Production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns

A production process, bamboo fiber technology, applied in the chemical post-treatment of fiber, fiber treatment, fiber mechanical separation, etc., can solve the problems of thick fiber, damaged fiber strength, poor quality of bamboo fiber, etc., to achieve high strength and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

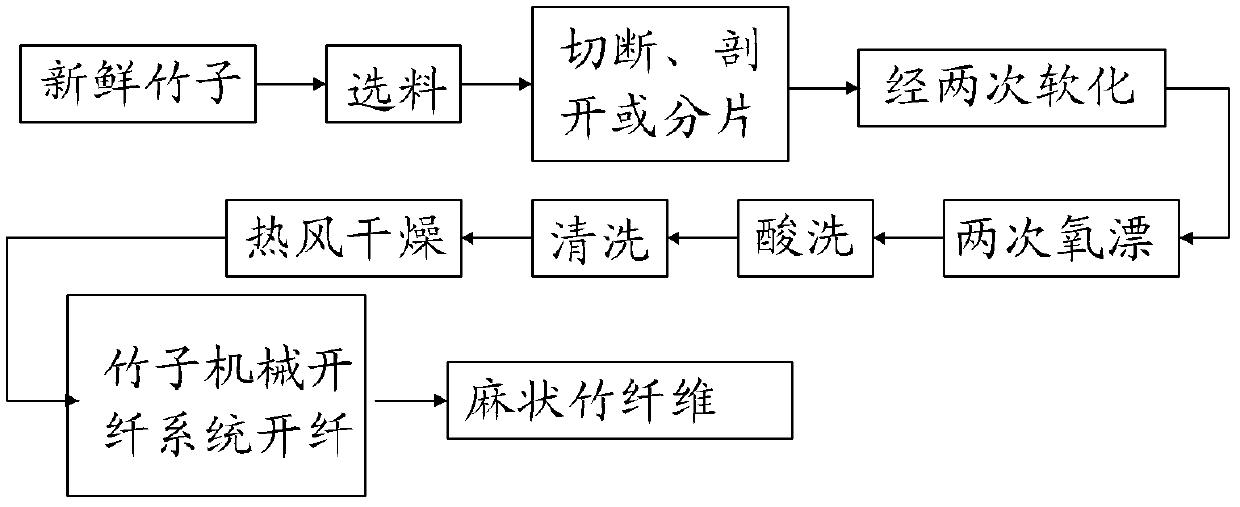

[0058] Such as figure 1 Shown, a kind of production technology of hemp-like bamboo fiber comprises the steps:

[0059] Step 1: Material selection: take 10-month-old Cizhu and stack them in the storage warehouse for moisture;

[0060] Step 2: Cutting, splitting or splitting: After cutting the bamboo, use a bamboo breaker to split and flatten the bamboo;

[0061] Step 3: Pre-softening: Put the bamboo slices split and flattened by the bamboo breaker into the No. 1 softening pool for soaking, the bath ratio of the softening solution is 1:5, the concentration of sodium hydroxide: 0.25%, the concentration of sodium carbonate: 0.5%, and water glass Concentration: 0.125%, time: 30 days;

[0062] Step 4: Secondary softening: add ammonia water to the No. 2 softening tank, the ammonia water accounts for 1% of the total softening liquid concentration, and then add the pre-softened bamboo chips into the No. 2 softening tank for secondary softening; time 6 hours;

[0063] Step 5: Pre-oxy...

no. 2 example

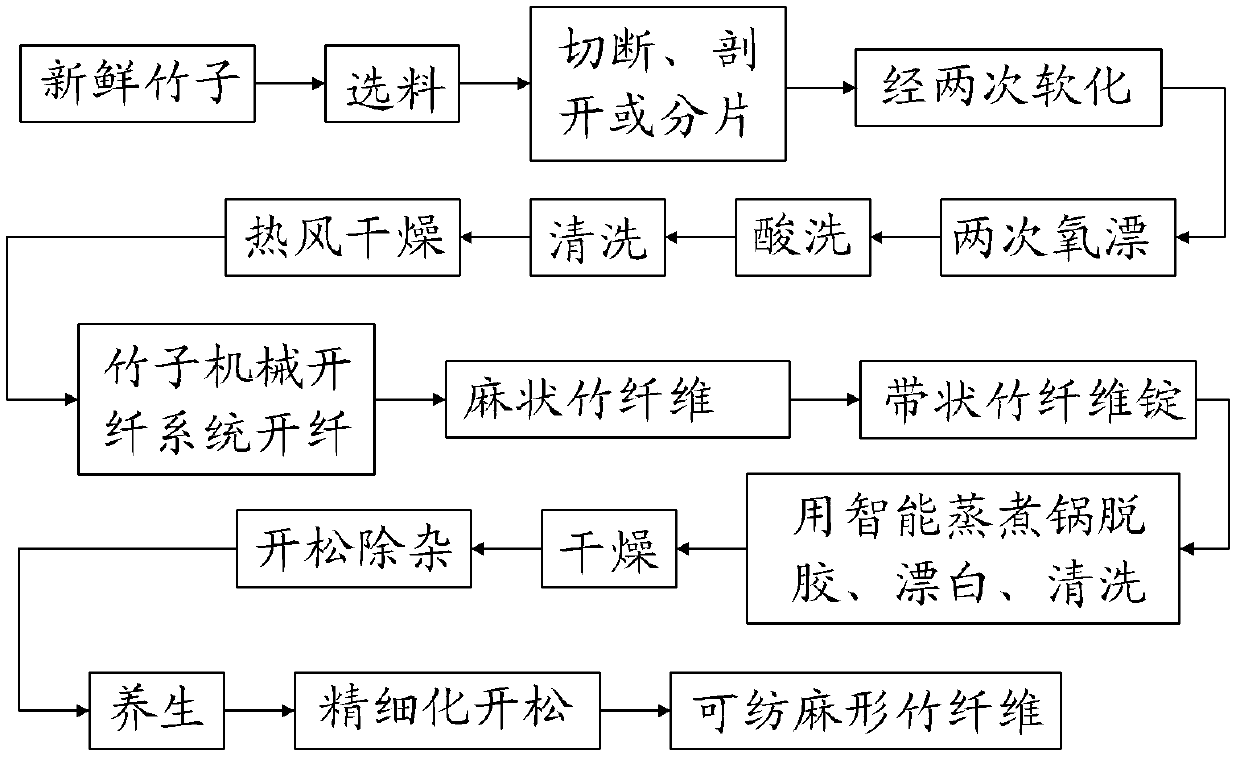

[0070] Such as figure 2 Shown, a kind of production technology of spinnable hemp-shaped bamboo fiber comprises the steps:

[0071] Step 1: Material selection: take 2-year-old moso bamboo and stack it in the storage warehouse to keep moisture;

[0072] Step 2: Cutting, splitting or splitting: After cutting the bamboo, use a bamboo bumper or a bamboo splitter to split it into pieces, then put the green bamboo and yellow bamboo into the softening pool for soaking;

[0073] Step 3-step 10 is identical with the first embodiment;

[0074] Step 11: Send the hemp-shaped bamboo fiber into the fiber unwinding machine to make strip-shaped bamboo fiber ingots.

[0075] Step 12: Send hemp-shaped bamboo fiber ingots into the intelligent cooking pot;

[0076] Step 13: Pre-degumming: bath ratio 1:80, sodium hydroxide concentration: 5%, sodium carbonate concentration: 10%, water glass concentration: 1%, temperature: 100°C, after reaching the set temperature, heat preservation: 30 minute; ...

no. 3 example

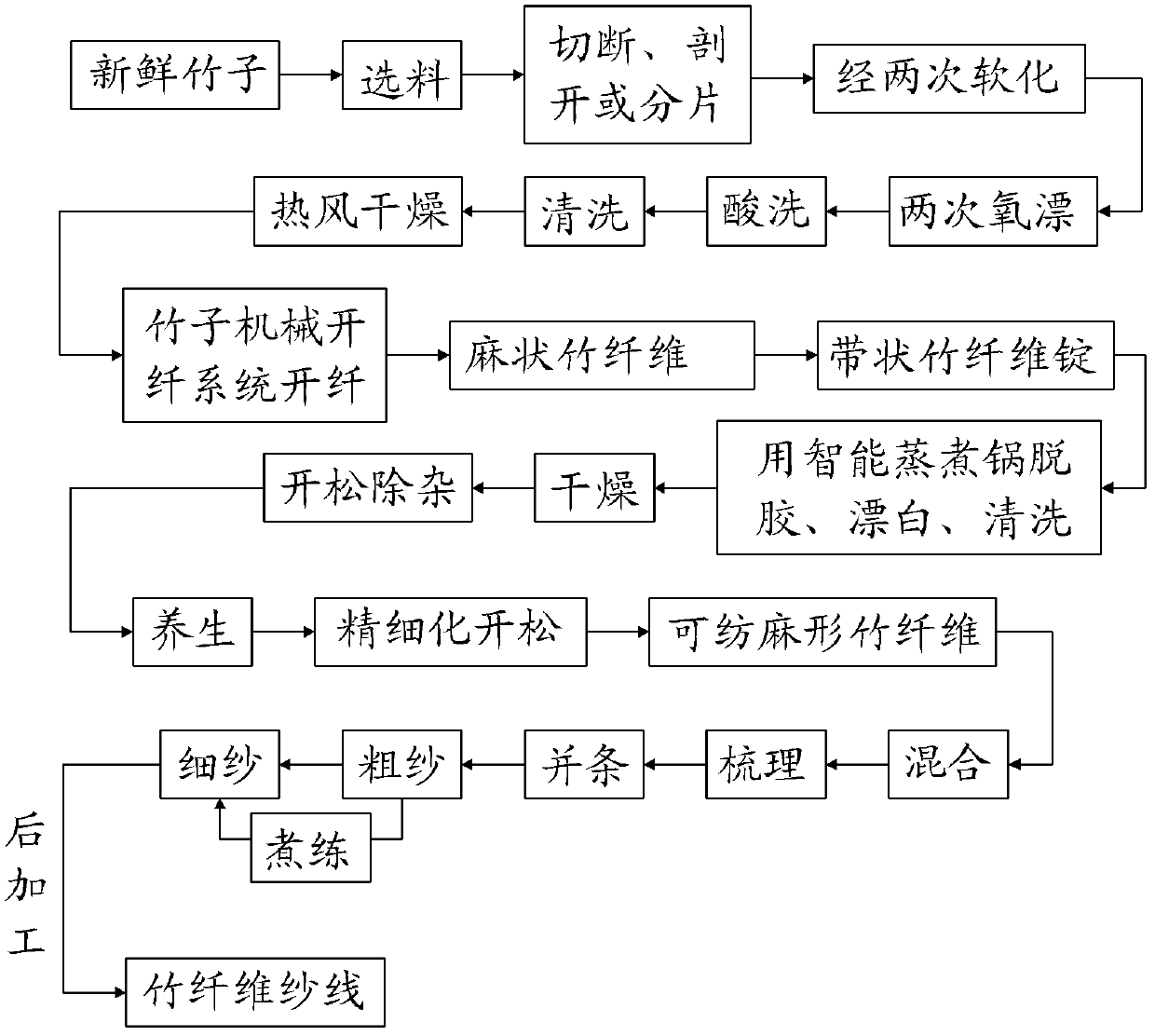

[0089] Such as image 3 Shown, a kind of production technology of bamboo fiber yarn comprises the step 1-step 23 of above-mentioned technical scheme two, also comprises the following steps:

[0090] Step 24: Blending: Add each batch of spinnable hemp-shaped bamboo fibers into the cotton blending box and mix them, then remove powder and impurities, and prepare the fibers for carding into strips;

[0091] Step 25: Carding: using a carding machine to card the bamboo fibers into strips;

[0092] Step 26: drawing: the bamboo fibers combed into strips are combined and drafted 5 times to make pure bamboo fiber strips, and then combined with cotton sliver or ramie, flax strips 5 times to make mixed fiber strips;

[0093] Step 27: Roving: process the mixed fiber strips into 6 non-twisted roving spindles;

[0094] Step 28: Scouring: Put the untwisted roving ingot into the smart scouring pot for scouring to remove impurities.

[0095] Step 29: spinning the mixed fiber sliver obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com