A kind of preparation method and application of rice granular α-ferric oxide

A technology of ferric oxide and rice grains, applied in the direction of iron oxide, iron oxide/iron hydroxide, nanotechnology, etc., to achieve the effects of concentrated particle size distribution, good comprehensive electrochemical performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 6.75 g of ferric chloride hexahydrate and 3.75 g of polyethylene glycol into 200 ml of deionized water, and stir mechanically for 0.5 hour to obtain a uniform mixed solution. The mixed solution was transferred to the bottom of the hydrothermal reaction tank and reacted at 160° C. for 12 hours. The hydrothermal product was washed several times by centrifugation with deionized water and absolute ethanol, and after vacuum freeze-drying, α-Fe 2 o 3 Precursor. The obtained material was calcined at 300°C for 2 hours and cooled to room temperature to obtain rice-like α-Fe 2 o 3 Material.

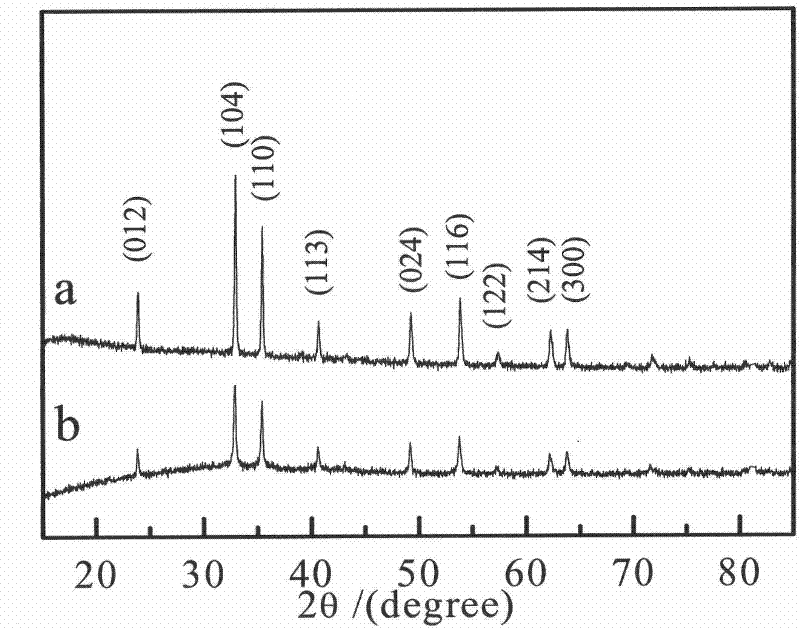

[0019] figure 1 a is the rice granular α-Fe that embodiment 1 obtains 2 o 3 The X-ray diffraction (XRD) pattern.

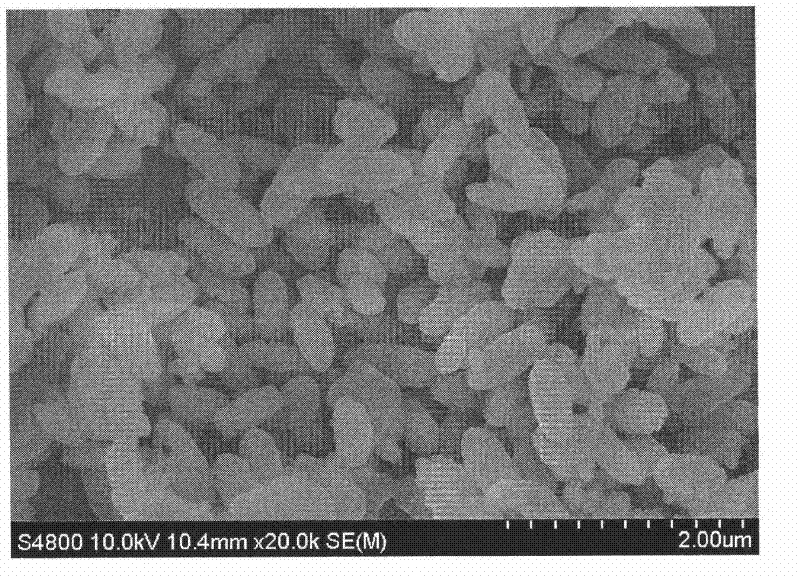

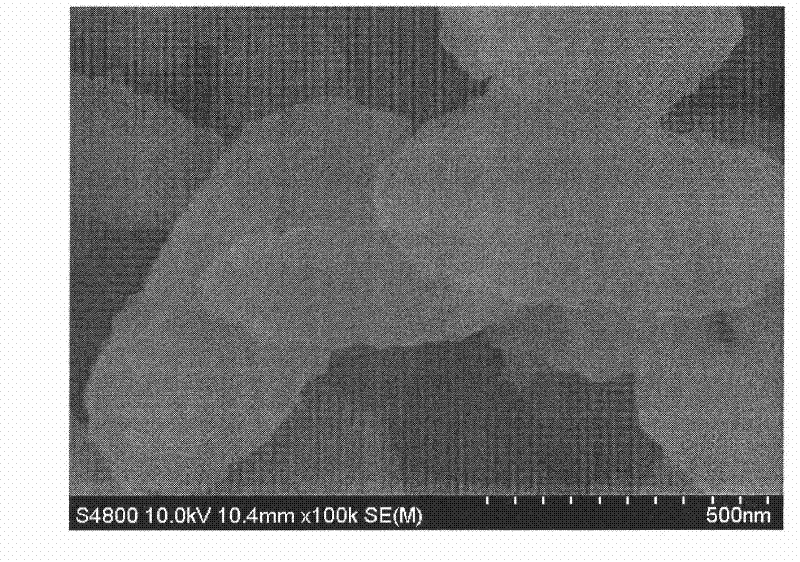

[0020] figure 2 and image 3 Be the rice granular α-Fe that embodiment 1 prepares 2 o 3 The morphology observed under the scanning electron microscope.

[0021] Research Electrode Pressed 40% Rice Granular α-Fe 2 o 3 Active material, 20% carbon black, 20% gra...

Embodiment 2

[0024] Add 6.75 g of ferric chloride hexahydrate and 6 g of polyethylene glycol into 400 ml of deionized water, and stir mechanically for 2 hours to obtain a uniform mixed solution. The above mixed solution was transferred to the bottom of the hydrothermal reaction tank, and reacted at 180° C. for 24 hours. The hydrothermal product was washed several times by centrifugation with deionized water and absolute ethanol, and after vacuum freeze-drying, α-Fe 2 o 3 Precursor. The obtained material was calcined at 500°C for 4 hours and cooled to room temperature to obtain rice-like α-Fe 2 o 3 Material.

[0025] figure 1 B is the rice granular α-Fe that embodiment 2 obtains 2 o 3 The X-ray diffraction (XRD) pattern.

[0026] Figure 5 and Figure 6 Be the rice granular α-Fe that embodiment 2 prepares 2 o 3 The morphology observed under the scanning electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com