Epitaxial structure of light emitting diode and preparation method thereof

A technology of light-emitting diodes and epitaxial structures, applied in the field of diodes, can solve the problems of lattice mismatch, poor crystal quality of epitaxial layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

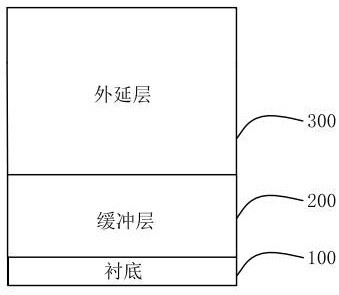

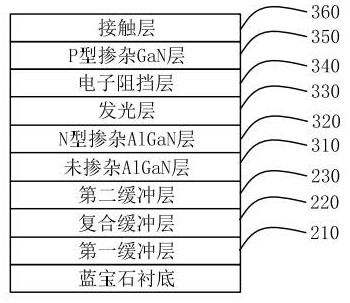

[0034] see Figure 1-Figure 2 , shows an epitaxial structure of a light emitting diode provided in the first embodiment of the present invention, which is applied to a micro light emitting diode or an ultraviolet light emitting diode. The epitaxial structure of a light emitting diode includes: a substrate 100, a buffer layer 200 and an epitaxial layer 300; , the substrate 100 is a substrate for subsequent growth of the epitaxial layer 300 , and is used to support and fix the subsequent growth of the epitaxial layer 300 . Among them, the material of the substrate 100 is the cornerstone of technological development in the field of lighting, and is the main factor determining the performance indicators such as the color, brightness, and life of the light-emitting diode. The packaging technology of the light emitting diode, and therefore the choice of the material of the substrate 100 determines the development route of the light emitting diode. The material of the substrate 100 ...

Embodiment 2

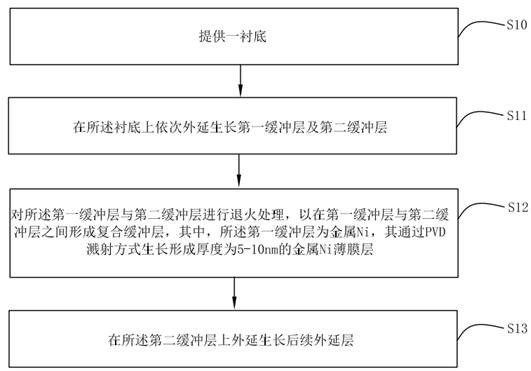

[0050] see image 3 , which shows a method for manufacturing a light-emitting diode provided in the second embodiment of the present invention, the method includes steps S10-S13:

[0051] Step S10, providing a substrate;

[0052]Among them, the crystal structure of the substrate material and the epitaxial material must be the same or similar, and the lattice constant mismatch degree is small, otherwise the growth quality of the subsequent epitaxial layer will be affected. In this embodiment, (0001) crystal orientation sapphire (Al 2 o 3 ) as a substrate, the chemical performance of the sapphire substrate is stable, and the structure of the sapphire substrate will not be damaged during the growth process of the subsequent epitaxial layer after high temperature growth. At the same time, the sapphire substrate does not absorb visible light, the price is moderate, and the preparation is simple.

[0053] Step S11, epitaxially growing a first buffer layer and a second buffer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com