Drainage device capable of changing flow direction of carrier gas

A carrier gas and drainage technology, applied in the field of crystal growth equipment, can solve the problems of supercooling, inconvenient measurement of crystal growth rate, difficulty in forming a rotating flow field, etc. Avoid local supercooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

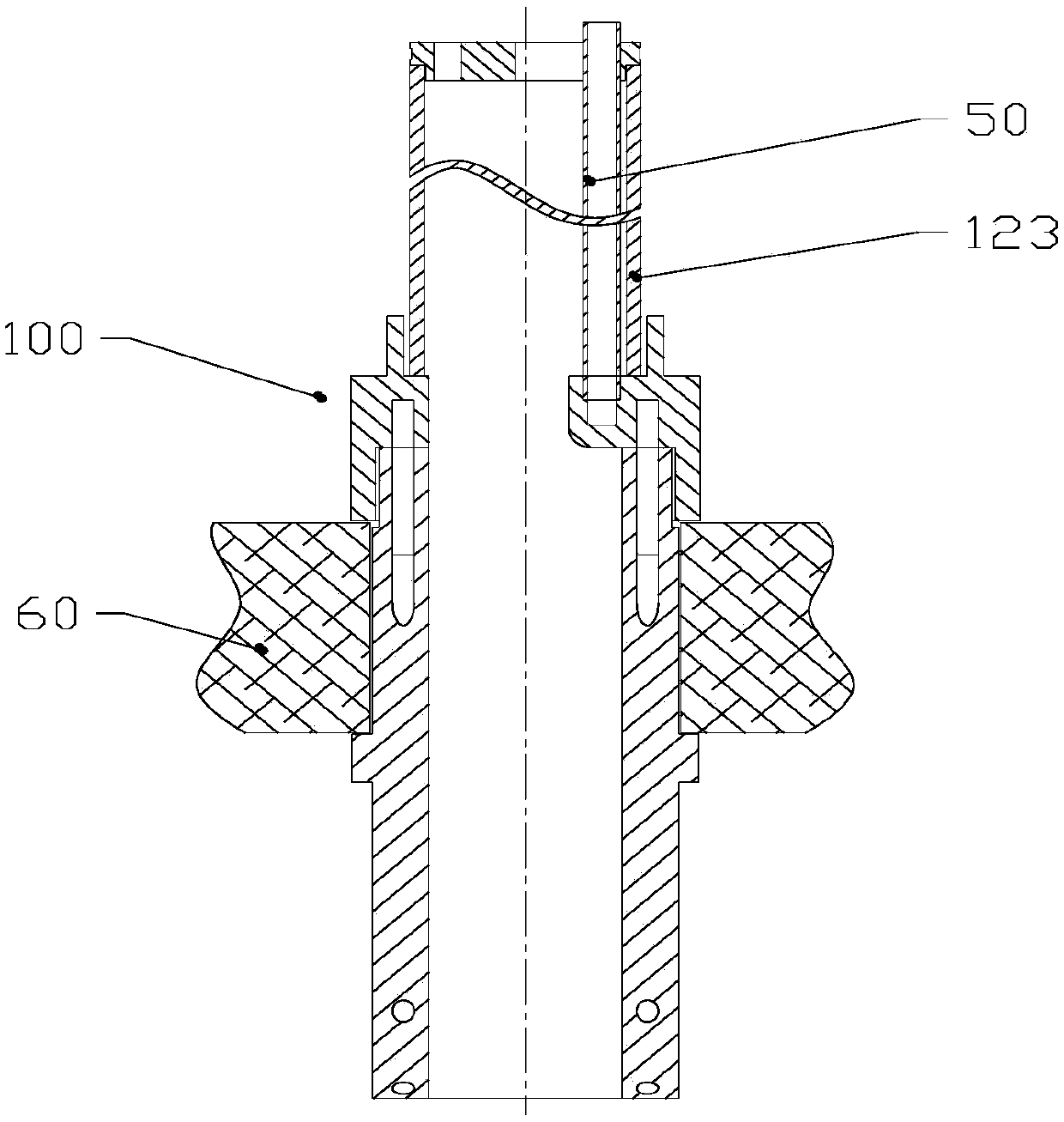

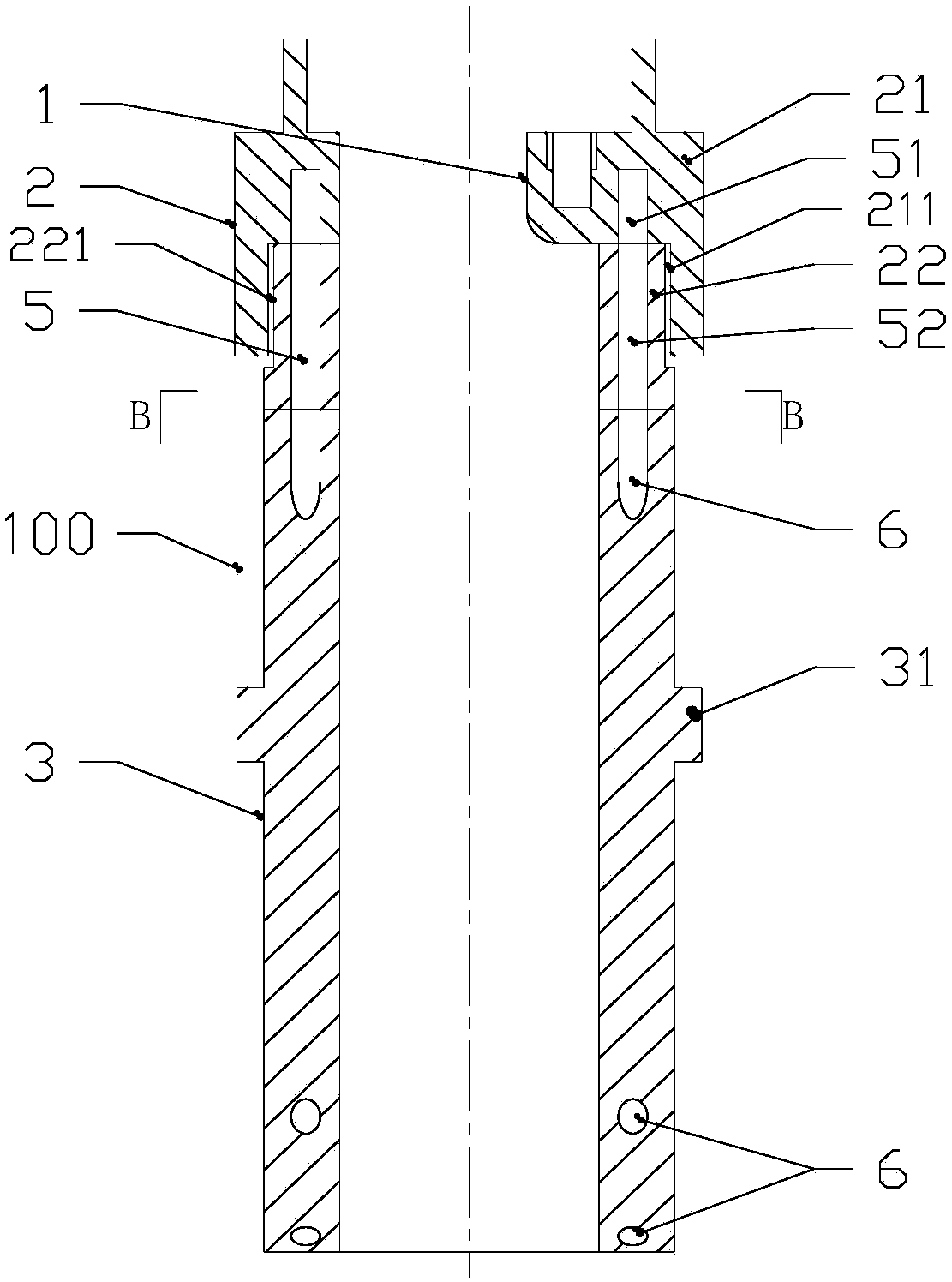

[0048] A drainage device for changing the direction of carrier gas in the present invention, such as figure 2 , image 3 As shown, the drainage device 100 includes an air intake part 1 , a diversion part 2 and a drainage part 3 . The air intake part 1 and the diverter part 2 are fixed, and the diverter part 2 and the drainage part 3 are fixed. Both the splitter part 2 and the drainage part 3 are columnar bodies with through holes arranged along the direction of their centerlines, preferably cylinders. Such as image 3 As shown, the diversion part 2 includes a first diversion part 21 and a second diversion part 22, and the second diversion part 22 and the drainage part 3 are integrally formed to form a drainage tube. The lower end of the first splitter 21 is provided with an internal thread 211, and the upper end of the second splitter 22 is provided with an external thread 221; the internal thread 211 and the external thread 221 are matched, such as image 3 shown. The m...

Embodiment approach 2

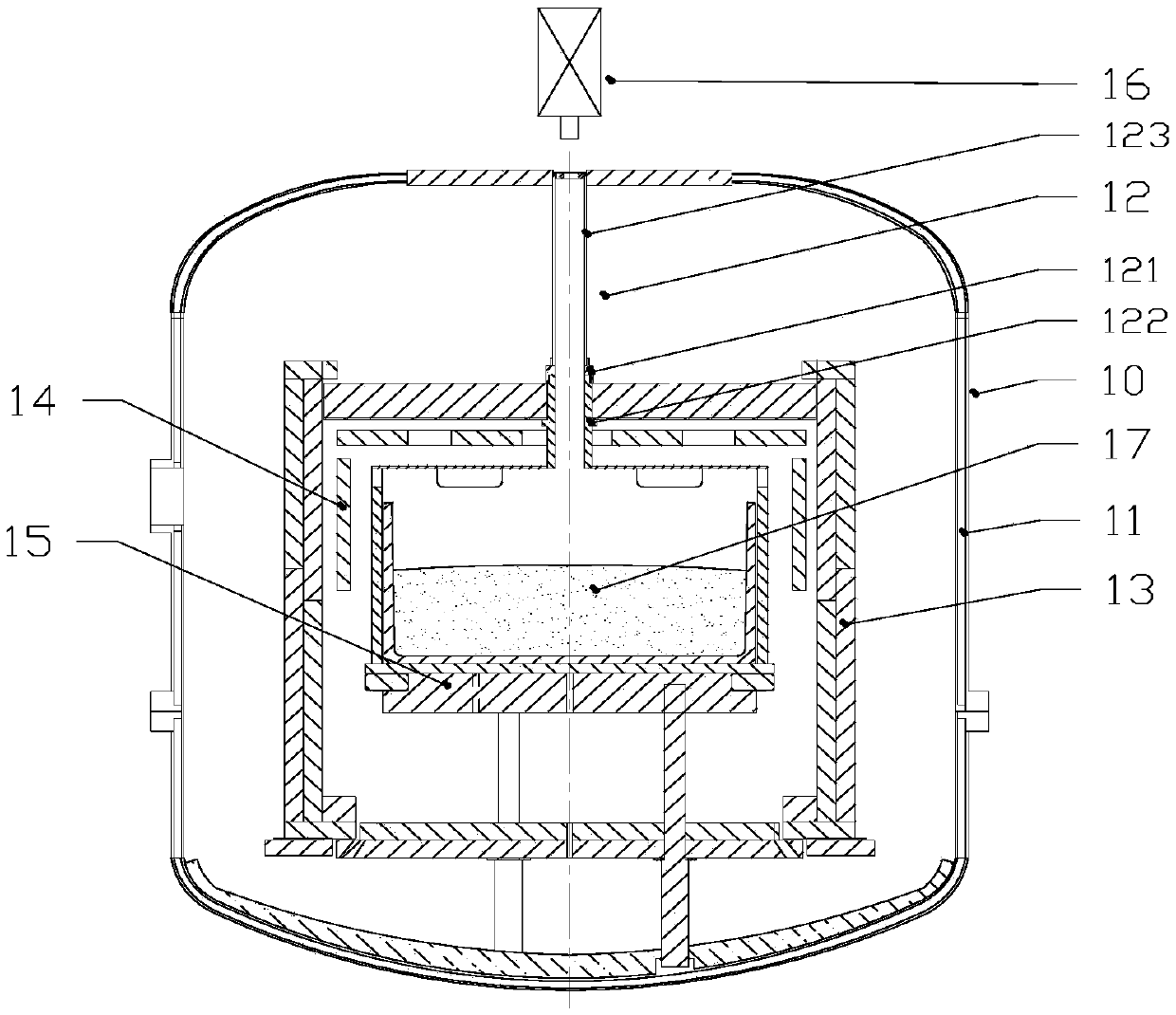

[0055] A drainage device for changing the direction of carrier gas in the present invention, such as Figure 11 , Figure 12 As shown, the drainage device 100 includes a fixing part 10 , an air intake part 1 , a diverter part 2 and a drainage part 3 . The air intake part 1 and the diverter part 2 are fixed, the fixed part 10 and the diverter part 2 are axially fixed, and the diverter part 2 and the drainage part 3 are axially fixed. Furthermore, the fixing part 10, the diverter part 2 and the drainage part 3 are formed integrally, and are columnar bodies with through-holes arranged along the direction of their centerlines, that is, cylinders, preferably cylinders. The drainage device 100 is made of relatively low-cost graphite, preferably isostatic graphite, and may also be relatively expensive molybdenum or titanium. An internal thread 11 for fixed connection is provided on the inner wall of the fixing part 10 , and the internal thread 11 extends along the centerline of the...

Embodiment approach 3

[0061] A drainage device for changing the direction of carrier gas in the present invention, such as Figure 18 , Figure 19 As shown: the drainage device 100 includes a fastening part 10 , an air intake part 1 , a diversion part 2 , and a drainage part 3 . The drainage device 100 is made of molybdenum, and high-cost high-temperature-resistant materials such as titanium can also be used. Both the fastening part 10 and the diverter part 2 are cylindrical bodies with through-holes arranged along the direction of their centerlines, that is, cylinders, preferably cylinders. The fastening part 10 and the top of the splitter part 2 are axially fixed. Internal threads 11 along the centerline direction of the fastening portion 10 are provided on the inner sidewall of the fastening part 10, and external threads can also be provided on the outer sidewall thereof as required. The splitter 2 is a closed cavity in the shape of an annular cylinder, mainly composed of an inner wall, an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com