Flexible and hard composite circuit board and manufacturing method thereof

A technology of soft-hard composite and manufacturing methods, which is applied in the directions of printed circuit components, structural connection of printed circuits, and assembly of printed circuits with electrical components, which can solve the problem of inability to meet the structural thickness and volume of light, thin, and soft-hard composite circuit boards. Increase and other problems, to achieve the effect of light and thin thickness, reduce the difficulty of alignment, and save the production process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

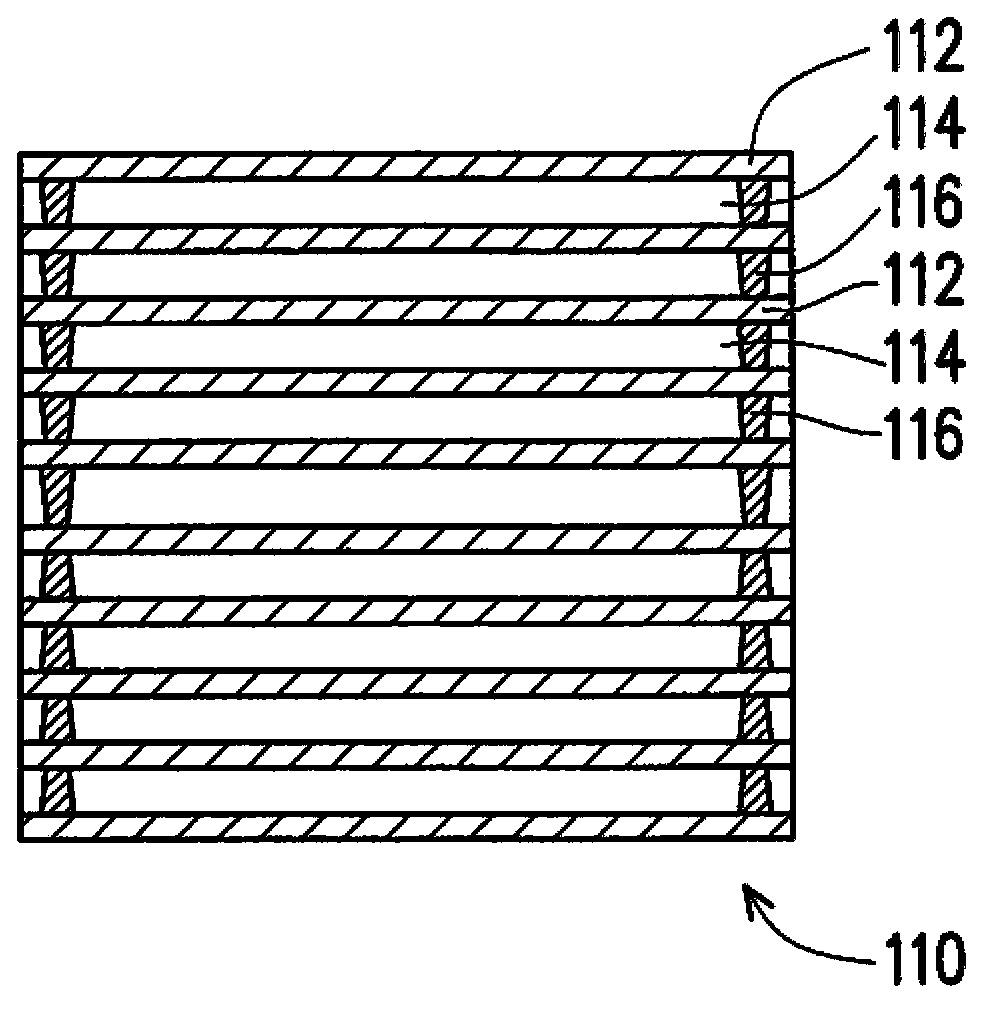

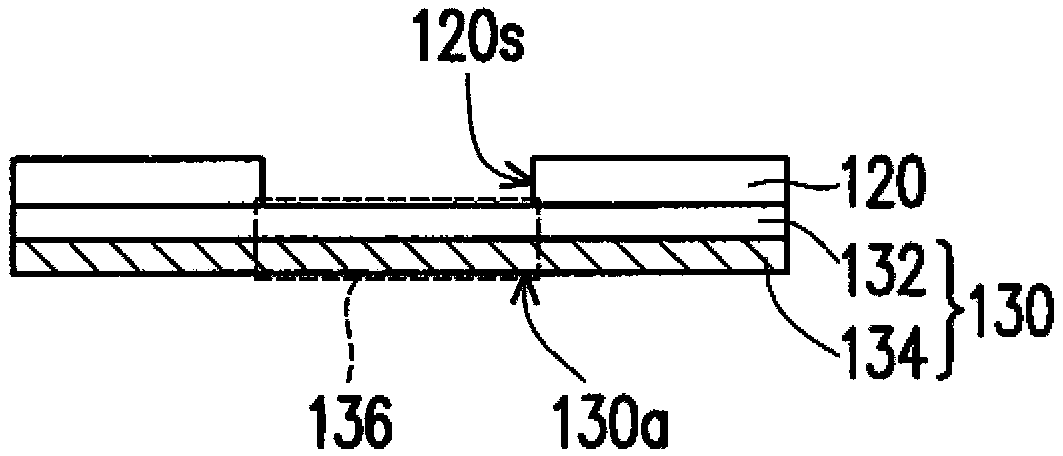

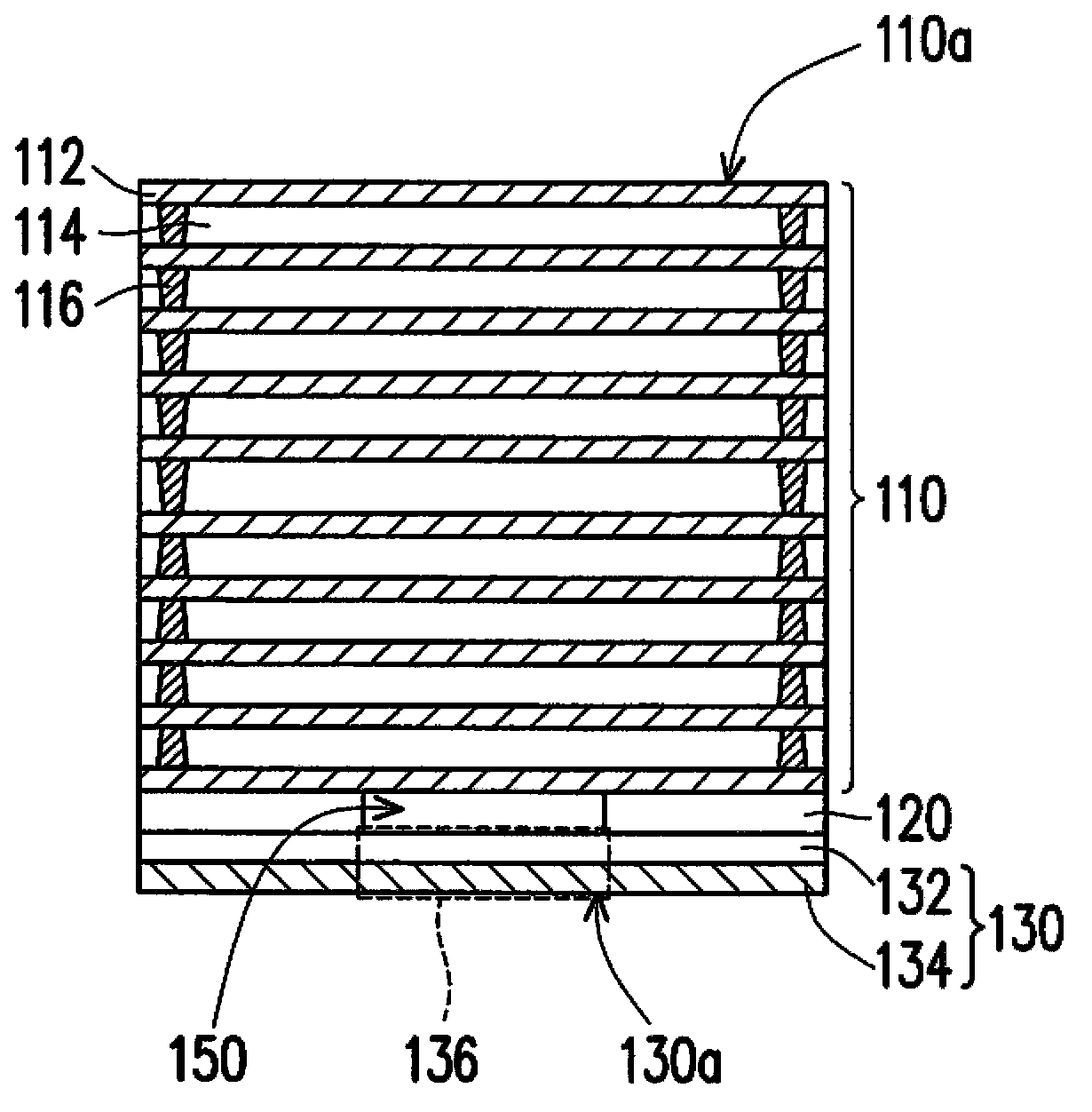

[0047] Figure 1 to Figure 9 It is a schematic cross-sectional view of a manufacturing method of a rigid-flex circuit board according to an embodiment of the present invention. Please refer to figure 1 , The manufacturing method of the rigid-flex circuit board 100 of this embodiment includes the following steps. Firstly, a rigid circuit board 110 is provided. The rigid circuit board 110 includes a plurality of conductive layers 112 , a plurality of dielectric layers 114 and a plurality of conductive vias 116 . The conductive layers 112 and the dielectric layers 114 are stacked alternately, and the conductive vias 116 are located between adjacent conductive layers 112 . In other words, the conductive via 116 penetrates through the dielectric layer 114 and electrically connects the adjacent conductive layer 112 . In this embodiment, the structure of the rigid circuit board 110 can be regarded as a build-up circuit structure, and the present invention does not limit the stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com