A preparation method of phosphate rock powder or crushed phosphate rock binder and a molded ore production method

A technology for preparing binder and phosphate rock powder is applied in the field of comprehensive utilization of mineral resources to achieve the effects of increasing production capacity, increasing viscosity and reducing production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

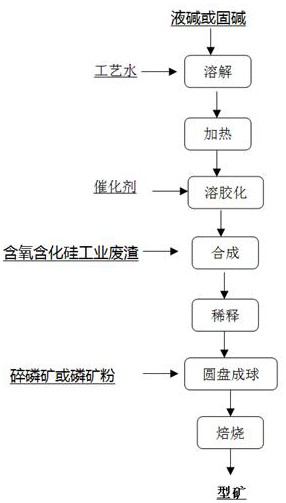

[0028] The phosphate rock powder or crushed phosphate rock binder preparation method, its specific steps are as follows:

[0029] Step 1. NaOH liquid caustic soda or solid caustic soda is configured into a 100kg alkali solution with a NaOH content of 50wt%, which is converted into 38.75kg of sodium oxide;

[0030] Step 2. Heat the alkali solution obtained in step 1 to 70°C, then add the catalyst and stir evenly to form a well-dispersed colloidal substance; the catalyst is a mixture of zirconium carbonate and nickel sulfate with a mass ratio of 7:3, and the amount of the catalyst added is the alkali solution 0.5% of the mass of sodium oxide in the medium, that is, the amount of catalyst added is 0.19kg;

[0031] Step 3, add the colloidal substance obtained in step 2 to the industrial by-products containing silicon oxide and stir evenly to prepare phosphate rock powder or crushed phosphate rock binder, wherein the industrial by-products containing silicon oxide have a silicon ox...

Embodiment 2

[0037] The phosphate rock powder or crushed phosphate rock binder preparation method, its specific steps are as follows:

[0038] Step 1. NaOH liquid caustic soda or solid caustic soda is configured into 100kg of alkali solution with NaOH content of 40wt%, which is converted into 31kg of sodium oxide;

[0039] Step 2. Heat up the alkali solution obtained in step 1 to 80°C, then add the catalyst and stir evenly to form a well-dispersed colloidal substance; the catalyst is a mixture of potassium sulfate and nickel sulfate with a mass ratio of 5:5, and the amount of the catalyst added is the alkali solution 1% of the mass of sodium oxide in the medium, that is, the amount of catalyst added is 0.31kg;

[0040] Step 3. Add the colloidal substance obtained in step 2 to the industrial by-products containing silicon oxide and stir evenly to obtain phosphate rock powder or crushed phosphate rock binder, wherein the industrial by-products containing silicon oxide have a silicon oxide co...

Embodiment 3

[0046] The phosphate rock powder or crushed phosphate rock binder preparation method, its specific steps are as follows:

[0047] Step 1. NaOH liquid caustic soda or solid caustic soda is configured into a 100kg alkali solution with a NaOH content of 45wt%, which is converted into 34.9kg of sodium oxide;

[0048] Step 2. Heat up the alkali solution obtained in step 1 to 75°C, then add the catalyst and stir evenly to form a well-dispersed colloidal substance; the catalyst is a mixture of potassium sulfate and nickel sulfate with a mass ratio of 5:5, and the amount of the catalyst added is the alkali solution 0.8% of the mass of sodium oxide in the medium, that is, the amount of catalyst added is 0.28kg;

[0049] Step 3, adding the colloidal substance obtained in step 2 to the industrial by-products containing silicon oxide and stirring evenly to prepare phosphate rock powder or crushed phosphate rock binder, wherein the industrial by-products containing silicon oxide are 62.5wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| drop strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com