Primer, polymer pre-laid waterproof coiled material and preparation method of polymer pre-laid waterproof coiled material

A waterproof membrane, polymer technology, applied in coatings, adhesives, mining equipment and other directions, can solve the problem of surface tension attenuation, can not solve the problem of pressure-sensitive adhesive layer detachment, etc., to achieve reduced degumming rate, excellent dimensional stability performance, improving degumming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

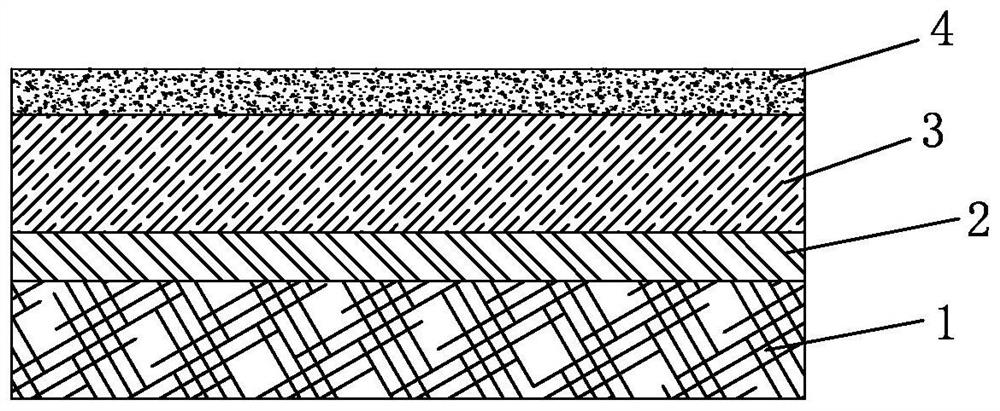

[0056] The macromolecule pre-paved waterproof membrane that present embodiment provides, as figure 1 As shown, it includes a substrate layer 1, a primer layer 2, an adhesive layer 3 and a release layer 4 that are stacked in sequence, wherein,

[0057] The raw material formula of the substrate layer 1 is composed of the following components: 70 parts of high-density polyethylene, 25 parts of linear low-density polyethylene, 1 part of antioxidant, 0.5 part of anti-aging agent and 3 parts of coloring agent.

[0058] The raw material formulation of the primer used in primer coat 2 is made of the following components: 30 parts of carboxylated butadiene-methacrylic acid copolymer emulsion LIPATON SB 10A11 (glass transition temperature is -55 ℃, solid content is 51% , viscosity is 250mPa.s), 70 parts of styrene-butadiene rubber latex (purchased from Shenzhen Yoshida Chemical Co., Ltd., model 106, solid content is 48%) and 0.3 parts of 1,1-(1,3 phenylene dicarbonyl) Bis[2-methylaziri...

Embodiment 2

[0075] The polymer pre-laid waterproof membrane provided in this example differs from Example 1 in that the primer used is different. Others are basically the same as in Example 1.

[0076] In this example, the raw material formula of the primer is composed of the following components: 70 parts of carboxylated butadiene-methacrylic acid copolymer emulsion, 30 parts of styrene-butadiene rubber latex and 1.2 parts of 1,1-(1,3 phenyldicarbonyl) bis[2-methylaziridine].

Embodiment 3

[0078] The polymer pre-laid waterproof membrane provided in this example differs from Example 1 in that the primer used is different. Others are basically the same as in Example 1.

[0079] In this example, the raw material formula of the primer is composed of the following components: 50 parts of carboxylated butadiene-methacrylic acid copolymer emulsion, 50 parts of styrene-butadiene rubber latex and 0.6 part of 1,1-(1,3 phenyldicarbonyl) bis[2-methylaziridine].

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com