Combined efficient dephosphorization treatment method of waste water

A treatment method and a combined technology are applied in the field of high-efficiency phosphorus removal of combined wastewater, which can solve the problems of inability to discharge wastewater up to the standard and continue to effectively remove it, so as to reduce the risk of eutrophication, simple design and operation, and realize recycling. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Combined treatment of wastewater with high efficiency phosphorus removal

[0032] Experimental wastewater: The initial concentration of phosphate in the wastewater was detected to be 190.28 mg / L, the initial concentration of ammonia nitrogen was 173.91 mg / L, and the initial pH value was 6.83.

[0033] Struvite precipitation reaction: 10m of the above-mentioned nitrogen and phosphorus-containing experimental wastewater 3 , the loading volume is 15m 3 In the left and right reaction sedimentation tanks, under mechanical stirring at a speed of 200-300r / min, magnesium chloride (228.3L of 1.0wt% magnesium chloride solution) was added in a ratio of Mg:P molar ratio of 1.2:1, and 2M (2mol / L ) sodium hydroxide solution, adjust the pH value to 9.0, the nitrogen and phosphorus contained in the struvite precipitate, continue to stir for 30 minutes until the precipitation is complete, the measured residual phosphate is 4.06mg / L, and the residual ammonia nitrogen concentr...

Embodiment 2

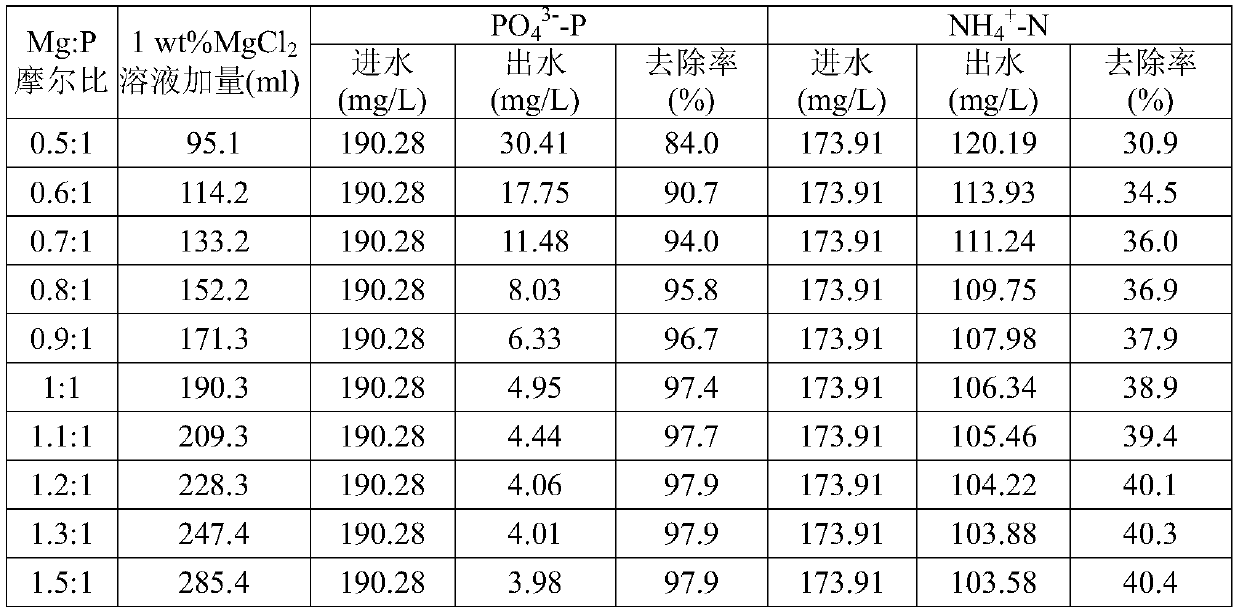

[0040] Embodiment 2: Magnesium source addition gradient experiment in the struvite precipitation reaction

[0041] Experimental wastewater: The initial concentration of phosphate in the wastewater was detected to be 190.28 mg / L, the initial concentration of ammonia nitrogen was 173.91 mg / L, and the initial pH value was 6.83.

[0042]Struvite precipitation reaction: In 10 20L plastic buckets, respectively fill 10L of the above-mentioned nitrogen and phosphorus-containing experimental wastewater, under mechanical stirring at a speed of 200-300r / min, according to the Mg:P molar ratio of 0.5:1, 0.6: 1. Add magnesium chloride (1.0wt% magnesium chloride solution) in the ratio of 0.7:1, 0.8:1, 0.9:1, 1:1, 1.1:1, 1.2:1, 1.3:1, 1.5:1, and add 2M hydrogen dropwise Sodium oxide solution, adjust the pH value to 9.0, the contained nitrogen and phosphorus form struvite precipitation, continue to stir for 30 minutes until the precipitation is complete, and measure the residual phosphate conc...

Embodiment 3

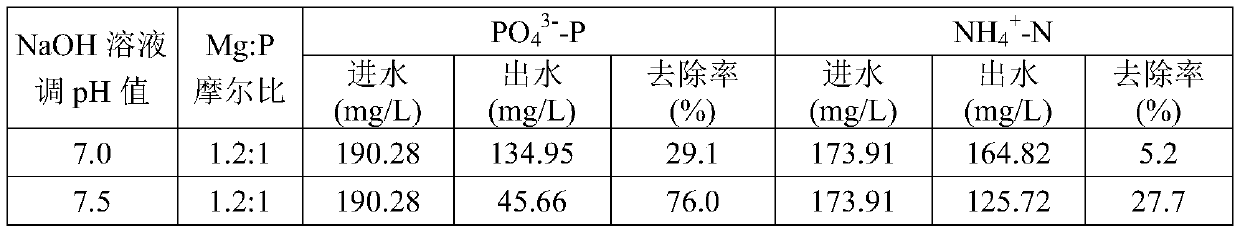

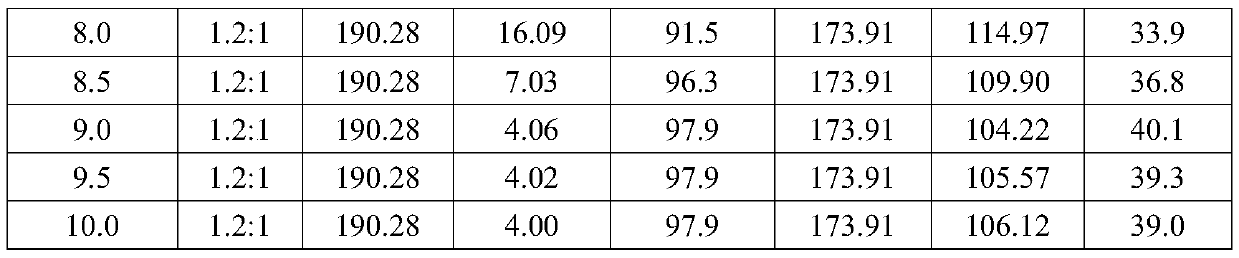

[0045] Embodiment 3: pH value gradient experiment in the struvite precipitation reaction

[0046] Experimental wastewater: The initial concentration of phosphate in the wastewater was detected to be 190.28 mg / L, the initial concentration of ammonia nitrogen was 173.91 mg / L, and the initial pH value was 6.83.

[0047] Struvite precipitation reaction: In seven 20L plastic barrels, put 10L of the above-mentioned nitrogen and phosphorus-containing experimental wastewater into each of them, and add them at a ratio of Mg:P molar ratio of 1.2:1 under mechanical stirring at a speed of 200-300r / min. Magnesium chloride (1.0wt% magnesium chloride solution 228.3mL), add dropwise 2M sodium hydroxide solution, adjust the pH value to 7.0, 7.5, 8.0, 8.5, 9.0, 9.5, 10.0, the nitrogen and phosphorus contained in it form struvite precipitation, continue to stir 30 minutes to precipitation completely, record residual phosphate concentration and ammonia nitrogen concentration as follows:

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com