LED packaging method

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of slow heat conduction, long manufacturing process time, and energy consumption, so as to reduce LED manufacturing costs, shorten manufacturing process time, reduce The effect of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

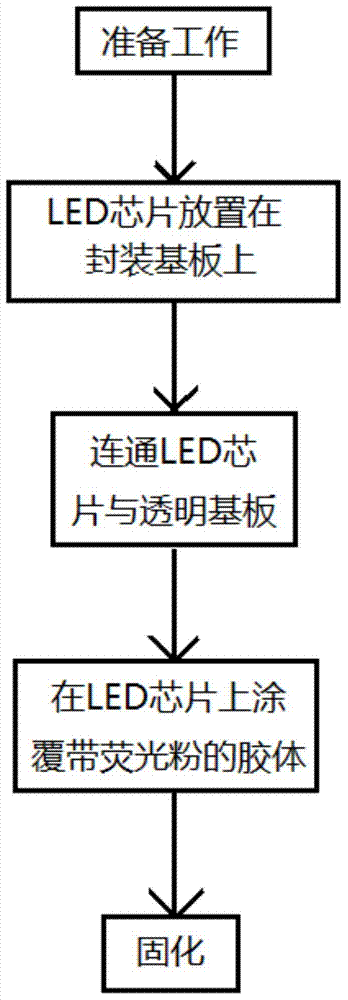

[0019] Such as figure 1 As shown, a kind of LED encapsulation method, first make preparations, make transparent substrate, heat-conducting reflective spacer, and reflective cup is arranged on the transparent substrate; Composed of a transparent substrate and a heat-conducting gasket, the heat-conducting reflective gasket is placed on the bottom of the reflective cup of the transparent substrate, and the LED chip is placed on the heat-conducting and reflective gasket; then, the LED chip and the transparent substrate are connected, and one end of the wire is welded to the LED chip On the other hand, solder the other end of the wire to the bottom of the reflective cup, so that the LED chip is connected to the transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com