Hypersonic wind tunnel parallel type separation model relative position continuous adjustment device

An adjustment device and relative position technology, which is applied in the field of continuous adjustment device for the relative position of parallel separation models in hypersonic wind tunnels, can solve problems such as inability to change separately, weakened support strength, and limited internal space, so as to improve repeatability accuracy and reduce The effect of step angle interference and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific work process of this embodiment is as follows:

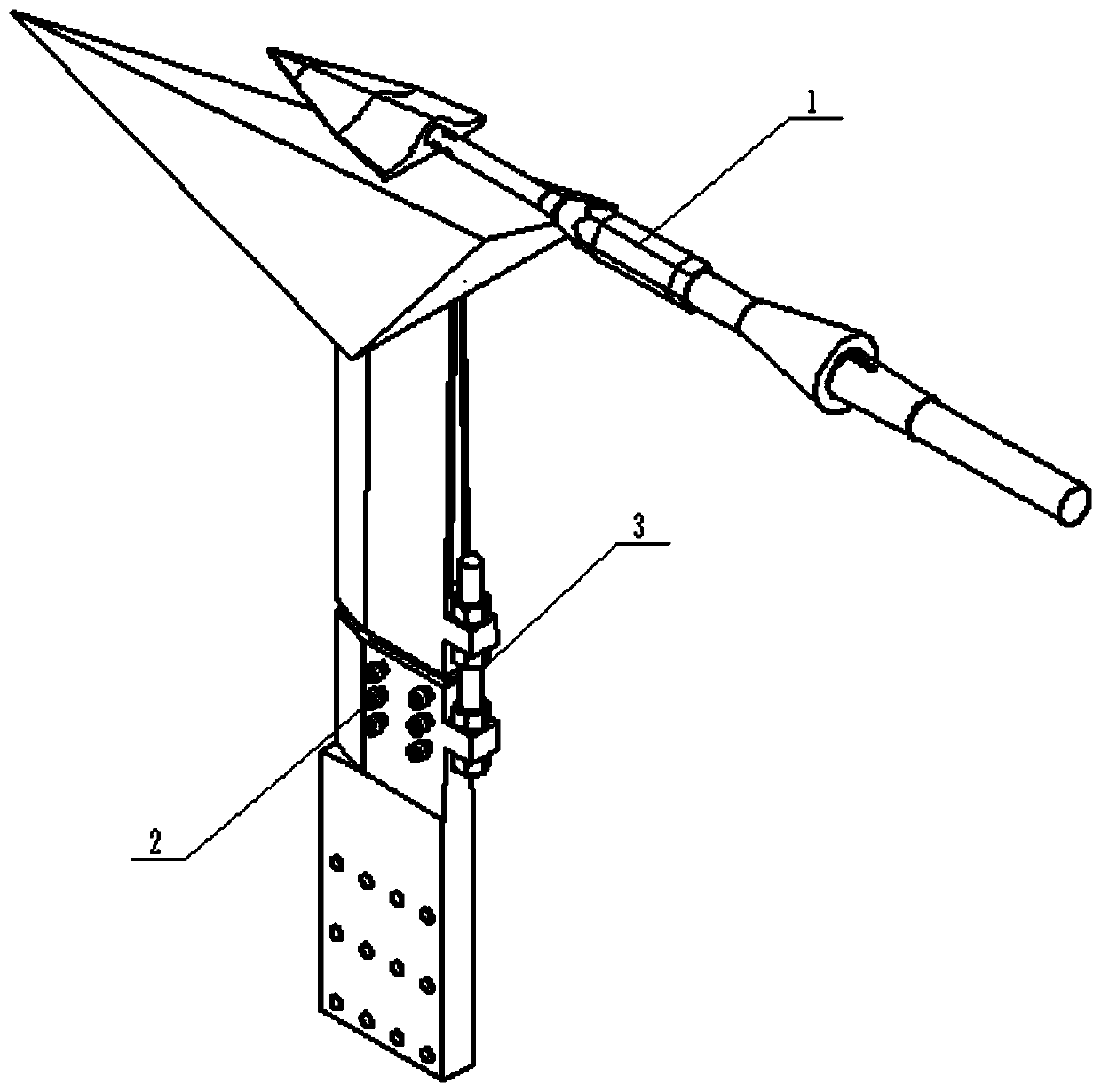

[0041] 1. Install the rear end of the X-direction relative position adjustment device 1 on the tail support interface of the conventional support mechanism of the hypersonic wind tunnel, and then fix the tail end of the secondary test model on the front end of the X-direction relative position adjustment device 1, and Set the initial angle of attack of the secondary test model to 0°.

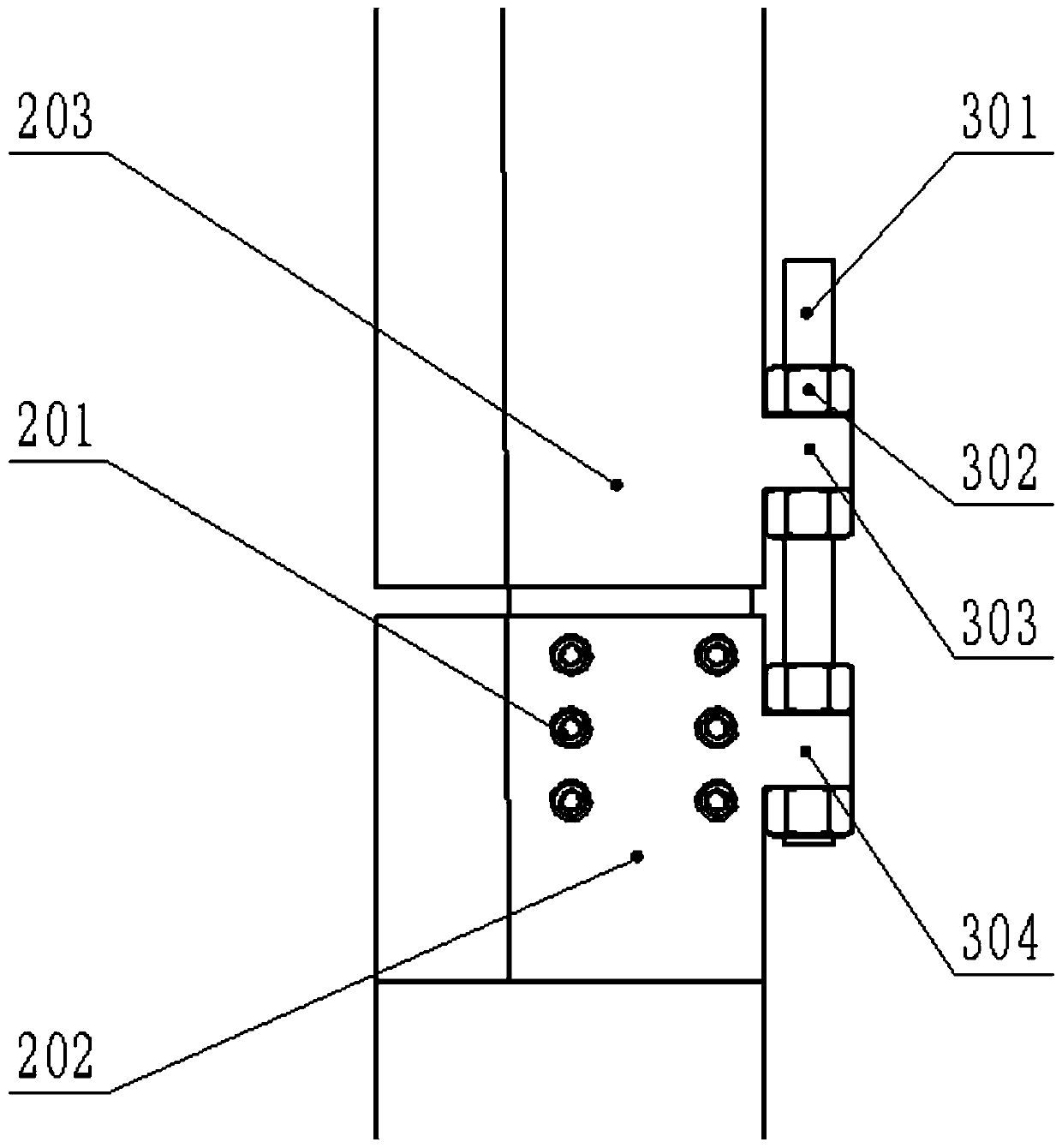

[0042] 2. Install the lower end of the relative position adjustment device 2 in the Y direction of the model on the abdominal support interface of the conventional support mechanism of the hypersonic wind tunnel, and then fix the abdominal support interface under the first-level test model on the relative position adjustment device 2 in the Y direction. The upper end, and set the initial angle of attack of the first-level test model to 0°.

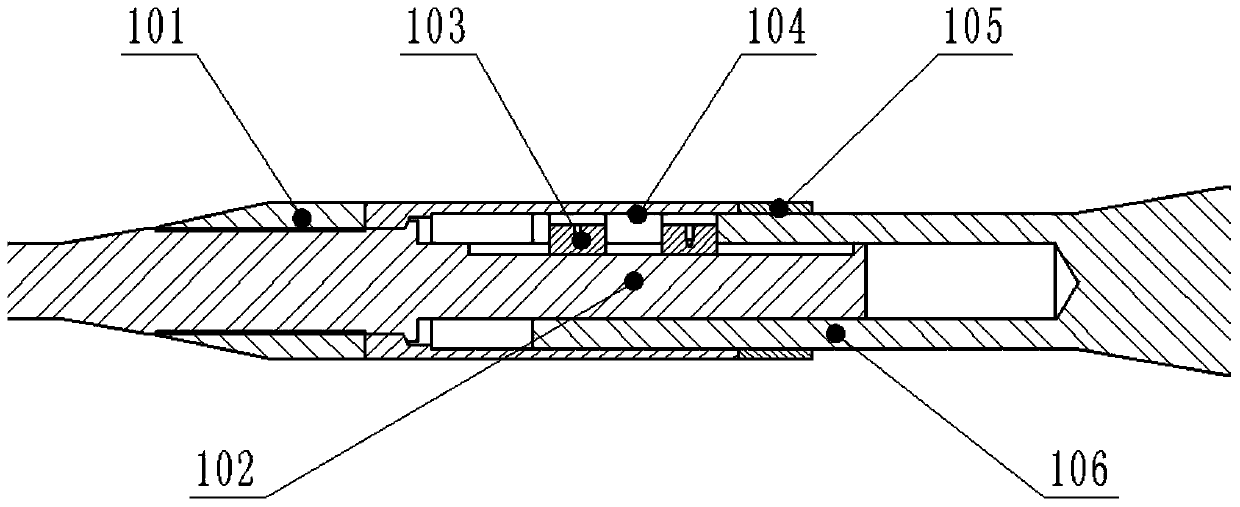

[0043] 3. According to the pre-set test state, loosen the front lock nut 101 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com