Epitaxial growing method of high-crystal-quality infrared light emitting diode

A technology of epitaxial growth and crystal quality, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of poor crystal quality of the epitaxial layer, and achieve the effect of improving crystal quality, increasing luminous efficiency, and improving internal quantum luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

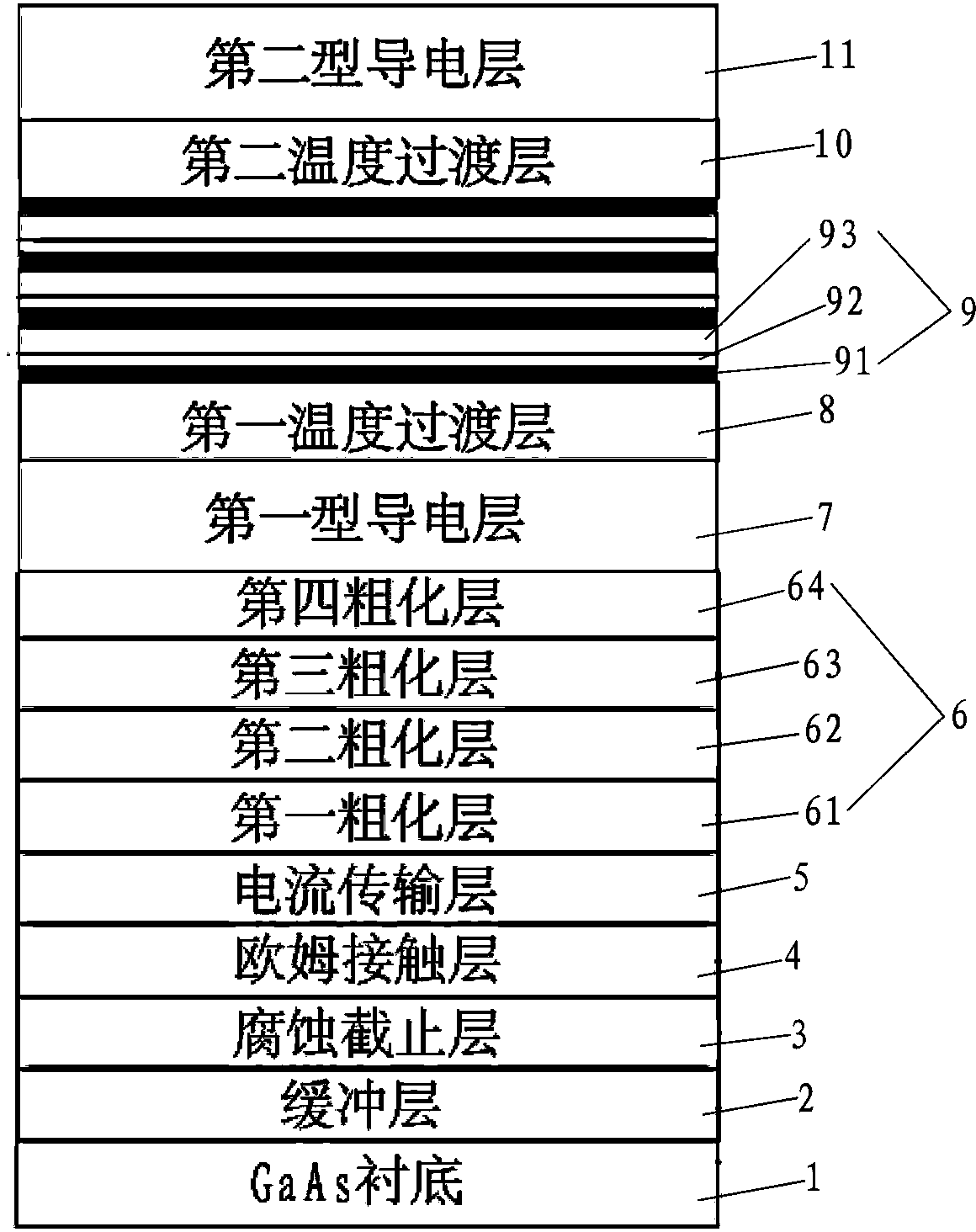

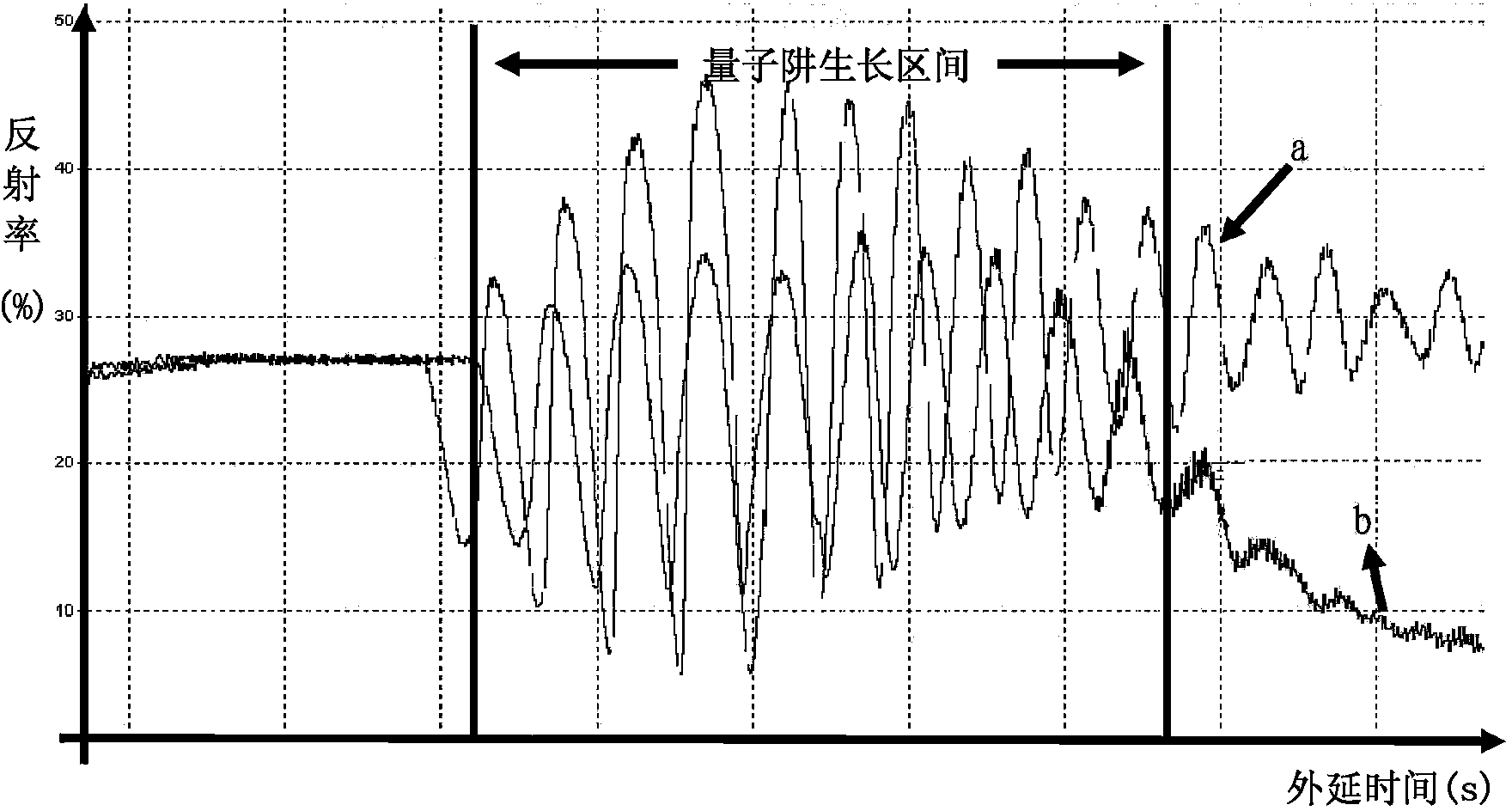

[0066] refer to Figure 1 to Figure 4 As shown, a high crystal quality infrared light-emitting diode disclosed by the present invention comprises growth buffer layer 2, corrosion stop layer 3, ohmic contact layer 4, current transport layer 5, and roughened layer 6 from substrate 1 to bottom to top. , the first type conduction layer 7 , the first temperature transition layer 8 , the active layer 9 , the second temperature transition layer 10 and the second type conduction layer 11 .

[0067] The roughened layer 6 is composed of four parts, namely a first roughened layer 61 , a second roughened layer 62 , a third roughened layer 63 , and a fourth roughened layer 64 .

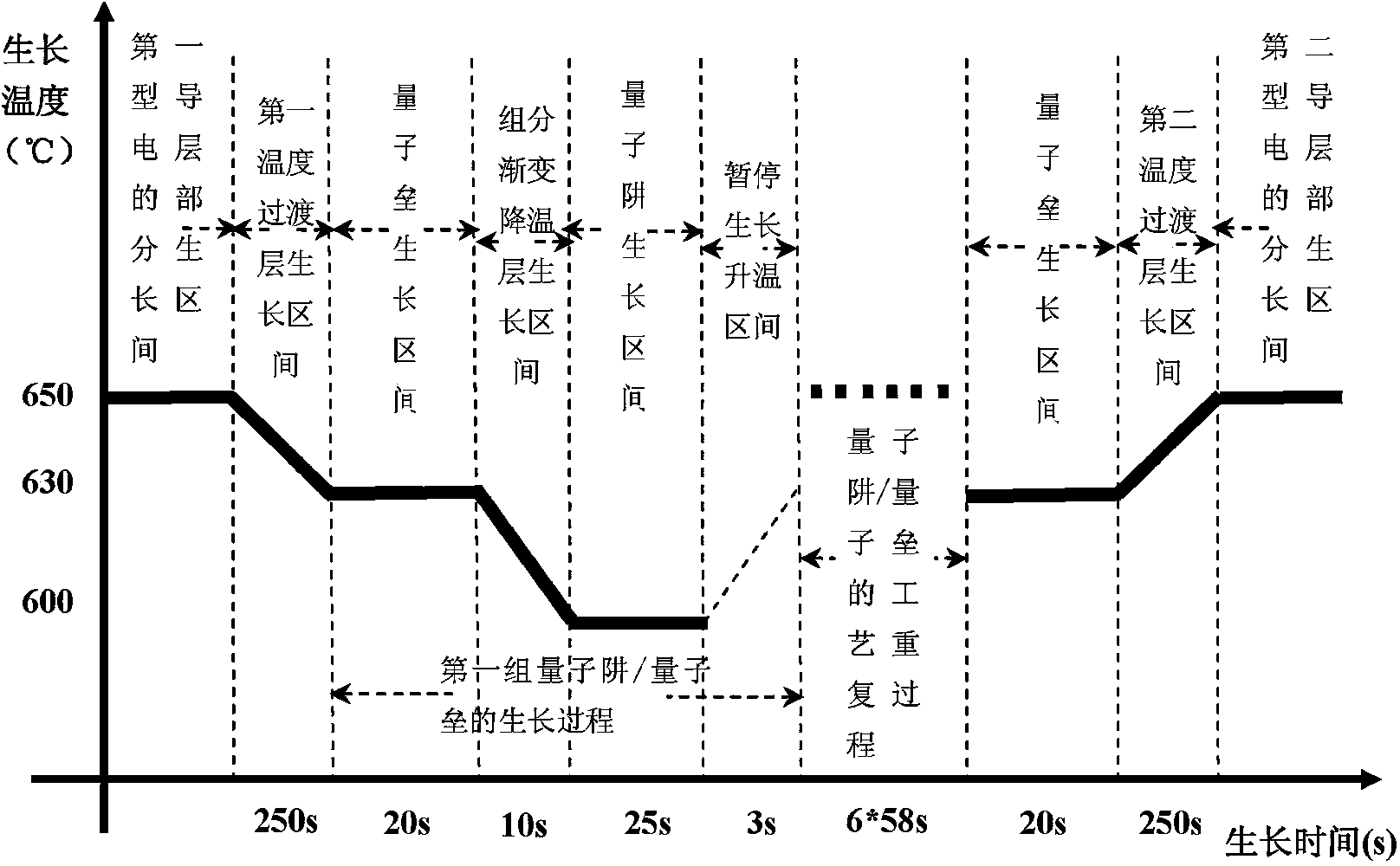

[0068] The active layer 9 is composed of seven sets of quantum barriers 91 , composition gradient cooling layers 92 and quantum wells 93 alternately.

[0069] A method for epitaxial growth of infrared light-emitting diodes with high crystal quality, the specific steps are as follows:

[0070] 1. Using a reaction...

Embodiment 2

[0089]The difference between the second embodiment and the first embodiment is that the active layer 9 is composed of six sets of quantum barriers 91 , composition gradient cooling layers 92 and quantum wells 93 alternately, while the first embodiment has seven sets.

[0090] like Figure 5 As shown, an infrared light-emitting diode, from the bottom to the top of the substrate 1 is a growth buffer layer 2, an etching stop layer 3, an ohmic contact layer 4, a current transmission layer 5, a roughening layer 6, and a first-type conductive layer 7 , a first temperature transition layer 8 , an active layer 9 , a second temperature transition layer 10 , and a second-type conductive layer 11 .

[0091] The roughened layer 6 is composed of four parts, namely the first roughened layer 61, the second roughened layer 62, the third roughened layer 63, and the fourth roughened layer 64; the active layer 9 consists of six groups of quantum barriers 91, Composition gradient cooling layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com