Spinning forming method for manufacturing magnetically soft alloy cylindrical part

A technology of spinning forming and soft magnetic alloy, which is applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of low forming quality and low magnetic performance, and achieve the goal of improving utilization rate, good magnetic performance and good forming quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

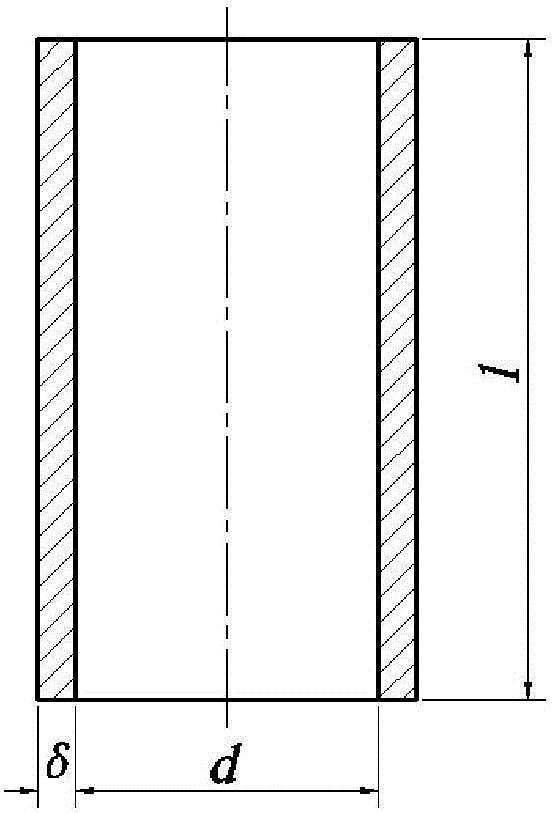

[0049] As shown in 1. The soft magnetic alloy cylindrical part is made of 1J50 soft magnetic alloy (the content of Fe and Ni is about 50%), the inner diameter d=50mm, the wall thickness δ=1mm, and the length l=240mm. Magnetic performance requirements: maximum permeability ≥ 65mH / m, coercive force ≤ 8.8A / m, saturation magnetic induction = (1.5±0.1)T.

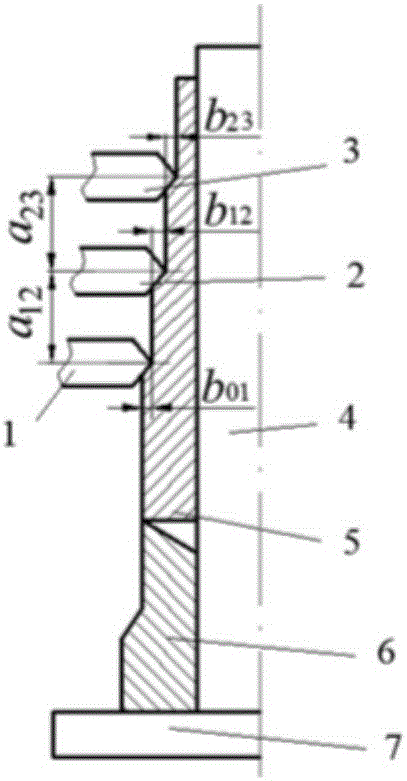

[0050] 1. Use the 1J50 soft magnetic alloy tube with a specification of Φ60*5mm prepared by the factory as the blank, with an inner diameter of 50mm and a wall thickness of 5mm (such as Figure 4 As shown), the wall thickness of the parts required for forming the tube blank of this specification is reduced from 5mm to 1mm, and the thinning rate is 80%.

[0051] A margin of 8mm is left at the bottom of the tube blank as a fixed part during spinning, and the trimming margin at the mouth is 10mm. According to the principle of constant volume, the length of the tube blank should be calculated to be 55mm.

[0052] 2. Put the tube bl...

Embodiment 2

[0058] The soft magnetic alloy cylindrical piece is made of 1J50 soft magnetic alloy (the content of Fe and Ni is about 50%), and the shape is as figure 1 Shown, its inner diameter d=80mm, wall thickness δ=2mm, length l=200mm. Magnetic performance requirements: maximum permeability ≥ 68mH / m, coercive force ≤ 7.5A / m, saturation magnetic induction = (1.5±0.1)T.

[0059] 1. Use the 1J50 soft magnetic alloy tube prepared by the factory with a specification of Φ90*5mm as the blank, with an inner diameter of 80mm and a wall thickness of 5mm (such as Figure 4 As shown), the wall thickness of the parts required for forming the tube blank of this specification is reduced from 5mm to 2mm, and the thinning rate is 60%.

[0060] A margin of 8mm is left at the bottom of the tube blank as a fixed part during spinning, and the trimming margin at the mouth is 10mm. According to the principle of constant volume, the length of the tube blank should be calculated to be 48mm.

[0061] 2. Put t...

Embodiment 3

[0066] The soft magnetic alloy cylindrical piece is made of 1J50 soft magnetic alloy (the content of Fe and Ni is about 50%), and the shape is as figure 1 Shown, its inner diameter d=60mm, wall thickness δ=2mm, length l=170mm. Magnetic performance requirements: maximum permeability ≥ 70mH / m, coercive force ≤ 7.0A / m, saturation magnetic induction = (1.5±0.1)T.

[0067] 1. Use the 1J50 soft magnetic alloy tube with a specification of Φ70*5mm prepared by the factory as the blank, with an inner diameter of 60mm and a wall thickness of 5mm (such as Figure 4 As shown), the wall thickness of the parts required for forming the tube blank of this specification is reduced from 5mm to 3mm, and the thinning rate is 40%.

[0068] 8mm margin is left at the bottom of the tube blank as a fixed part during spinning, and the trimming margin at the mouth is 10mm. According to the principle of constant volume, the length of the tube blank should be calculated to be 112mm.

[0069] 2. Put the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com