Chamfering abrasive wheel, preparation method thereof and wafer machining device

A grinding wheel and chamfering technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as diamond coating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

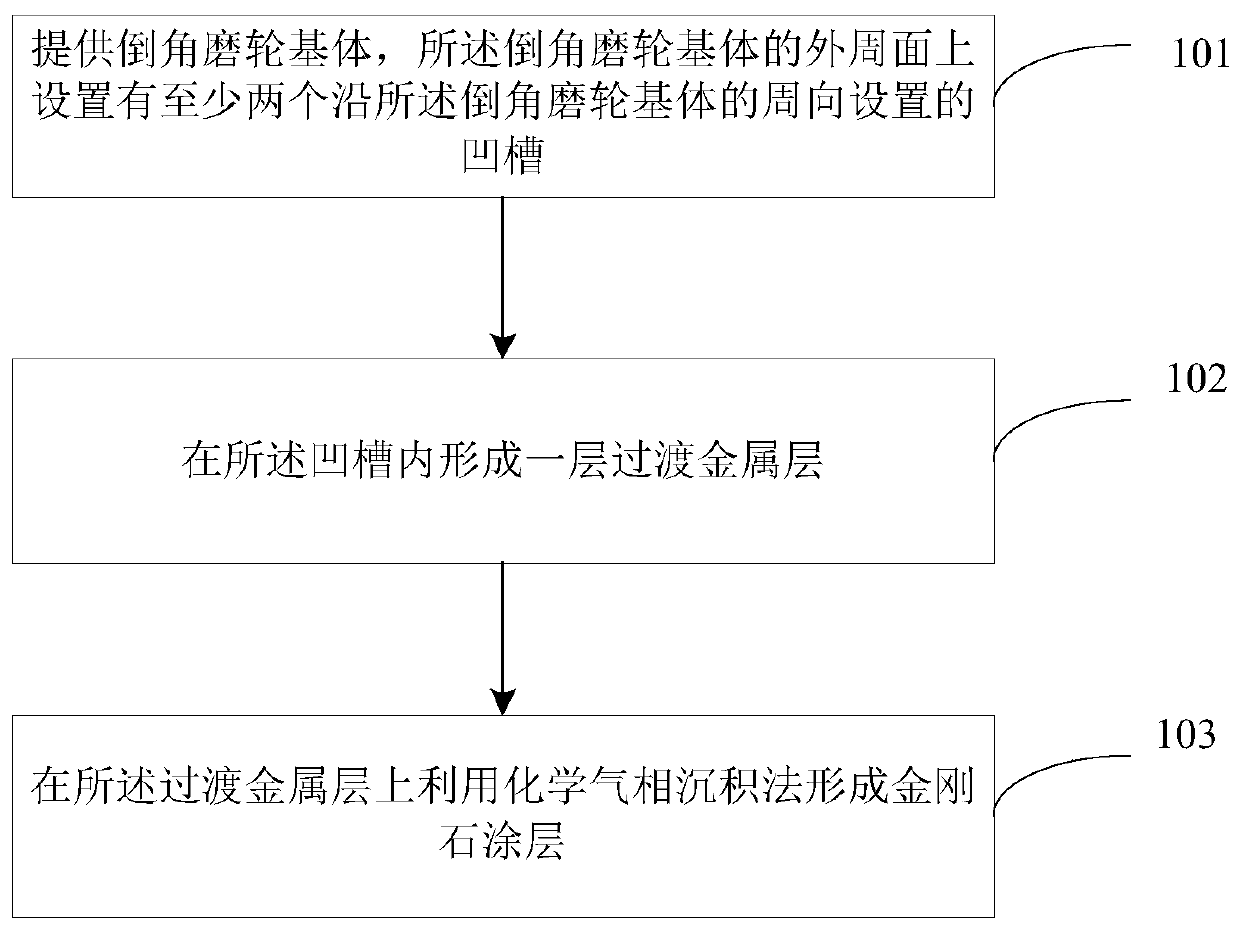

Method used

Image

Examples

preparation example Construction

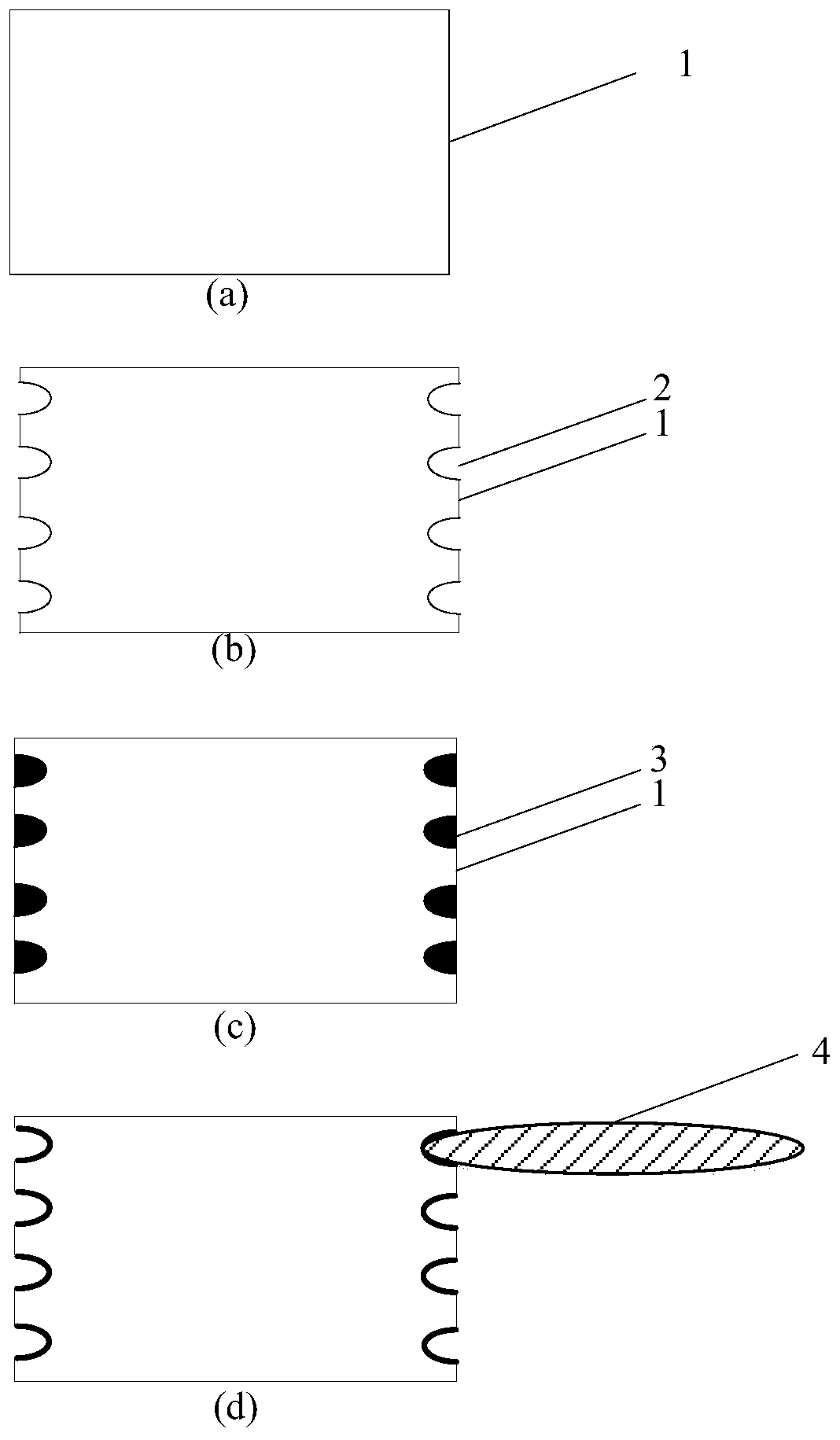

[0036] figure 1 It is a schematic diagram of the preparation process of the existing chamfering grinding wheel, such as figure 1 As shown, the manufacturing method of the existing chamfering grinding wheel comprises: step a, making the chamfering grinding wheel base 1; step b, opening the grinding groove 2 on the side of the chamfering grinding wheel according to the shape requirements of use; step c, adding a certain proportion of diamond particles 3. Fill the grinding groove 2 with adhesive, and combine it with the chamfering grinding wheel base 1 through high-temperature sintering; step d, use a dressing wheel 4 with a certain shape to grind off the excess diamond particles 3 to form a grinding groove of the desired shape 2.

[0037] However, due to the high interfacial energy and chemical inertness of diamond, the bonding performance between the diamond coating of the existing chamfering grinding wheel and the substrate 1 of the chamfering grinding wheel is very poor. , ...

Embodiment 1

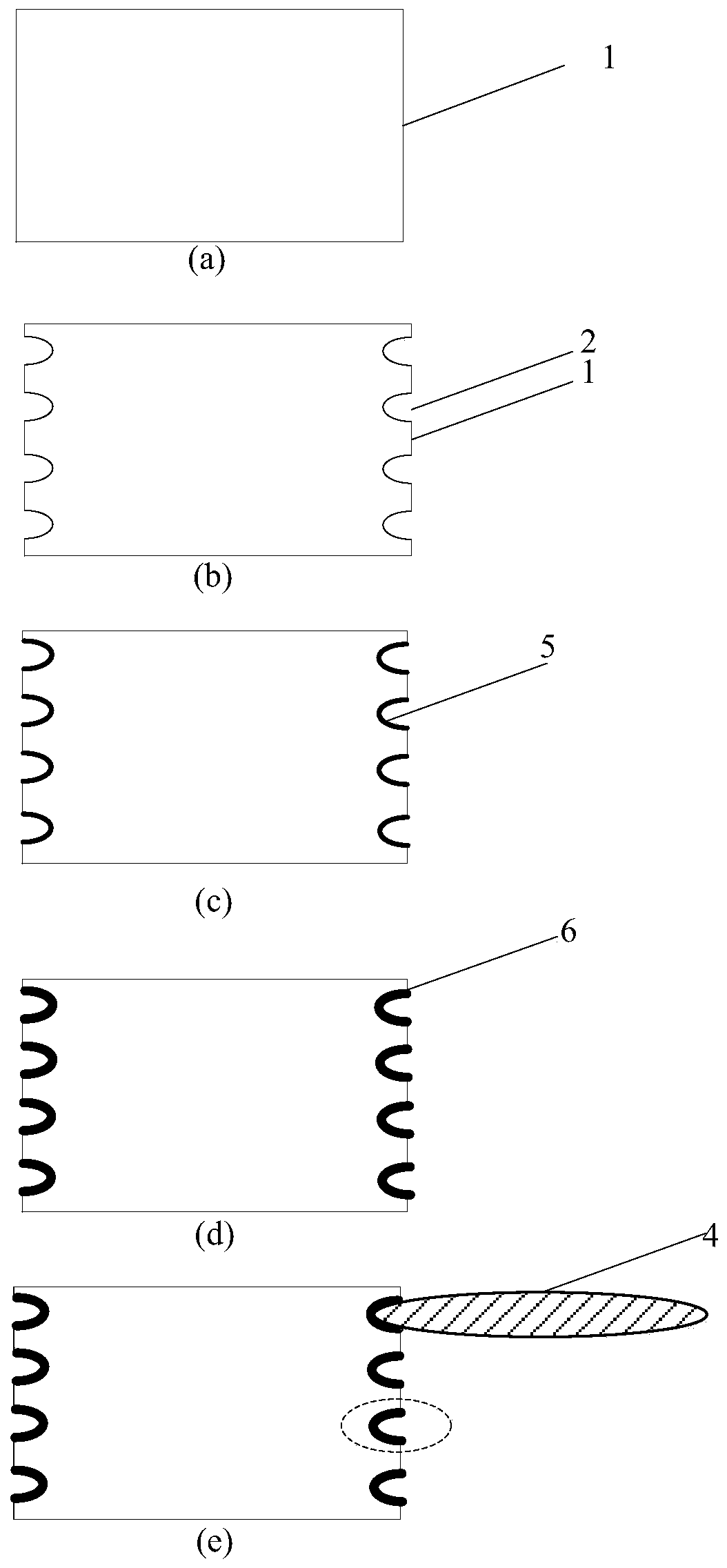

[0052] Metal Mo is used as the transition metal layer, such as image 3 Shown, the preparation technology of chamfering grinding wheel comprises the following steps:

[0053] Step a. making the chamfering grinding wheel base 1;

[0054] Step b. Open the grinding groove 2 on the side of the chamfering grinding wheel according to the shape requirements;

[0055] Step c. Prepare a metal molybdenum layer in the grinding tank 2 as the transition metal layer 5 by magnetron sputtering. Specifically, a Mo plate with a purity of 99.999% can be used as the sputtering target, and argon gas is used as the shielding gas , the deposition temperature is 800°C, the chamber pressure is 0.8Pa, and the deposition time is 60min;

[0056] Step d. Deposit a layer of diamond coating 6 on the transition metal layer 5 using hot filament plasma chemical vapor deposition (HFCVD), specifically CH 4 and H 2 As a plasma reactive gas, CH 4 and H 2 The ratio is 4%, CH 4 and H 2 The flow rates are 16scc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com