A kind of method for heterogenous growth of aln on sic seed crystal by pvt method

A seed crystal and heterogeneous technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high impurity content, cracks, and low single crystal rate of AlN seed crystal, so as to achieve low impurity content and guarantee The effect of high flatness and single crystal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 One-step growth

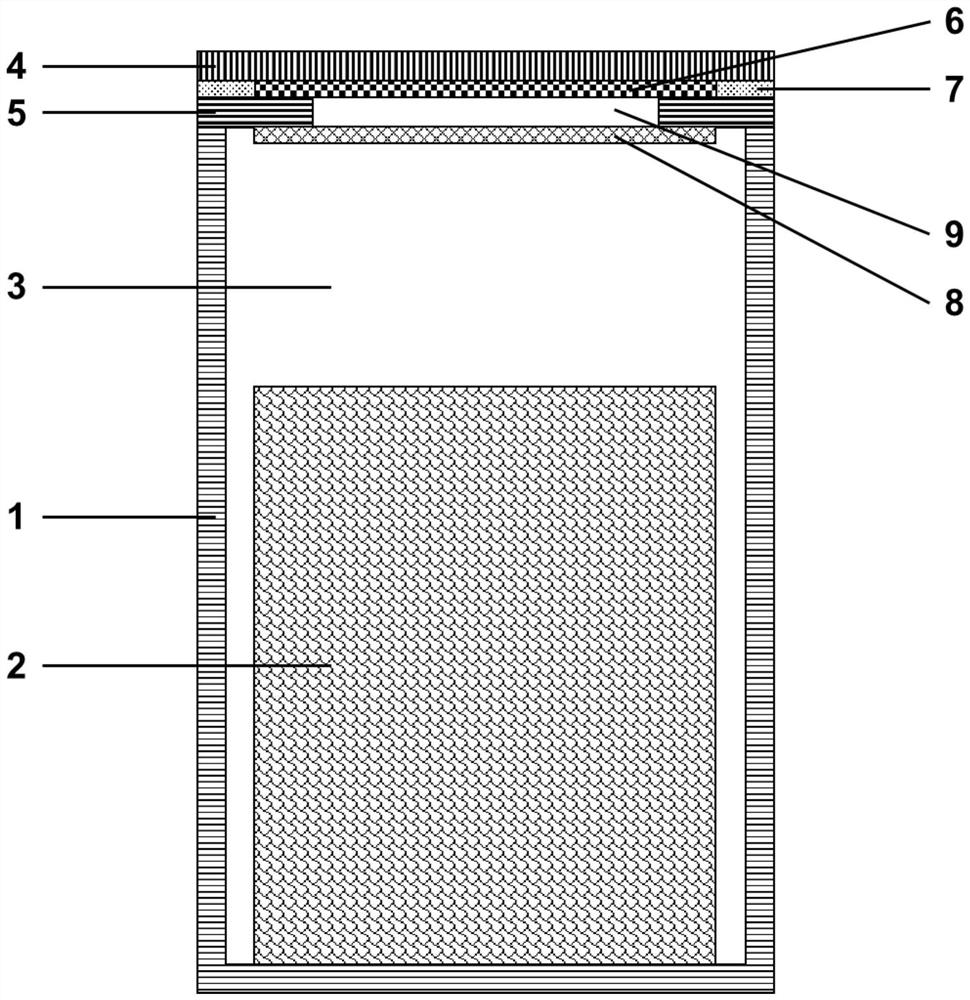

[0036] 1) SiC seed crystal fixation:

[0037] Clean the seed crystal holder polished on one side, the SiC seed crystal and ring polished on both sides, place the seed crystal on the polished surface of the seed crystal holder to ensure a good fit, apply an appropriate amount of AlN adhesive evenly around the seed crystal, and then apply it to the seed crystal. A ring is placed on the crystal to press the edge of the seed crystal and the adhesive to ensure that the seed crystal holder, the seed crystal and the ring are concentric, and the adhesive is solidified, which can inhibit the decomposition and sublimation of the SiC side;

[0038] 2) AlN polycrystalline spacer is fixed:

[0039] The AlN polycrystalline ingot is cut, ground and polished to obtain an AlN polycrystalline wafer with a size similar to that of the SiC seed crystal. The edge of the AlN polycrystalline ingot is bonded to the placed ring with an adhesive, and it is also kept con...

Embodiment 2

[0048] Example 2 Two-step growth

[0049] 1) SiC seed crystal fixation:

[0050] Clean the seed crystal holder polished on one side, the SiC seed crystal and ring polished on both sides, place the seed crystal on the polished surface of the seed crystal holder to ensure a good fit, apply an appropriate amount of AlN adhesive evenly around the seed crystal, and then apply it to the seed crystal. A ring is placed on the crystal to press the edge of the seed crystal and the adhesive to ensure that the seed crystal holder, the seed crystal and the ring are concentric, and the adhesive is solidified, which can inhibit the decomposition and sublimation of the SiC side;

[0051] 2) AlN polycrystalline spacer is fixed:

[0052] The AlN polycrystalline ingot is cut, ground and polished to obtain an AlN polycrystalline wafer with a size similar to that of the SiC seed crystal. The edge of the AlN polycrystalline ingot is bonded to the placed ring with an adhesive, and it is also kept c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com