Multi-cavity heat insulation flow guide pipe with heat insulation structure and preparation method thereof

A diversion tube and heat insulation technology, which is applied in heat exchange equipment, lighting and heating equipment, and pipeline protection through heat insulation, can solve the problems of large engineering volume, low utilization rate, and low temperature of soil heat energy, and achieve the goal of occupying an area The effect of small area and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

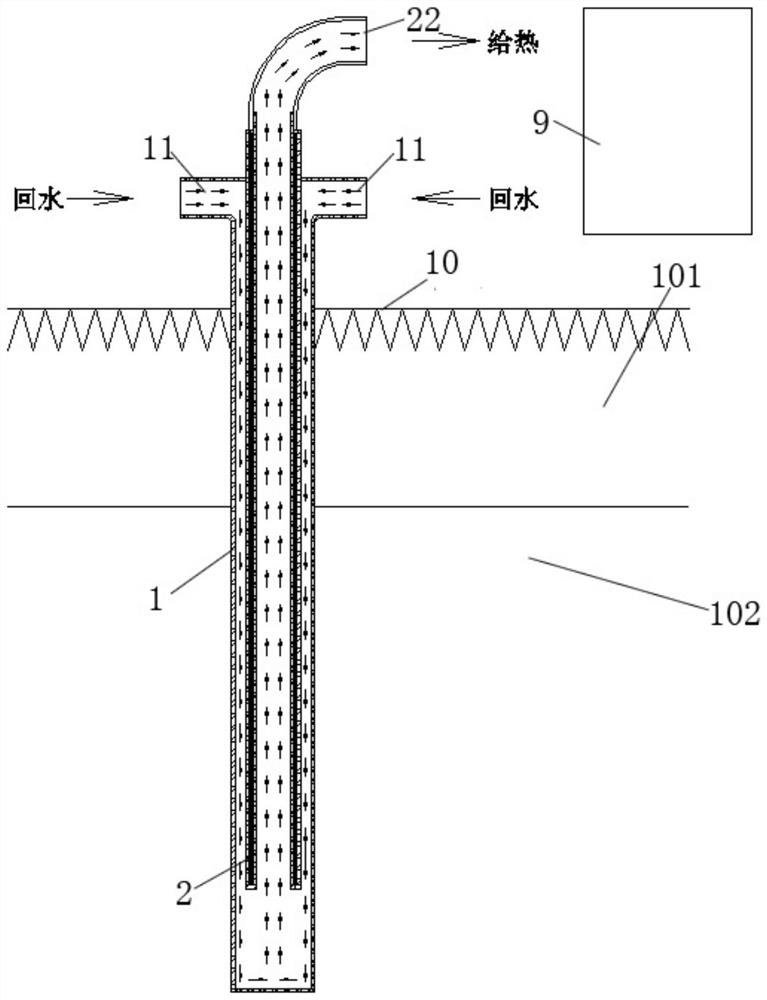

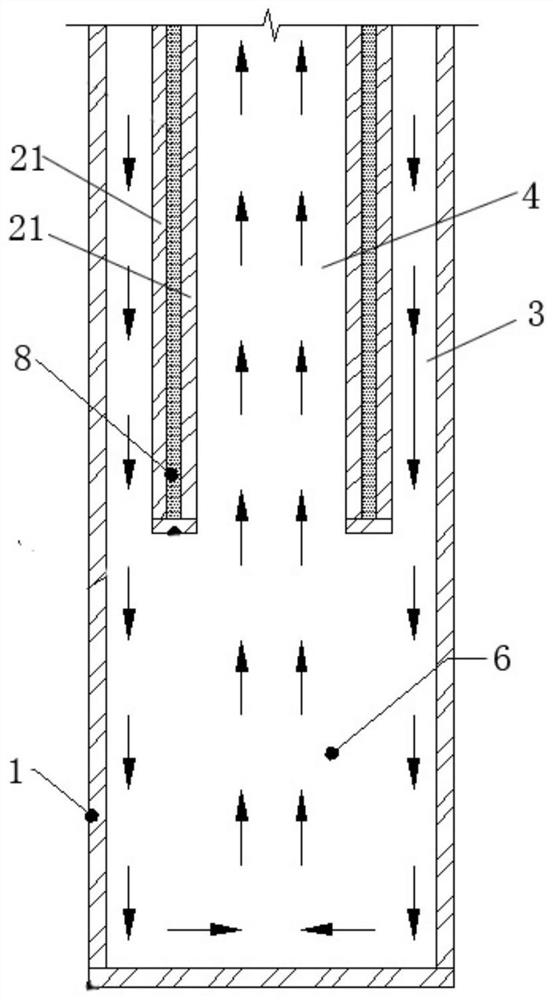

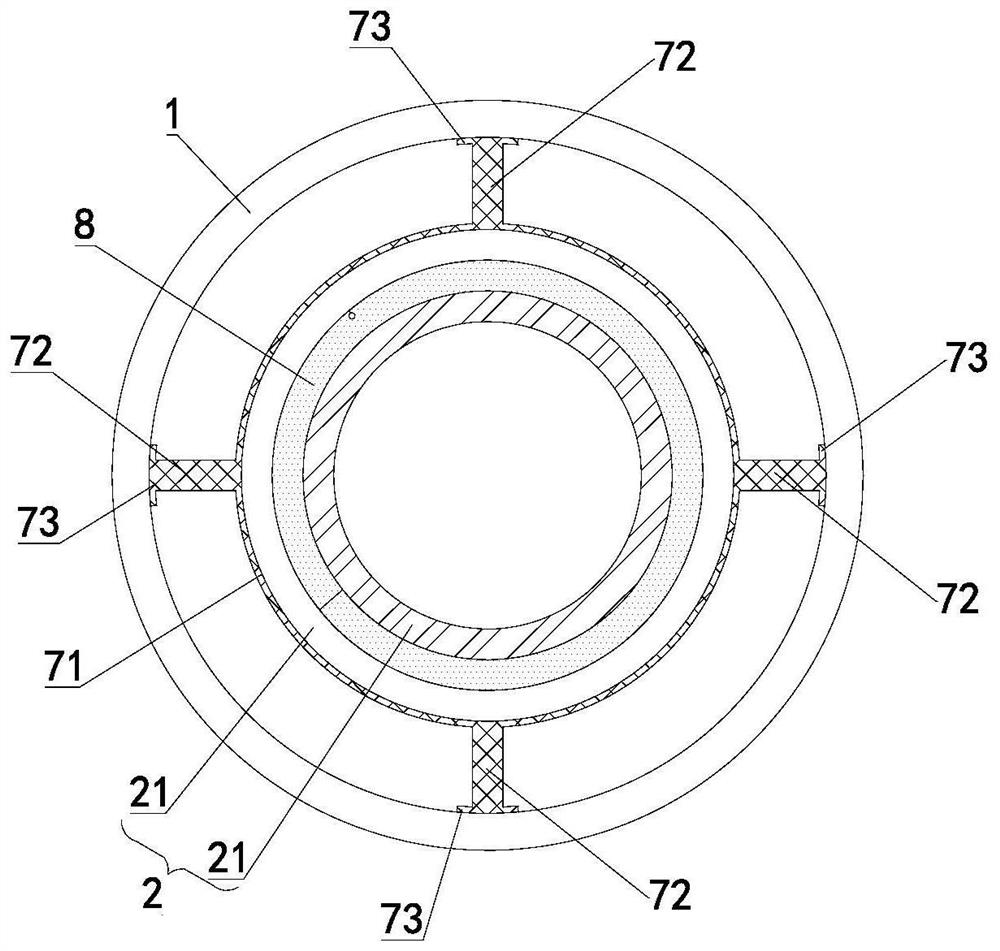

[0040] Such as Figure 1 ~ Figure 3As shown, a multi-chamber thermally insulated draft tube with a thermal insulation structure in this embodiment includes an outer tube 1 and an inner tube 2, the bottom of the outer tube 1 is a sealed structure, and the top and bottom of the inner tube 2 are both It is an open structure; a first cavity 3 is formed between the inner tube 2 and the outer tube 1, and the middle part of the inner tube 2 has a second cavity 4 axially penetrated, and the inner tube 2 is sleeved on the In the outer tube 1, a communication area 6 is reserved between the bottom of the inner tube 2 and the bottom of the outer tube 1, and the first cavity 3 communicates with the second cavity through the communication area 6. The body 4 is connected; a third cavity 5 is formed between the inner wall and the outer wall of the inner tube 2, and the third cavity 5 is a vacuum cavity, and an insulating material 8 is sealed in the third cavity 5.

[0041] Wherein, the therm...

Embodiment 2

[0054] A method for preparing a multi-cavity heat-insulated draft tube with a heat-insulating structure described in Example 1, comprising the following steps: setting two steel pipes 21 together to form a double-layer steel pipe, welding and sealing one end of the double-layer steel pipe, The cavity between the double-layer steel pipes is the third cavity 5; the thermal insulation material 8 is filled into the third cavity 5, and then the other end of the double-layer steel pipe is evacuated while welding, and after the welding is completed, a There is an inner tube 2 with a sealed vacuum cavity; the inner tube 2 is sheathed in the outer tube 1 , and a communication area 6 is reserved between the bottom of the inner tube 2 and the bottom of the outer tube 1 .

[0055] Specifically, one end of the double-layer steel pipe uses a steel plate of the same material, and the workpiece is melted by laser welding to form a specific molten pool, thereby forming a second cavity with a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com