Preparation method of bismuth vanadate molybdate pigment

A technology of bismuth molybdovanadate and pigments, which is applied in the field of preparation of bismuth molybdovanadate pigments, can solve the problems of insufficient quality and high temperature resistance, liquid phase precipitation-calcination method consumes a lot of acid and alkali, etc., and achieves good product quality, Easy to achieve industrialization and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

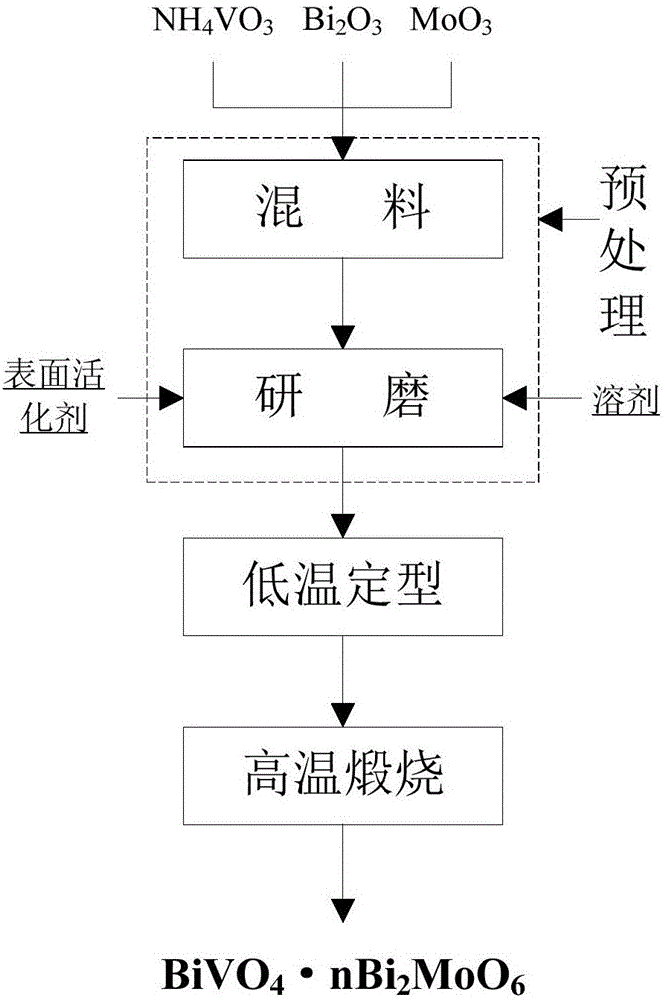

Method used

Image

Examples

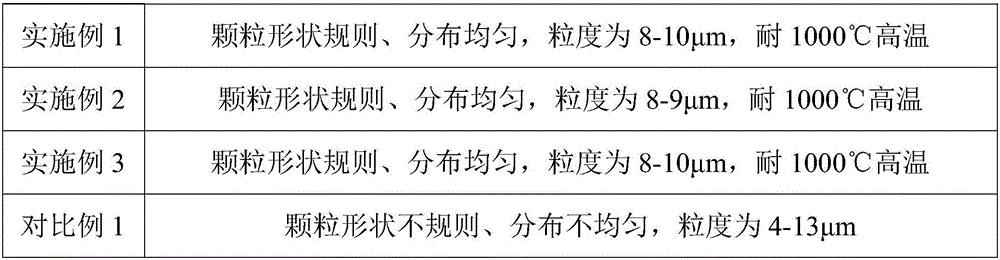

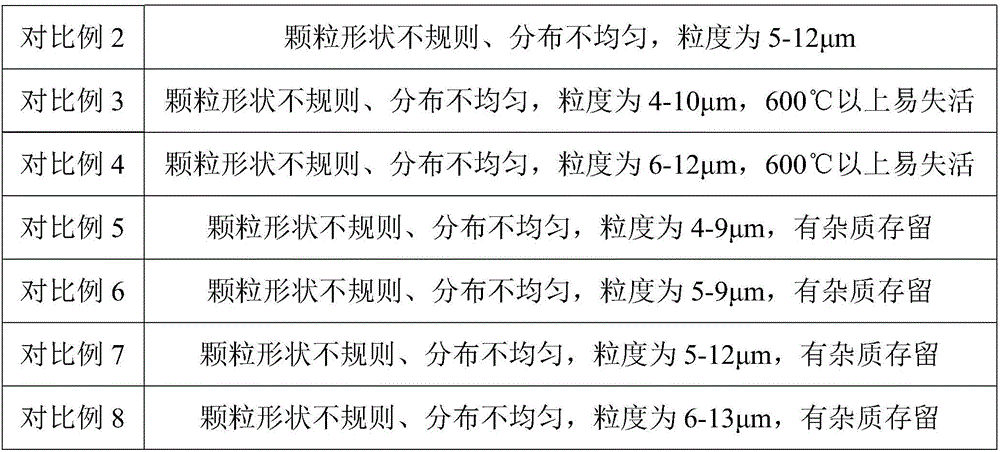

Embodiment 1

[0068] Weigh 40g grade 99.95wt% NH 4 VO 3 , 199.2gBi 2 o 3 , 34.36gMoO 3 The materials were mixed, and 91.2 g of ethylene glycol and 1.4 g of surfactant were added to the mixture, followed by ball milling and filtering after 60 min of ball milling. After filtration, it is roasted in a muffle furnace. First, the temperature is raised to 180°C at a rate of 3.5°C / min, and kept for 80 minutes; then the temperature is raised to 550°C at a rate of 2.5°C / min, and kept for 8 hours. Then continue to raise the temperature in the muffle furnace to 1100°C at a heating rate of 4°C / min, and keep it for 5 hours; then cool it down to 960°C at a rate of 5°C / min, and hold it for 8 hours. A BiVO with composite structure was prepared 4 0.75Bi 2 MoO 6 product.

Embodiment 2

[0070] Weigh 45g grade 99.95wt% NH 4 VO 3 , 161.3gBi 2 o 3 , 20.62gMoO 3 The materials were mixed, and 50.42 g of ethylene glycol and 2.27 g of surfactant were added to the mixture, and then ball milled, and filtered after 100 min of ball milling. After filtration, it is roasted in a muffle furnace. Firstly, the temperature is raised to 210°C at a rate of 3.3°C / min and kept for 100 minutes; then the temperature is raised to 580°C at a rate of 2.7°C / min and kept for 9 hours. Then continue to raise the temperature in the muffle furnace to 1050°C at a rate of 3.8°C / min, and keep it for 6 hours; then cool it down to 900°C at a rate of 5.2°C / min, and keep it for 6 hours. A BiVO with composite structure was prepared 4 0.4Bi 2 MoO 6 product.

Embodiment 3

[0072] Weigh 50g grade 99.95wt% NH 4 VO 3 , 139.4gBi 2 o 3 , 11.45gMoO 3 The materials were mixed, and 33.5 g of ethylene glycol solution and 4.07 g of surfactant were added to the mixture, and then ball milled, and filtered after 30 minutes of ball milling. After filtration, it is roasted in a muffle furnace. Firstly, the temperature is raised to 240°C at a rate of 4°C / min, and kept for 120 minutes; then, the temperature is raised to 600°C at a rate of 2°C / min, and kept for 11 hours. Then continue to raise the temperature in the muffle furnace to 1200°C at a rate of 4.5°C / min, and keep it for 3h; then cool it down to 1000°C at a rate of 4.5°C / min, and keep it for 4h. A BiVO with composite structure was prepared 4 0.2Bi 2 MoO 6 product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com