Preparation method and application of corn starch porous carbon packaged core-shell structure silicon/carbon material

A technology of corn starch and core-shell structure, which is applied in the field of nanomaterials and chemical power sources, can solve problems such as shedding, powdering of active substances, and affecting the cycle life of materials, and achieve the effects of simple and safe preparation process, good cycle life and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

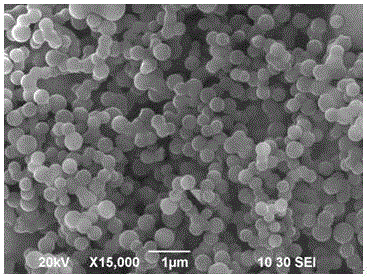

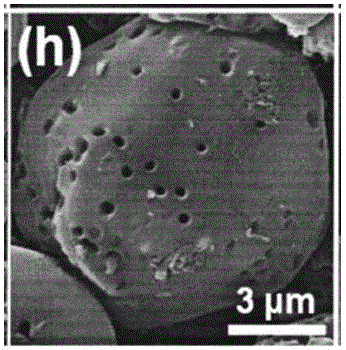

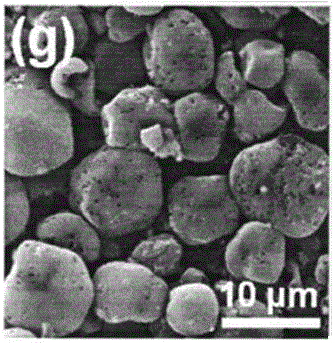

[0030] 1. Preparation of cornstarch porous carbon

[0031] Weigh 4.523 g of disodium hydrogen phosphate and 0.774 g of citric acid to prepare a pH=4.5 buffer solution; stir 20 g of cornstarch and 40 mL of buffer solution in a water bath at 50°C for 10 min with magnetic force to obtain a starch suspension; Weighed 0.2 g of amylase and 20 mL of buffer solution, stirred evenly to prepare an enzyme liquid; slowly added the enzyme liquid into the starch suspension, and reacted for 12 h in a water bath at 50 °C with magnetic stirring. Suction filtration, washing, drying and grinding the porous starch. The porous starch was transferred to an oven and reacted at 180 °C for 24 h to obtain pre-oxidized porous starch; the pre-oxidized porous starch was placed in a tube furnace and calcined in a protective atmosphere at 900 °C for 3 h at a heating rate of 5°C / min, cooled to room temperature, and ground to obtain cornstarch porous carbon.

[0032] 2. Preparation of core-shell silicon / car...

Embodiment 2

[0037] 1. Preparation of cornstarch porous carbon

[0038]Weigh 4.523 g of disodium hydrogen phosphate and 0.774 g of citric acid to prepare a pH=4.5 buffer solution; stir 20 g of cornstarch and 40 mL of buffer solution in a water bath at 50°C for 10 min with magnetic force to obtain a starch suspension; Weighed 0.2 g of amylase and 20 mL of buffer solution, stirred evenly to prepare an enzyme liquid; slowly added the enzyme liquid into the starch suspension, and reacted for 12 h in a water bath at 50 °C with magnetic stirring. Suction filtration, washing, drying and grinding the porous starch. The porous starch was transferred to an oven and reacted at 150 °C for 8 h to obtain pre-oxidized porous starch; the pre-oxidized porous starch was placed in a tube furnace and calcined in a protective atmosphere at 800 °C for 2 h at a heating rate of 5°C / min, cooled to room temperature, and ground to obtain cornstarch porous carbon.

[0039] 2. Preparation of core-shell silicon / carbo...

Embodiment 3

[0044] 1. Preparation of cornstarch porous carbon

[0045] Weigh 4.523 g of disodium hydrogen phosphate and 0.774 g of citric acid to prepare a pH=4.5 buffer solution; stir 20 g of cornstarch and 40 mL of buffer solution in a water bath at 50°C for 10 min with magnetic force to obtain a starch suspension; Weighed 0.2 g of amylase and 20 mL of buffer solution, stirred evenly to prepare an enzyme liquid; slowly added the enzyme liquid into the starch suspension, and reacted for 12 h in a water bath at 50 °C with magnetic stirring. Suction filtration, washing, drying and grinding the porous starch. The porous starch was transferred to an oven and reacted at 200 °C for 36 h to obtain pre-oxidized porous starch; the pre-oxidized porous starch was placed in a tube furnace and calcined in a protective atmosphere at 1000 °C for 6 h at a heating rate of 5°C / min, cooled to room temperature, and ground to obtain cornstarch porous carbon.

[0046] 2. Preparation of core-shell silicon / ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com