Modularization direct current traction feeder cabinet

A technology for DC traction and feeder cabinets, which is applied in the direction of pull-out switch cabinets, switchgear, electrical components, etc. It can solve the problems affecting the working stability of DC traction feeder cabinets, the influence of internal electronic components, and poor interchangeability, etc., to achieve Improve electrical stability performance, simple structure, and overcome the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

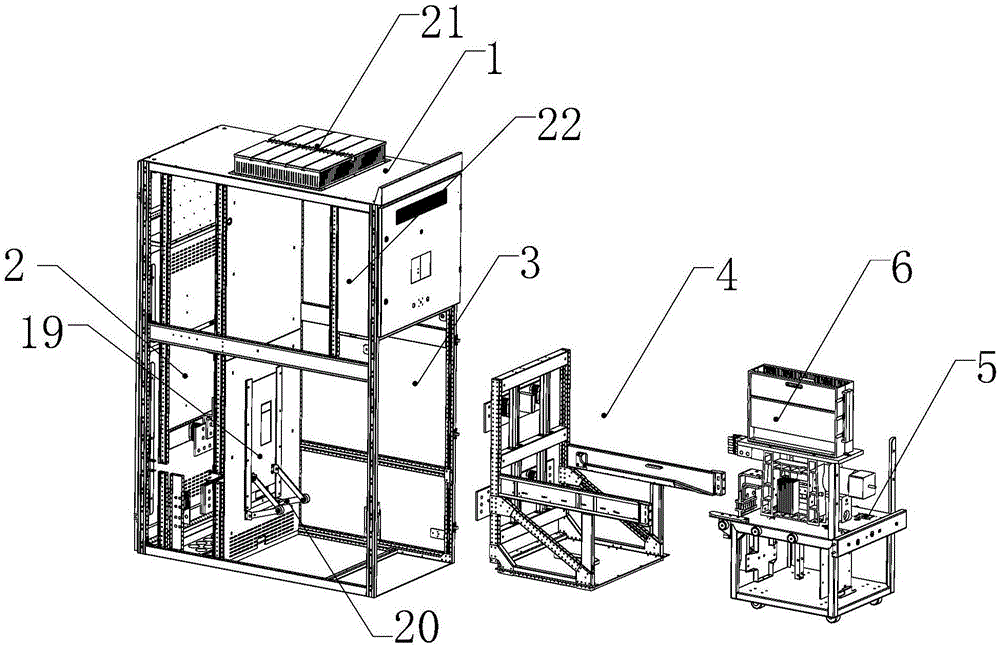

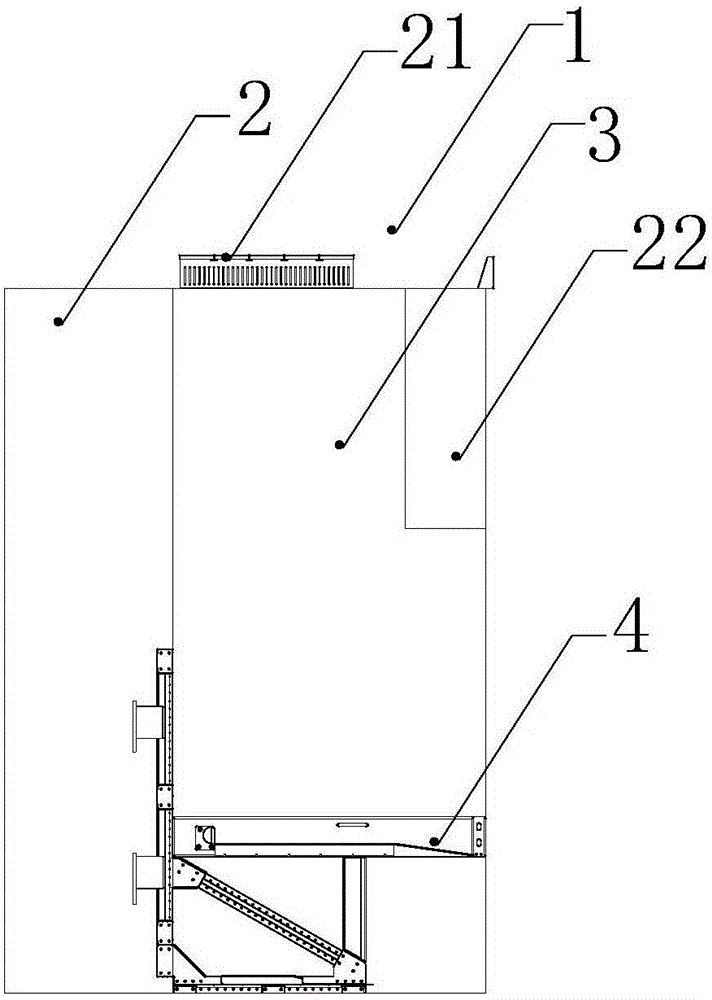

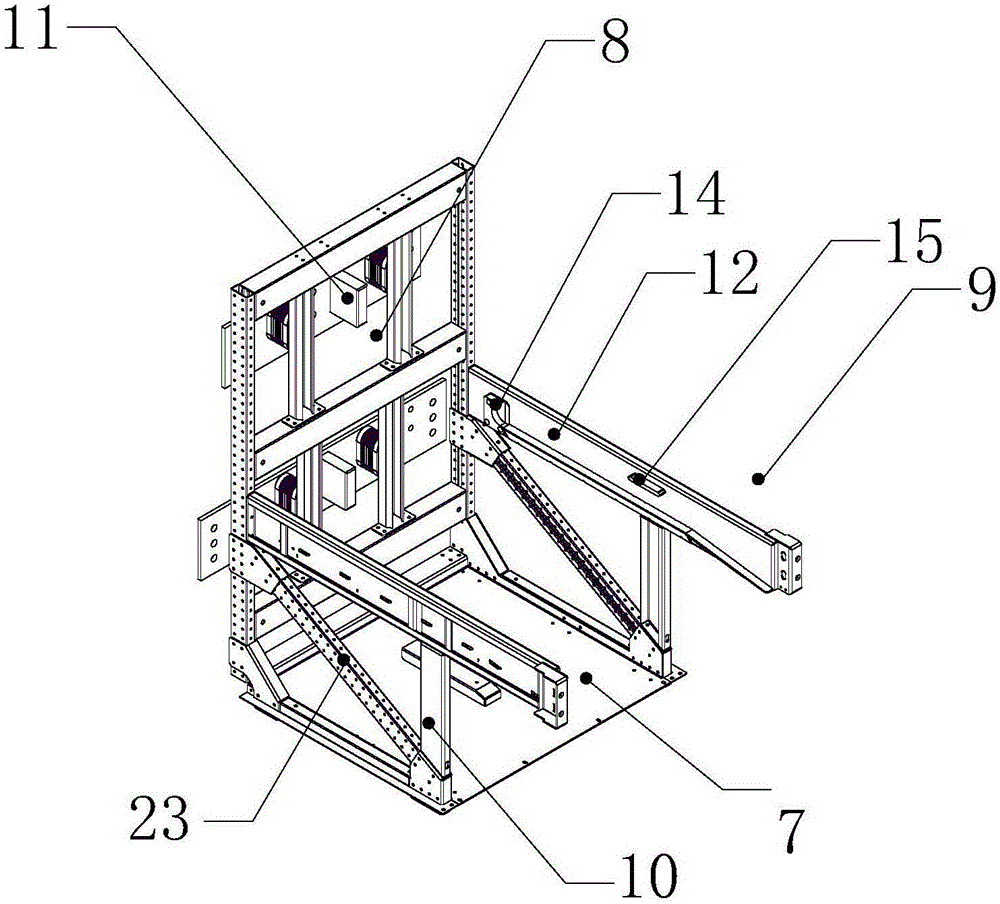

[0039] Such as figure 1 , 2As shown, a modular DC traction feeder cabinet includes a cabinet body 1, the front side of the cabinet body is provided with a cabinet door that can be opened or closed, and the inside of the cabinet body 1 is divided into a busbar room 2 and a circuit breaker by a partition The circuit breaker room 3, and the circuit breaker room (3) is located at the front side of the busbar room (2), the circuit breaker room 3 is provided with a circuit breaker distribution cabinet unit 4 and a circuit breaker handcart 5, the circuit breaker The circuit breaker distribution cabinet unit 4 is fixedly arranged on the inner bottom surface of the circuit breaker chamber 3, the circuit breaker handcart 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com