Concentrated Liuwei dihuang pill preparation method

A technology of Liuwei Dihuang Pills and Rehmannia glutinosa, which is applied in the field of preparation of Liuwei Dihuang Pills (concentrated pills), can solve the problems of low dissolution efficiency, long extraction time, and low transfer rate, so as to improve transfer rate, shorten extraction time, increase The effect of solid-liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

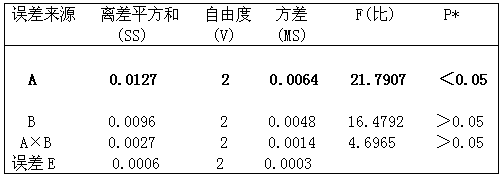

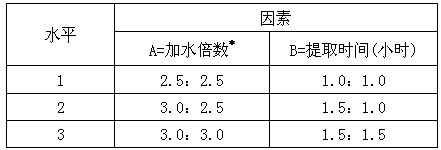

Method used

Image

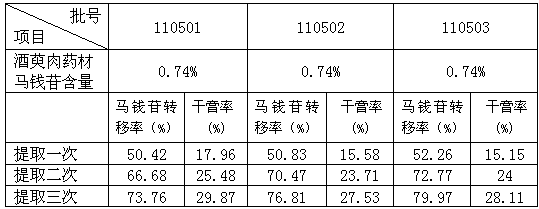

Examples

Embodiment 1

[0063] (1) Weigh raw materials according to the following parts by weight: 120 parts of Rehmannia glutinosa, 60 parts of wine cornus, 45 parts of Moutan bark, 60 parts of Chinese yam, 45 parts of Poria cocos, 45 parts of Alisma;

[0064] (2) Put the Moutan cortex into the extraction tank, and extract paeonol by steam distillation. Open the condensed water first, then open the direct steam valve, adjust the steam pressure at 0.1Mpa--0.3Mpa, keep the temperature in the tank at 100-110°C, and the pressure at <0.05Mpa, adjust the flow of condensed water so that the material pipe above the crystallization tank flows out of Dan The temperature of the distillate of paeonol is 40°C-60°C, collect the distillate of paeonol, refrigerate, crystallize, and collect paeonol crystals;

[0065] (3) Take 120 parts of Rehmannia glutinosa, 20 parts of wine cornus, 45 parts of Poria cocos, and 45 parts of Alisma, use dynamic extraction method, add water to decoct twice, the amount of water added i...

Embodiment 2

[0070] (1) Weigh raw materials according to the following parts by weight: 120 parts of Rehmannia glutinosa, 60 parts of wine cornus, 45 parts of Moutan bark, 60 parts of Chinese yam, 45 parts of Poria cocos, 45 parts of Alisma;

[0071] (2) Put the Moutan cortex into the extraction tank, and extract paeonol by steam distillation. Open the condensed water first, then open the direct steam valve, adjust the steam pressure at 0.1Mpa--0.3Mpa, keep the temperature in the tank at 100-110°C, and the pressure at <0.05Mpa, adjust the flow of condensed water so that the material pipe above the crystallization tank flows out of Dan The temperature of the distillate of paeonol is 40°C-60°C, collect the distillate of paeonol, refrigerate, crystallize, and collect paeonol crystals;

[0072] (3) Take 120 parts of Rehmannia glutinosa, 20 parts of wine cornus, 45 parts of Poria cocos, and 45 parts of Alisma, use dynamic extraction method, add water to decoct twice, the amount of water added i...

Embodiment 3

[0076] (1) Weigh raw materials according to the following parts by weight: 120 parts of Rehmannia glutinosa, 60 parts of wine cornus, 45 parts of Moutan bark, 60 parts of Chinese yam, 45 parts of Poria cocos, 45 parts of Alisma;

[0077] (2) Put the Moutan cortex into the extraction tank, and extract paeonol by steam distillation. Open the condensed water first, then open the direct steam valve, adjust the steam pressure at 0.1Mpa--0.3Mpa, keep the temperature in the tank at 100-110°C, and the pressure at <0.05Mpa, adjust the flow of condensed water so that the material pipe above the crystallization tank flows out of Dan The temperature of the distillate of paeonol is 40°C-60°C, collect the distillate of paeonol, refrigerate, crystallize, and collect paeonol crystals;

[0078] (3) Take 120 parts of Rehmannia glutinosa, 20 parts of wine cornus, 45 parts of Poria cocos, and 45 parts of Alisma, and use the dynamic extraction method, add water and decoct twice, the amount of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com