Leather and fur integrated cloth and production process

A production process and fur technology, applied in liquid/gas/steam textile material processing, heating/cooling fabric, roughening, etc., can solve the problems of shortening the production cycle of fabric manufacturing, hard feeling of composite fabric, reducing production cost, etc. The effect of shortening the production cycle, soft hand feeling and lowering production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

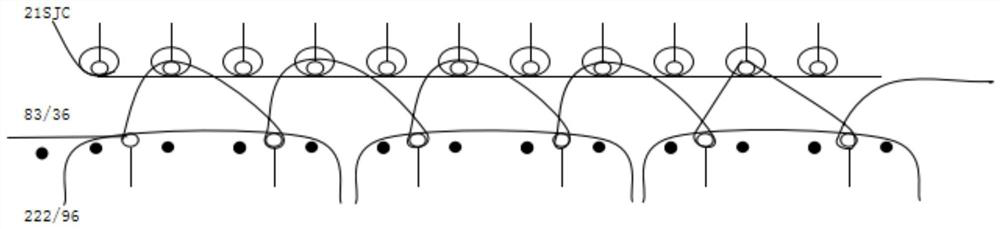

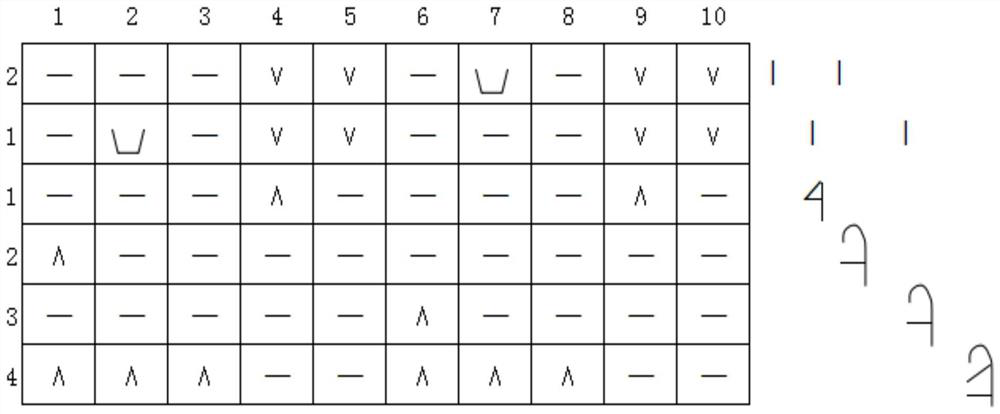

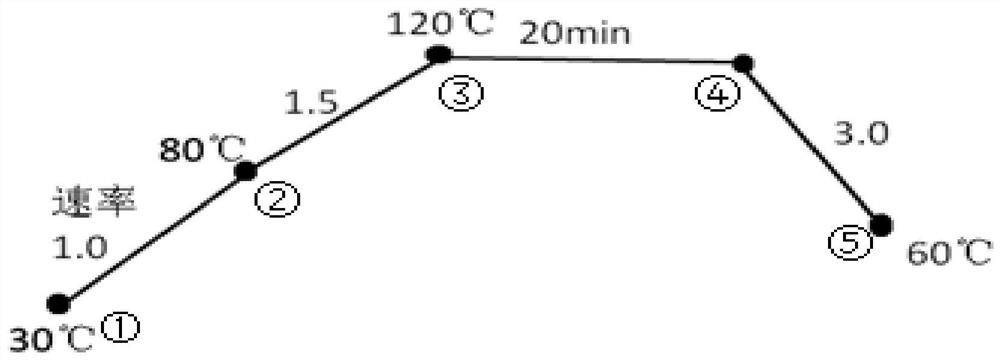

[0023] The present invention adopts a weft-knitting double-sided machine structure. The front side of the fabric is made of 222dtex / 96F polyester filament, the reverse side is 21SJC, and the middle link yarn is 83dtex / 36F polyester filament. When the tension is appropriate, the knitting machine cuts and rolls directly. Weaving according to specific weaving process parameters, after pre-ordering, dyeing, softening, dehydration, drying, combing, fleece, and setting, this fabric is made. The wool height of the gray cloth weaving machine is between 20-35mm, and the weight of the gray cloth is Between 180-550G, the yarn count can be adjusted according to the gray cloth weight, and the structure can be diversified; the diameter of the needle cylinder is 9mm (36 inches), the needle pitch is 16 / 22 needles / inch, and the number of incoming lines is 16.

[0024] refer to figure 1 , 2 , the present invention refers to the upper needle disc ABAB two-stage needle row, 10-way one cycle whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com