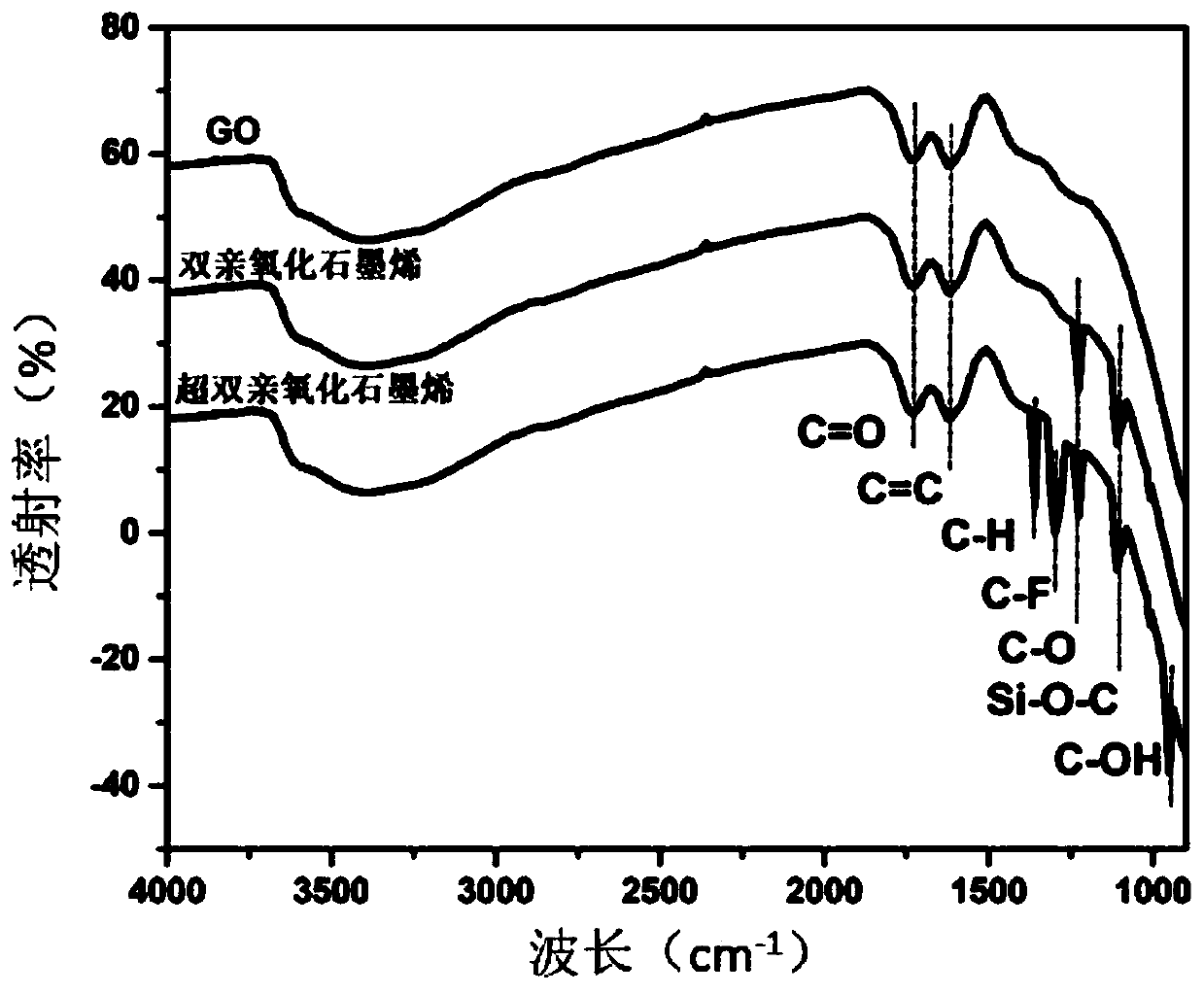

Super-amphiphilic graphene oxide as well as preparation method and application thereof

A graphene and graphene dispersion technology, applied in the field of chemical materials, can solve the problems of not being super-hydrophilic, toxic, and expensive, and achieve the effects of excellent lipophilicity, low cost, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Dilute the graphene oxide purchased with deionized water to obtain a deionized water dispersion of graphene oxide with a concentration of 1.0mg / ml, and use a high-speed mixer to perform high-speed shearing on the deionized water dispersion of graphene oxide , the control stirring rate is 2000rpm, and the stirring time is 3 hours. After high-speed shearing, the particle size of graphene oxide is measured by a nanometer particle size-zeta potential meter to be 100-200nm, and the graphene oxide after shearing is diluted again, To obtain a 0.1 mg / ml graphene oxide aqueous dispersion.

[0060] (2) Weigh 13ml of kerosene for later use, hydrolyze 0.08g of perfluorodecyltriethoxysilane in 12ml of ethanol, and prepare 25ml of kerosene / perfluorodecyltriethoxysilane / ethanol dispersion.

[0061] (3) 100ml of the graphene oxide aqueous dispersion after shearing in step (1) is added dropwise in the kerosene / perfluorodecyltriethoxysilane / ethanol dispersion prepared in the step (2)...

Embodiment 2

[0067] (1) Dilute the graphene oxide purchased with deionized water to obtain a deionized water dispersion of graphene oxide with a concentration of 2mg / ml, and use a high-speed stirrer to carry out high-speed shearing to the deionized water dispersion of graphene oxide, The control stirring rate is 1000rpm, and the stirring time is 3 hours. After high-speed shearing, the particle diameter of the graphene oxide measured by a nanoparticle diameter-zeta potential meter is 100-200nm, and the graphene oxide after shearing is diluted again to A 0.2 mg / ml graphene oxide aqueous dispersion was obtained.

[0068] (2) Weigh 10 g of paraffin for later use, hydrolyze 0.1 g of perfluorododecylsilane in 15 ml of methanol, and prepare 25 ml of paraffin / perfluorododecylsilane / methanol dispersion.

[0069] (3) Add 100ml of the graphene oxide aqueous dispersion after shearing in step (1) dropwise into the prepared paraffin / perfluorododecylsilane / methanol dispersion in step (2), then at a speed...

Embodiment 3

[0075] (1) Dilute the graphene oxide purchased with deionized water to obtain a deionized water dispersion of graphene oxide with a concentration of 1.5mg / ml, and use a high-speed mixer to perform high-speed shearing on the deionized water dispersion of graphene oxide , the control stirring rate is 1500rpm, and the stirring time is 2.5 hours. After high-speed shearing, the particle diameter of graphene oxide is measured by a nanometer particle size-zeta potential meter to be 100-200nm, and the graphene oxide after shearing is diluted again, To obtain a 0.12 mg / ml graphene oxide aqueous dispersion.

[0076] (2) Weigh 10 ml of kerosene for later use, hydrolyze 0.12 g of perfluorodecyltrimethoxysilane in 20 ml of ethanol, and prepare 30 ml of kerosene / perfluorodecyltrimethoxysilane / ethanol dispersion.

[0077] (3) 100ml of the graphene oxide aqueous dispersion after shearing in the step (1) is added dropwise in the kerosene / perfluorodecyltrimethoxysilane / ethanol dispersion prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com