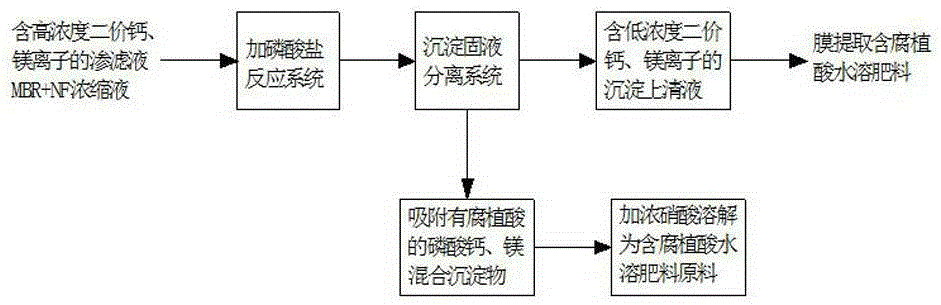

Method for removing and recycling high-concentration Ca<2+> and Mg<2+> in leachate MBR and NF concentrate

A concentrated liquid and high-concentration technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of high energy consumption, difficulty in high-fold concentration, difficulty in stable operation of membrane system, etc. The effects of secondary pollution, simple process and equipment, and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In the following, Ca in the MBR+NF concentrate of the leachate mixture of a domestic waste landfill and waste incineration plant leachate 2+ , Mg 2+ The removal and reuse are taken as examples to further illustrate the present invention.

[0019] The leachate of the domestic waste leachate treatment plant is the mixed leachate of landfill and incineration plant, which produces 1,500 tons of leachate per day. It adopts water quality balance as the pretreatment process, MBR as the main biochemical treatment process, and NF as the advanced treatment process flow. The treatment plant produces about 300 tons of MBR+NF concentrate per day, and its water quality is as follows: Ca 2+ and Mg 2+ The concentrations were 2646mg / L and 1224mg / L, PO 4 3- =5mg / L. The MBR+NF concentrate is lifted from the raw material pump to the reaction system through the collection tank, according to the stoichiometric ratio n (Ca 2+ +Mg 2+ ) / n (PO 4 3- )=1.6 add Na 3 PO 4 12H 2 O, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com