Organophosphorus wastewater treatment process

A wastewater treatment and organic phosphorus technology, applied in multi-stage water treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of environmental water pollution and difficulty in meeting discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

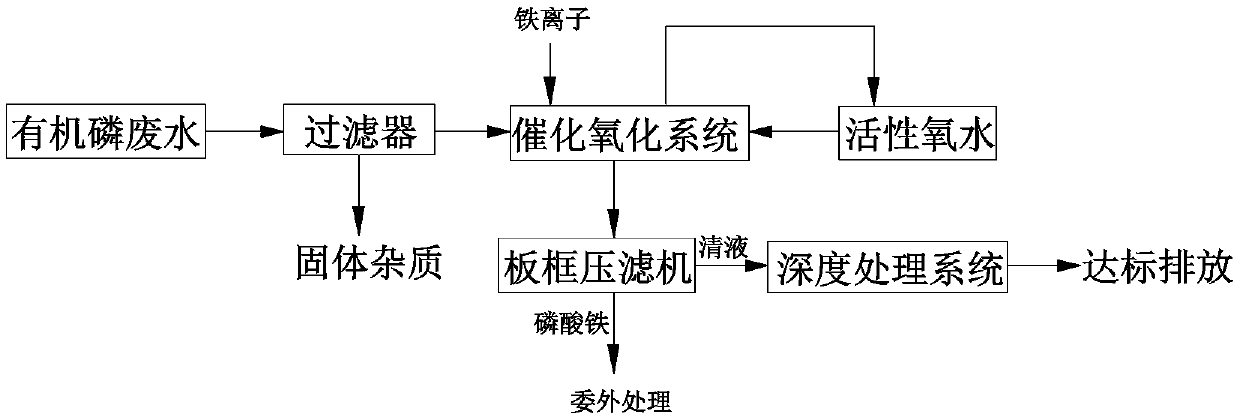

[0016] like figure 1 Shown, a kind of organophosphorus wastewater treatment process, it comprises the following steps:

[0017] S1. Use a pump to pump the organic phosphorus wastewater into the filter, and the filter filters out solid impurities in the organic phosphorus wastewater;

[0018] S2. Preload the catalytic oxidation filler in the catalytic oxidation system; set the voltage of the catalytic oxidation system to 5~10V under normal temperature and pressure;

[0019] S3. Pump the organophosphorus wastewater filtered out of solid impurities in step S1 into the catalytic oxidation system, and at the same time pump the active oxygen water into the catalytic oxidation system. The catalytic oxidation filler reacts with the active oxygen water to generate hydroxyl radicals, hydroxyl radicals for-O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com