Polysilicon ingot furnace with diversion device

A technology of polysilicon ingot casting furnace and diversion device, which is applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problem that the automatic crystal growth process cannot be carried out normally, the liquid silicon is difficult to form a rotating flow field, and the crystal growth speed Inconvenient measurement and other problems, to achieve the effect of reduced undercooling, uniform radial resistivity, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

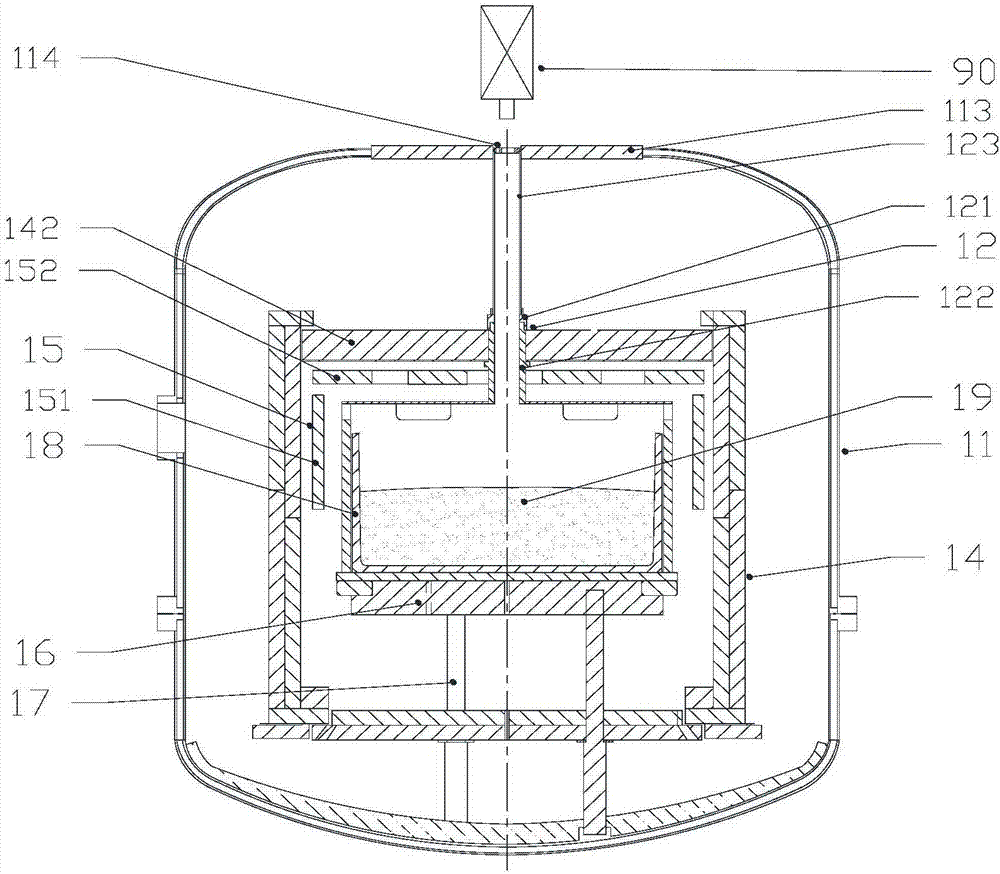

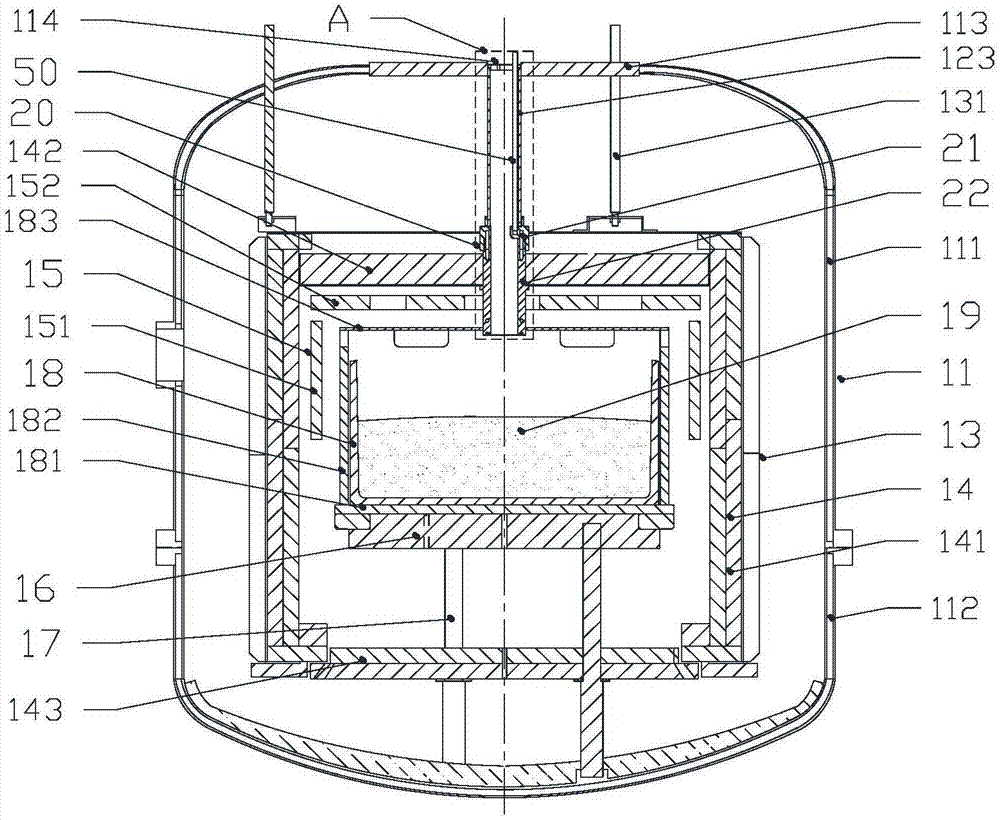

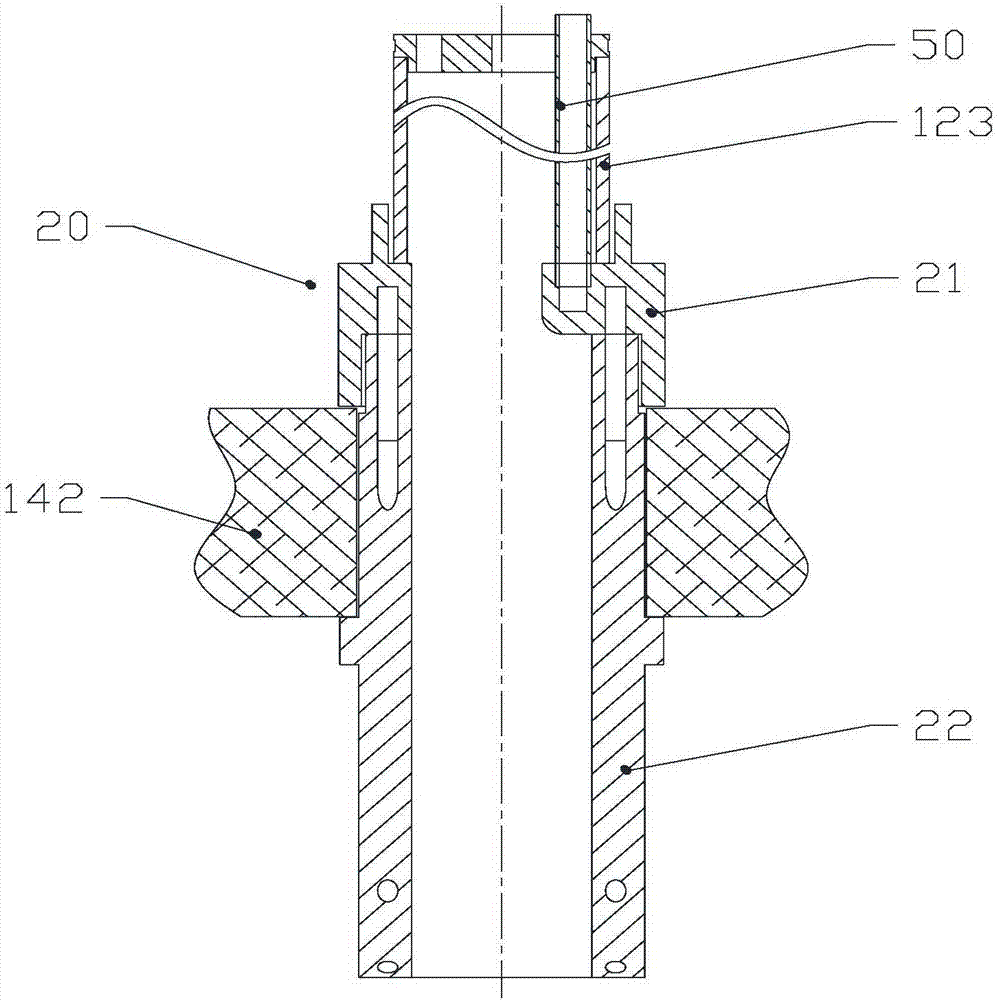

[0061] A kind of polysilicon ingot furnace with guide device of the present invention, as figure 2 As shown, the ingot casting furnace includes a furnace body 11, a cage frame 13, a lifting screw 131, a heat insulation cage 14, a heater 15, a heat exchange platform 16, a graphite column 17, a graphite tube 123, a gas delivery pipe 50 and a flow guide device 20. The furnace body 11 includes an upper furnace body 111 , a lower furnace body 112 and a top end cover 113 , the upper furnace body 111 covers the lower furnace body 112 , and the top end cover 113 covers the top opening of the upper furnace body 111 . Described cage frame 13 is made of 4 side walls, and top surface and bottom surface are open. The cage frame 13 is arranged in the furnace body 11 , and is suspended on the furnace roof of the upper furnace body 111 through a lifting screw 131 . The heat insulation cage 14 is a square cavity composed of four side heat insulation panels 141 , one top insulation panel 142...

Embodiment approach 2

[0070] A kind of polysilicon ingot furnace with guide device of the present invention, as Figure 9 As shown, the ingot casting furnace includes a furnace body 11, a guide assembly 12, a cage frame 13, a lifting screw 131, a heat insulation cage 14, a heater 15, a heat exchange platform 16, a graphite column 17, a gas pipe 50 and a guide Flow device 30. The furnace body 11 comprises an upper furnace body 111, a lower furnace body 112 and a top end cover 113. The upper furnace body 111 is covered on the lower furnace body 112, and the top end cover 113 is covered on the top opening of the upper furnace body 111. The top end cover 113 There is an observation window 114 in the middle. The cage 13 is composed of four sidewalls, the top and the bottom are open, and the cage 13 is suspended on the furnace roof of the upper furnace body 111 through a lifting screw 131 . The heat insulation cage 14 is a square cavity composed of four side heat insulation panels 141 , one top insulat...

Embodiment approach 3

[0078] A kind of polysilicon ingot furnace with guide device of the present invention, as Figure 16 As shown, the polysilicon ingot casting furnace includes a furnace body 11, a guide assembly 12, a cage frame 13, a lifting screw 131, a heat insulation cage 14, a heater 15, a heat exchange platform 16, a graphite column 17, a gas delivery pipe 50 and Flow guiding device 40. The furnace body 11 comprises an upper furnace body 111, a lower furnace body 112 and a top end cover 113. The upper furnace body 111 is covered on the lower furnace body 112, and the top end cover 113 is covered on the top opening of the upper furnace body 111. The top end cover 113 There is an observation window 114 in the middle. The cage 13 is composed of four sidewalls, the top and the bottom are open, and the cage 13 is suspended on the furnace roof of the upper furnace body 111 through a lifting screw 131 . The heat insulation cage 14 is a square cavity composed of four side heat insulation panels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com