A high temperature curable silicone structural sealant and its application

A high-temperature curing and sealant technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor elastic recovery rate, fast response speed, low elongation, etc., to achieve Improved stability, increased contact speed, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

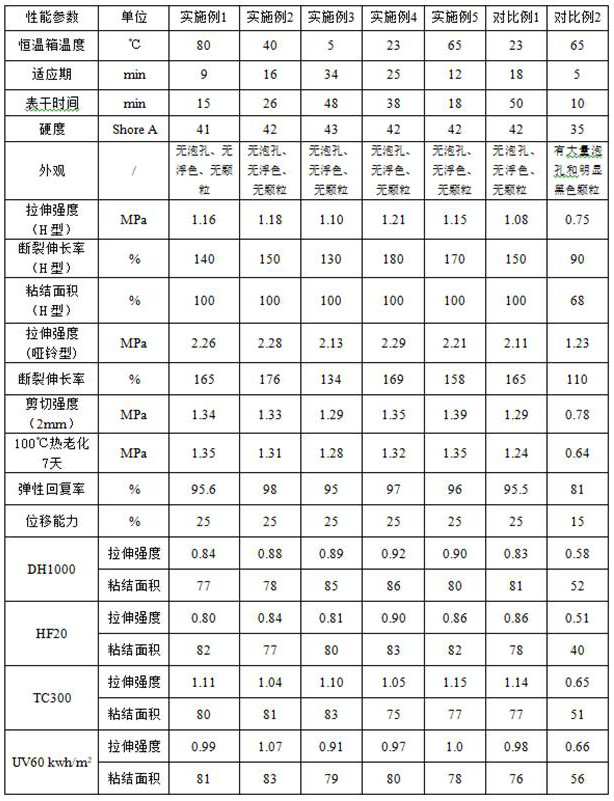

Examples

Embodiment 1

[0077] Preparation of modified additives:

[0078] (1) In a reaction kettle equipped with a thermometer, a reflux condenser, and a stirrer, first add 25 wt % of propyltrimethoxysilane, 10 wt % of propyltriethoxysilane, and 25 wt % of 3-(2 , 3-glycidyloxypropoxy)propyltriethoxysilane, 25wt% of 3-aminopropyltrimethoxysilane, 12wt% of 3-aminopropyltriethoxysilane, slowly warming up to 55°C, react for 2 hours;

[0079] (2) Slowly raise the temperature to 150°C, and add 3wt% hydroxyl-terminated liquid polybutadiene resin with a viscosity of 10000cs into the reaction kettle while stirring;

[0080] (3) In the reflux state, continue to react for 10 hours while stirring, and cool naturally to 25~30°C with nitrogen gas, then discharge the material to prepare the additive.

[0081] Prepare component A:

[0082] 30 wt % of hydroxy-terminated polydimethylsiloxane with a viscosity of 20000 cs, 10 wt % of hydroxyl-modified silicone oil with a viscosity of 8000 cs, 1 wt % of methyltrimeth...

Embodiment 2

[0087] Preparation of modified additives:

[0088] (1) In a reaction kettle equipped with a thermometer, a reflux condenser, and a stirrer, first add 30 wt % of propyltrimethoxysilane, 20 wt % of 3-(2,3-glycidyloxy) propyltri Ethoxysilane, 17wt% of 3-aminopropyltrimethoxysilane, 23wt% of 3-aminopropyltriethoxysilane, slowly heated to 60°C while stirring, and reacted for 1.5 hours;

[0089] (2) Slowly raise the temperature to 130°C, and add 10wt% silane-modified polyether resin with a viscosity of 3500cs into the reaction kettle while stirring;

[0090] (3) In the reflux state, continue to react for 18 hours while stirring, and cool naturally to 25~30°C with nitrogen gas, and discharge the material to prepare the auxiliary agent.

[0091] Prepare component A:

[0092] 50 wt % of hydroxyl-terminated polydimethylsiloxane with a viscosity of 1000 cs, 5 wt % of polyether modified silicone oil with a viscosity of 10000 cs, 5 wt % of propyltrimethoxysilane coupling agent and 30 wt ...

Embodiment 3

[0097] Preparation of modified additives:

[0098] (1) In a reaction kettle equipped with a thermometer, a reflux condenser, and a stirrer, first add 36 wt% of propyltrimethoxysilane, 6wt% of propyltriethoxysilane, and 5wt% of 3-(2 , 3-glycidoxy) propyltriethoxysilane, 23wt% of 3-aminopropyltrimethoxysilane, 24wt% of 3-aminopropyltriethoxysilane, then slowly heat up to 75°C, react for 2 hours;

[0099] (2) Slowly raise the temperature to 100°C, and add 6wt% silane-modified polyurethane resin with a viscosity of 2000cs into the reaction kettle while stirring;

[0100] (3) In the reflux state, continue to react for 24 hours while stirring, and cool naturally to 25~30°C with nitrogen gas, then discharge the material to prepare the additive.

[0101] Prepare component A:

[0102]24 wt% of the viscosity of 100000cs hydroxyl-terminated polydimethylsiloxane, 6wt% of the viscosity of 500cs alkoxy-modified silicone oil, 5wt% of methyltriethoxysilane, 5wt% of 3-aminopropyl Active si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com