Method for preparing double-component metallic oxide catalytic ozonation catalyst

An ozone catalytic oxidation, two-component technology, applied in the direction of oxidized water/sewage treatment, etc., to achieve the effect of wide range of raw materials, low production cost, good mechanical properties and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

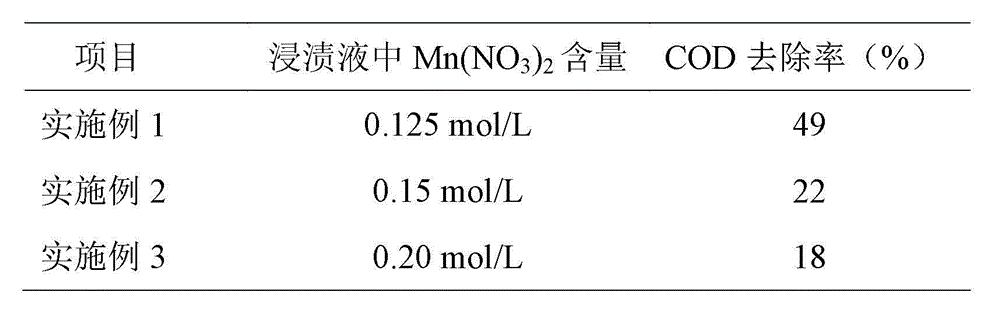

[0022] Take 44.75 ml of 50% Mn(NO 3 ) 2 solution (0.125 mol / L) and 5.43 g Ce(NO 3 ) 3 ·6H 2 O (molar ratio of manganese to cerium is 10:1), mixed with water, dissolved and diluted to 1 L, slowly added 500 g of activated γ-Al 2 o 3 Microspheres, impregnated overnight, then removed γ-Al 2 o 3 The microspheres were dried at 100±2 °C, placed in a muffle furnace and calcined at 450 °C for 4 h to obtain a manganese-cerium dual-component supported catalyst.

[0023] Prepare the above concentrations of Mn(NO 3 ) 2 solution and Ce(NO 3 ) 3 solution, and operate according to the above process, the manganese and cerium single-component supported catalysts can be obtained respectively.

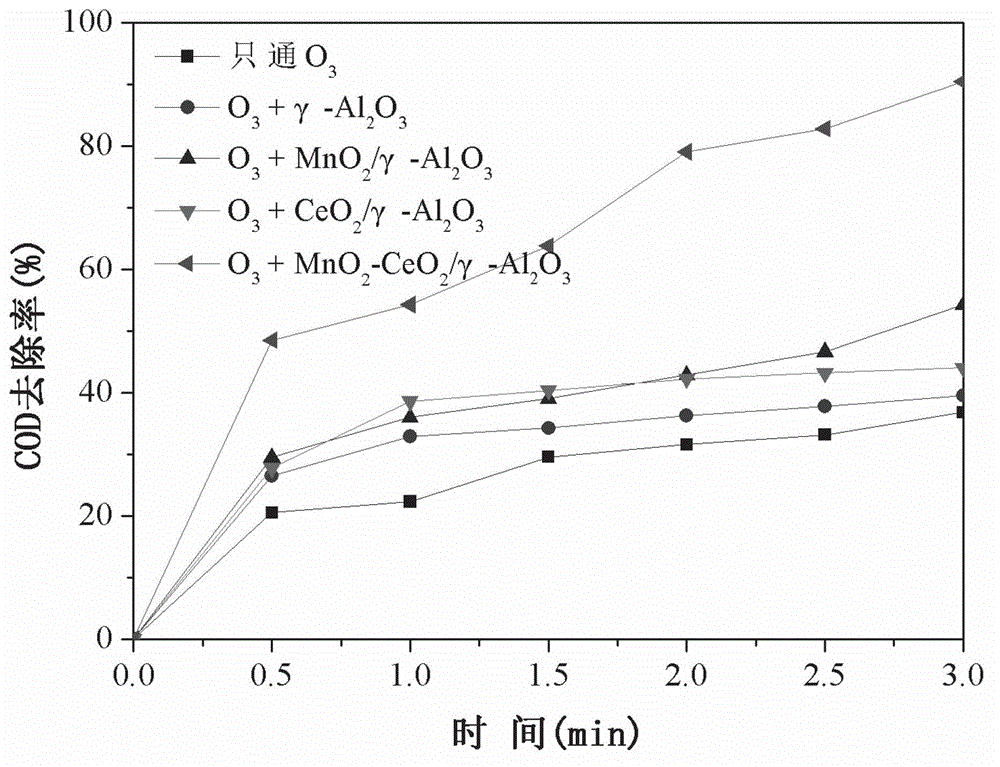

[0024] The performance of the catalyst was evaluated by the ozone catalytic degradation experiment: carried out in a plexiglass reactor, the volume of the reactor was 1 L, ozone was provided by a WH-X ozone generator, and the ozone concentration was 5 g / h, and the ozone was passed through aerat...

Embodiment 2

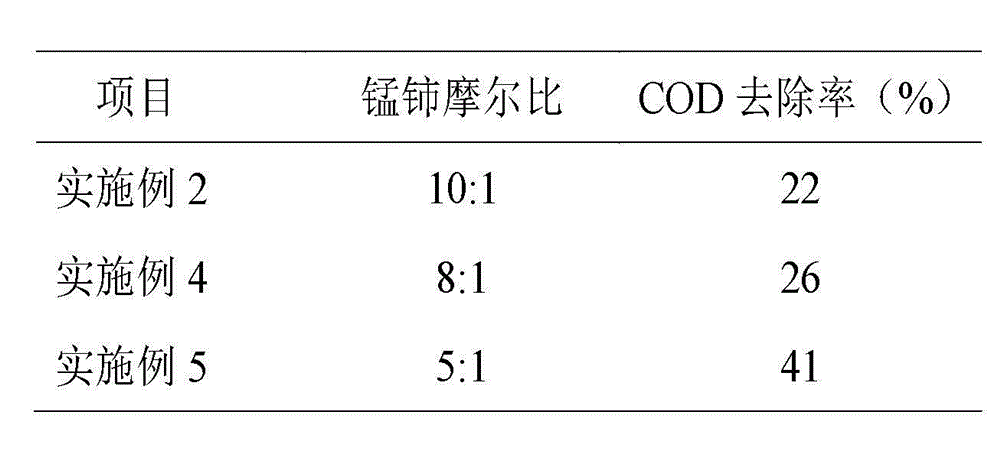

[0029] Take 53.70 ml of 50% Mn(NO 3 ) 2 solution (0.15 mol / L) and 6.51 g Ce(NO 3 ) 3 ·6H 2 O (manganese-cerium ratio 10:1) was mixed, and other preparation steps were as in Example 1. The performance evaluation method of the prepared catalyst was the same as in Example 1, except that the reaction was carried out for 30 minutes, and the COD value was measured by sampling. The evaluation results are shown in Table 1

Embodiment 3

[0031] Get 71.60ml mass fraction 50% Mn(NO 3 ) 2 solution (0.2mol / L) and 8.69 g Ce(NO 3 ) 3 ·6H 2 O (manganese-cerium ratio 10:1) was mixed, and other preparation steps were as in Example 1. The performance evaluation method of the prepared catalyst is the same as in Example 2, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com