Tool facilitating ink box chip removal

A technology of ink cartridge chips and tooling, which is applied in the field of tooling for easy removal of ink cartridge chips, can solve problems such as not very smooth operation, and achieve the effect of easier separation and tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

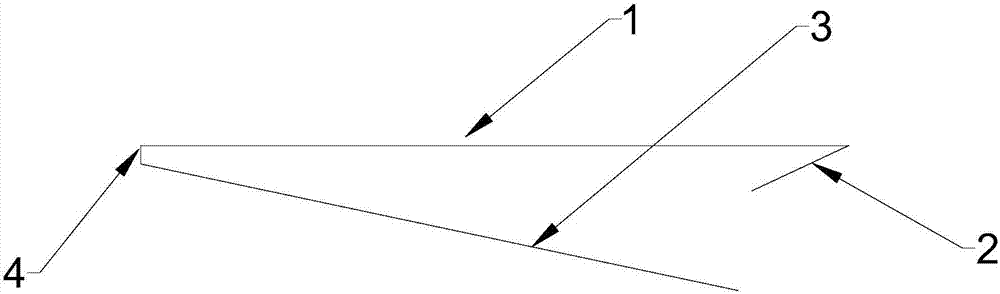

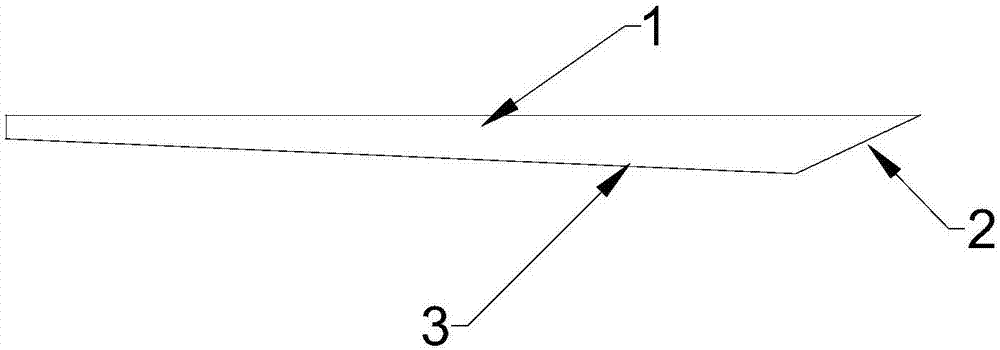

[0015] see figure 1 and figure 2 , a kind of frock that is convenient for removing the ink cartridge chip is characterized in that: it includes a first metal sheet 1 and a second metal sheet 3, and one end of the first metal sheet 1 is bent inwards into a hook shape to form a spatula 2, and the first metal sheet The other end of 1 and one end of the second metal sheet 3 are connected by connecting piece 4, so that there is a relative distance between the other end of the first metal sheet 1 and one end of the second metal sheet 3, when the first metal sheet 1 and the second metal sheet 3 are compressed When two metal pieces 3 are used, the other end of the second metal piece 3 is in contact with the free end of the shovel blade 2 .

[0016] During operation, the work first hooks the shovel 2 from the edge of the chip bonded to the ink cartridge, and then applies tension to make the shovel shovel under the chip for a long enough distance, and then compress the first metal she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com