Preparation method for bismuth oxyiodide/graphene oxide compound visible light catalytic material

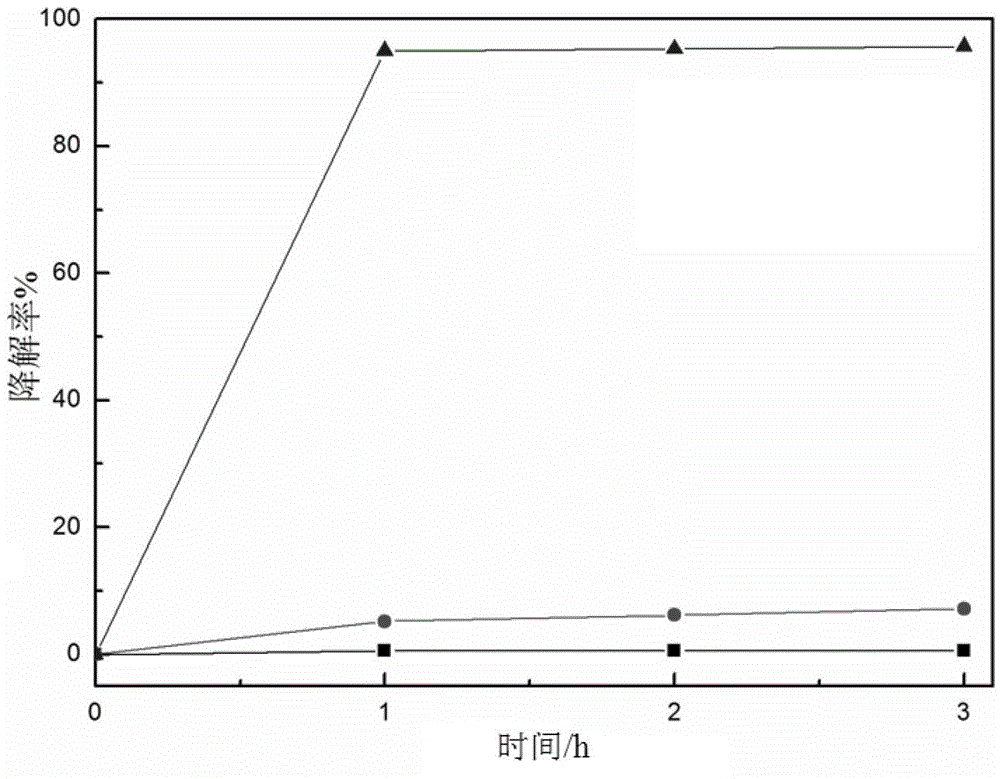

A graphene composite, bismuth oxyiodide technology, applied in the field of visible light catalytic material preparation, can solve the problems of complex photocatalyst operation, unsuitable for large-scale production, and high equipment requirements, achieve large-scale production, improve photocatalysis Active, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: This embodiment is a preparation method of bismuth oxyiodide / graphene oxide composite visible light catalytic material, which is specifically completed according to the following steps: 1. Preparation of graphene oxide dispersion: first, graphite powder is used as raw material Graphite oxide is produced by the improved Hummers method, and then the graphite oxide is dispersed in deionized water at an ultrasonic frequency of 40Hz~250Hz. Graphene dispersion; 2. Add iodide to the graphene oxide dispersion with a concentration of 0.1mg / mL~1.0mg / mL prepared in step 1, and stir for 10min~50min at a stirring speed of 200r / min~900r / min , then add Bi(NO 3 ) 3 ·5H 2 O, and continue to mix and stir at a stirring speed of 200r / min~900r / min for 10min~60min to make a suspension; 3. In a water bath with a temperature of 60°C~90°C, an ultrasonic frequency of 40Hz~250Hz and a stirring speed of Under the condition of 200r / min~900r / min, the suspension obtained in ...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, graphite oxide is dispersed in deionized water at an ultrasonic frequency of 80 Hz to 200 Hz, and the ultrasonic dispersion time is 1.5 h to 2.5 h, which is obtained A graphene oxide dispersion with a concentration of 0.1 mg / mL to 1.0 mg / mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of the iodide added in step 2 to the graphite oxide described in step 1 is (80-150):1. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com