Device for manufacturing tempered glass using chemical strengthening and manufacturing method therefor

A chemical tempering and tempering glass technology, which is applied in glass tempering, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of reducing production productivity, prolonging standby time, and reducing the turnover rate of preheating furnace, so as to shorten the production process time, save replacement costs, and shorten warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

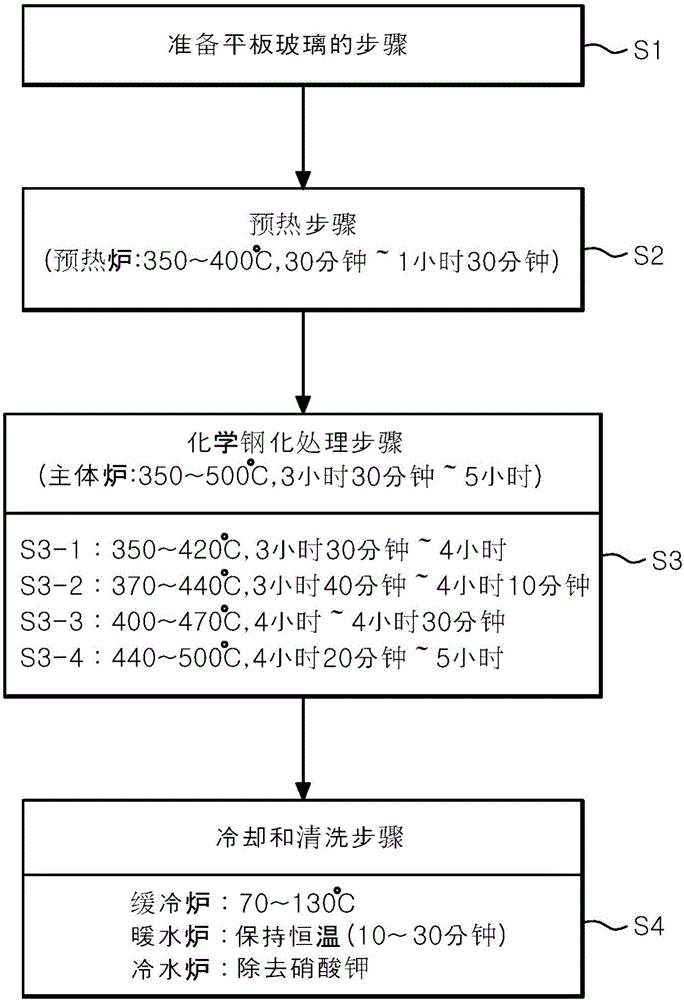

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0061] It should be noted that the accompanying drawings, which illustrate preferred embodiments of the present invention, are not drawn to exact scale and the thickness of lines or the size of components may be exaggerated for descriptive convenience and clarity. In addition, the terms used herein are defined by considering the functions of the present invention, and may be changed according to user's or operator's habit or purpose.

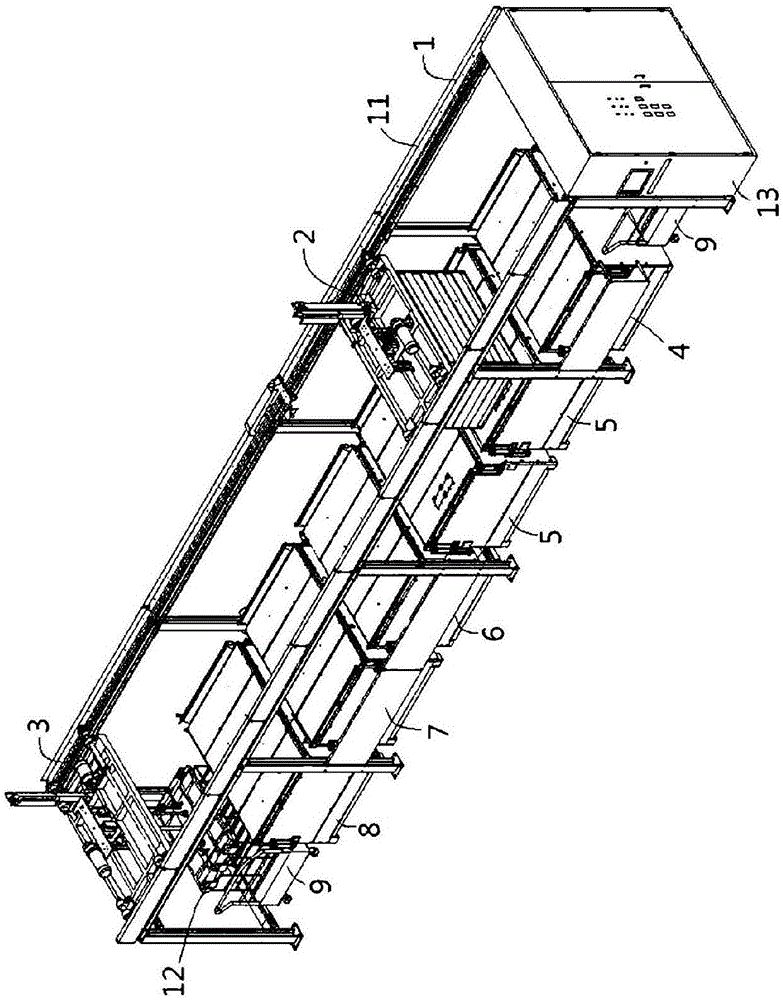

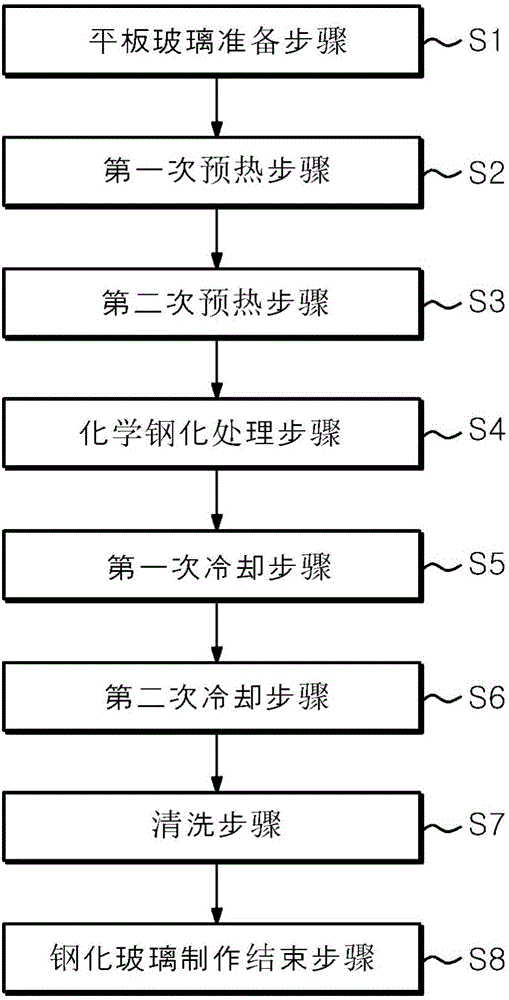

[0062] Such as Figure 4 to Figure 6As shown, the tempered glass manufacturing device according to the present invention includes such as conveying unit parts 200, 201, fixture supply part 300, first preheating part 400, second preheating part 500, chemical tempering part 600, first slow cooling part 700 , the second slow cooling unit 800 , the cleaning unit 900 , and the jig discharge unit 301 are a stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com