Hot-press

A technology of a hot press and a hot press device, applied in the field of hot presses, can solve the problems of inability to fully reach the temperature, waste of manpower, false welding, etc., and achieve the effects of shortening the production process time, preventing false welding, and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

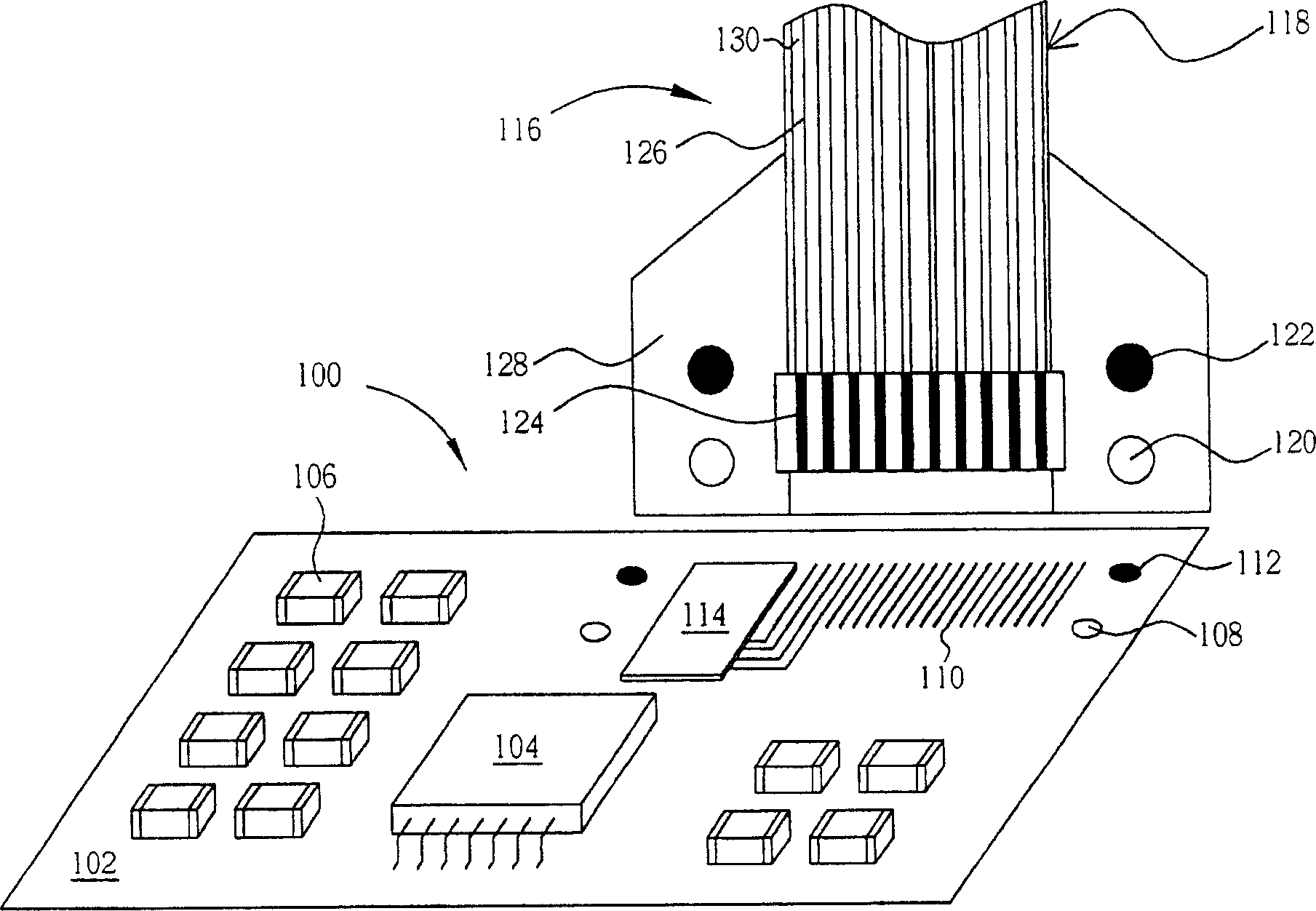

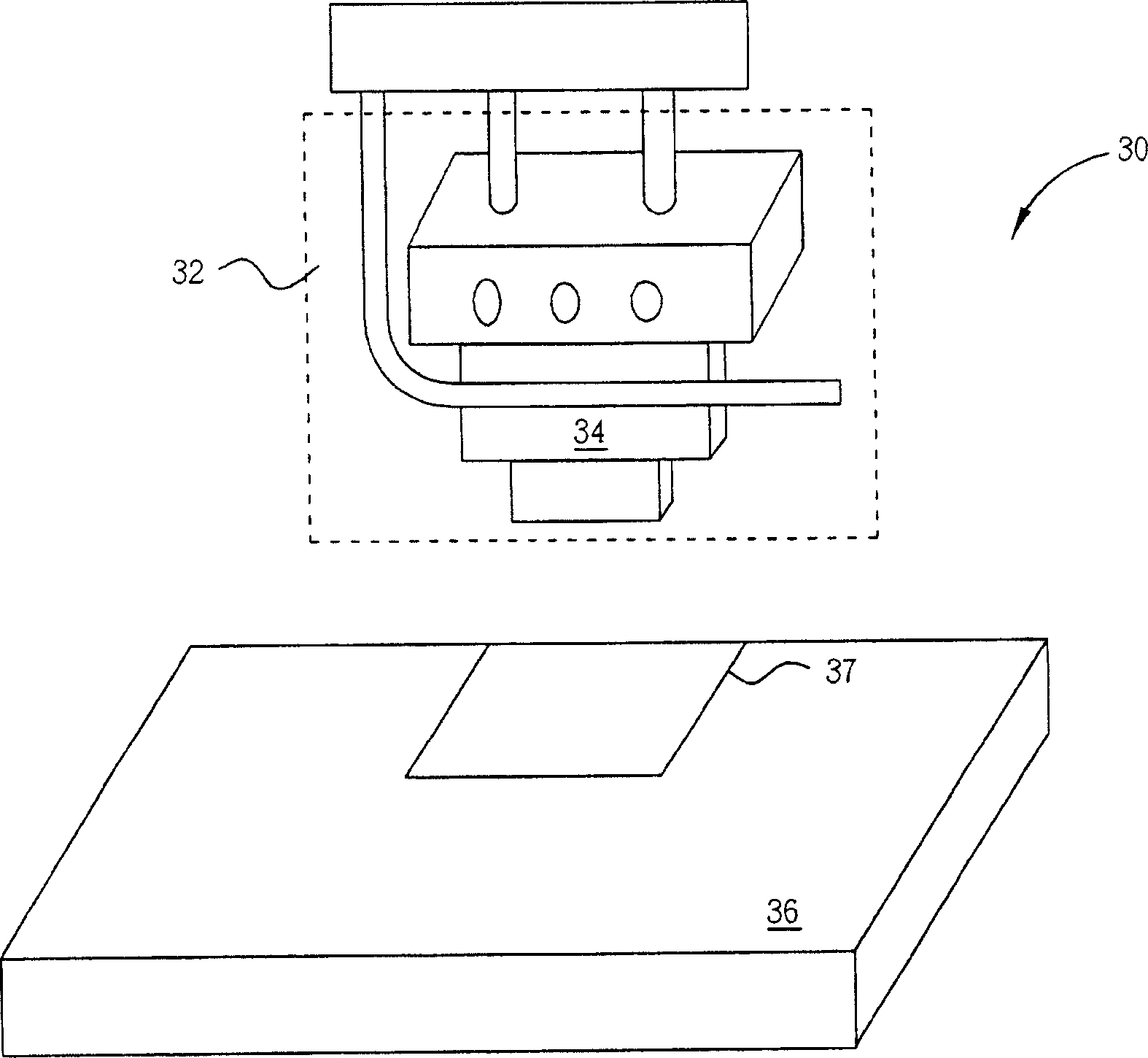

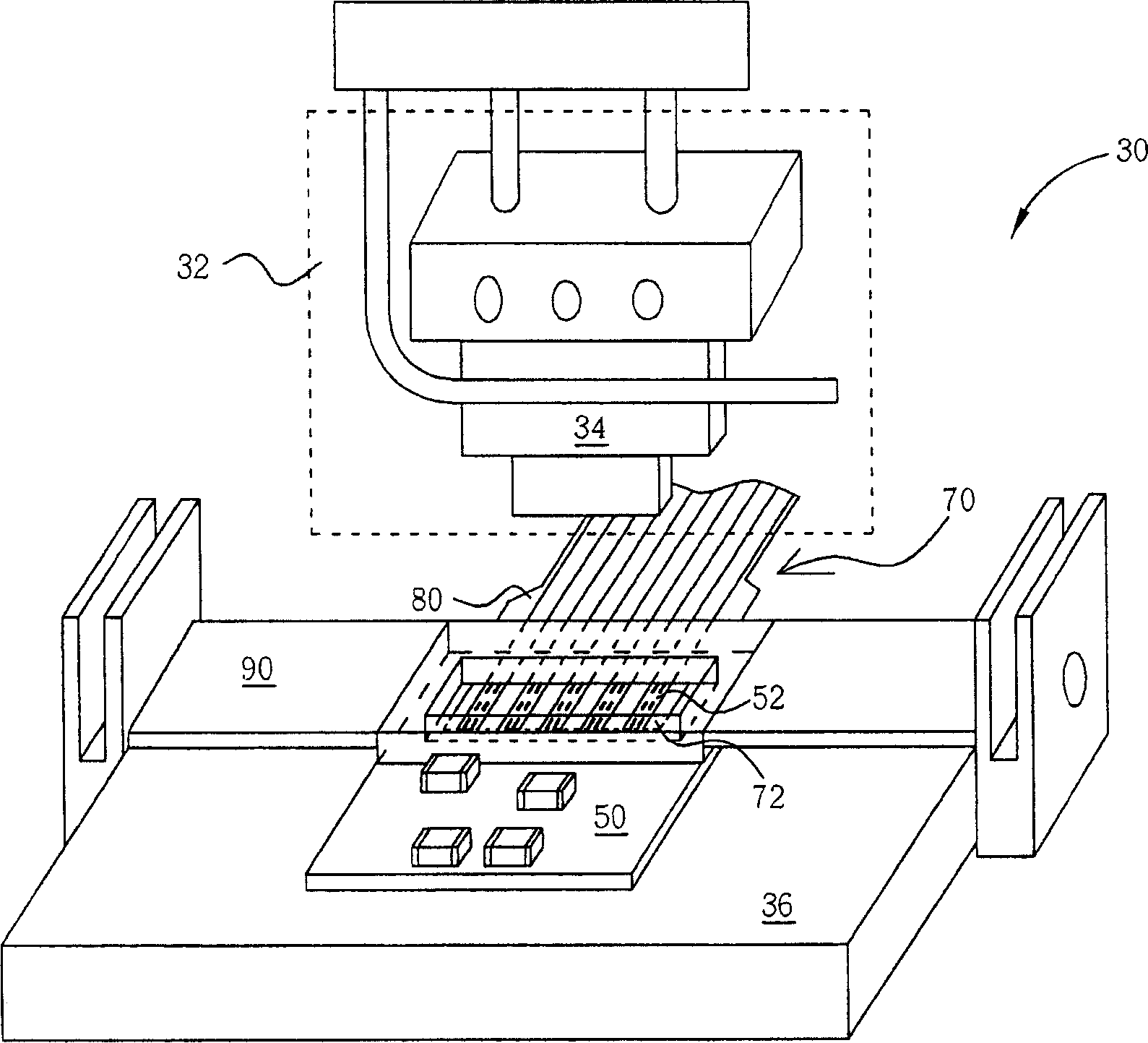

[0014] first pass figure 2 and image 3 Briefly describe the basic structure and operating principle of the hot press of the present invention. see figure 2 , figure 2 It is a three-dimensional schematic view of the heat press 30 in the first preferred embodiment of the present invention. Such as figure 2 As shown, the heat press 30 of the present invention includes a movable upper module 32 and a lower module 36 . Wherein, the movable upper module 32 has a thermal pressing device 34, such as a thermal pressing head, and at least one high resistance material (not shown) is included in the thermal pressing device 34, and a high current module (not shown) ) provides a pulse current to the high-resistance material of the hot-pressing device 34, so that the hot-pressing device 34 can generate high temperature instantaneously. The lower module 36 has a temperature-adjustable heating device 37, which can set an appropriate heating temperature range according to the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com