Detachable epoxy adhesive for multi-wire cutting and preparation method thereof

An epoxy adhesive and multi-wire cutting technology, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of affecting production efficiency, long degumming time, and chip dropping, so as to improve product yield and increase The effect of glue application efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

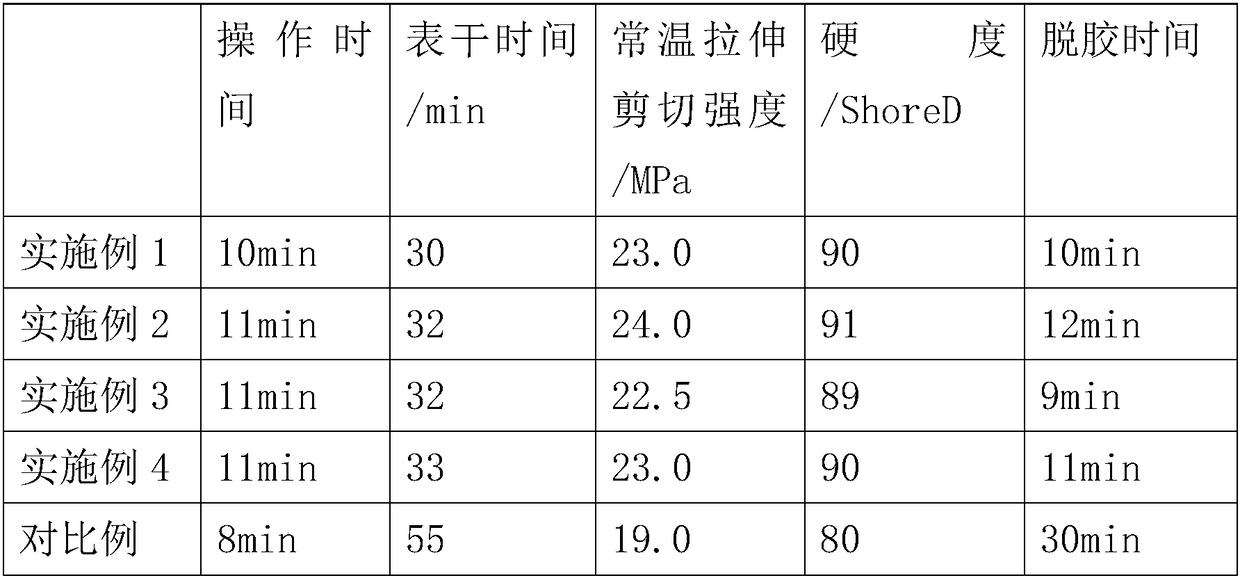

Examples

Embodiment 1

[0027] Weigh the following component A raw materials by mass: bisphenol A epoxy resin 55kg, carboxyl-terminated nitrile rubber and epoxy resin prepolymer 8kg, dibutyl sebacate (DBS) 3kg, silicon micropowder 20kg, talcum powder 15kg 1. Blue pulp 1kg. Add the above raw materials into the reaction kettle in order, stir for 1 hour until the material is uniform and there is no color difference, then vacuumize for 1-2 hours to remove the air bubbles generated during stirring.

[0028] Weigh the following component B raw materials by mass: CAPCURE3-800 polythiol curing agent 45kg, modified amine curing agent 18kg, 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30) 1kg, silicon 35kg of fine powder, 1kg of yellow paste, the above raw materials are put into the reaction kettle in order, stirred for 1h until the material is uniform and there is no color difference, and then vacuumed for 1~2h to remove the bubbles generated during stirring, after the end, discharge the material and pack it, an...

Embodiment 2

[0030] Weigh the following component A raw materials by mass: bisphenol A epoxy resin 45kg, bisphenol F epoxy resin 10kg, polyurethane modified epoxy resin 8kg, dioctyl phthalate (DOP) 3kg, calcium carbonate 35kg 1. Blue pulp 1kg. Add the above raw materials into the reaction kettle in order, stir for 1 hour until the material is uniform and there is no color difference, then vacuumize for 1-2 hours to remove the air bubbles generated during stirring.

[0031] Weigh the following component B raw materials by mass: CAPCURE3-800 polythiol curing agent 25kg, modified amine curing agent 38kg, 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30) 1kg, silicon 35kg of fine powder, 1kg of yellow paste, the above raw materials are put into the reaction kettle in order, stirred for 1h until the material is uniform and there is no color difference, and then vacuumed for 1~2h to remove the bubbles generated during stirring, after the end, discharge the material and pack it, and seal it for stora...

Embodiment 3

[0033] Weigh the following component A raw materials by mass: bisphenol A epoxy resin 20kg, bisphenol F epoxy resin 35kg, amino-terminated nitrile rubber 8kg, dibutyl phthalate (DBP) 3kg, calcium carbonate 35kg, 1kg blue slurry, add the above raw materials into the reaction kettle in order, stir for 1h until the material is uniform and there is no color difference, then vacuumize for 1~2h to remove the bubbles generated during stirring, after the end, discharge the material and pack it, and seal it for storage;

[0034] Weigh the following component B raw materials by mass: 45kg of CAPCURE3830 polythiol curing agent, 18kg of modified amine curing agent, 1kg of benzyldimethylamine (BDMA), 35kg of talcum powder, and 1kg of yellow paste, and add the above-mentioned raw materials to the reaction kettle in order , stir for 1 hour until the material is uniform without color difference, and then vacuumize for 1 to 2 hours to remove the air bubbles generated during stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com