Reactor core structure of heat pipe reactor fuel element adopting hexagonal prism cladding

A fuel element and core structure technology, which is applied in the direction of fuel element, moderator/core structure, reactor, etc., can solve the problems of excessive deformation of the reactor, failure of core function, failure of heat transfer of heat pipes, etc., to reduce the temperature difference , strong heat transfer ability, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment, the present invention is further introduced:

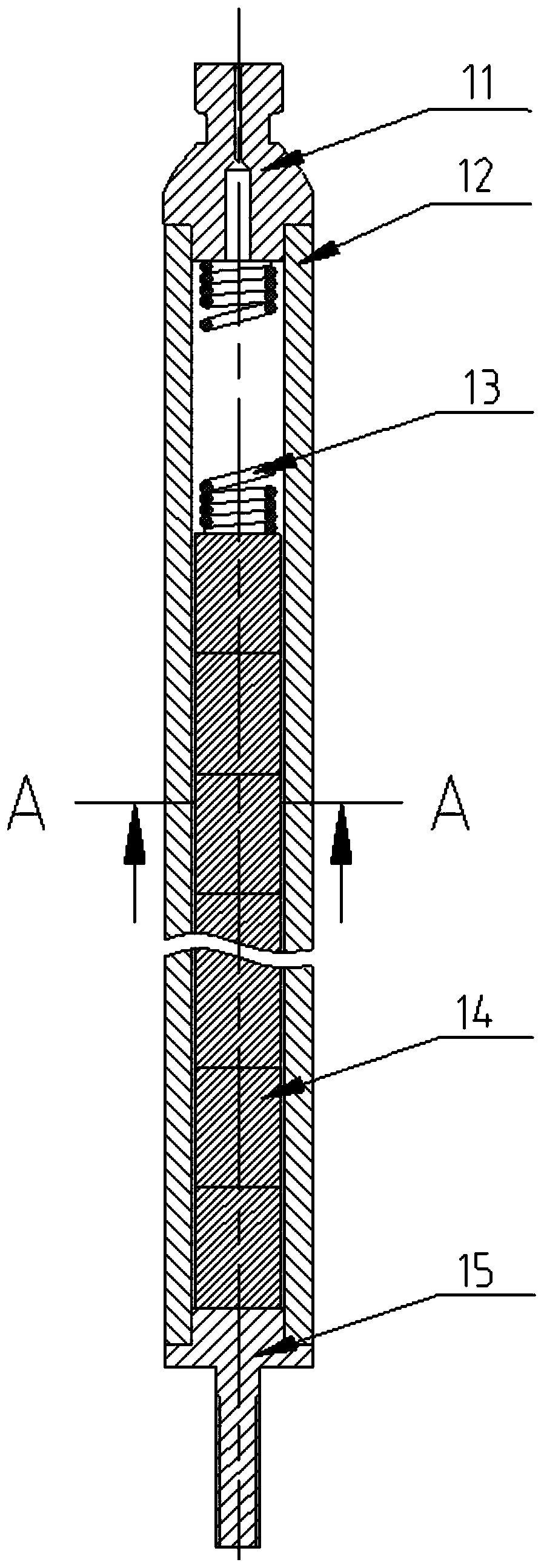

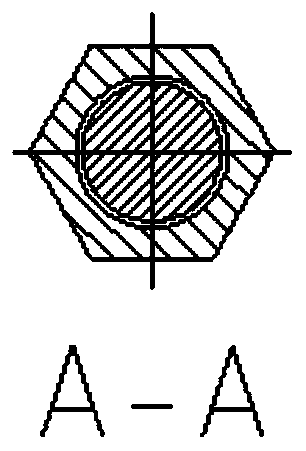

[0033] A core structure of a heat pipe reactor fuel element using a hexagonal prism cladding, comprising a fuel element 1, a heat pipe 2, a limit base 3, a cylindrical container 4 and a core upper grid plate 5; wherein the fuel element 1 and the heat pipe 2 is arranged in a honeycomb shape inside the barrel container 4, a limit base 3 is provided between the arrangement and combination of the fuel elements 1 and the heat pipes 2 and the inner wall of the barrel container 4, and the upper grid plate 5 of the core is arranged in the barrel. body container 4.

[0034] The fuel element 1 and the heat pipe 2 are both hexagonal prism structures with the same shape, and six fuel elements 1 are arranged on the outside of each heat pipe 2 to form a perfectly matched honeycomb structure.

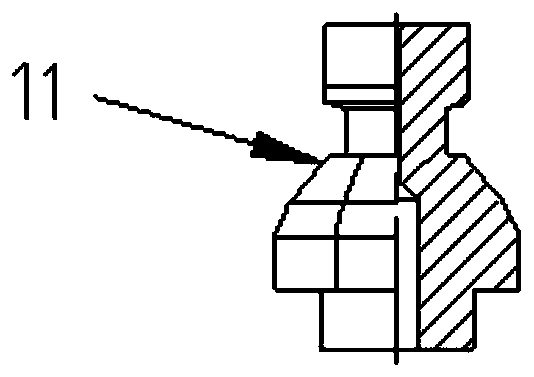

[0035] The fuel element 1 includes: an upper end plug 11, a fuel element hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com