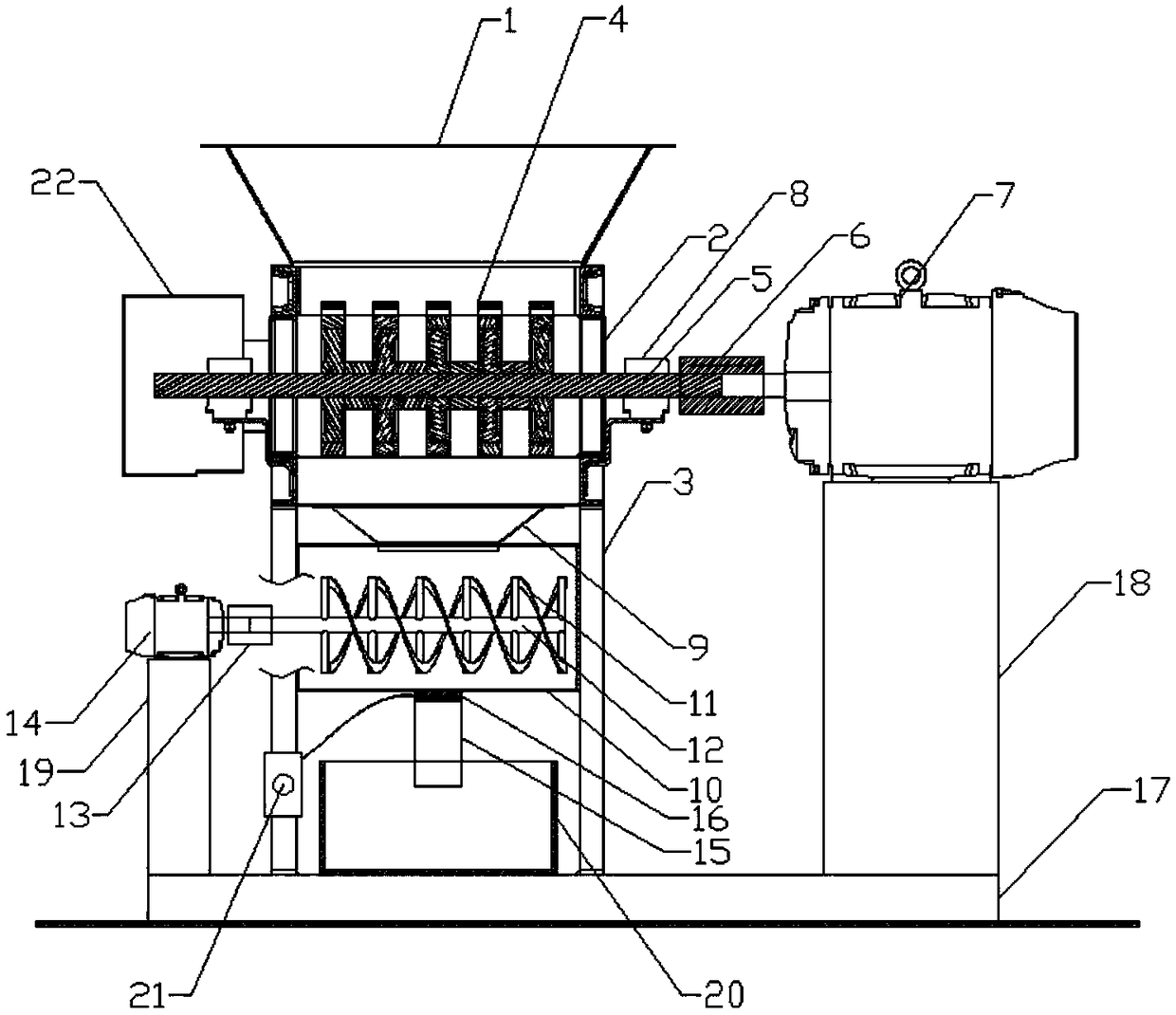

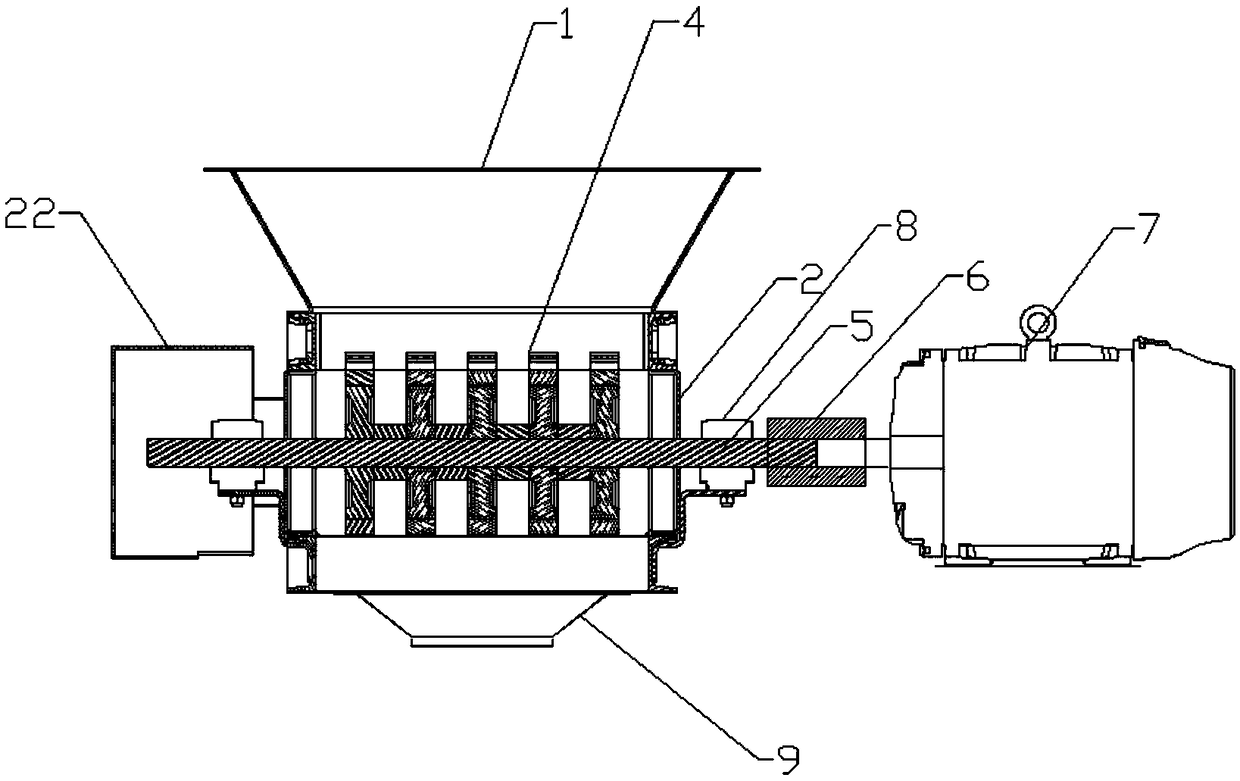

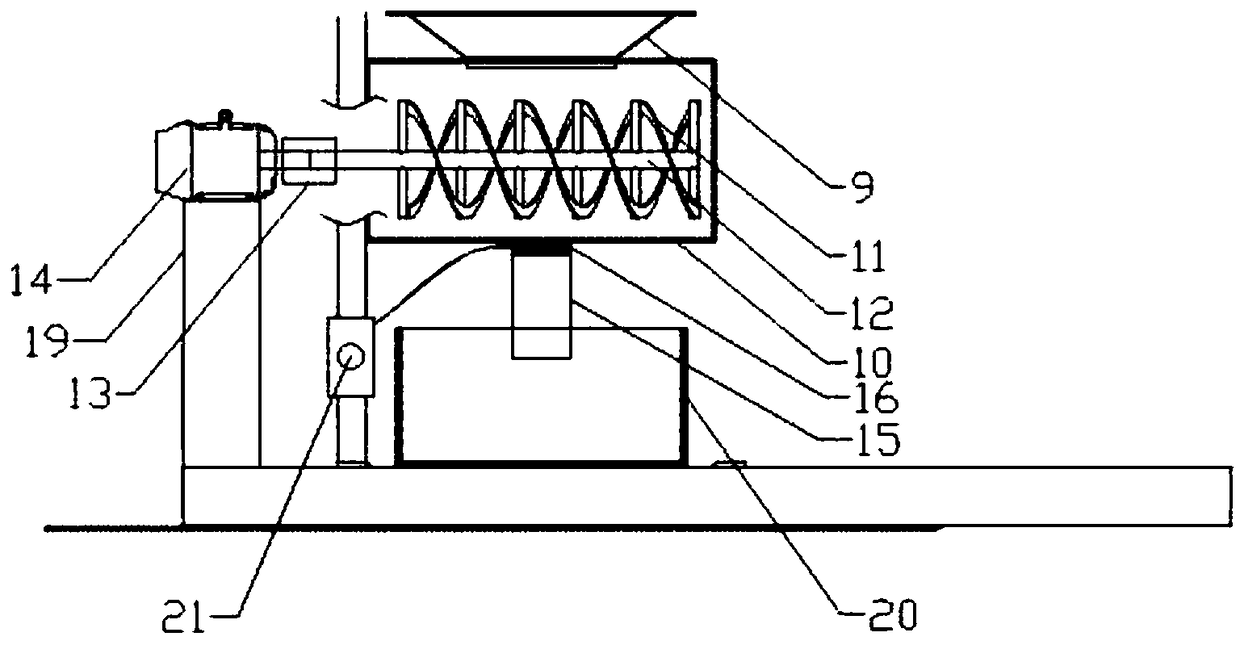

Crushing and mixing device for tea tree fertilization

InactiveCN108855394ARealize an integrated structureGuaranteed crushing effectTransportation and packagingRotary stirring mixersDevice formCoupling

The invention relates to the technical field of tea tree fertilization, in particular to a crushing and mixing device for tea tree fertilization. The device comprises a fertilizer feed port; a crusherouter shell is welded at the end, near the ground, of the fertilizer feed port; the end, near the ground, of the crusher outer shell is connected with a support frame through screws; a crushing pieceis arranged in the crusher outer shell; a crushing piece rotating shaft is sleeved in the crushing piece; a first coupling sleeves the end of the crushing piece rotating shaft; a crushing motor sleeves one end of the first coupling; the crushing piece rotating shaft sleeves bearing bases on two edges of the crusher outer shell; a guide port is welded at the end, far from the fertilizer feed port,of the crusher outer shell; the end, far from the crusher outer shell, of the guide port is connected with a mixing outer shell by screws; a mixing and stirring piece is arranged in the mixing outershell; a mixing and stirring shaft is welded in the mixing and stirring piece; and a second coupling sleeves the end, far from the crushing motor, of the mixing and stirring shaft. Through crushing and mixing integral design, the device forms fertilizers.

Owner:ANHUI XIANGFEI TEA CO LTD

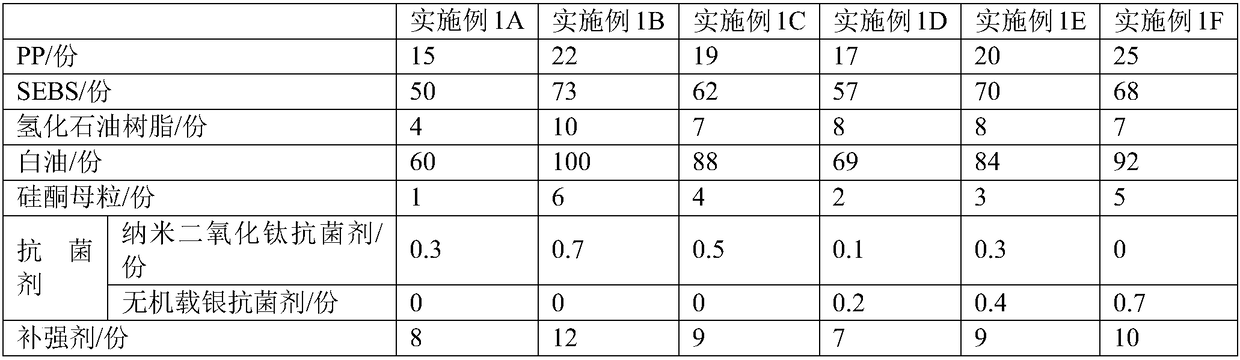

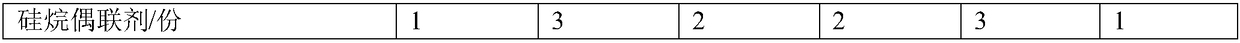

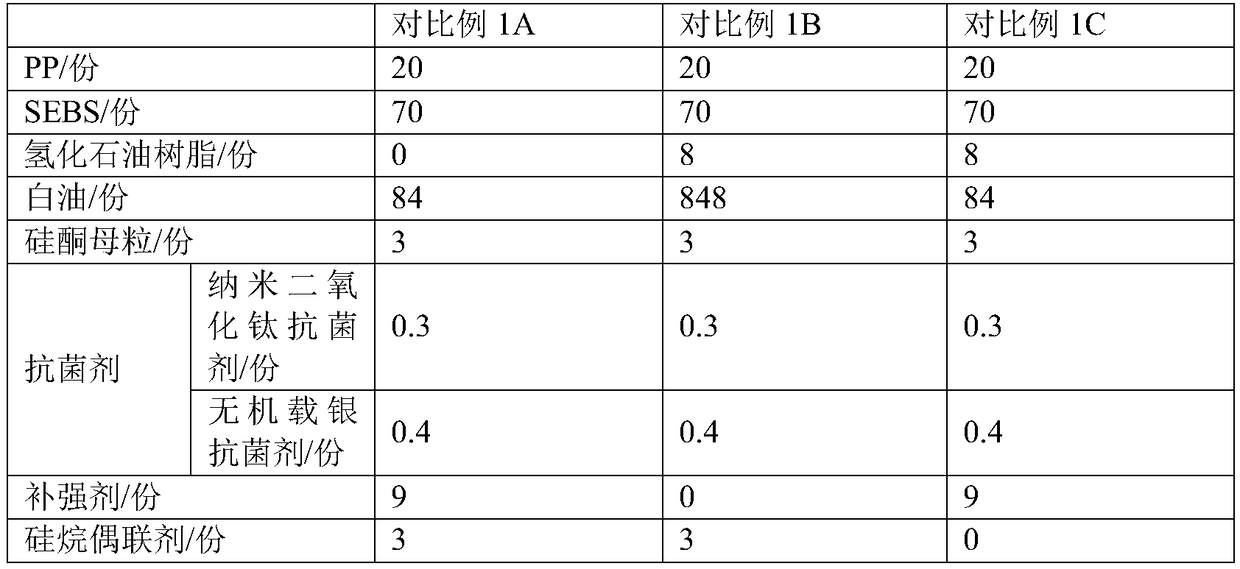

TPE (thermoplastic elastomer) for syringe piston and preparation method thereof

The invention relates to a thermoplastic elastomer (TPE) material, and discloses a TPE for a syringe piston and a preparation method of the TPE. The technical scheme is as follows: the TPE for the syringe piston comprises the following raw materials by mass fraction: 15-25 parts of PP, 50-73 parts of SEBS, 4-10 parts of hydrogenated petroleum resin, 60-100 parts of white oil, 1-6 parts of siliconemaster batch, 0.3-0.7 part of antibacterial agent, 8-12 parts of reinforcing agent and 1-3 parts of silane coupling agent, the antibacterial agent is one or two of inorganic silver-loaded antibacterial agent and nanometer titania antibacterial agent, the reinforcing agent is prepared from a carbon black and a fumed silica, and the TPE achieves the effects that the TPE does not fracture easily when being extruded, stretched and twisted by external force, and the crushed material and the fine powder on the fracture surface are reduced after the fracturing.

Owner:慈溪市山今高分子塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com