Preparation method of ionic liquid monomer with homopolymer having UCST property

An ionic liquid, homopolymer technology, applied in organic chemistry and other directions, can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

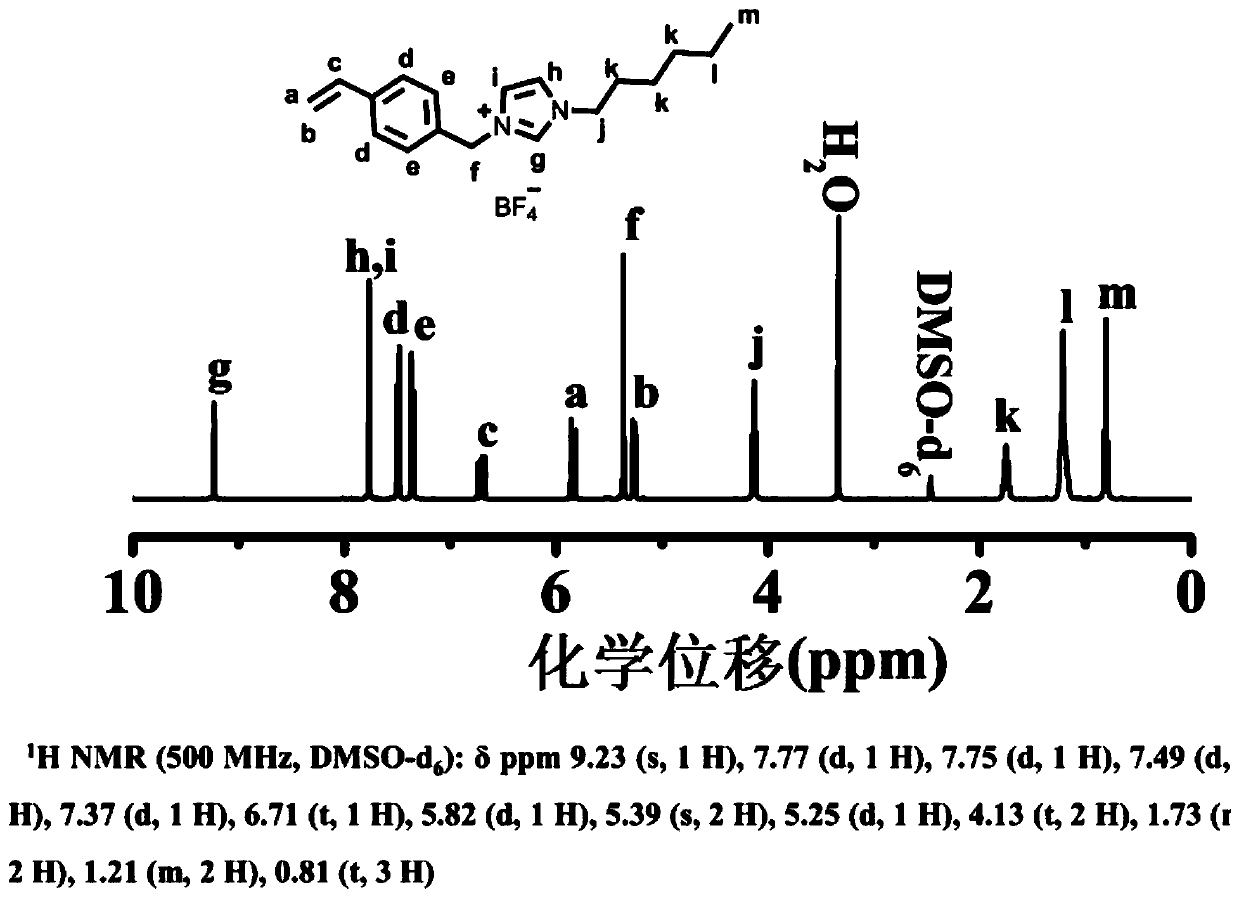

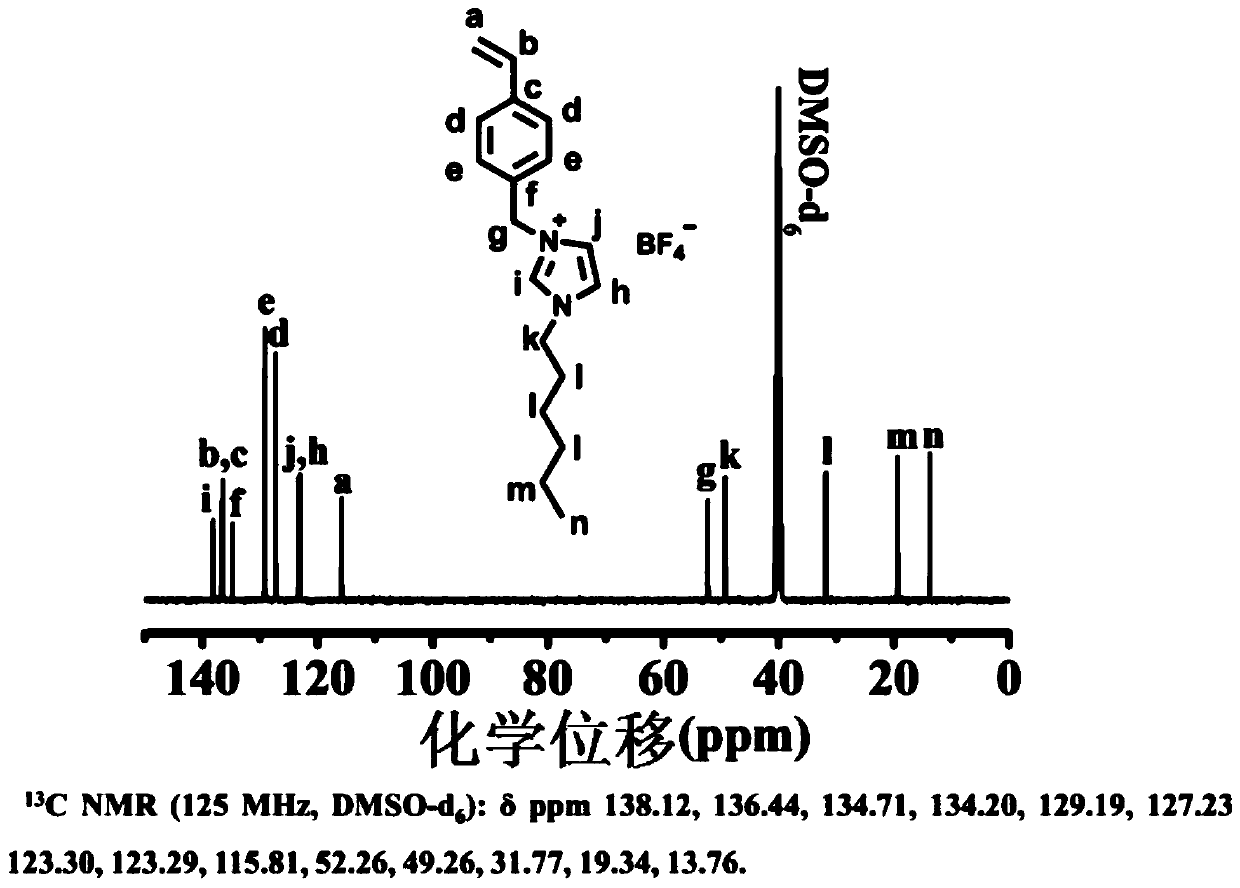

[0031] The invention provides a method for preparing an ionic liquid monomer whose homopolymer has UCST properties, comprising the steps of:

[0032] step one

[0033] At room temperature, dissolve hexylimidazole in ethyl acetate and stir for 15-30 minutes; then slowly add benzyl chloride methyl styrene for quaternization reaction to obtain intermediate product 1;

[0034] In the present invention, the reaction time of the quaternization reaction is 8-12 hours. The ethyl acetate and benzyl chloride methyl styrene used in the present invention are analytically pure.

[0035] The mass ratio of hexylimidazole to ethyl acetate is 1:1; the molar ratio of hexylimidazole to benzyl chloride methyl styrene is 1:0.89~0.99.

[0036] The method of slowly adding benzyl chloride methyl styrene is to add drop by drop or add in 10-20 times; this operation can always keep the concentration of hexylimidazole greater than that of benzyl chloride methyl styrene, increase the reaction rate and r...

Embodiment 1

[0055] Weigh 30.45g of hexylimidazole, dissolve it in 35.00mL of ethyl acetate and stir for 1h; then add 30.21g of benzylchloromethylstyrene dropwise into the above reaction solution, and react at room temperature for 8h to obtain intermediate product 1.

[0056] Pour the above-mentioned intermediate product 1 into a container, then add 50.00 mL of deionized water, stir for 15 minutes, then let it stand for stratification, continue to add the same volume of deionized water, repeat the operation three times, and collect the lower layer of intermediate product 2.

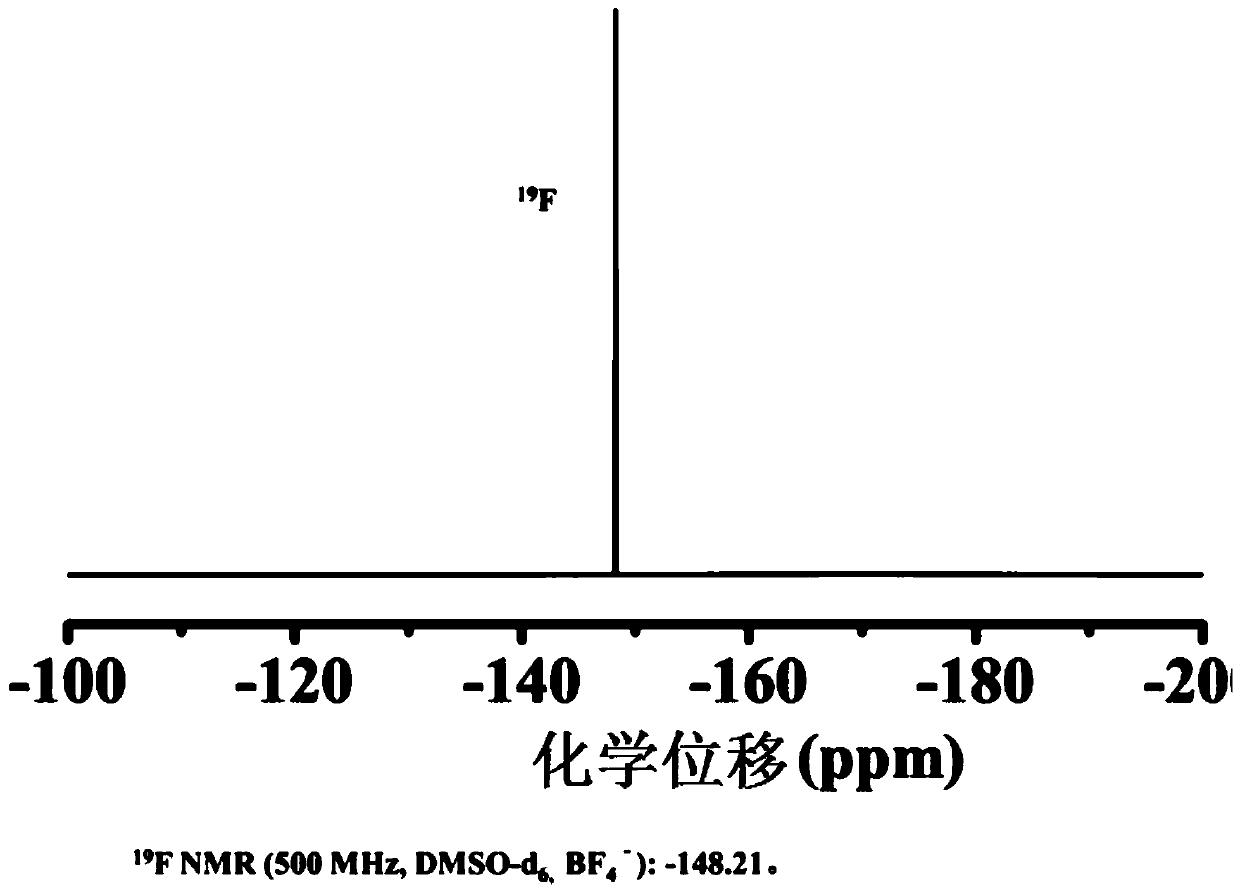

[0057] Add 200mL of deionized water and accurately weighed 43.95g of sodium fluoroborate into the container, and stir for 30 minutes until the sodium fluoroborate solid is completely dissolved to obtain a sodium fluoroborate solution; add the above-mentioned intermediate product 2 to the sodium fluoroborate solution dropwise, Stir while adding dropwise, carry out counter ion exchange reaction, the reaction time is 120m...

Embodiment 2

[0061] Weigh 30.45g of hexylimidazole, dissolve it in 35.00mL of ethyl acetate and stir for 1h; then add 28.70g of benzylchloromethylstyrene dropwise into the above reaction solution, and react at room temperature for 8h to obtain intermediate product 1.

[0062] Pour the above-mentioned intermediate product 1 into a container, then add 50.00 mL of deionized water, stir for 15 minutes, then let it stand for stratification, continue to add the same volume of deionized water, repeat the operation three times, and collect the lower layer of intermediate product 2.

[0063] Add 200mL of deionized water and accurately weighed 43.95g of sodium fluoroborate into the container, and stir for 30 minutes until the sodium fluoroborate solid is completely dissolved to obtain a sodium fluoroborate solution; add the above-mentioned intermediate product 2 to the sodium fluoroborate solution dropwise, Stir while adding dropwise, carry out counter ion exchange reaction, the reaction time is 120m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com