Tea oil production equipment and processing technology

A production equipment and camellia oil technology, applied in the field of tea oil production equipment and processing technology, can solve the problems of low production efficiency, difficult cleaning, difficult separation, etc., and achieve the effect of improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

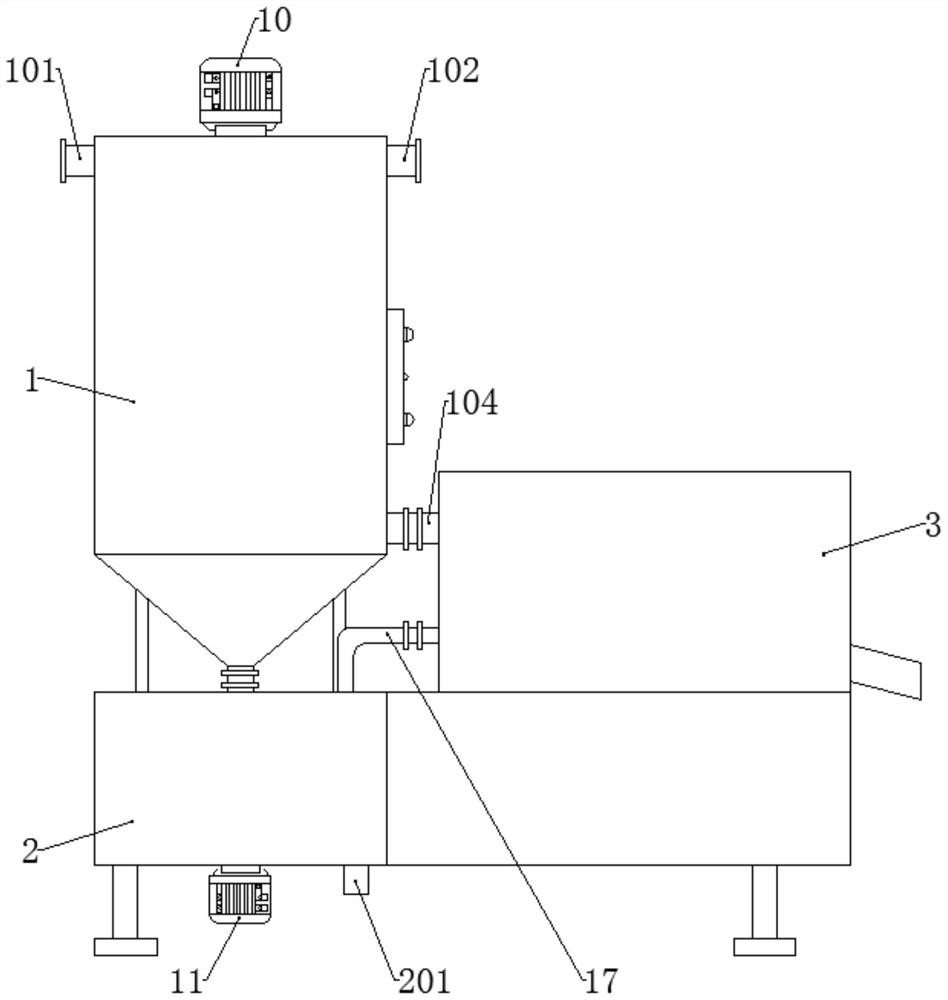

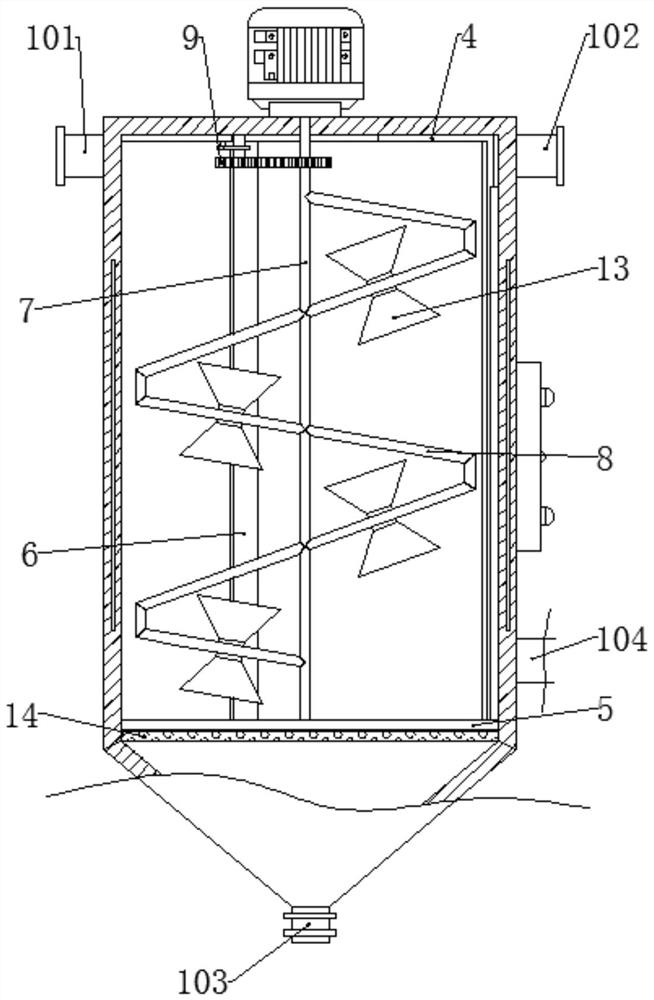

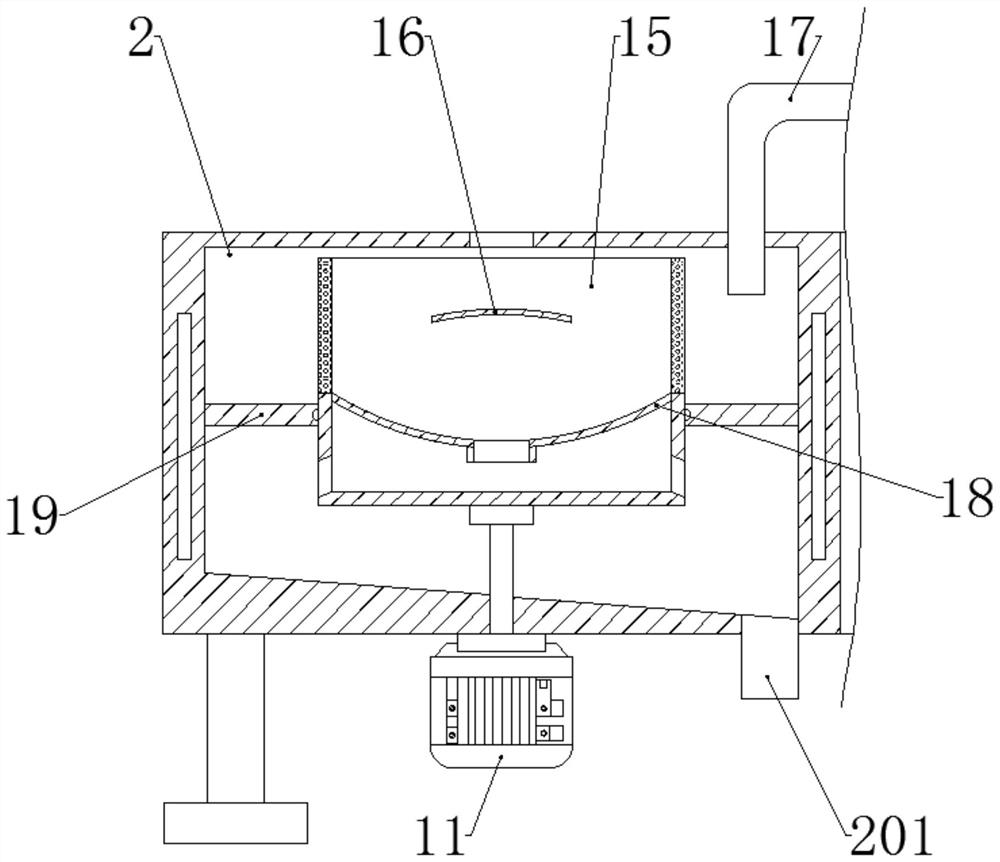

[0025] see Figure 1 to Figure 5 , the present invention provides a technical solution: a tea oil production equipment and processing technology, including a hydration tank main body 1, an oil foot box 2 and a vacuum drying tank 3, the top of the hydration tank main body 1 is respectively provided with an oil inlet pipe 101 and ingredients Inlet pipe 102, a filter plate 14 is installed under the inside of the hydration tank main body 1, and the filter plate 14 divides the inside of the hydration tank main body 1 into a stirring zone and a sedimentation zone. Inside the barrel, the main body of the hydration tank 1 at the bottom of the mixing zone and the vacuum drying tank 3 are connected through an oil outlet pipe 104, and an annular partition 19 is fixed inside the oil foot tank 2, and a centrifugal cylinder is installed in the middle of the annular partition 19 15. The annular partition 19 divides the inside of the oil foot tank 2 into an oil chamber at the top and an oil f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com