Preparation method of scandium nitride cubic crystal

A technology of cubic crystals and scandium nitride, which is applied in the field of preparation of scandium nitride cubic crystals, can solve the problems of restricting the development of semiconductor materials, harsh preparation conditions, cumbersome preparation process, etc., and achieves no template, good crystallinity and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] Example 2 The whole process of preparing ScN cubic crystal.

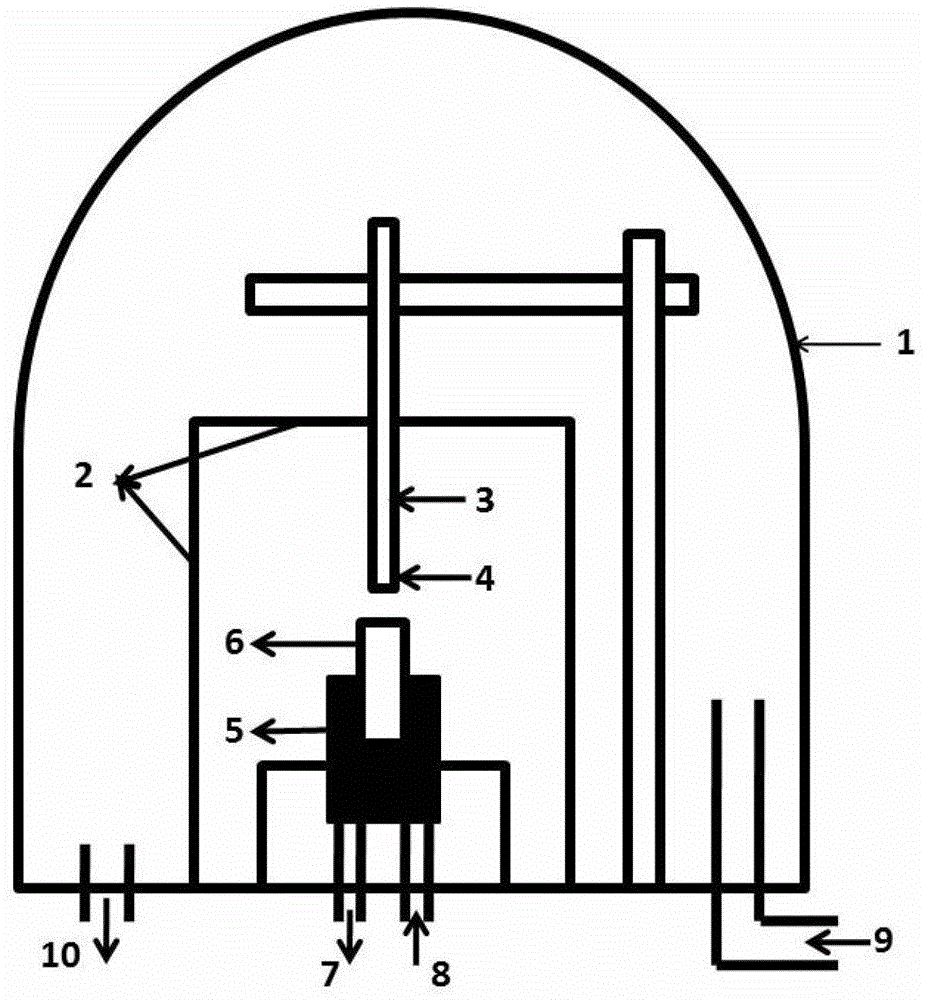

[0032] Using high-purity rare earth metal Sc and nitrogen as raw materials, metal Sc (purity 99.99%) is pre-bridged, and pressed into a metal ingot with a diameter of 12mm and a thickness of 1-3mm. Place the pressed metal Sc ingot in the graphite pot, put it into the anode of the copper pot in the reaction chamber of the DC arc discharge device, and place the cathode of the tungsten rod and the anode of the copper pot opposite to each other. First evacuate the reaction chamber until the air pressure is lower than 1Pa, fill it with high-purity nitrogen (volume fraction greater than 99.99%), repeat vacuuming to below 1Pa to wash away the residual air in the vacuum system, and then pass high-purity nitrogen to the pre- Discharge after setting the pressure at 20kPa. When starting the arc, set the arc current to 100~120A, keep the arc stable at 15~25V, and the length of the positive arc column area is 0.5cm (keep...

Embodiment 3

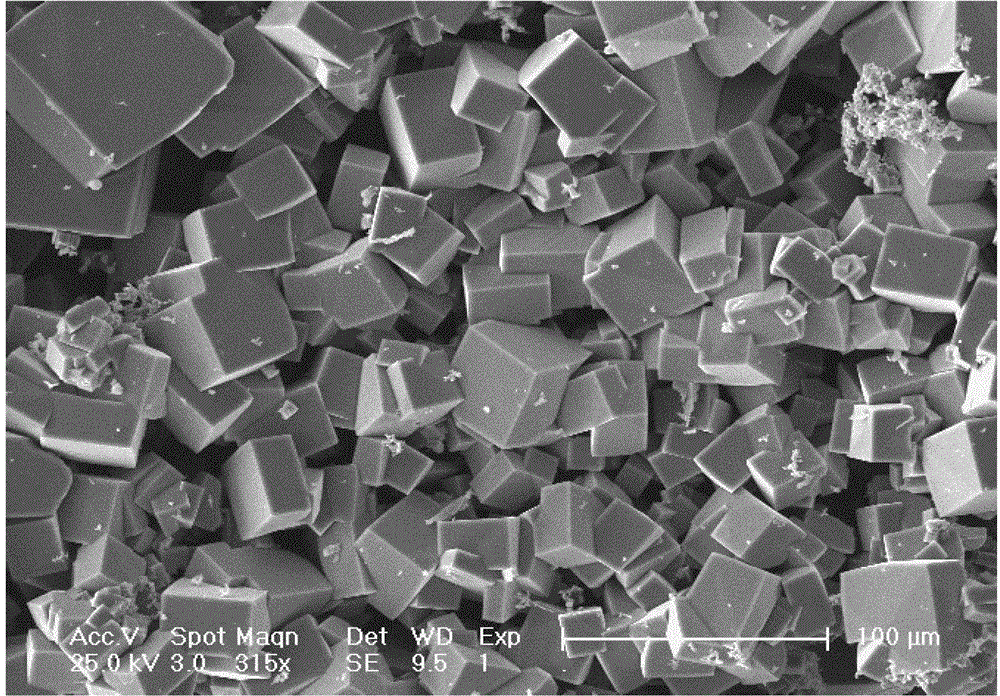

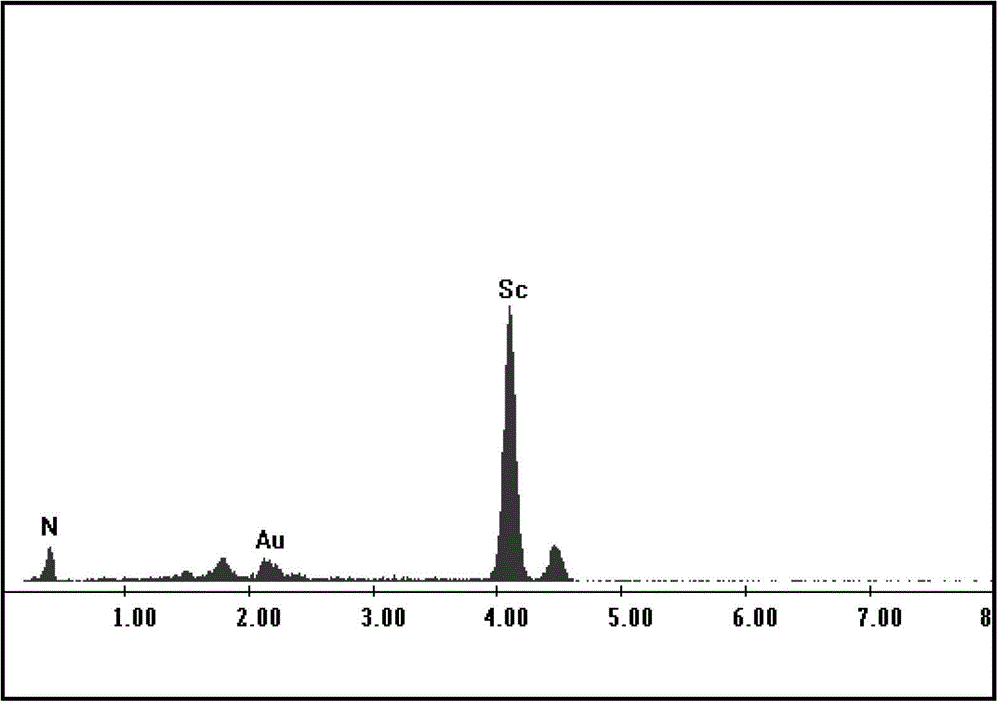

[0035] Embodiment 3 prepares the whole process of ScN cubic crystal

[0036] In embodiment 3, the amount of changing reaction gas is 40kPa, and the reaction time is controlled at 15min. All the other experimental conditions are the same as in embodiment 2. After the reaction, a metal luster, blue-green powder is collected in the anode deposition area (graphite pot). body. Figure 9 The scanning electron microscope pictures of the ScN samples obtained by the improved preparation method are given. The pictures show that the prepared ScN cubic crystals are also sharp-edged, smooth and flat, with a quasi-cubic or cuboid block structure in shape and a size of 20-50 μm.

Embodiment 4

[0037] Embodiment 4 prepares the whole process of ScN cubic crystal

[0038] In embodiment 4, the amount of reaction gas is changed to 10kPa, and the reaction time is controlled at 10min. All the other experimental conditions are the same as in embodiment 2. After the reaction, metallic luster and blue-green are still collected in the anode deposition area (graphite pot). Powder. Figure 10 The scanning electron microscope picture of the ScN sample obtained by this preparation method is given. The picture shows that the prepared ScN cubic crystal is not much different from the samples prepared in Examples 2 and 3, and still maintains a quasi-cubic or cuboid block structure. .

[0039] In Examples 3 and 4, the gas pressure and reaction time were changed respectively, and metallic luster, blue-green powder was still collected in the deposition area of the anode graphite pot. It can be considered that the reaction gas pressure and reaction time have little effect on the morph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com