Nano-imprint template as well as making method and application thereof

A technology of nanoimprinting and manufacturing methods, which is applied in the direction of nanotechnology, pattern surface photolithography, semiconductor/solid-state device manufacturing, etc. It can solve problems such as hindering the development of NIL technology, limited process technology, and etching problems, and achieves Improve degumming problem, simple process, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

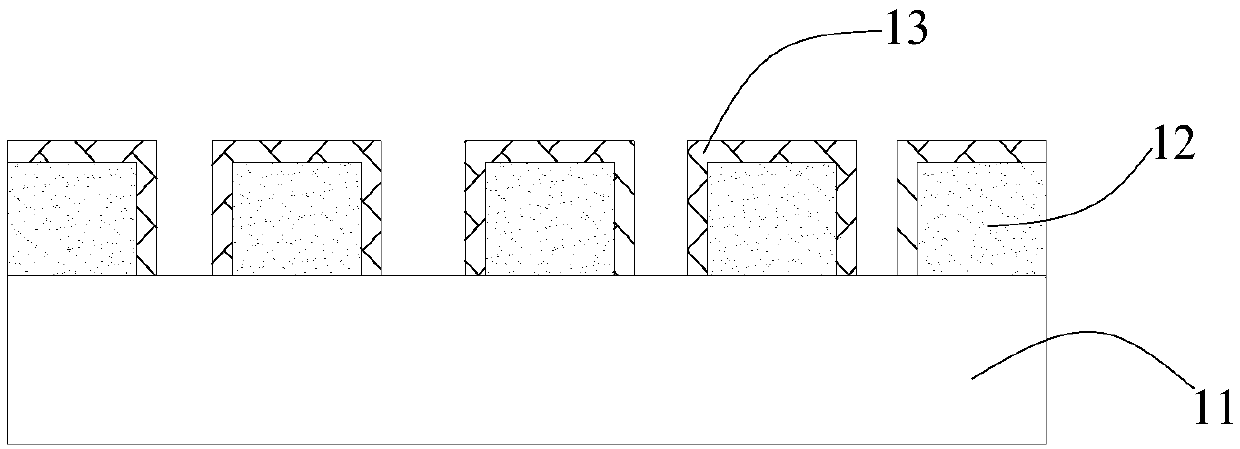

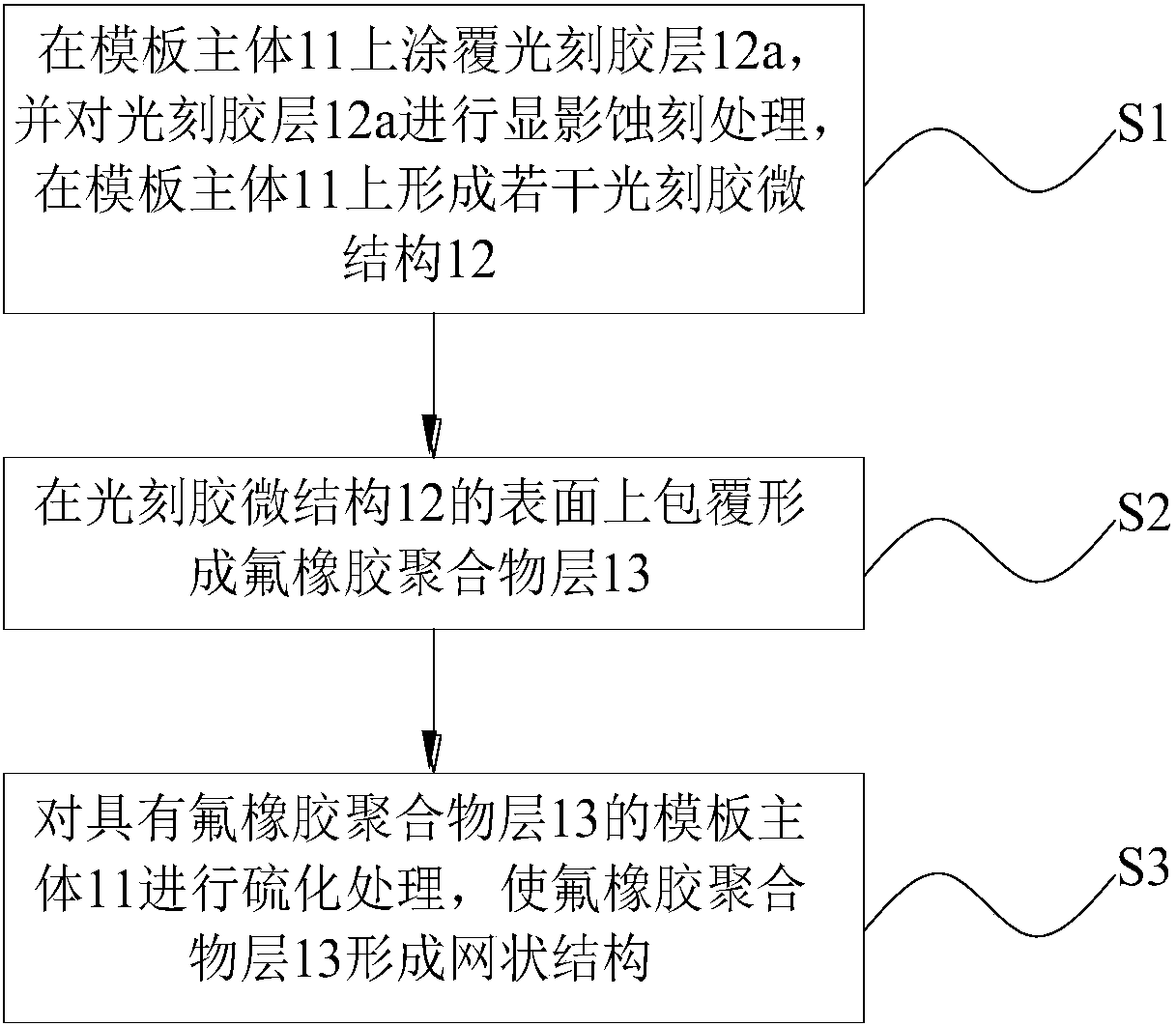

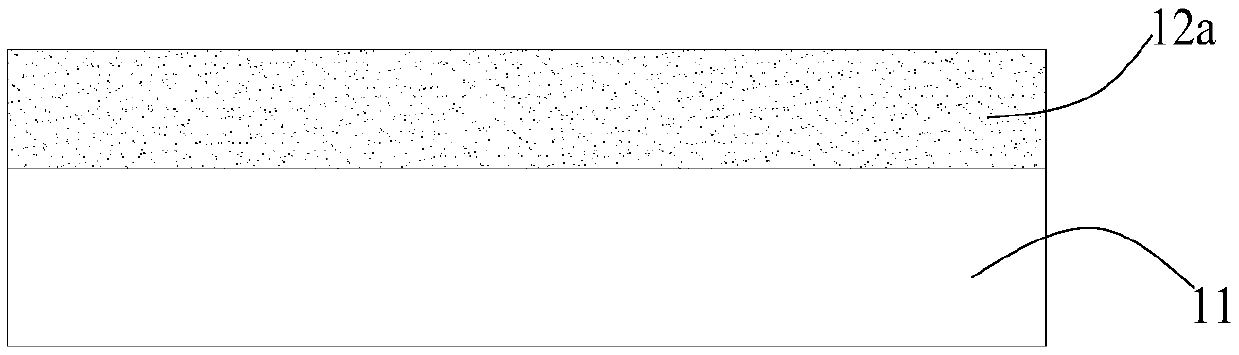

[0036] This embodiment provides a brand new nanoimprint template, refer to figure 1 The nanoimprint template includes a template main body 11 , several photoresist microstructures 12 arranged on the template main body 11 , and a fluororubber polymer layer 13 covering the outer layer of the photoresist microstructures 12 .

[0037] Further, the thickness of the fluororubber polymer layer 12 is 50nm-100nm.

[0038] Furthermore, the material of the fluororubber polymer layer 12 has a structure as shown in formula 1:

[0039]

[0040] In Formula 1, n represents the degree of polymerization, and is not particularly limited here.

[0041] It can be seen from the structural formula of formula 1 that, on the one hand, the silicon oxygen atom group in the main chain of the material of the fluororubber polymer layer 13 can form an interaction with the silicon oxygen atom group in the template main body 11, and the fluororubber polymerizes The role of bonding force can be formed bet...

Embodiment 2

[0059] The purpose of this embodiment is to provide an application of the nano-imprint template as described in the above-mentioned embodiment 1 in the nano-imprint technology, that is, to use the nano-imprint template in the above-mentioned embodiment 1 to fabricate a microstructure substrate.

[0060] The following will refer to Figure 6-Figure 10 The manufacturing method of the microstructure substrate of this embodiment is described in detail. The manufacturing method of the microstructure substrate according to the present embodiment comprises the following steps:

[0061] Step Q1, coating the embossing adhesive layer 22 on the embossing substrate 21; Image 6 shown.

[0062] The imprint substrate 21 is generally selected from flexible substrates such as glass substrates, silicon substrates, and sapphire substrates.

[0063] Step Q2, coating the polytetrafluoroethylene powder layer on the embossed rubber layer 22, and after calcination and cooling treatment, an isolat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com