Concentration and flow control method used in recovery of diluted phosphoric acid by virtue of phosphoric ore pulp filter device

A technology of filtering equipment and flow control, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., to achieve the effect of ensuring stability and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

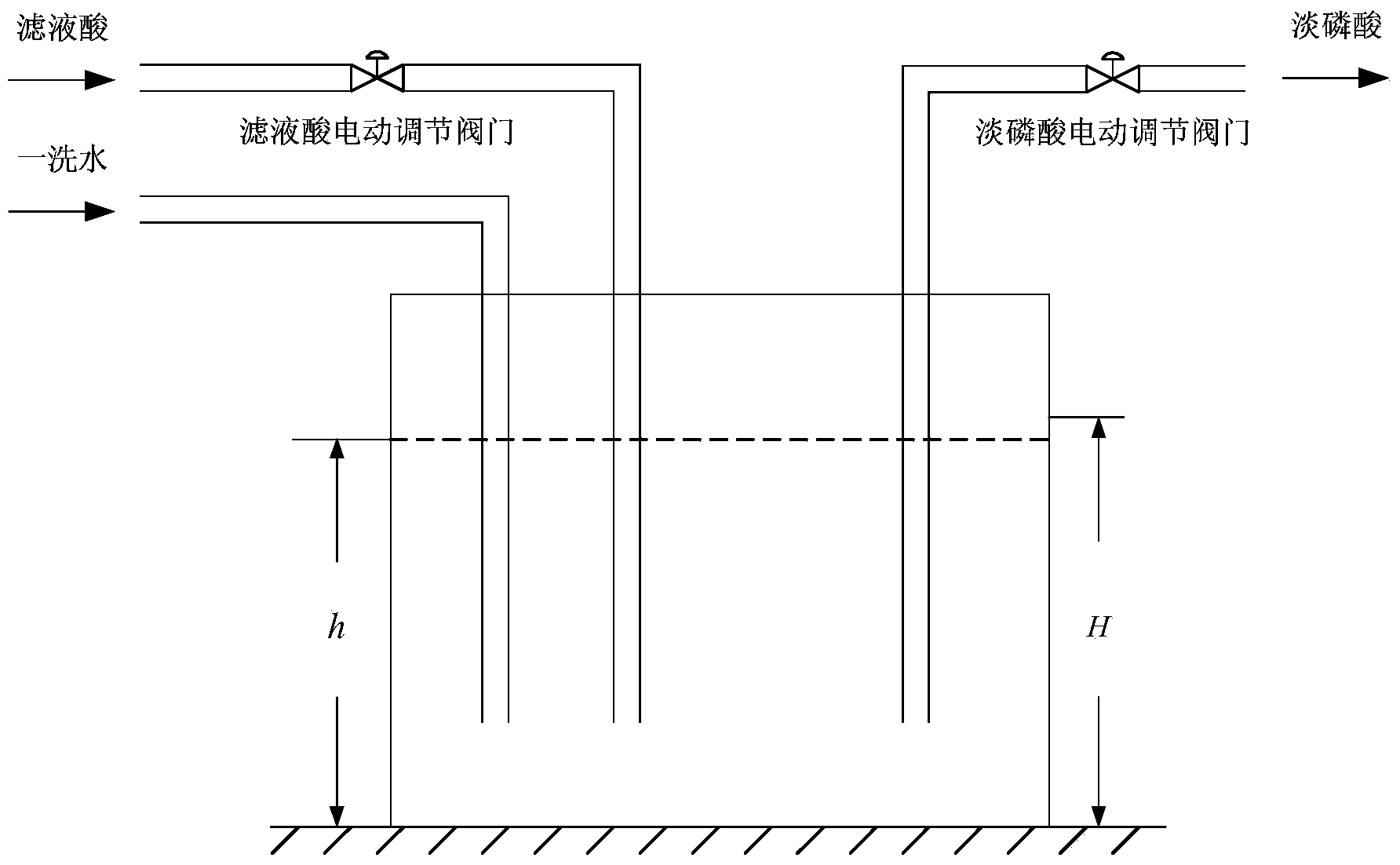

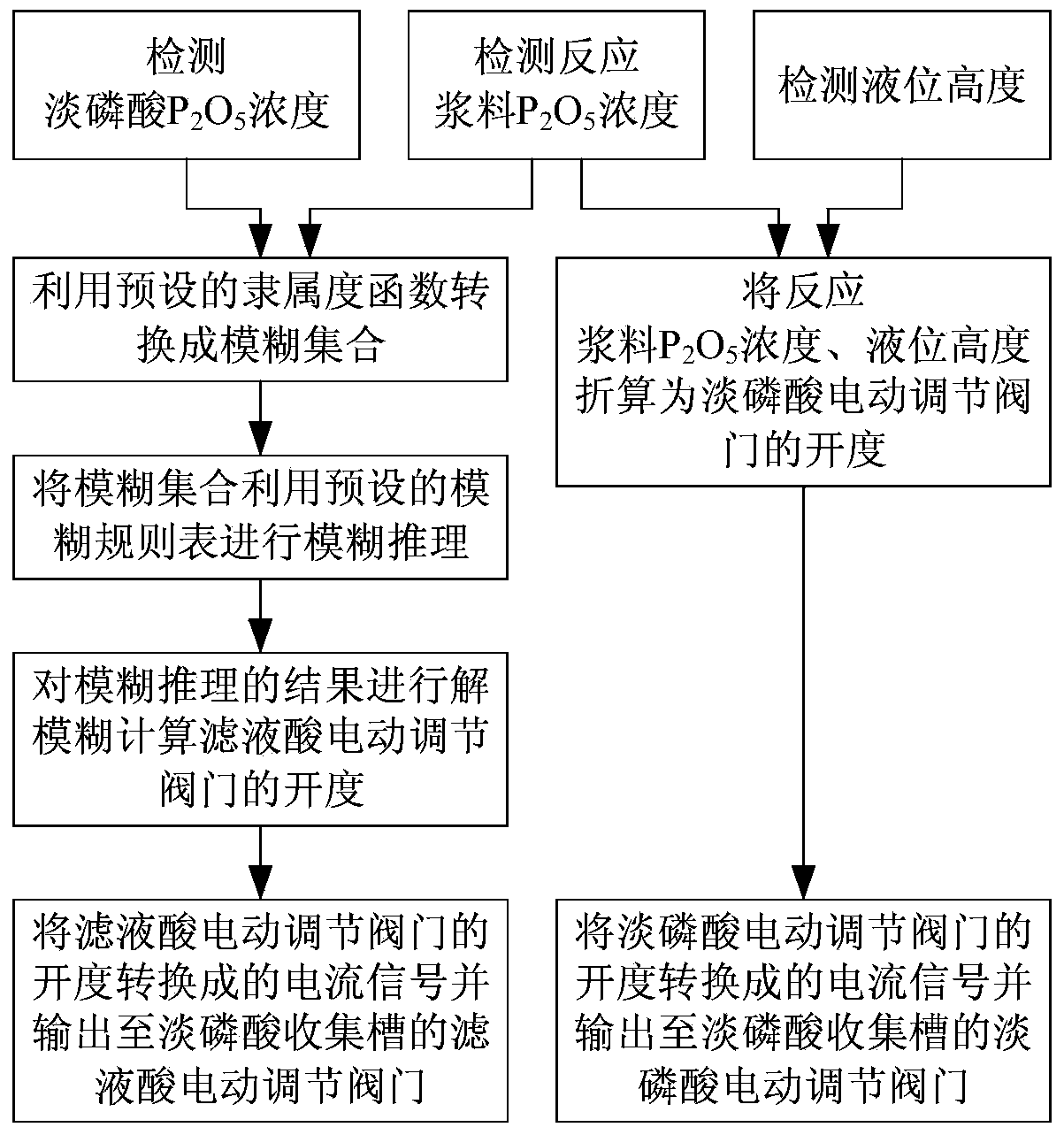

[0040] like figure 2 As shown, the implementation steps of the method for controlling the concentration and flow of light phosphoric acid recovered by the phosphate rock slurry filtration equipment in this embodiment are as follows:

[0041] 1) Detect the light phosphoric acid P in the light phosphoric acid collection tank of the phosphate rock slurry filtration equipment 2 o 5 Concentration (P of light phosphoric acid in the output pipeline of light phosphoric acid collection tank 2 o 5 Concentration), reaction slurry P 2 o 5 Concentration (P of the reaction slurry in the extraction tank 2 o 5 Concentration) and liquid level height;

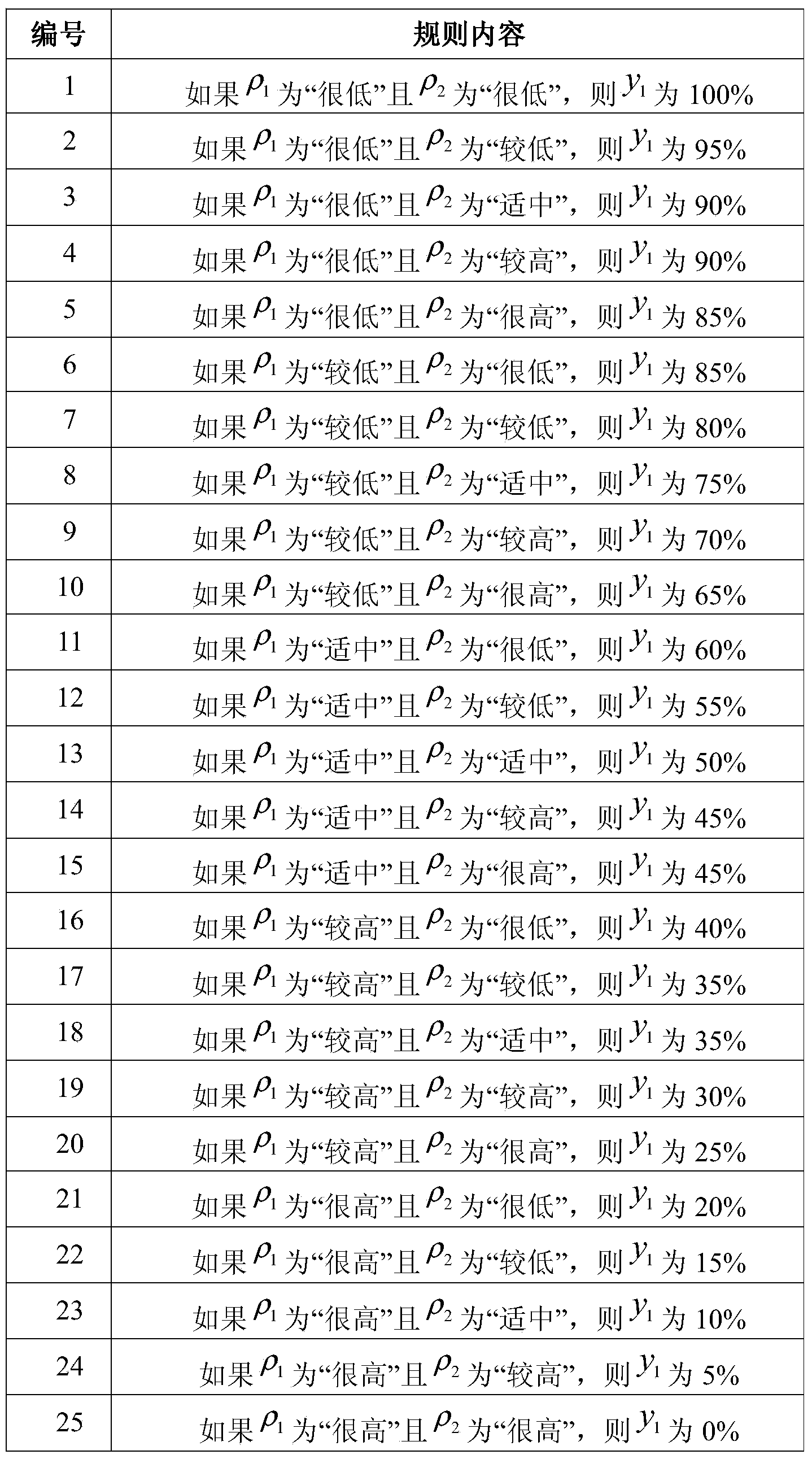

[0042] 2) Light phosphoric acid P 2 o 5 Concentration, reaction slurry P 2 o 5 Concentrations are converted into fuzzy sets using preset membership functions and fuzzy reasoning is performed using preset fuzzy rule tables, and the results of fuzzy reasoning are defuzzified to obtain the opening degree of the filtrate acid electric co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com