Ultrasonic sound and sound wave detector based on triboelectricity nanometer generator

A nano-generator, triboelectric technology, applied in triboelectric generators, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of parasitic capacitance and distributed capacitance sensitivity and measurement accuracy, which are not suitable for low-intensity acoustic waves and high Ultrasonic detection of frequency, inability to detect ultrasonic signals in all directions, etc., to achieve the effect of being conducive to popularization and application, simplifying structure, simplifying structure and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

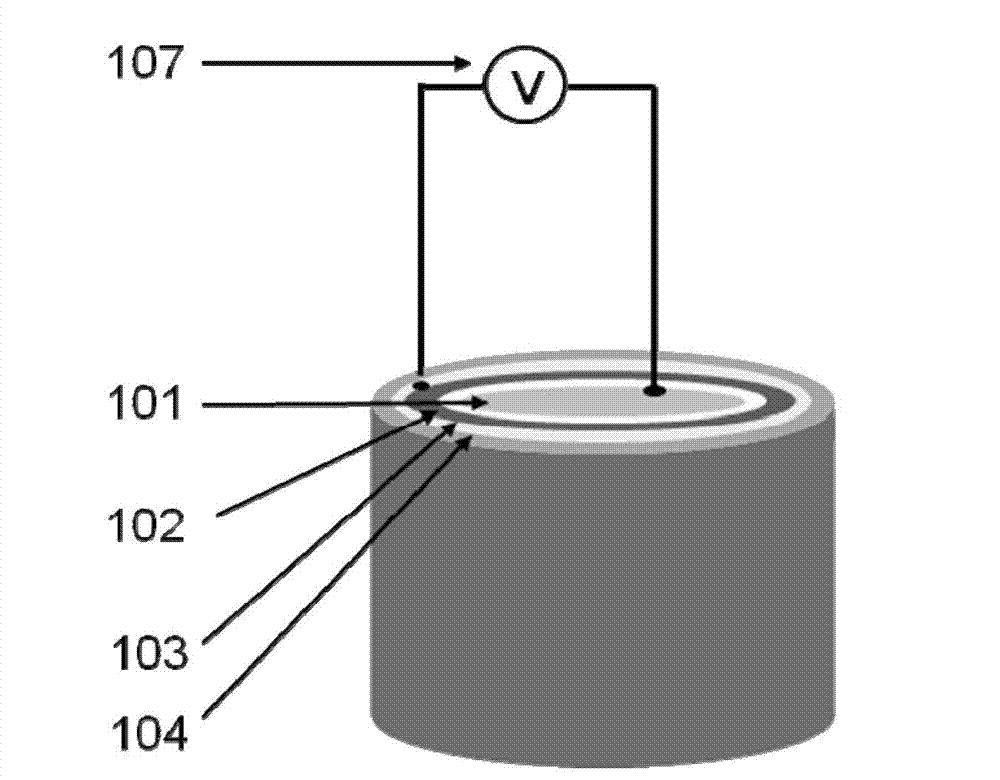

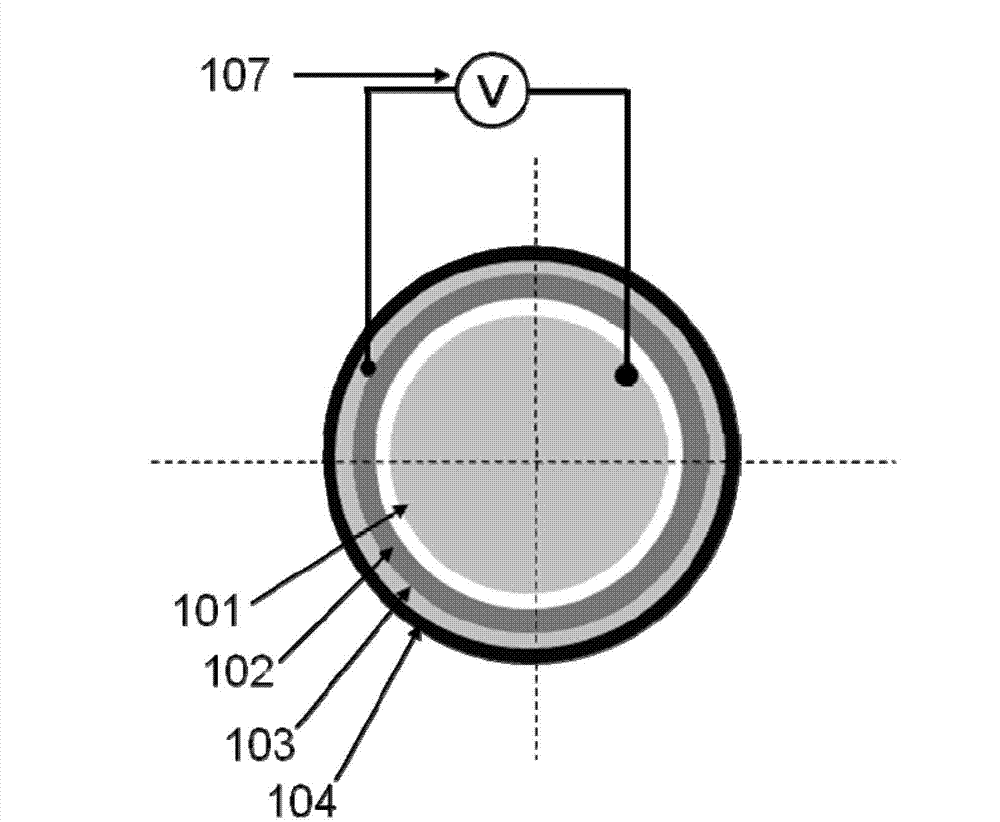

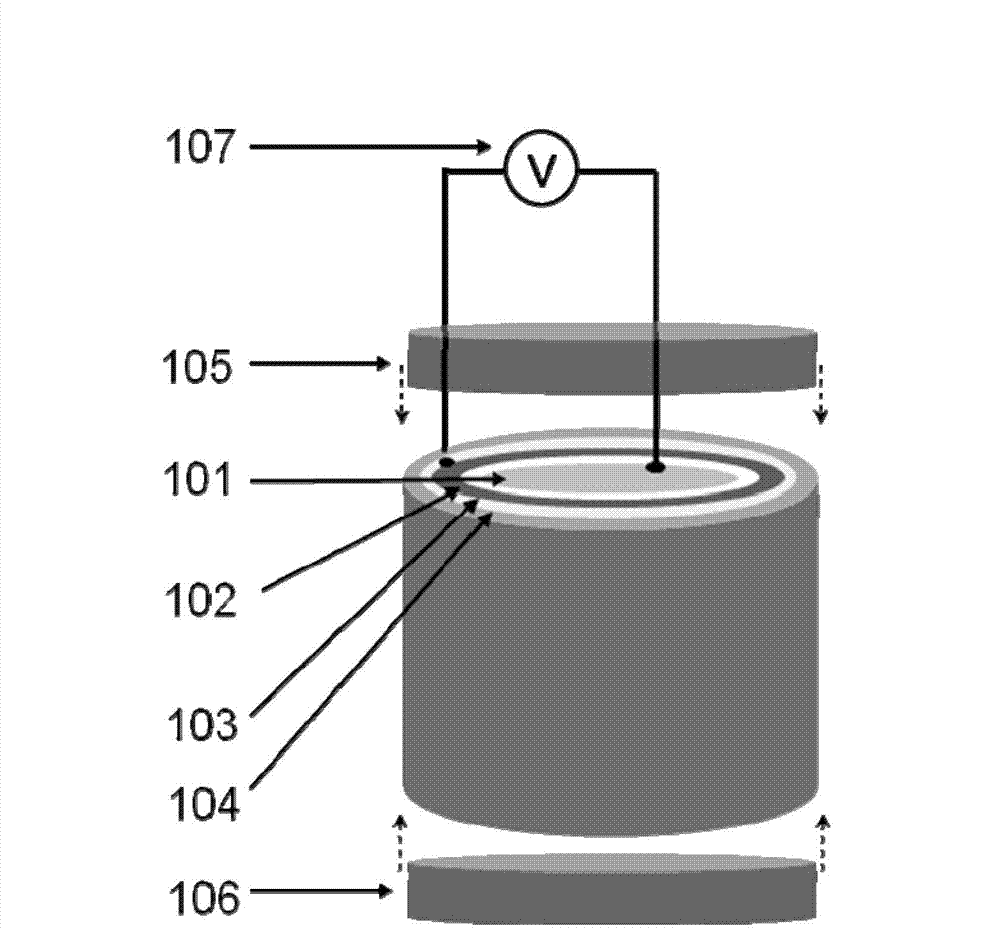

[0068] Example 1: Preparation of triboelectric nanogenerator

[0069] A layer of gold Au thin film is evenly plated on the lower surface of the polyimide with a length of 5 cm × width 6.5 cm × thickness 50 μm by evaporation method, and after cooling, one end of a wire is fixed on the outer side of the thin gold Au layer by welding. Realize the connection between the gold Au thin layer and the wire; on the surface of the gold Au thin film, evenly deposit a certain thickness of aluminum oxide as an insulating anti-corrosion layer by magnetron sputtering, so that the polyimide, Au thin film and aluminum oxide are formed. Flexible outer membrane made of thin layers of aluminum. An aluminum cylinder with a bottom diameter of 2cm and a height of 5cm is used as the conductive inner core, and one end of a wire is fixed on the top of the conductive inner core to realize the connection between the wire and the conductive inner core. Put the flexible outer film connected with the wires ...

Embodiment 2

[0071] Example 2: Preparation of triboelectric nanogenerator

[0072] A layer of indium tin oxide (ITO) film is evenly plated on the lower surface of polyimide with a length of 15cm × width 6.5cm × thickness 10μm by evaporation method, and after cooling, one end of a wire is fixed on the indium tin by welding. The outer side of the thin oxide layer is to realize the connection between the thin layer of indium tin oxide and the wire; on the surface of the indium tin oxide film, a certain thickness of aluminum oxide is evenly deposited by magnetron sputtering as an insulating anti-corrosion layer, thus forming a layer composed of Flexible outer membrane composed of polyimide, indium tin oxide thin film and aluminum oxide thin layer. A glassy carbon rod with a bottom diameter of 2 cm and a height of 15 cm is used as the conductive inner core, and one end of a wire is fixed on the top of the conductive inner core to realize the connection between the wire and the conductive inner ...

Embodiment 3

[0074] Embodiment 3: the preparation of ultrasonic detector

[0075] The lower surface of the poly(p-dimethylsiloxane) with a size of 10 cm x 12.8 cm x 100 μm is evenly coated with a layer of aluminum Al film by evaporation method, and after cooling, one end of a wire is fixed on the aluminum by welding. The outer side of the Al thin layer realizes the connection between the aluminum Al thin layer and the wire; on the surface of the aluminum Al thin film, a certain thickness of aluminum oxide is evenly deposited by magnetron sputtering as an insulating anti-corrosion layer, thus forming a polyimide, A flexible outer membrane composed of aluminum Al thin film and aluminum oxide thin layer. A copper cylinder with a bottom diameter of 2 cm and a height of 10 cm is used as the conductive inner core, and one end of a wire is fixed on the top of the conductive inner core to realize the connection between the wire and the conductive inner core. Put the flexible outer film connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com