Patents

Literature

58 results about "Polymer morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Morphology. Polymer morphology is the overall form of polymer structure, including crystallinity, branching, molecular weight, cross-linking, and so on 14. Small molecules usually have crystalline solids, which are highly-ordered 3-dimensional arrays of the molecules.

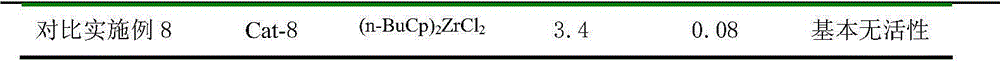

Process for preparing olefin polymerization ball type catalytic component and carrier

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

The invention discloses an equivoluminal dipping loading method of non-metallocene olefin polymeric catalyst as well as application of copolymerizing course within two or more different olefins, which comprises the following steps: dissolving non-metallocene olefin polymeric catalyst in the solvent; mixing solution and carrier; stirring wet solid material evenly; drying; obtaining the load-typed non-metallocene olefin polymeric catalyst; making the solvent and carrier satisfy specific relationship.

Owner:SINOPEC YANGZI PETROCHEM

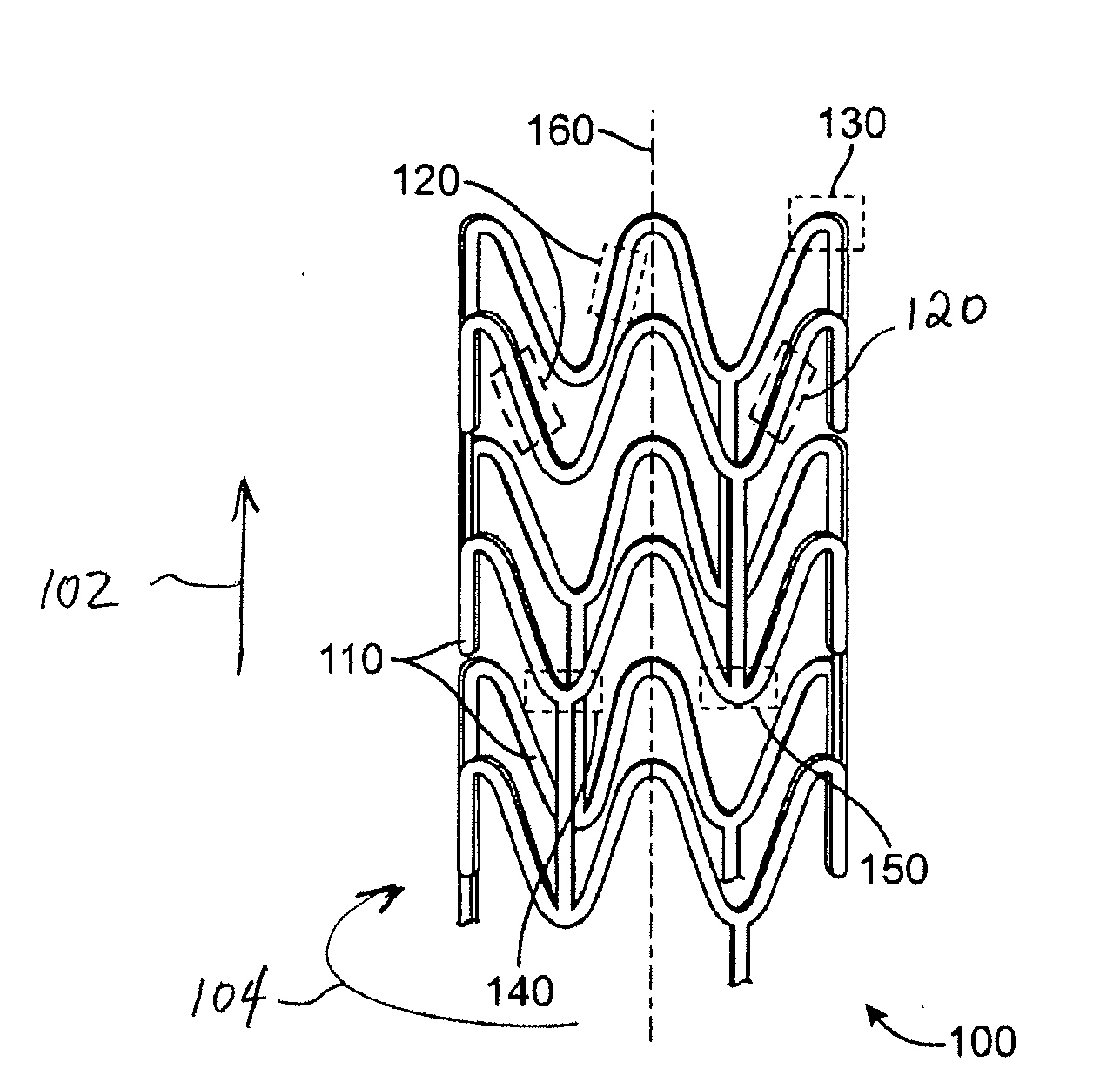

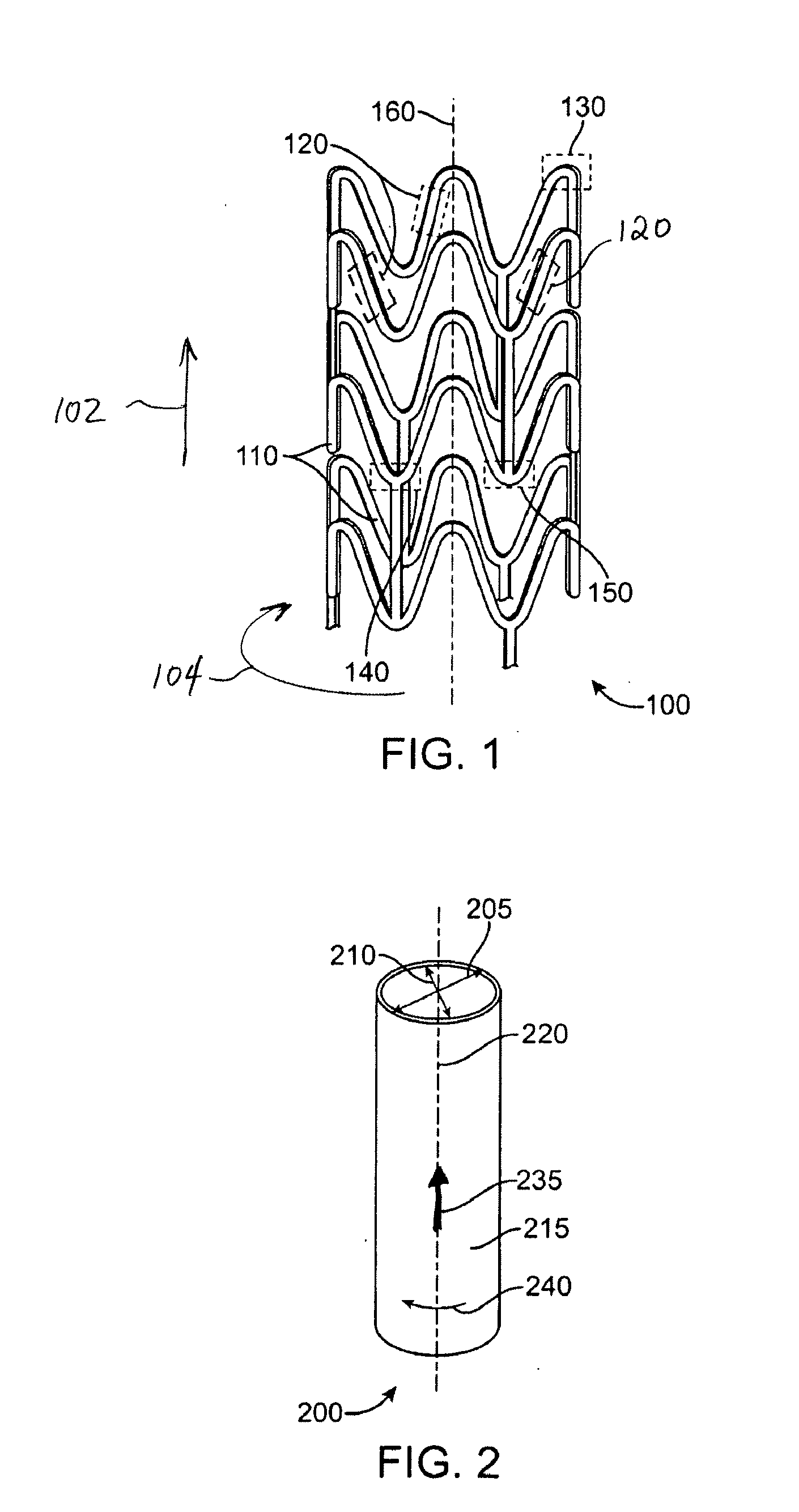

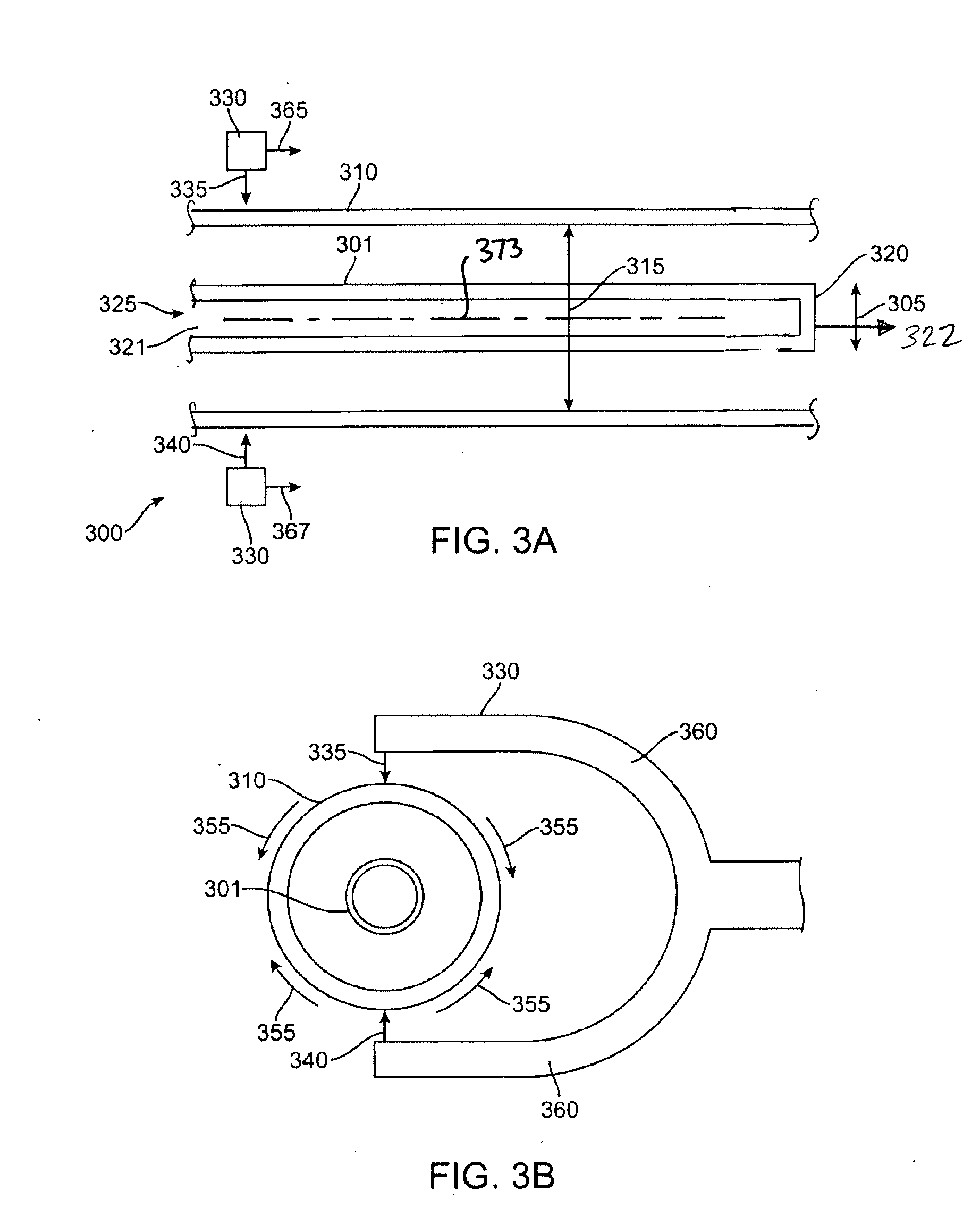

Polymeric Stent and Method of Making Same

A stent may be formed from a PLLA tubular polymer construct that is deformed in a blow mold. A desirable polymer morphology resulting in improved stent performance is obtained with a selected radial axial expansion ratio from about 20% to about 70%, a selected radial expansion ratio from about 400% to about 500%, a selected axial rate of deformation propagation at or about 0.3 mm / minute, a selected expansion pressure at or about 130 psi, and a selected expansion temperature that does not exceed 200 deg F. The tubular polymer construct may also be made of PLGA, PLLA-co-PDLA, PLLD / PDLA stereocomplex, and PLLA-based polyester block copolymer containing a rigid segment of PLLA or PLGA and a soft segment of PCL or PTMC.

Owner:ABBOTT CARDIOVASCULAR

Biodegradable fibers exhibiting storage-stable tenacity

InactiveUS20060159918A1Desired level of strengthFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention provides a drawn and / or crimped fiber comprising a biodegradable polymer, such as polylactic acid, wherein the drawn and / or crimped fiber exhibits a storage-stable tenacity that does not decrease from an initial tenacity upon manufacture by more than about 10% after storage for 120 days in ambient conditions. The polymer composition used to form the fiber may comprise a softening agent. The fiber can be a drawn and crimped bicomponent fiber that is helically self-crimped and which comprises a first biodegradable polymer component and a second biodegradable polymer component, wherein the first polymer component and the second polymer component exhibit different polymer morphology such that each polymer component will undergo a different extent of longitudinal shrinkage upon application of heat. The outer surface of the fiber may carry a water-repellant coating. The invention also provides a method of forming a drawn and / or crimped fiber exhibiting storage-stable tenacity.

Owner:FIBER INNOVATION TECH

Multi-phase structural adhesives

InactiveUS20050022929A1Easy to shapeSolve the lack of flexibilityLamination ancillary operationsAdhesive processes with adhesive heatingThermoplasticElastomer

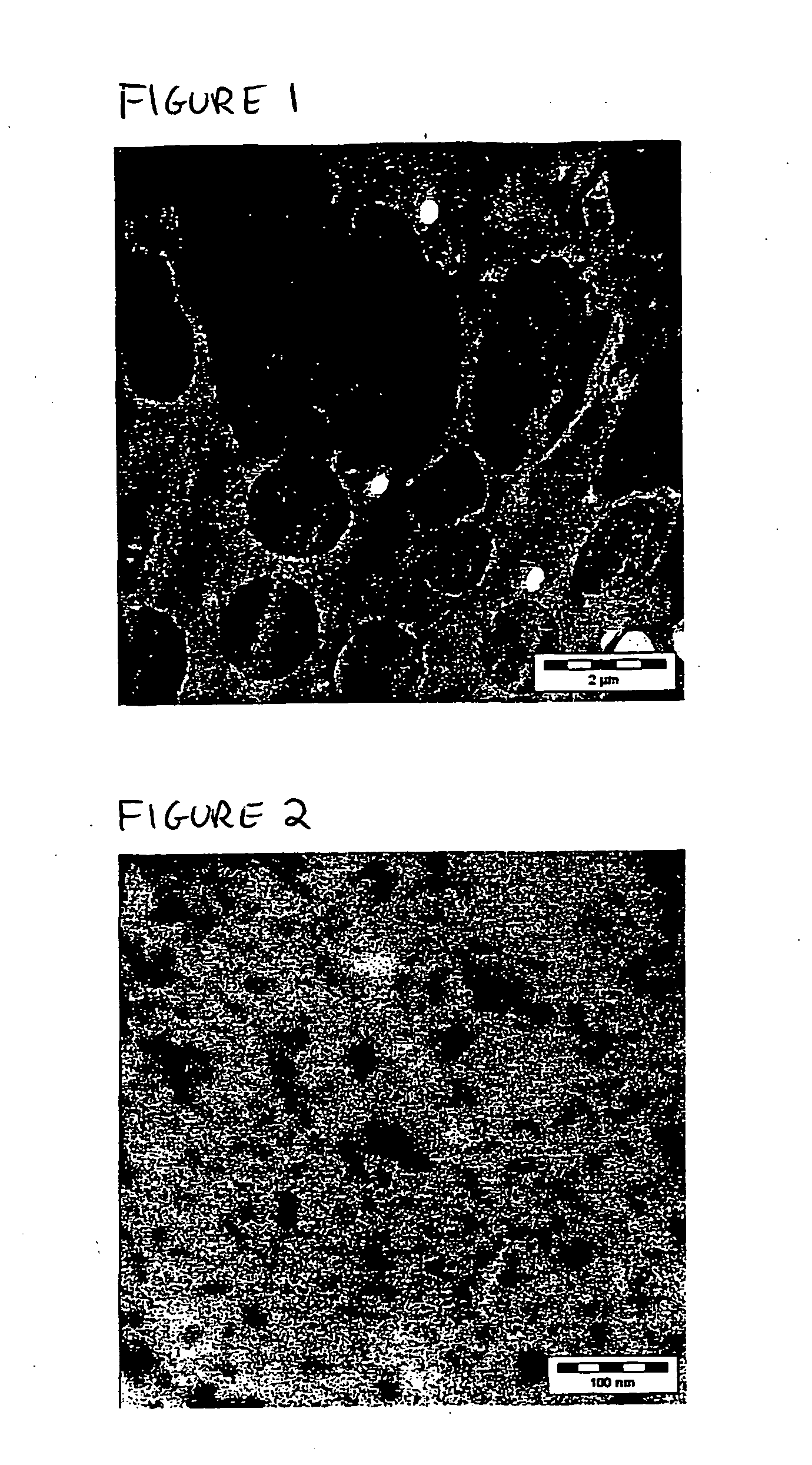

Hot-curing structural adhesives with multiphase polymer morphology, wherein the binder matrix of the cured chemically reactive adhesive displays (a) a continuous phase containing a polymer P1 having a glass transition temperature of over 100° C.; (b) a heterodisperse phase consisting of individual continuous domains of a thermoplastic or elastomeric polymer P2 having a glass transition temperature of below −30° C. and an average particle size of between 0.5 and 50 μm, which itself contains separate phases of another thermoplastic or elastomeric polymer P3 having a glass transition temperature of below −30° C. and a size of between 1 nm and 100 nm, parts of which can be in aggregated form as larger agglomerates; and (c) another heterodisperse phase embedded in the continuous phase and consisting of domains of the polymer P3, at least parts of which have an average particle size of between 1 nm and 50 nm, wherein P3 is not identical to P2; are suitable as high-strength, impact resistant structural adhesives, for internal stiffeners for cavities in automobile construction and for the production of reinforcing coatings for thin-wall sheet components.

Owner:HENKEL KGAA

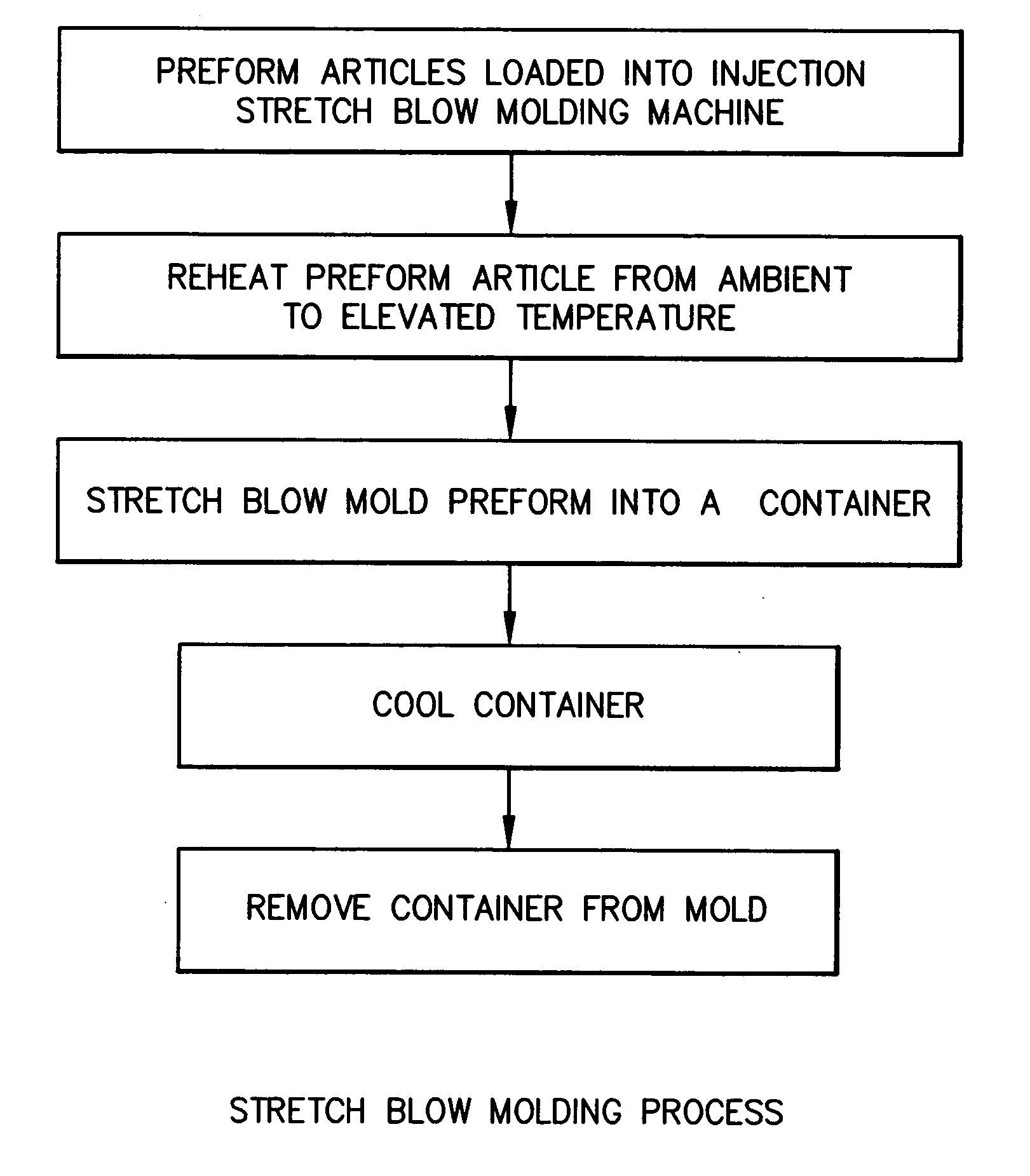

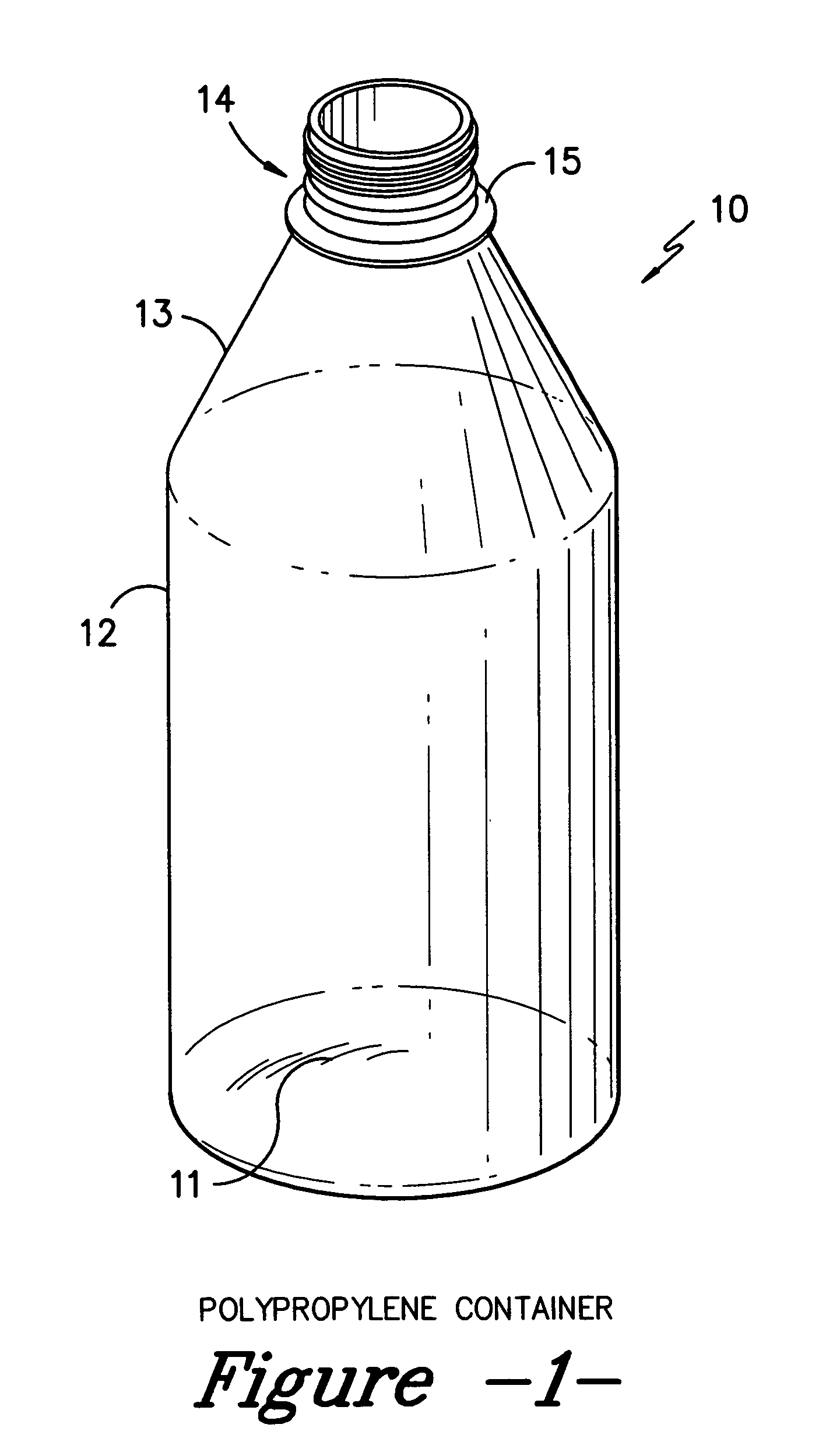

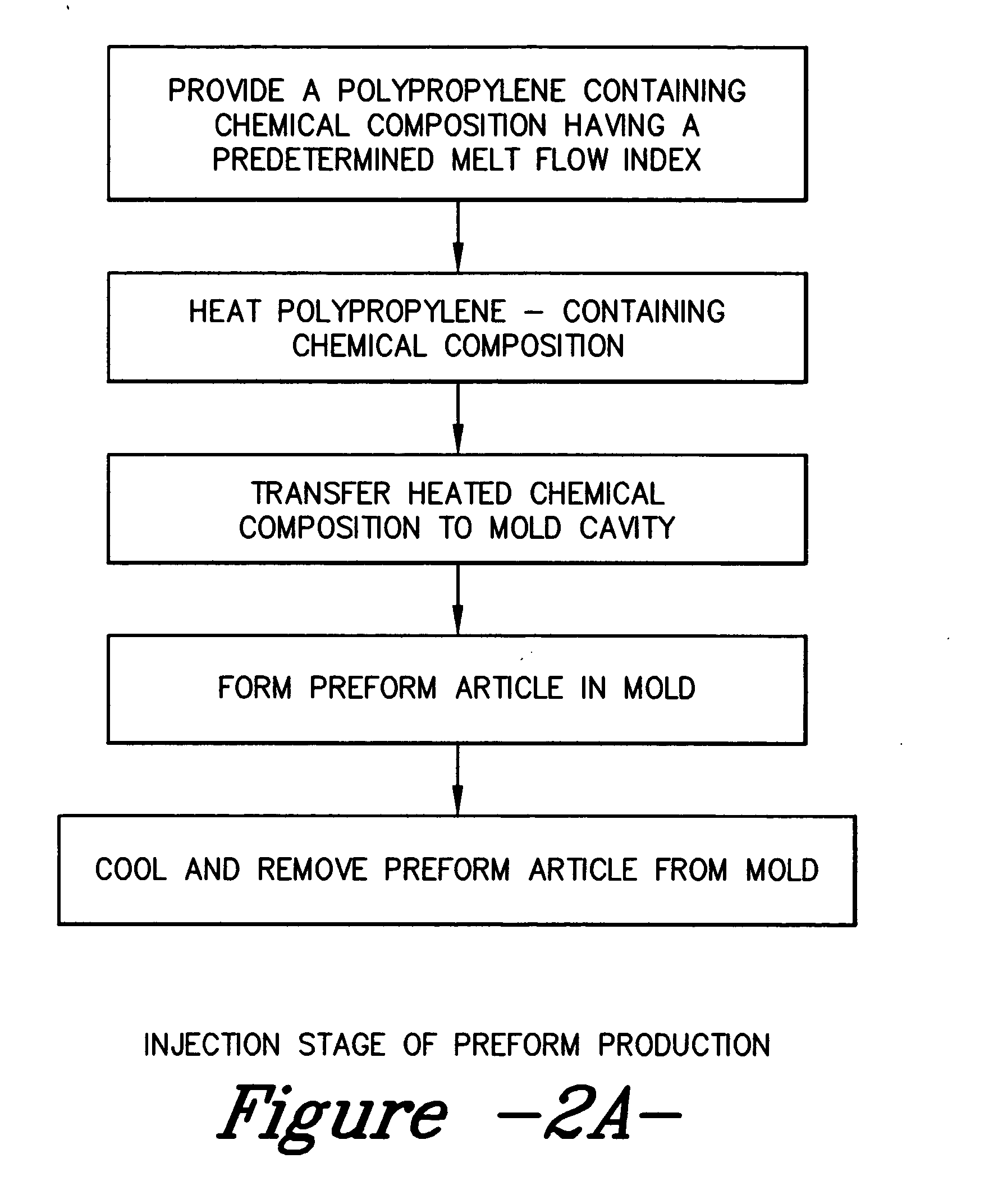

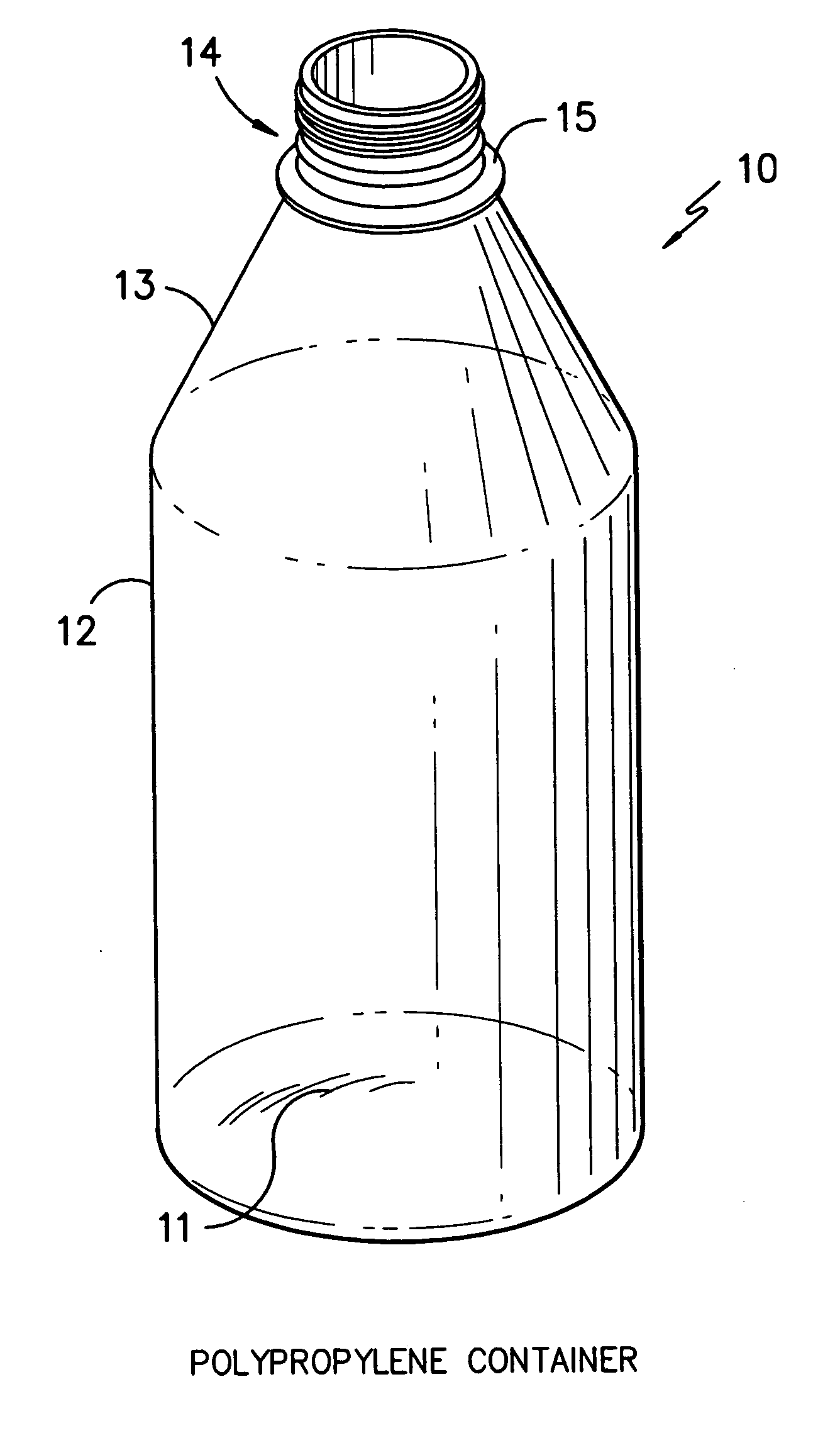

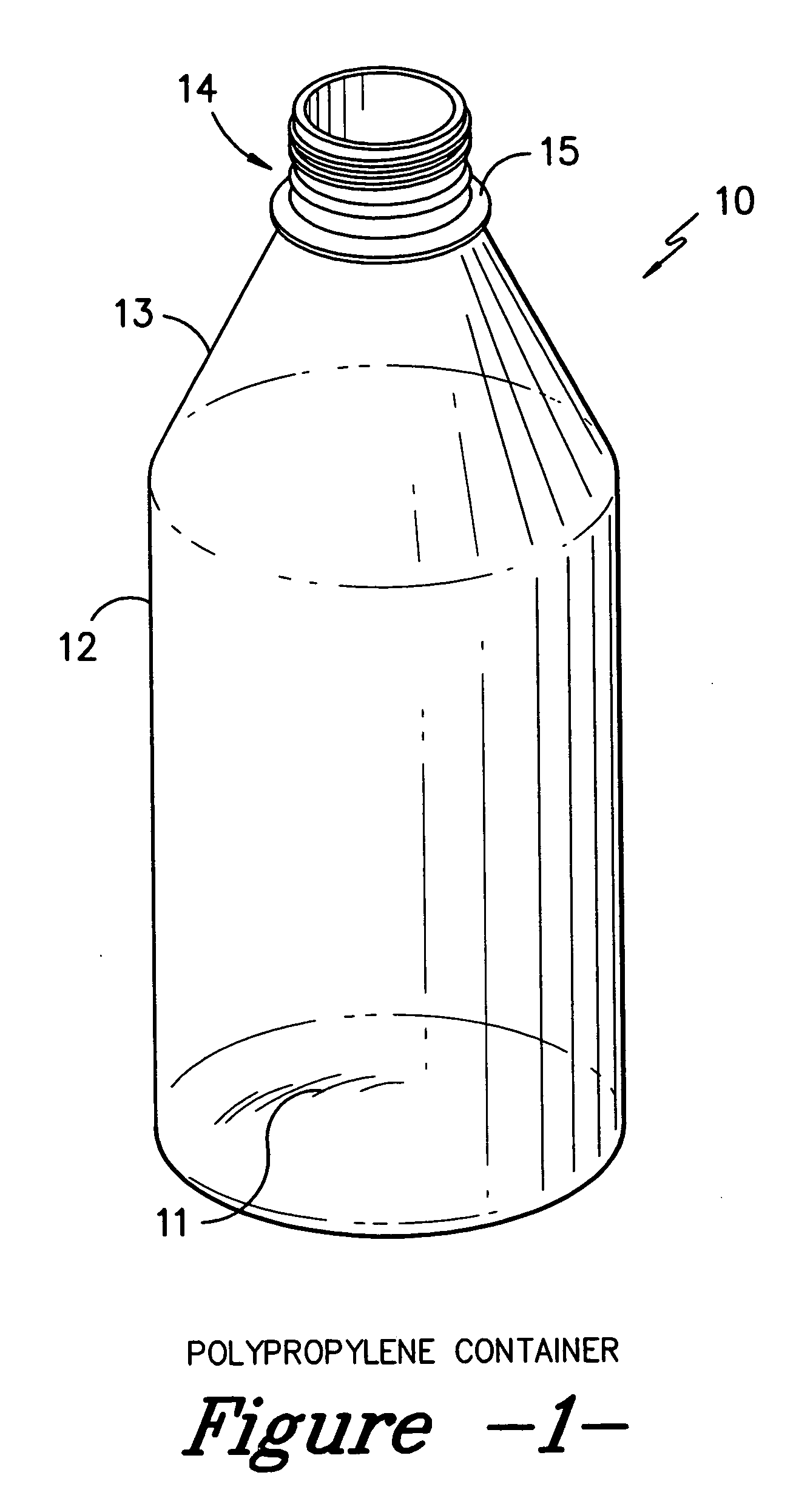

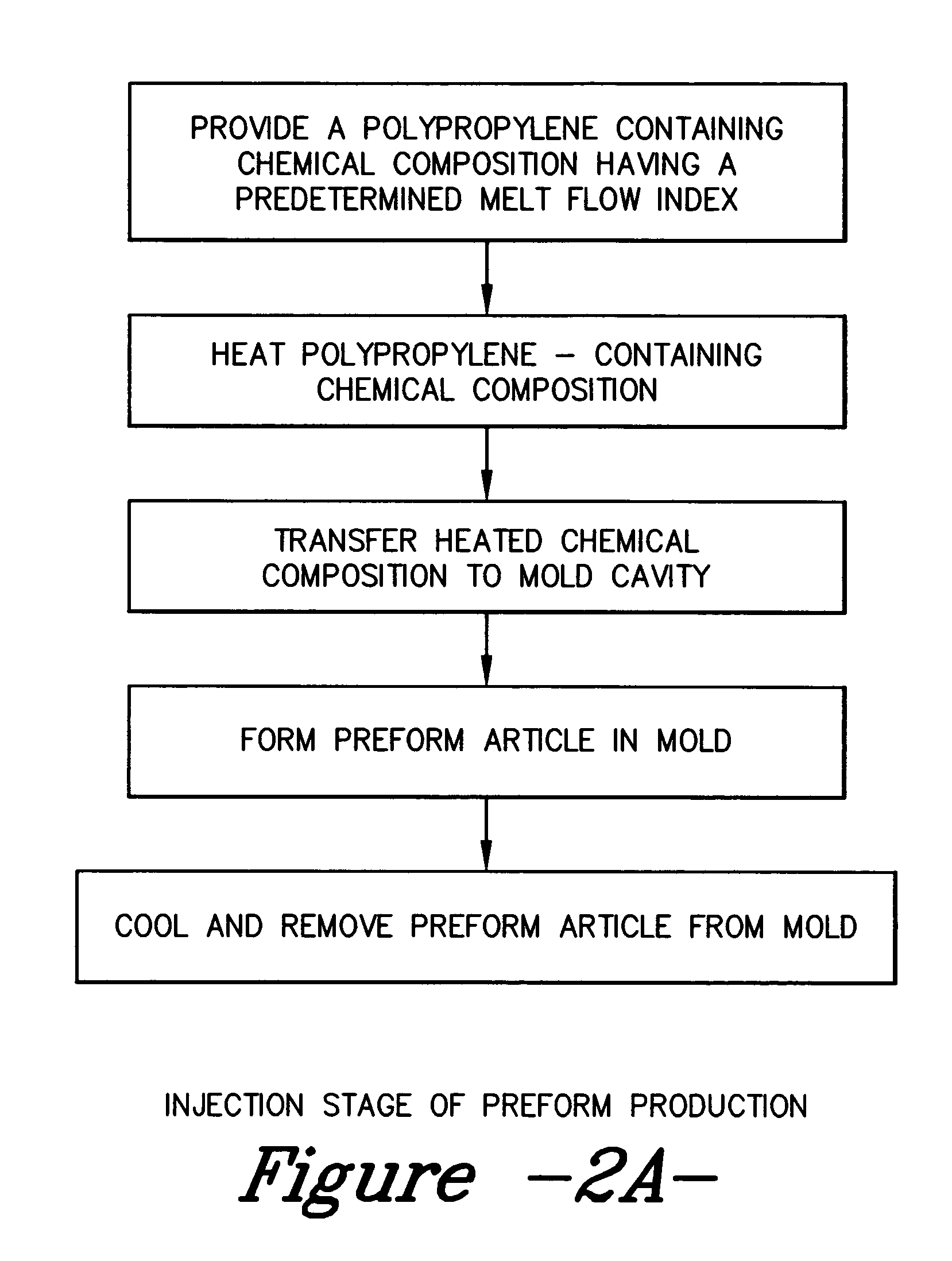

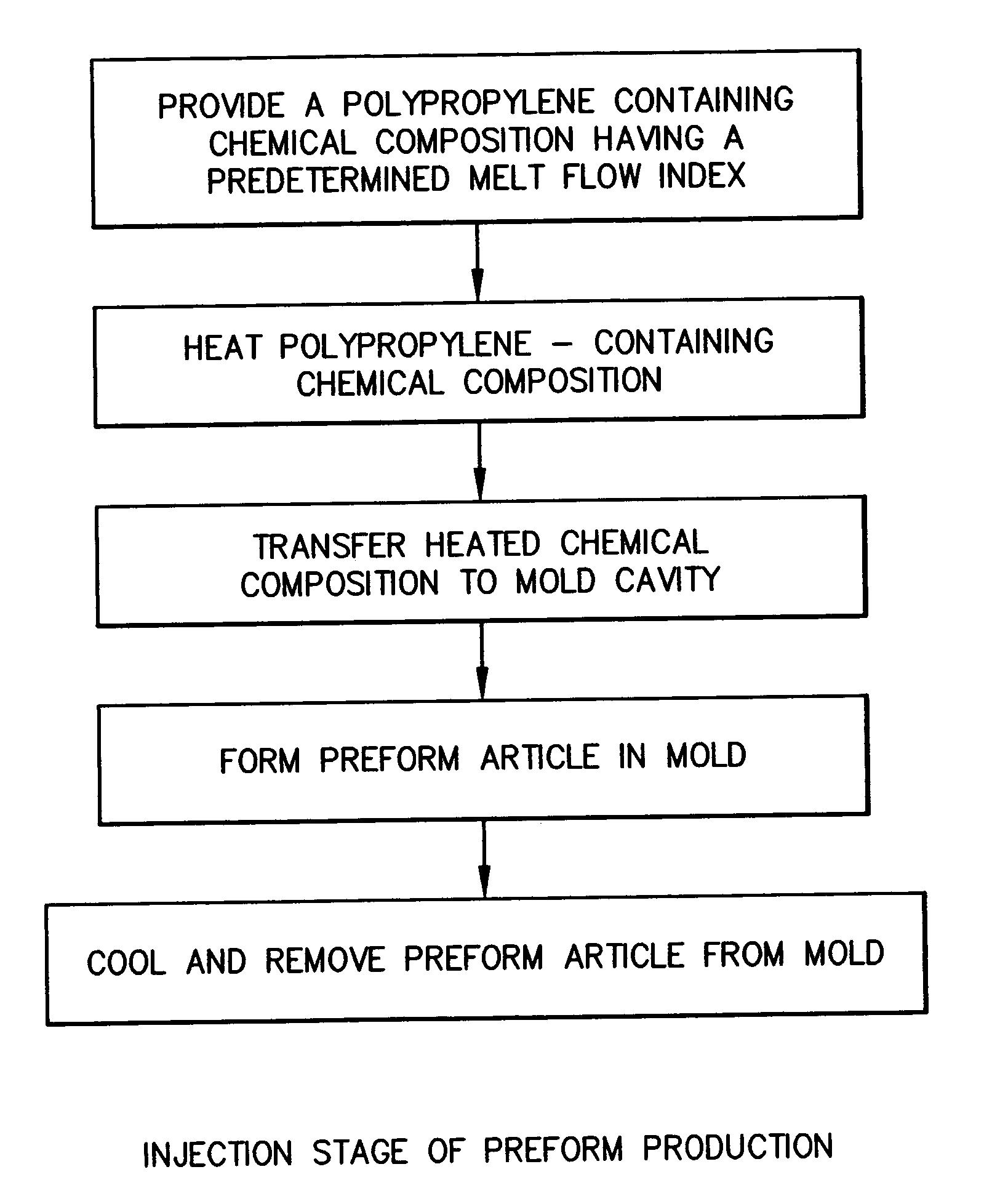

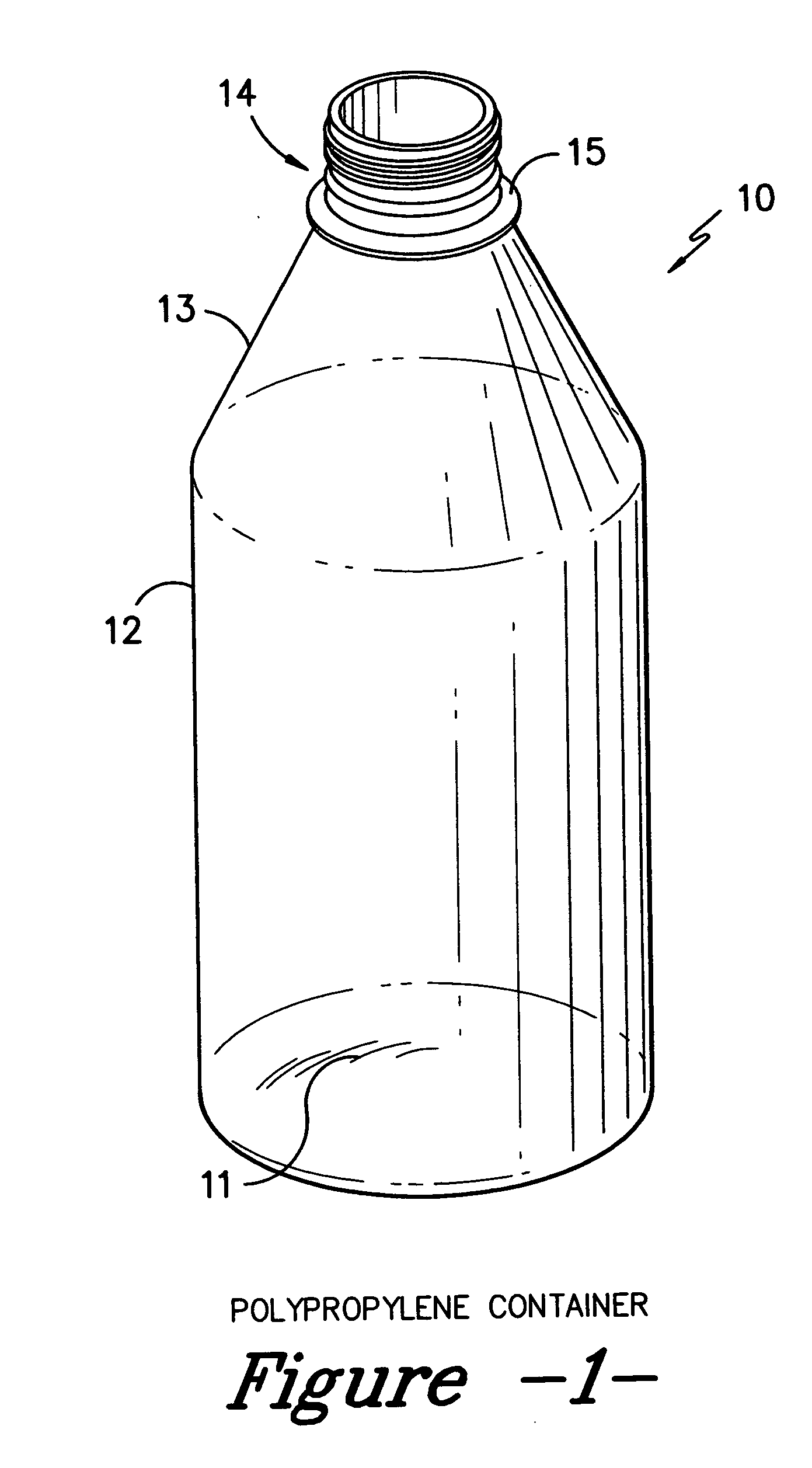

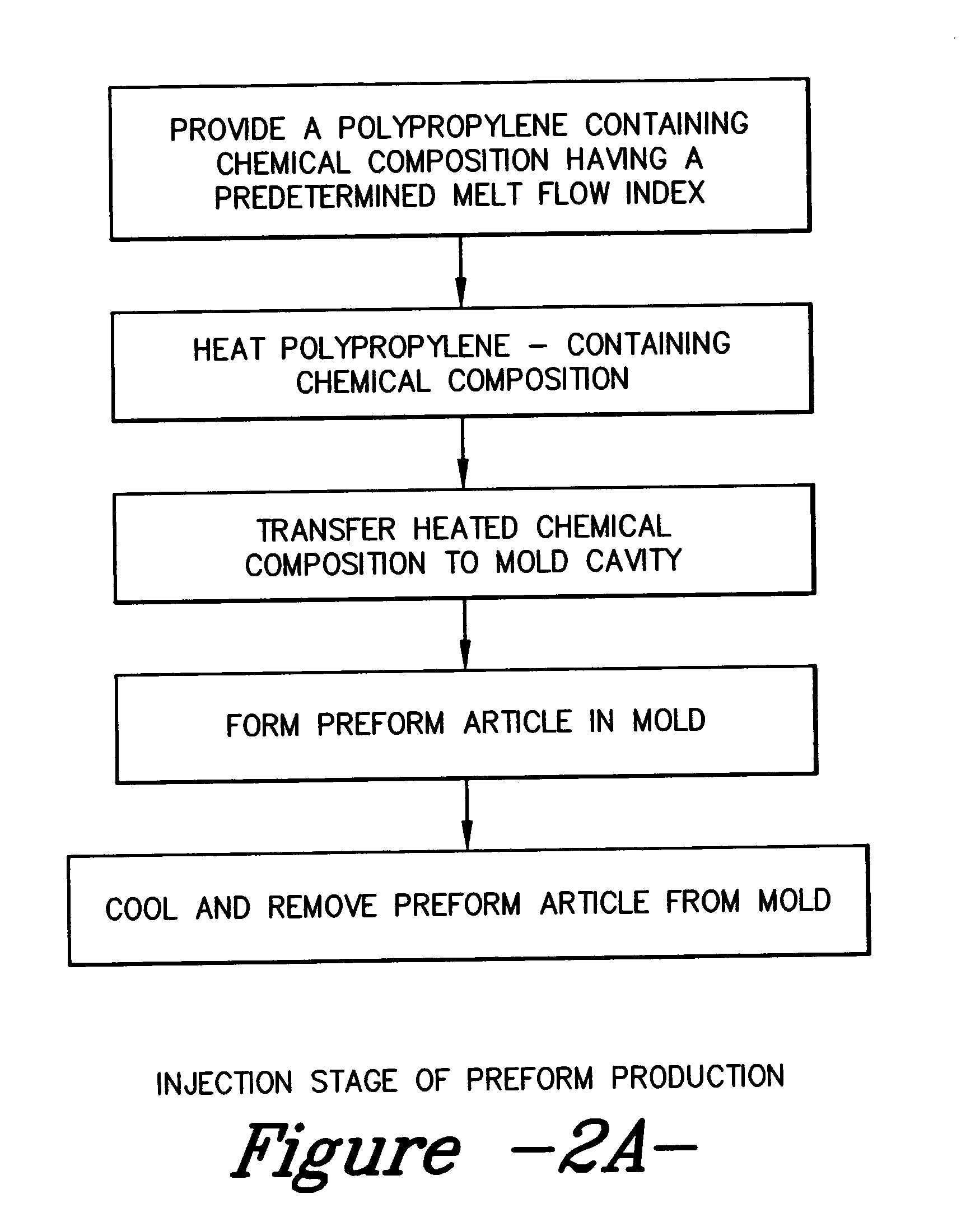

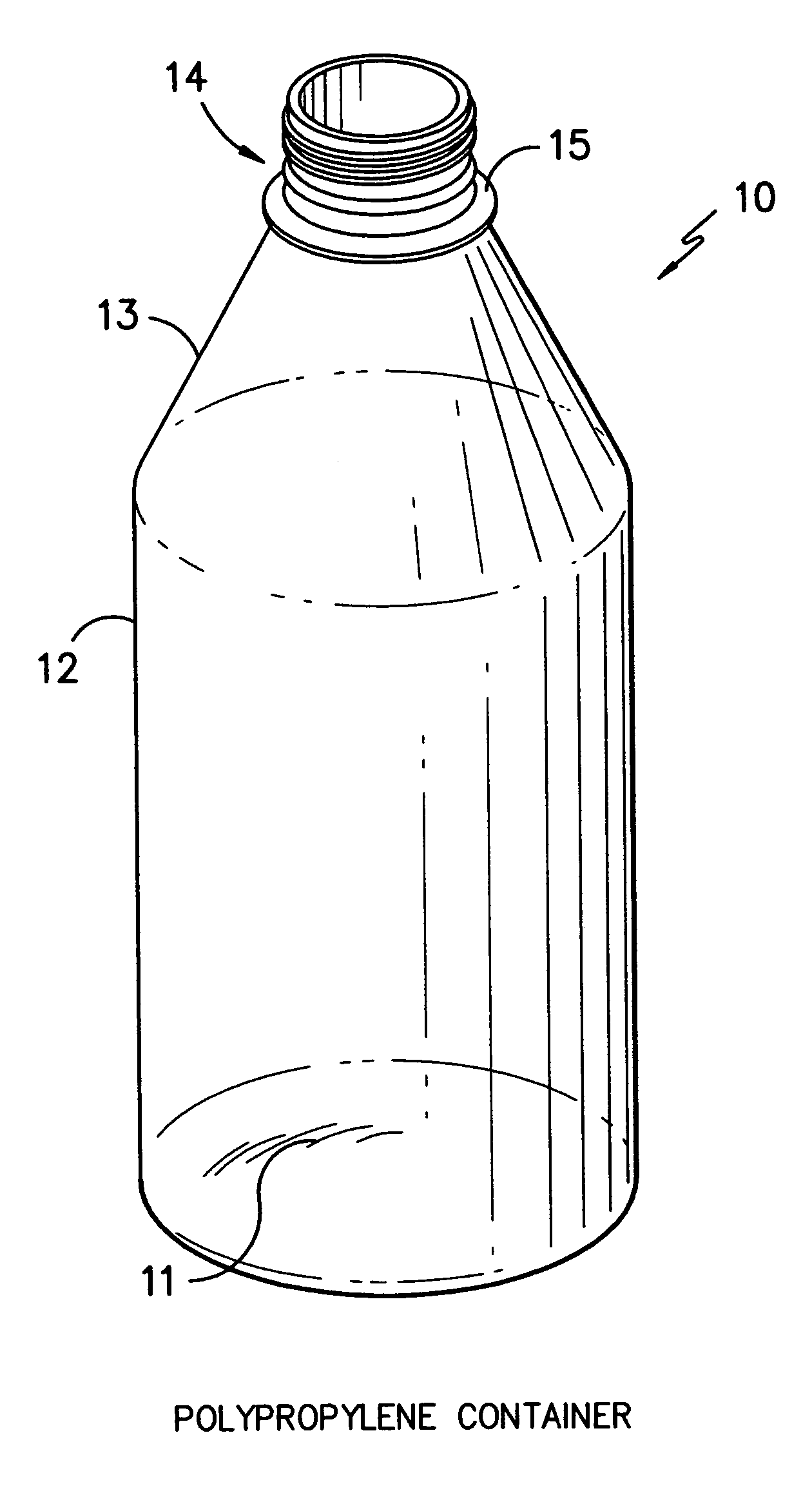

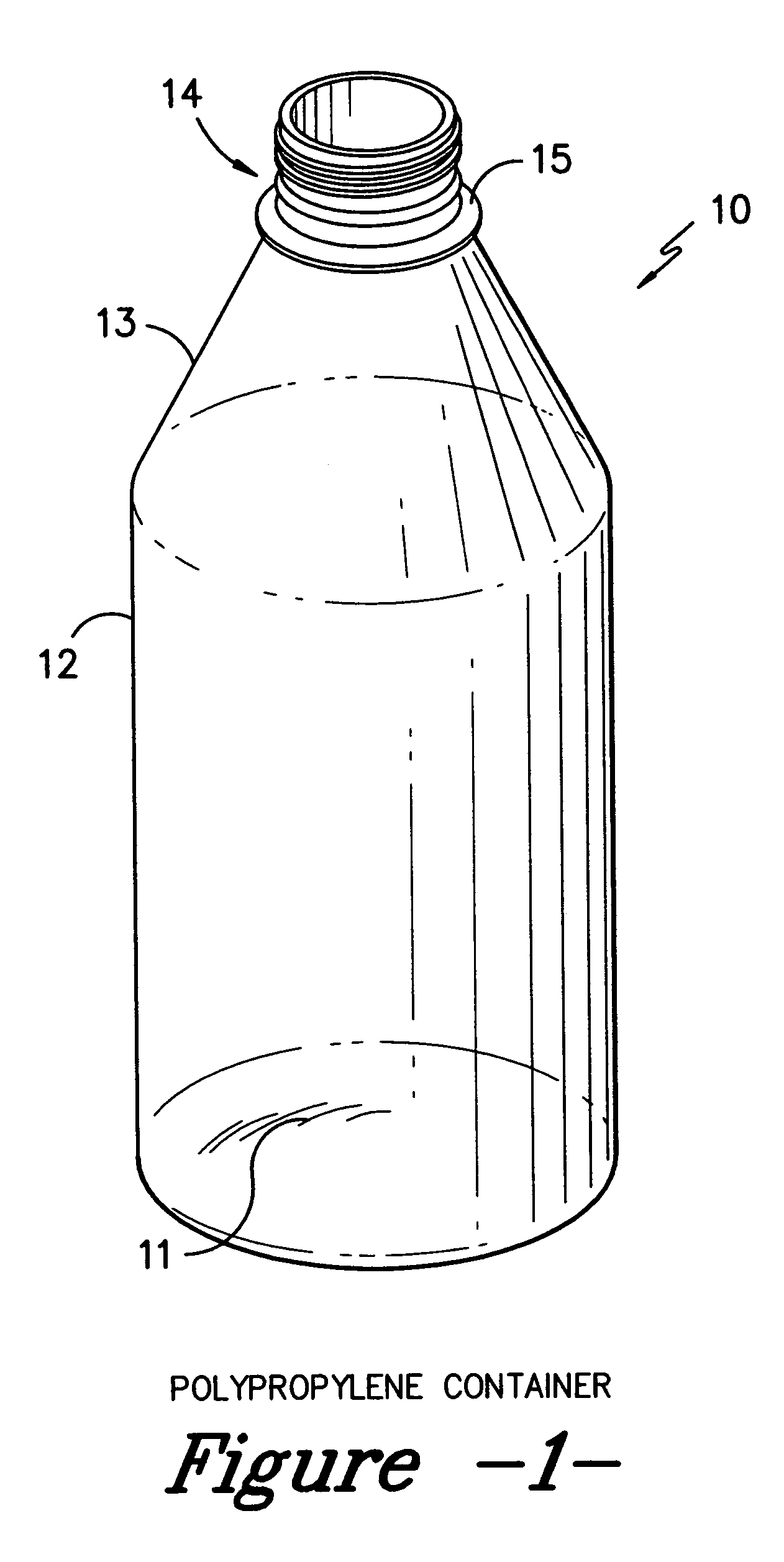

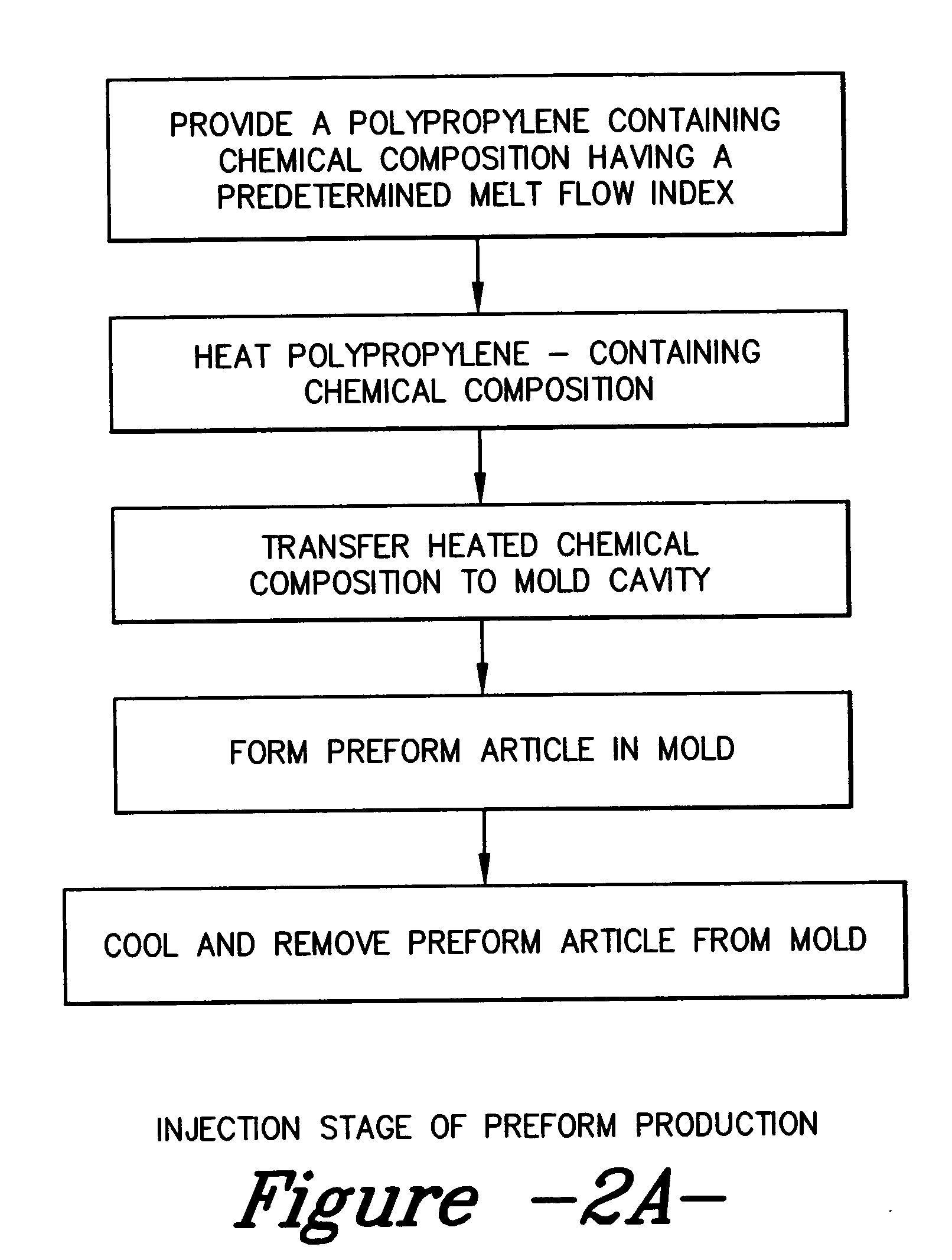

Process of making two-stage injection stretch blow molded polypropylene articles

The two stage production of clear, low-haze, injection stretch blow molded polypropylene container articles is disclosed. In the first processing stage, a preform article is manufactured on an injection molding machine. In a second and subsequent step, which may occur remotely from apparatus used in the first step, the preform article is heated and stretch blown into a container. The process may employ the selection of processing parameters to produce preform articles that facilitate stretch blow molding at relatively high rates of speed, while still maintaining an appropriate polypropylene polymer morphology that results in clear, low haze containers.

Owner:MILLIKEN & CO

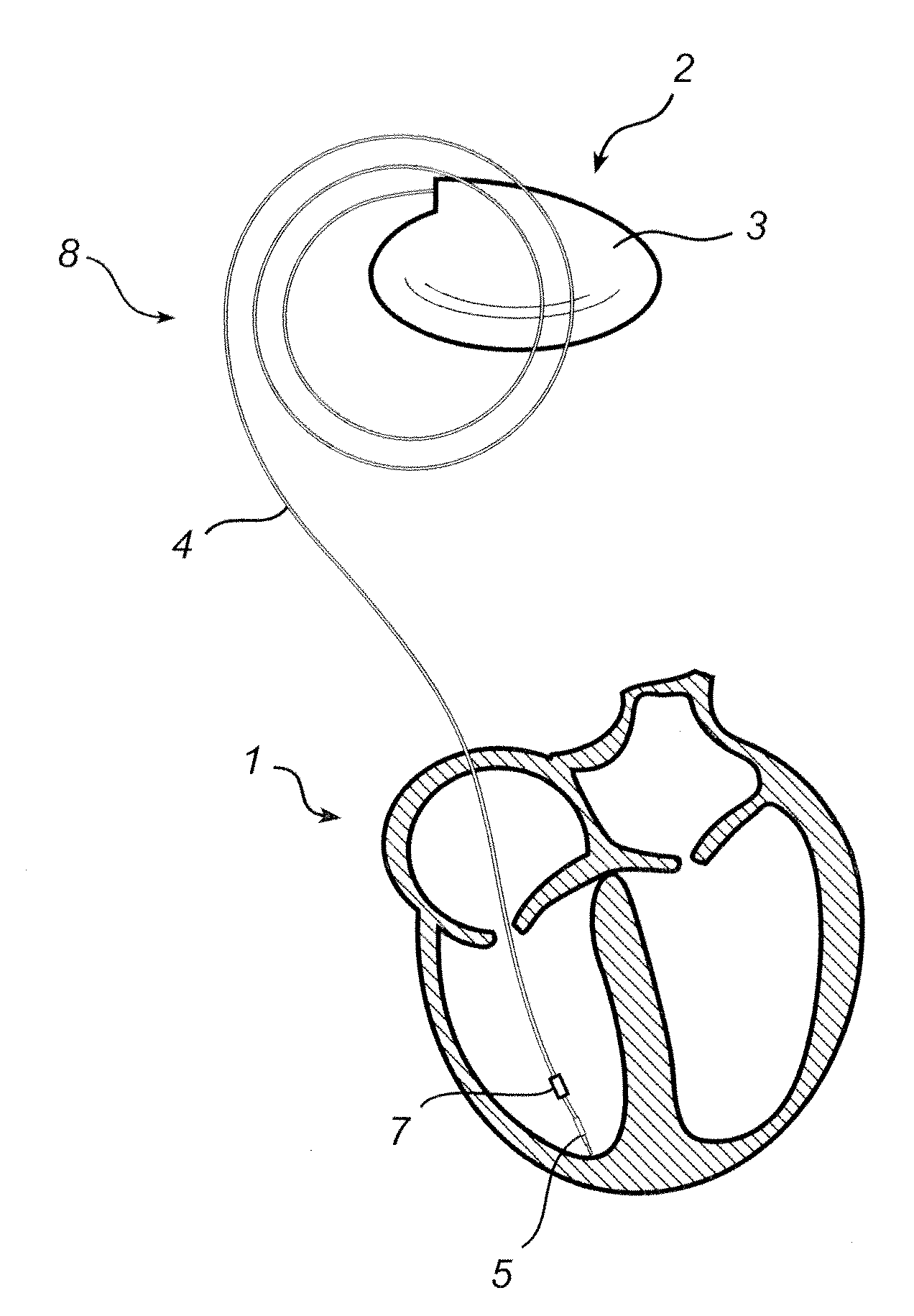

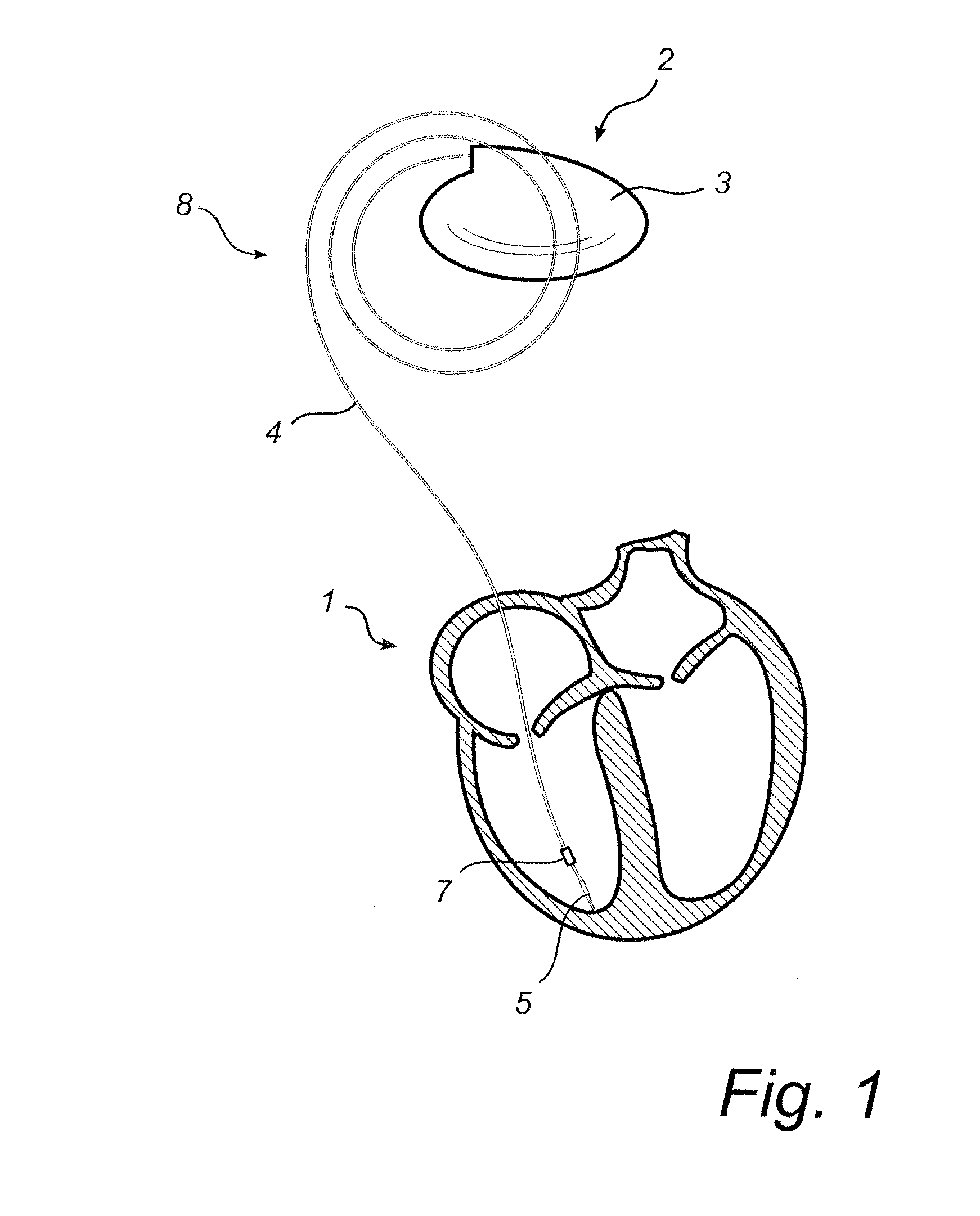

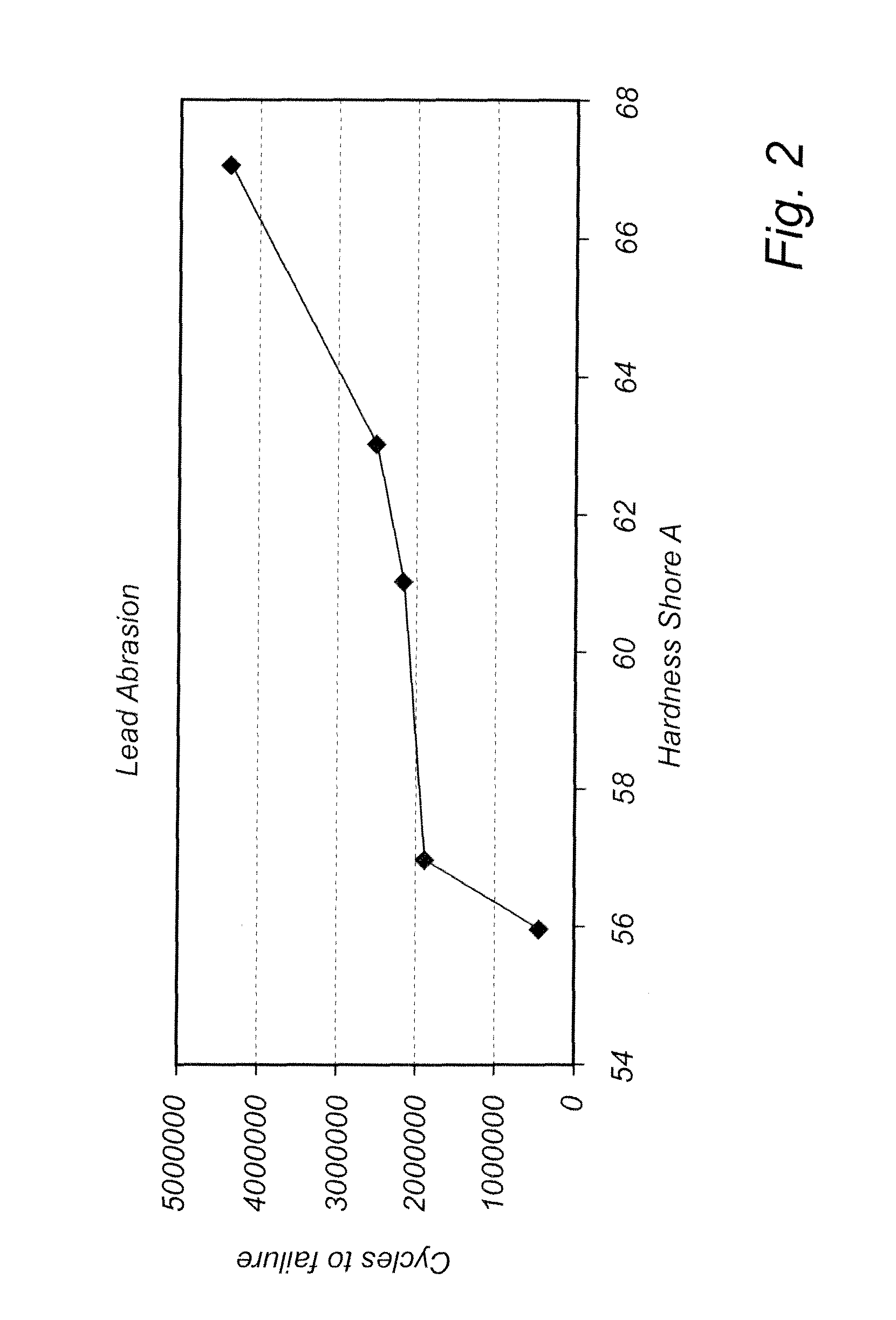

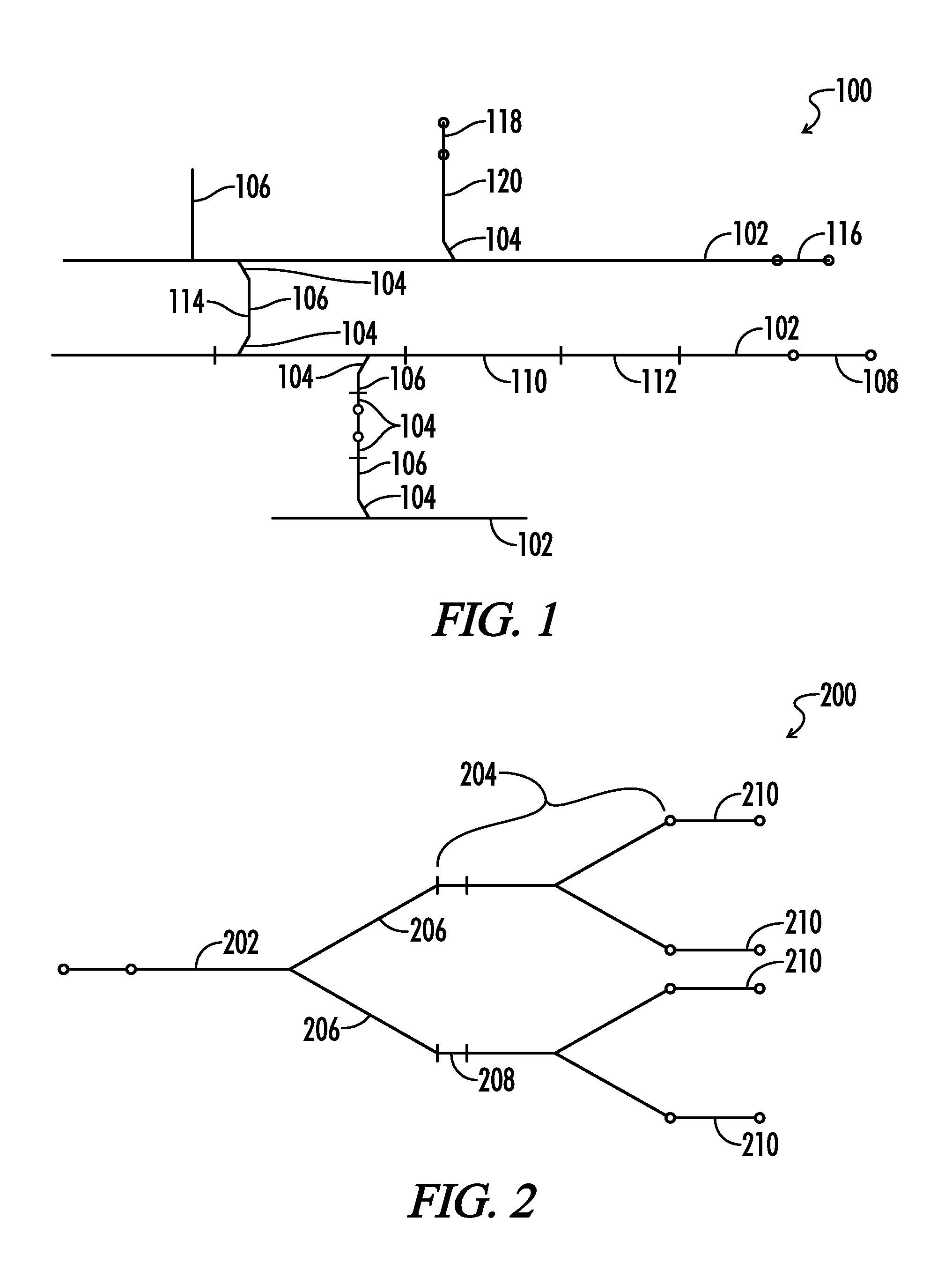

Implantable medical lead and method for manufacture thereof

InactiveUS20110009938A1Reduce decreaseExtended service lifeLayered productsTransvascular endocardial electrodesElectrical conductorDistal portion

An implantable medical lead for implantation in a patient which has at least one electrical conductor connected to at least one electrode and / or sensor of said lead. The at least one conductor is arranged within a continuous sheet of a polymer material. A distal portion of the lead is adapted to be located in or at a heart of said patient and a proximal portion of said lead is connectable to an implantable medical device and arranged such that, when connected to the device, at least a part of the proximal portion of the sheet is placed in close proximity to said medical device. At least the proximal portion of the polymer sheet material is processed in at least a first heat process stage such that an inherent resistance to wear of the polymer sheet material is substantially maintained, and the distal portion of said polymer sheet material is processed in at least a second heat process stage in which a polymer morphology of said polymer material is altered such that an inherent flexibility of the polymer sheet material is substantially increased.

Owner:ST JUDE MEDICAL

Articles and process of making polypropylene articles having ultraviolet light protection by injection stretch blow molding of polypropylene

InactiveUS20050249904A1Synthetic resin layered productsThin material handlingBlow moldingPolymer science

The two stage production of clear, low-haze, injection stretch blow molded polypropylene container articles is disclosed. In the first processing stage, a preform article is manufactured on an injection molding machine. In a second and subsequent step, which may occur remotely from apparatus used in the first step, the preform article is heated and stretch blown into a container. The process may employ the selection of processing parameters to produce preform articles that facilitate stretch blow molding at relatively high rates of speed, while still maintaining an appropriate polypropylene polymer morphology that results in clear, low haze containers, with ultraviolet light protection. In some applications, the resulting containers are capable of withstanding hot fill operations.

Owner:MILLIKEN & CO

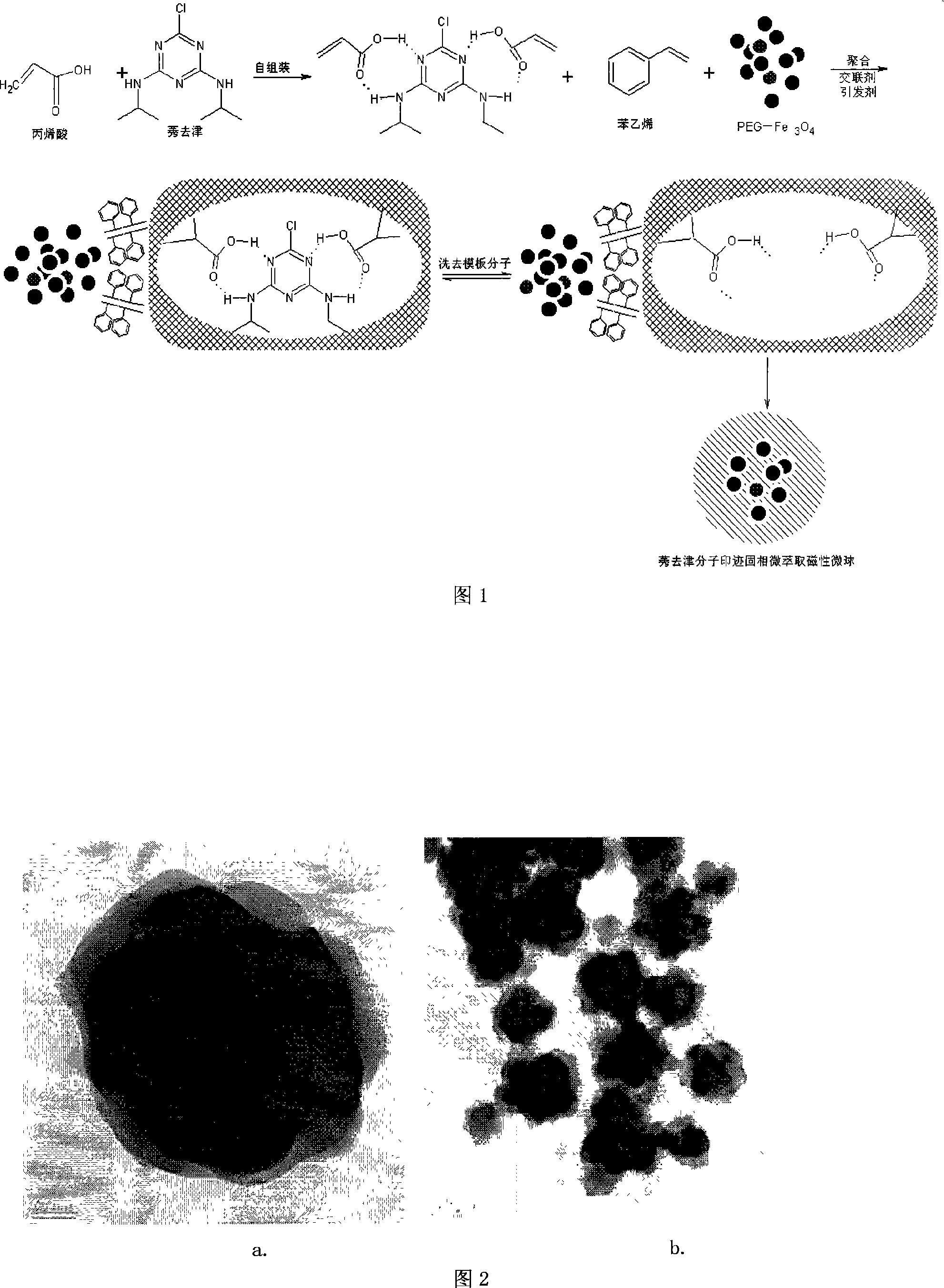

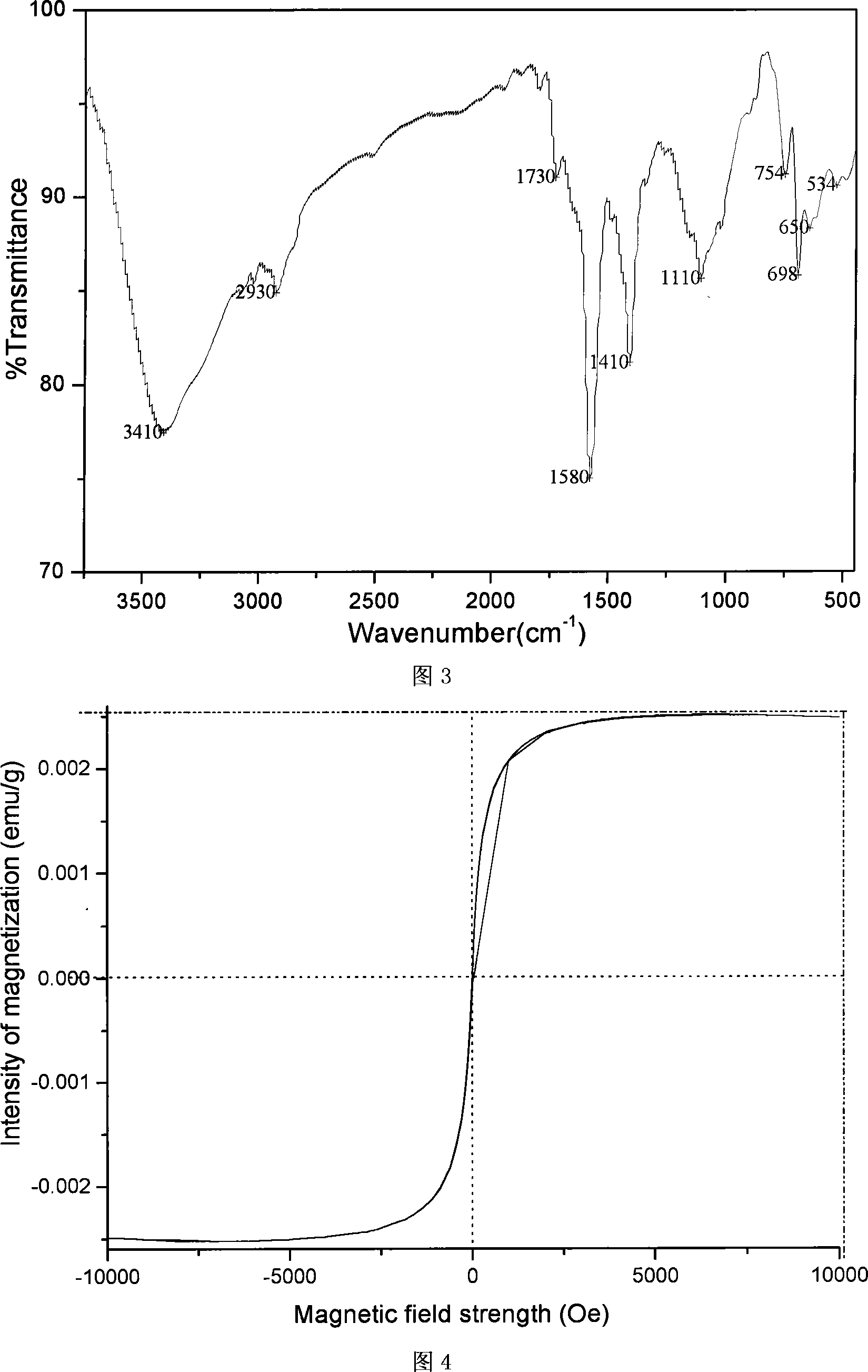

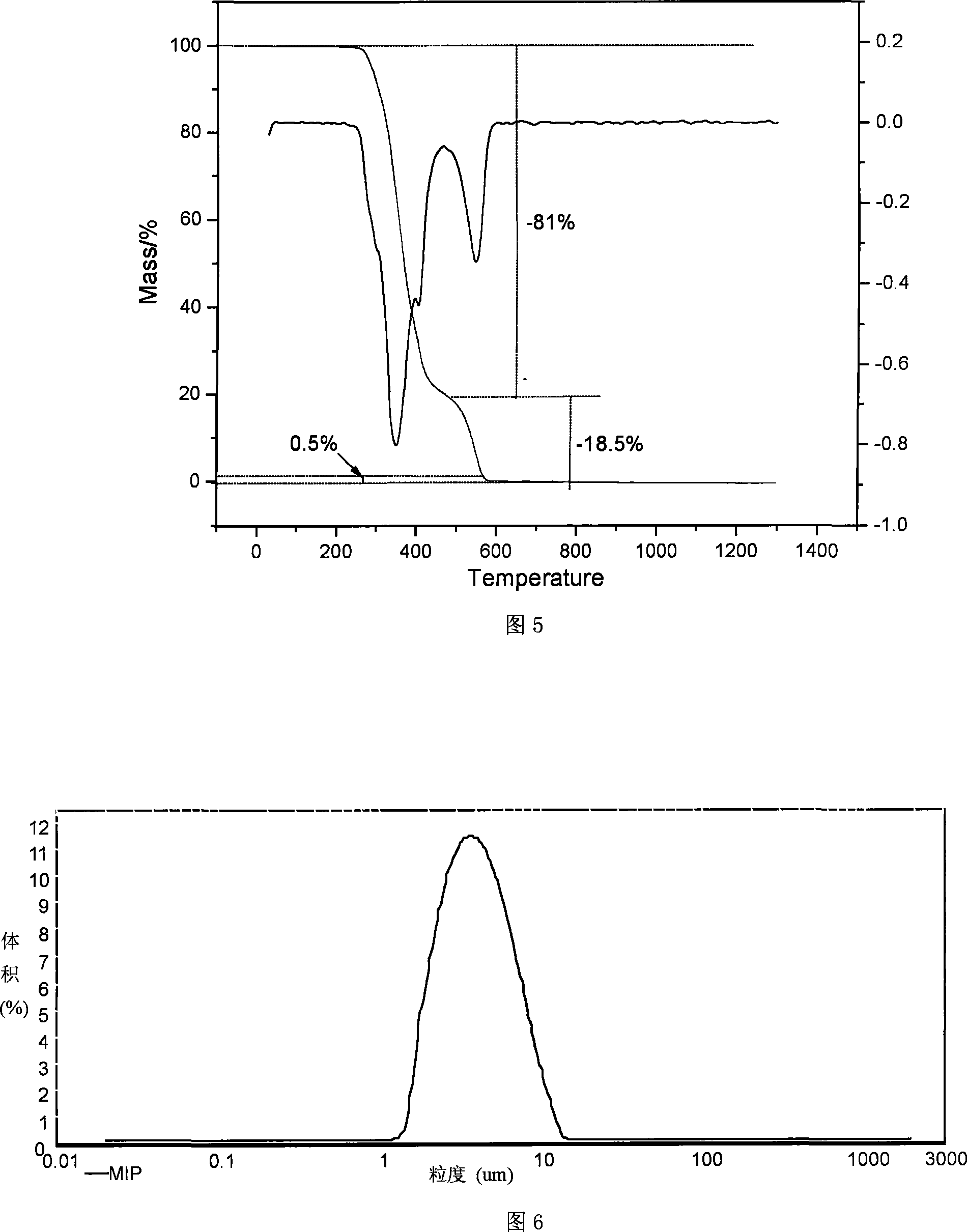

Microwave assisted molecular blotting magnetic microsphere preparation method and uses

InactiveCN101101282AUniform particle sizeParticle size controllableComponent separationPreparing sample for investigationCross-linkFunctional monomer

The invention belongs to the field of modern isolation analysis materials science and engineering, it relates to preparation method and application of microwave assistant molecular print magnetic microsphere, the procedure as follows: adopting microwave chemical reactor, taking nanometer magnetic fluid as magnetic nuclei, by cleaning and external modification, ultrasound detracting to water; mounted pattern molecule and functional monomer self-assembly; adding polymeric liquor by step, cross link agent and initiator, making it mixes and separates with magnetic fluid fully by stirring of machine, microwave procedure controlled temperature and heats up, until raising polymerization; Magnetic separates the foregoing magnetic microsphere, removing mounted pattern molecule, vacuum drying, aging. The molecular print magnetic microsphere has not only recognize ability of mounted pattern molecule and its analogue, but also has the approved characteristic of 'gathering hyphen recycle', the process of preparation heats up with microwave, decreasing the time of print aggregation, improving homogeneity and print efficiency of polymer form. The molecular print magnetic sphere applies to gather, isolate and analysis of structure analogue in the environmental sample, eatable etc complex samples.

Owner:SUN YAT SEN UNIV

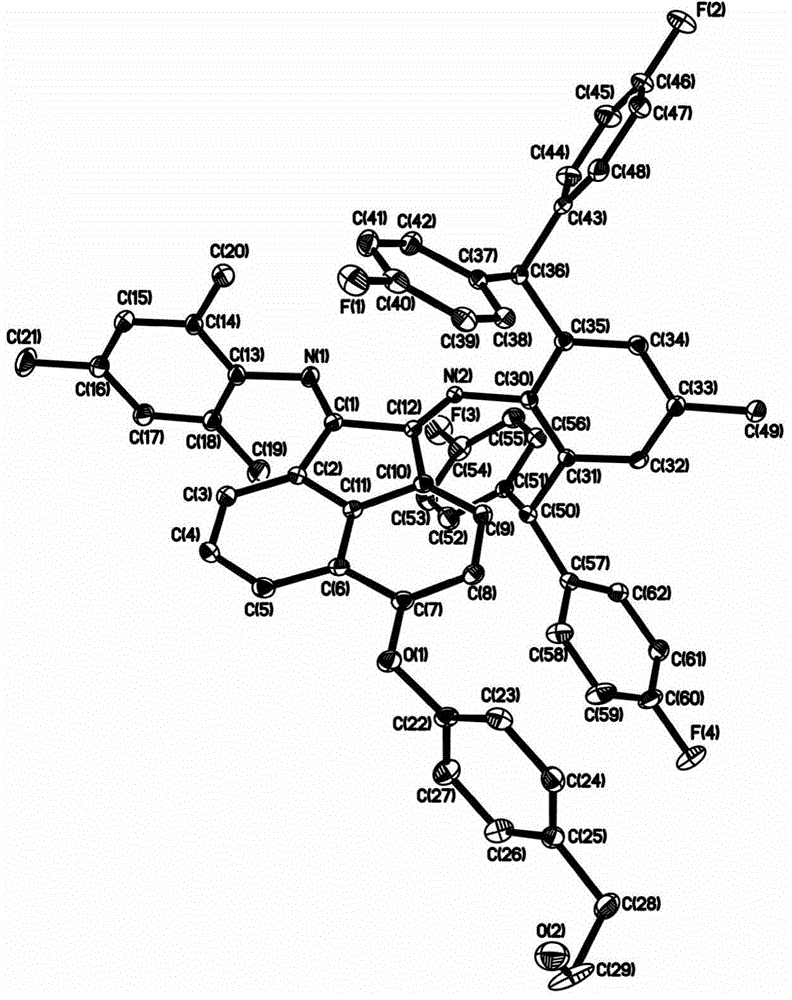

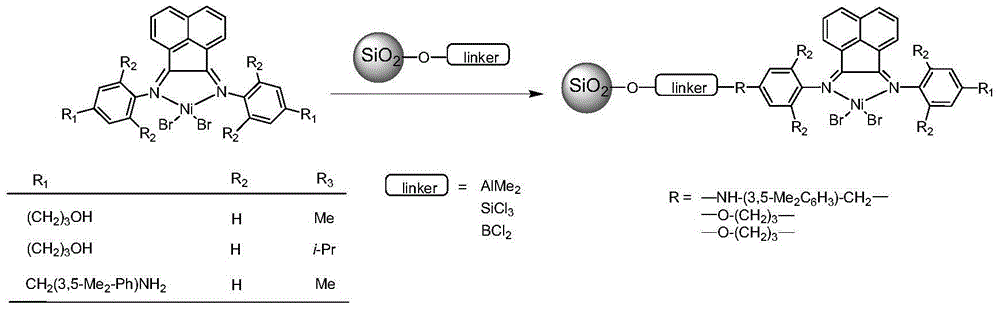

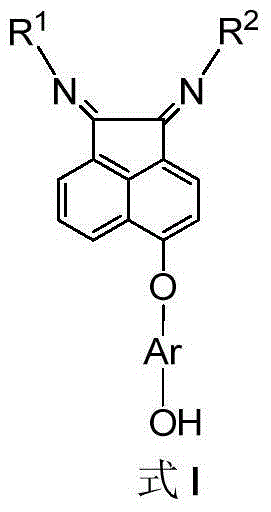

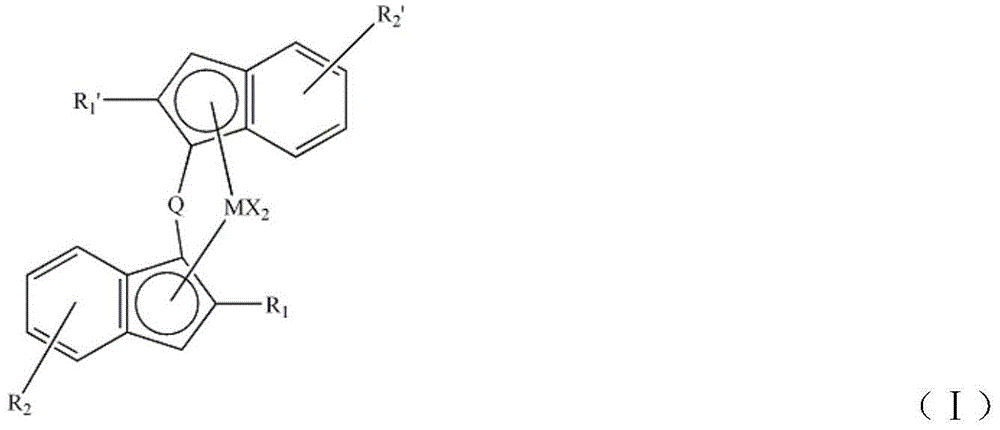

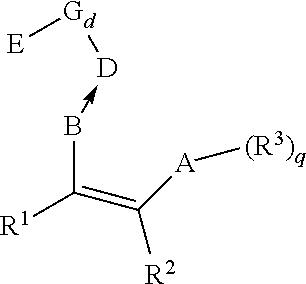

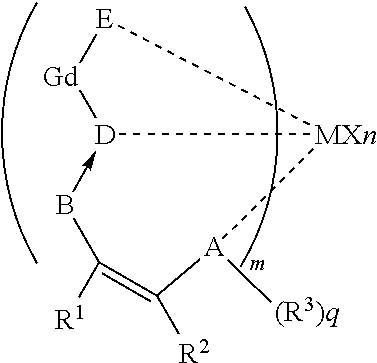

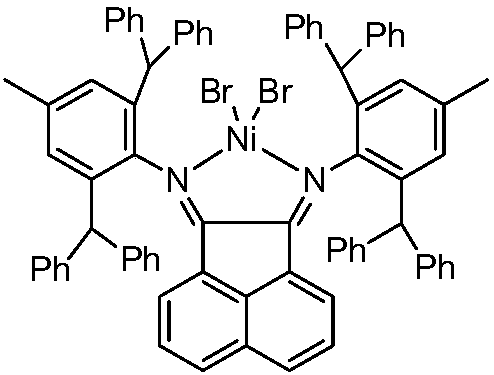

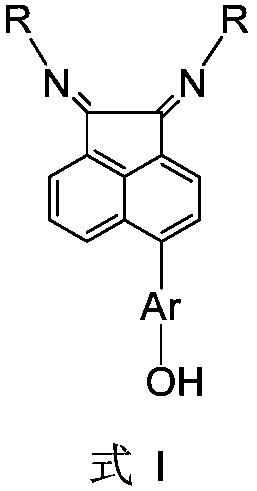

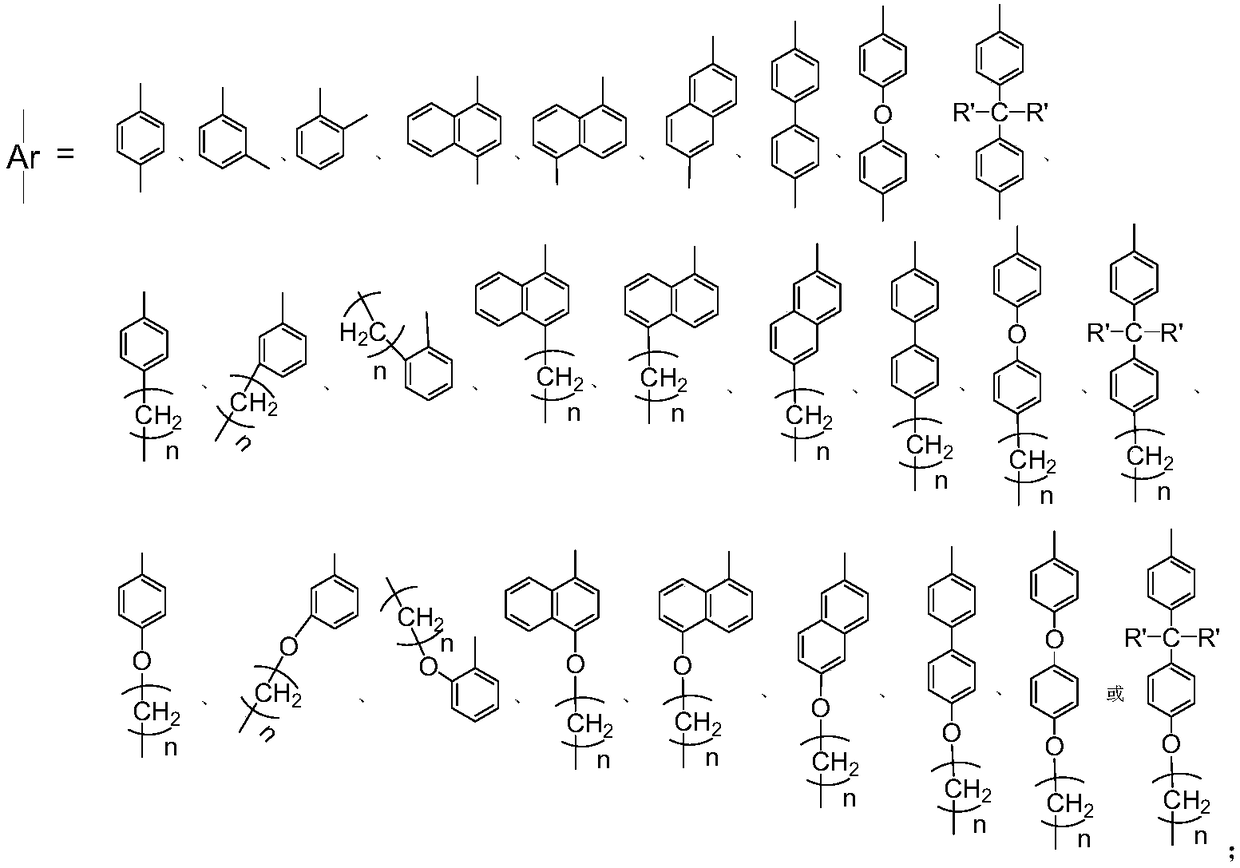

Alpha-diimine compound, metal complex and load containing compound and application thereof

ActiveCN104926686AHighly adjustableInhibit sheddingNickel organic compoundsImino compound preparationDiimineHeat stability

The invention relates to an alpha-diimine compound, a metal complex and a load containing the compound and application thereof. The structural formula of the compound is shown as a formula I. The alpha-diimine compound is provided with a hydroxyl radical on a substituent group connected to an acenaphthene ring, the compound can react with active radicals on a carrier after chemical modification to form covalent bonds, so that the alpha-diimine compound is loaded on the carrier in a covalent bonding manner; and the metal complex containing the alpha-diimine compound, the load containing the alpha-diimine compound and a load of the metal complex containing the alpha-diimine compound can be further obtained. The metal complex containing the alpha-diimine compound and the load containing the metal complex can be used in polymerization of olefins as main catalysts. The metal complex of the load-type alpha-diimine compound can overcome the disadvantages of kettle adhesion, difficult control for polymer conformation, large using amount of catalyst promoter, poor heat stability and the like, and the covalent bonding load manner avoids the complex from being separated from the carrier .

Owner:HEBEI UNIV OF TECH

Process of making two-stage injection stretch blow molded polypropylene articles

The two stage production of clear, low-haze, injection stretch blow molded polypropylene container articles is disclosed. In the first processing stage, a preform article is manufactured on an injection molding machine. In a second and subsequent step, which may occur remotely from apparatus used in the first step, the preform article is heated and stretch blown into a container. The process may employ the selection of processing parameters to produce preform articles that facilitate stretch blow molding at relatively high rates of speed, while still maintaining an appropriate polypropylene polymer morphology that results in clear, low haze containers.

Owner:BATLAW RAJNISH +6

Polymer nanometer array electrochemical biological sensor

InactiveCN101354373AImprove stabilityHigh sensitivityMaterial analysis by electric/magnetic meansSocial benefitsElectrochemical biosensor

The invention discloses an electrochemical biological sensor with a polymer nano array, which comprises the following three parts: a supporting electrode, polymers that are combined on the supporting electrode and a biological sensing element that is connected with the polymers. The electrochemical biological sensor is characterized in that the polymers take the shape of a nano fiber array or a nanotube array with permutation directivity. Compared with the existing electrochemical biological sensing techniques, the electrochemical biological sensor with the polymer nano array is characterized by simple techniques and high testing sensitivity, has enormous application prospect and can produce considerable economic and social benefits.

Owner:中国医科大学 +1

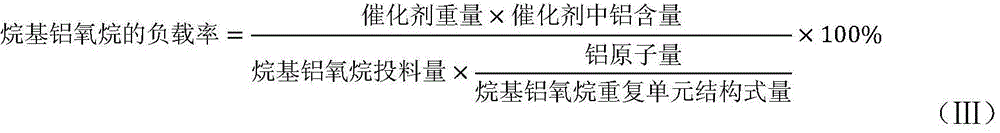

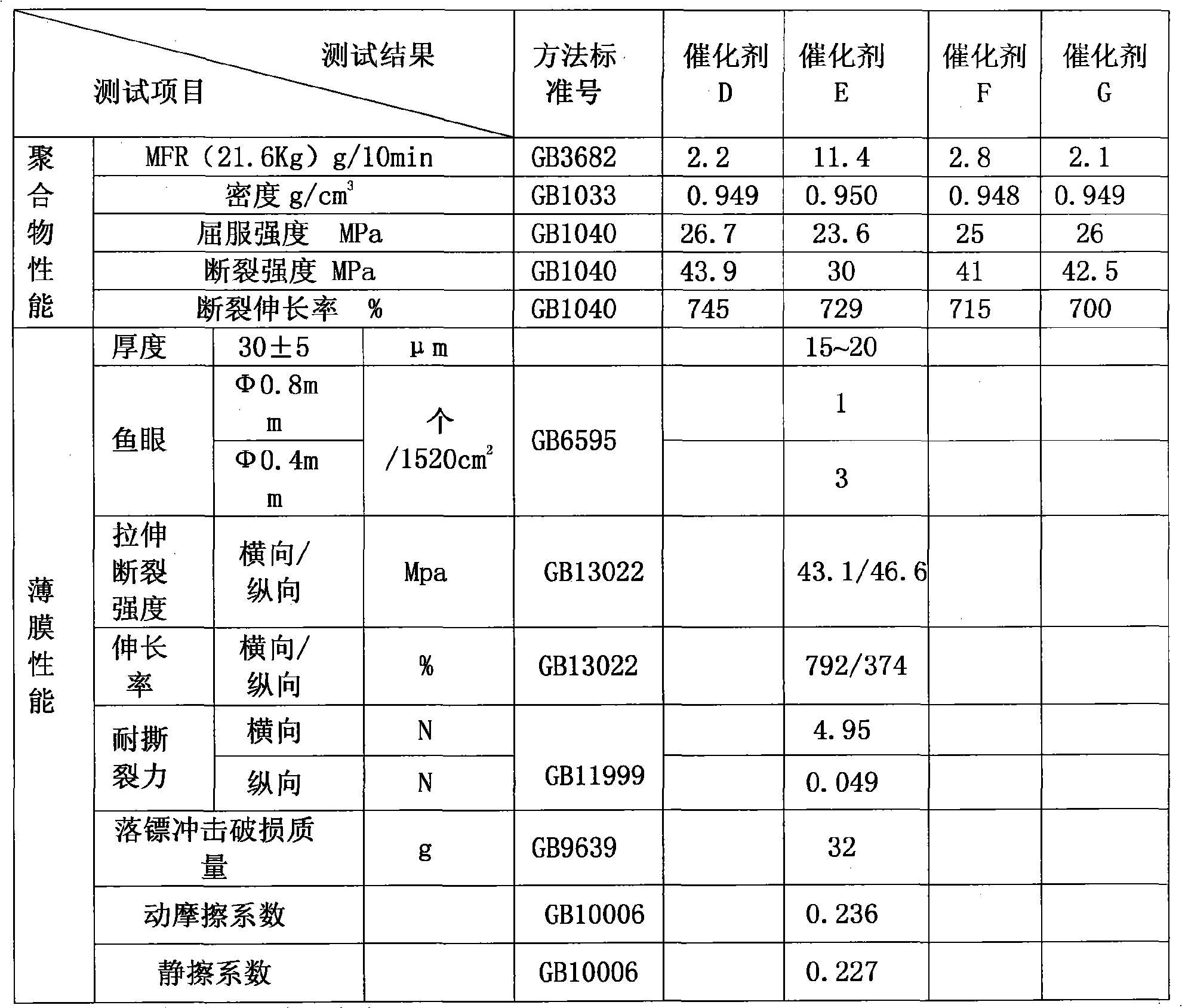

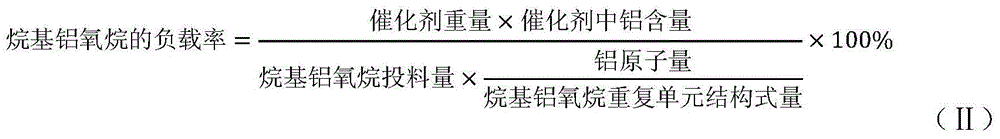

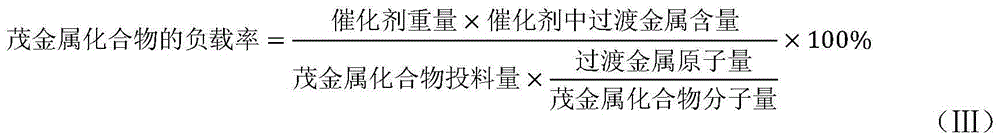

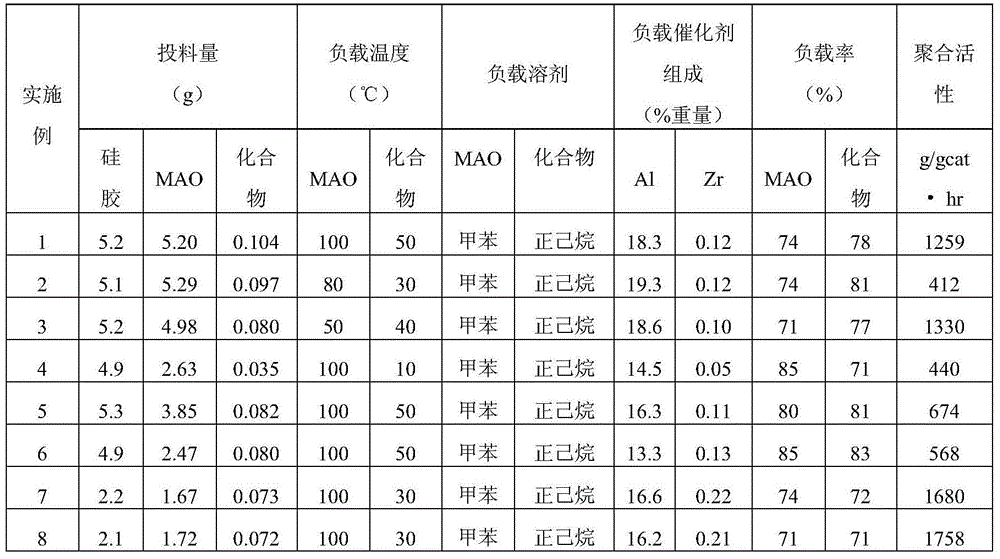

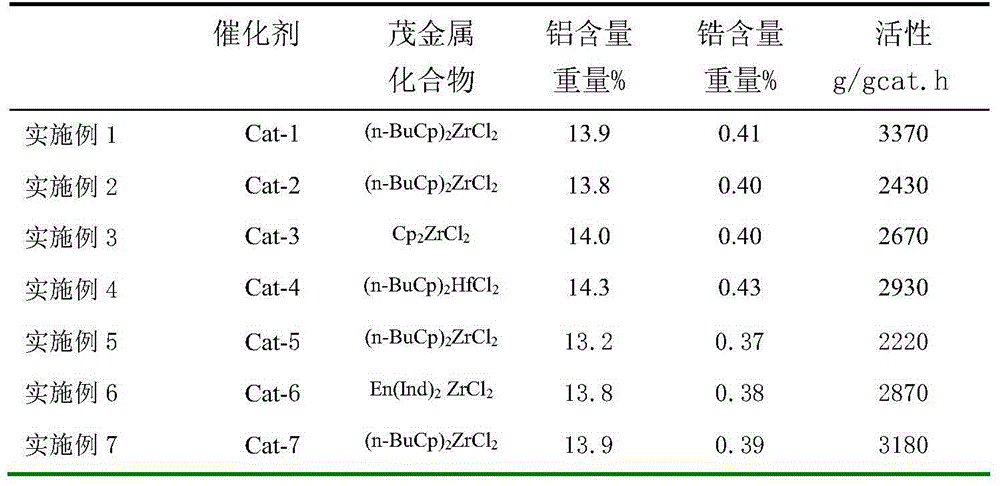

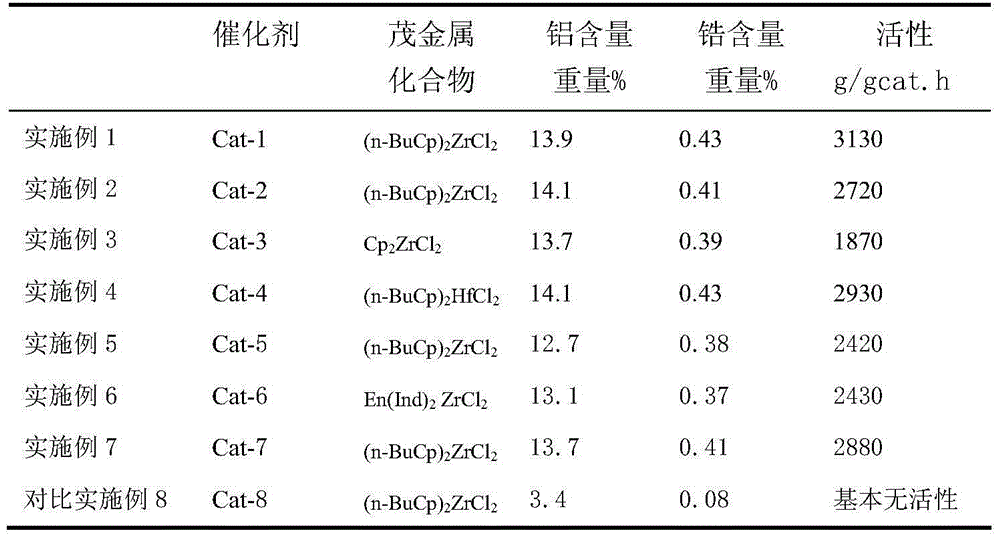

Supported metallocene catalyst and preparation method thereof

The invention relates to a supported metallocene catalyst. The catalyst contains 5-20wt% of Al, and 0.01-0.3wt% of a transition metal. The catalyst can be used for homopolymerization and copolymerization reactions of olefin, a polymer prepared in the invention has good form and is not sticky to kettles, and the olefin polymerization catalysis activity is not lower than 1000 times / h. The invention also relates to a preparation method of the supported metallocene catalyst. The alkylaluminoxane load rate and the metallocene compound load rate of the supported metallocene catalyst prepared through the method are greater than 70wt% respectively. The preparation method has the advantages of simple process, short production period, efficient preparation of the supported metallocene catalyst under mild reaction conditions, small loss of alkylaluminoxane in the loading process, and production cost reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of loading method of metallocene catalyst

The invention relates to a loading method of a metallocene catalyst. In different stages of catalyst preparation in a closed reaction system, a certain negative pressure is formed in the system, namely: 1) the relative vacuum degree of the inorganic carrier pretreatment step system is ( -0.1)~(-0.075)MPa; 2) The relative vacuum of the system is (-0.065)~(-0.075)MPa when aluminoxane is added to the inorganic carrier; 3) Aluminoxane and metallocene compounds are added to the inorganic carrier After the system returns to normal pressure, each component can enter the pores of the inorganic carrier uniformly and quickly, the loading effect of the catalyst and the polymerization activity are greatly improved, and the polymer morphology is obviously improved. This method is simple and easy to implement, and can greatly improve the The preparation time of the metallocene catalyst is shortened, and the preparation efficiency of the supported catalyst is improved.

Owner:PETROCHINA CO LTD

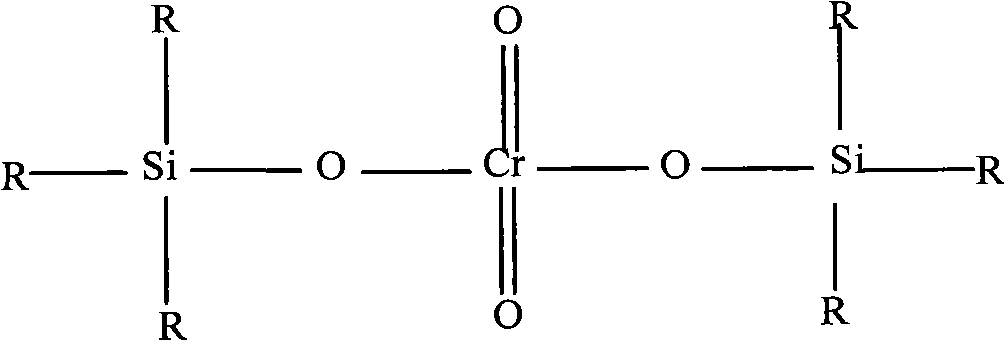

Olefin polymerizing catalyst, preparation and use thereof

ActiveCN101343336AImprove ethylene polymerization performanceImprove the efficiency of chromeDiagnostic Radiology ModalitySilanes

The invention relates to an improved olefin polymerization catalyst and the preparation method as well as the application, which comprises a carrier and organoaluminium compound reducing agent loaded on the carrier and double triphenyl silane chromate active ingredient. The invention is characterized in that the carrier is a compound carrier adopting SiO2 and AlCl3 as materials, and the mass ratio of SiO2 and AlCl3 in the carrier is 1 to 20:1. By adopting the SiO2 / AlCl3 compound carrier prepared through the invention, the efficiency of chromium in the catalyst can be effectively improved, thus the ethylene polymerization activity of the catalyst is enhanced, and the hydrogen sensibility and the copolymerization performance of the catalyst are adjusted; the modality of the obtained polymeric compound is good and the bulk density is high, therefore the prepared polyvinyl resin can be used to produce high performance tubular products and coating materials, and the like.

Owner:ZIBO XINSU CHEM

Metallocene catalyst composition and preparation method thereof

The invention relates to a metallocene catalyst composition. The catalyst composition contains a polymer, and alkylaluminoxane and a metallocene compound supported metallocene catalyst component which are supported on a carrier, wherein a weight ratio of the polymer to the supported metallocene catalyst component is 0.1-10:1, and the alkylaluminoxane loading rate and the metallocene compound loading rate are respectively greater than 70wt%. The catalyst can be used for homopolymerization and copolymerization reactions of olefin, the olefin polymerization reaction catalysis activity is high, and a polymer prepared in the invention has good form and few fine powders and is not sticky to kettles. The invention also relates to a preparation method of the metallocene catalyst composition. The method has the advantages of simple process, short production period, efficient preparation of metallocene catalysts under mild reaction conditions, small loss of alkylaluminoxane in the loading process, and production cost reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of making preform articles and polypropylene molded containers from preform articles using injection stretch blow molding techniques

The two stage production of clear, low-haze, injection stretch blow molded polypropylene container articles is disclosed. In the first processing stage, a preform article is manufactured on an injection molding machine. In a second and subsequent step, which may occur remotely from apparatus used in the first step, the preform article is heated and stretch blown into a container. The process may employ the selection of processing parameters to produce preform articles that facilitate stretch blow molding at relatively high rates of speed, while still maintaining an appropriate polypropylene polymer morphology that results in clear, low haze containers.

Owner:MILLIKEN & CO

Loaded metallocene catalyst and preparation method thereof

The invention relates to a loaded metallocene catalyst. The load rates of alkylaluminoxane and a metallocene compound of the catalyst are greater than 70% (by weight). The catalyst is relatively high in activity, and can be used for homopolymerization and copolymerization reactions of olefins and does not fall in the polymerization process. The prepared polymer is good in shape and less in polymer fine powder and is not sticky to a kettle. The invention further relates to a method for preparing the loaded metallocene catalyst. The method is simple in process and short in production period, and can be used for efficiently preparing the loaded metallocene catalyst under a mild reaction condition. The loss of alkyl aluminum in the loading process is less, the production cost is low, and the prepared catalyst is high in load rate and good in polymerization reaction activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported nonmetallocene catalyst and preparation thereof

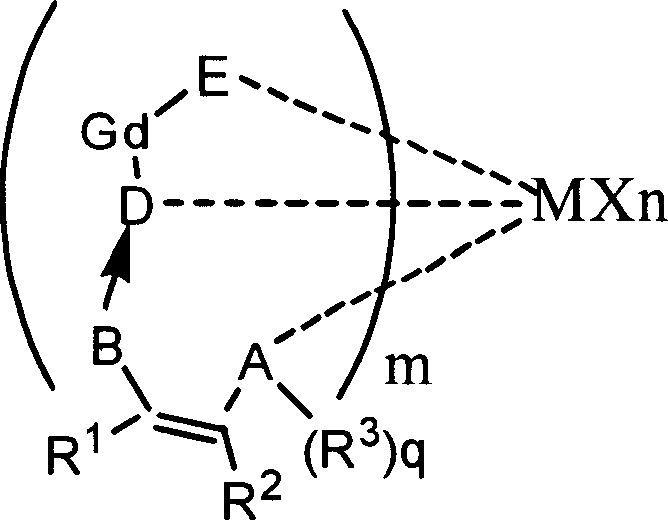

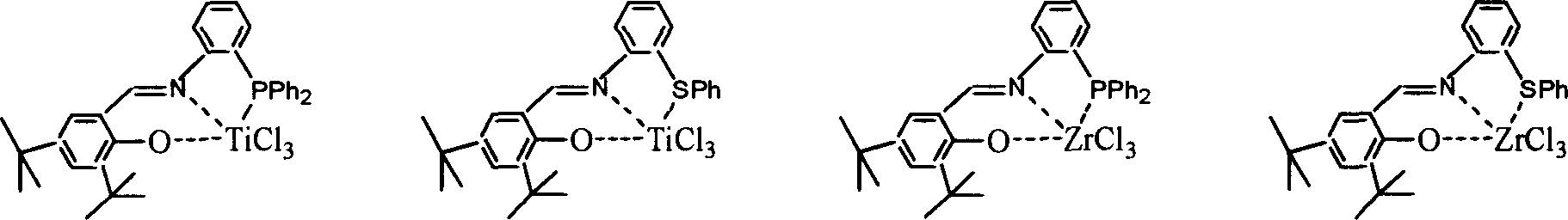

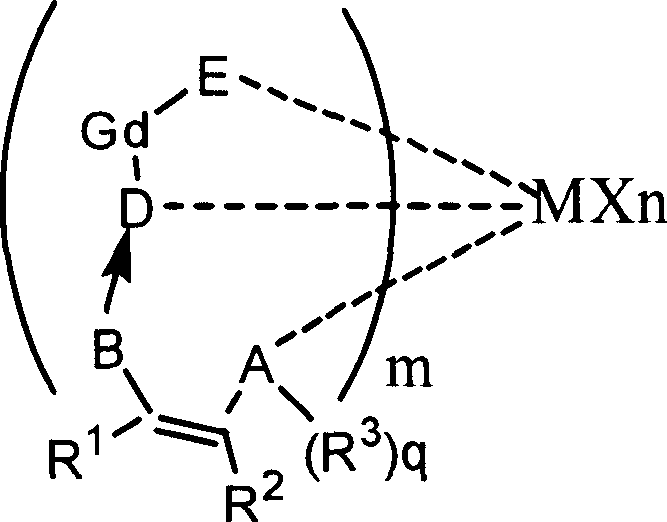

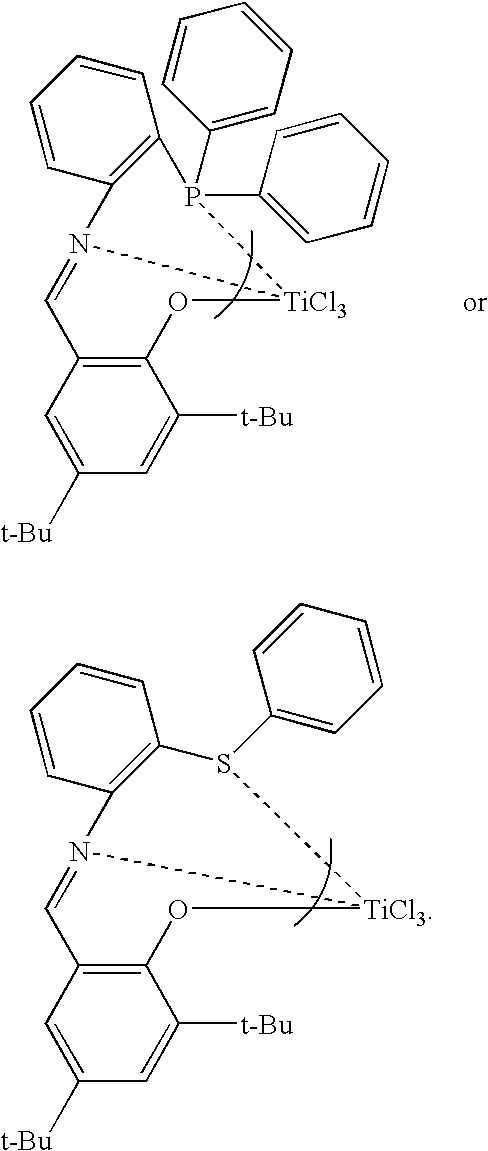

ActiveUS8193288B2Easy loadingReduce impactMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolymer morphology

This invention relates to a supported nonmetallocene catalyst for olefin polymerization, which is produced by directly reacting a nonmetallocene ligand with a catalytically active metallic compound on a carrier through an in-situ supporting process. The process according to this invention is simple and feasible, and it is easy to adjust the load of the nonmetallocene ligand on the porous carrier. The supported nonmetallocene catalyst according to this invention can be used for olefin homopolymerization / copolymerization, even in combination with a comparatively less amount of the co-catalyst, to achieve a comparatively high polymerization activity. Further, the polymer product obtained therewith boasts desirable polymer morphology and a high bulk density.

Owner:SINOPEC YANGZI PETROCHEM

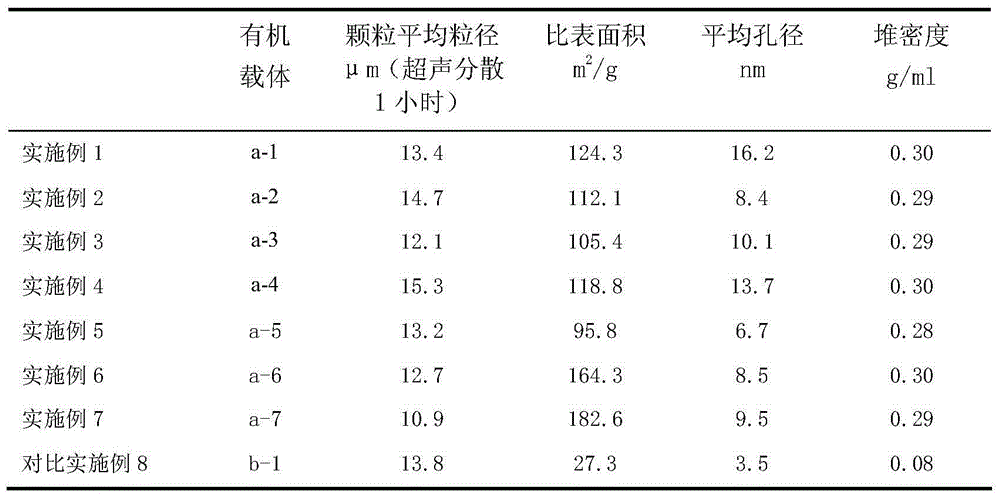

Supported metallocene catalyst system and preparation method thereof

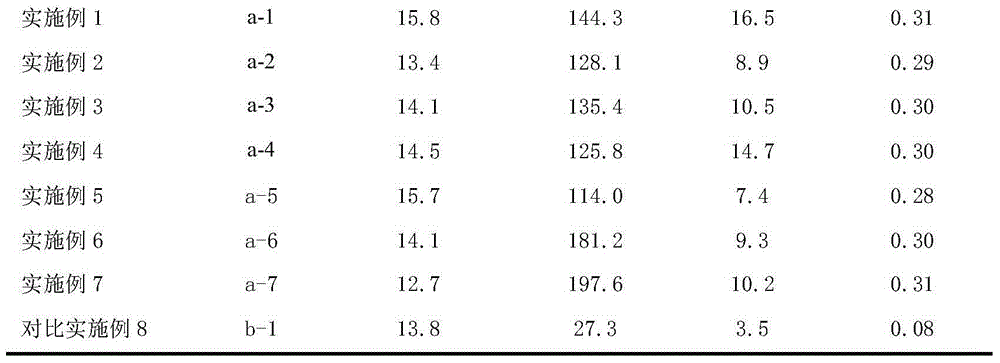

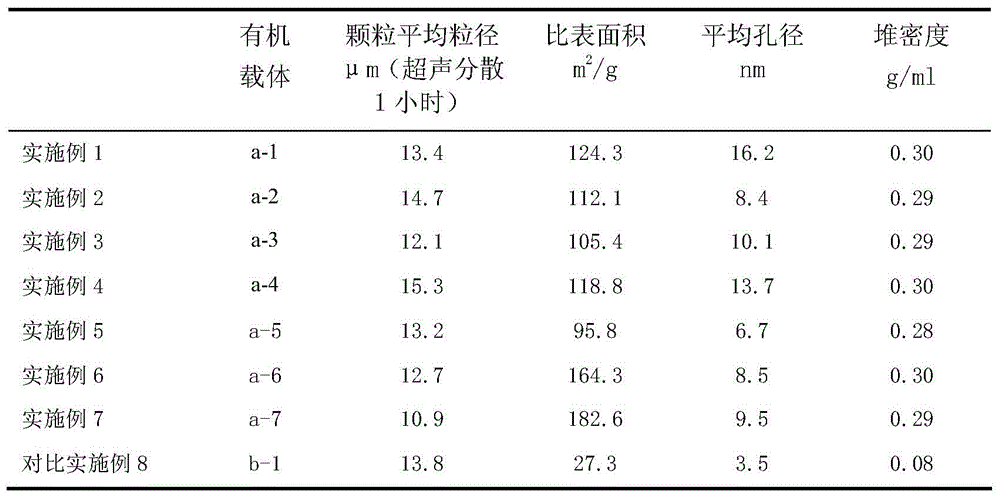

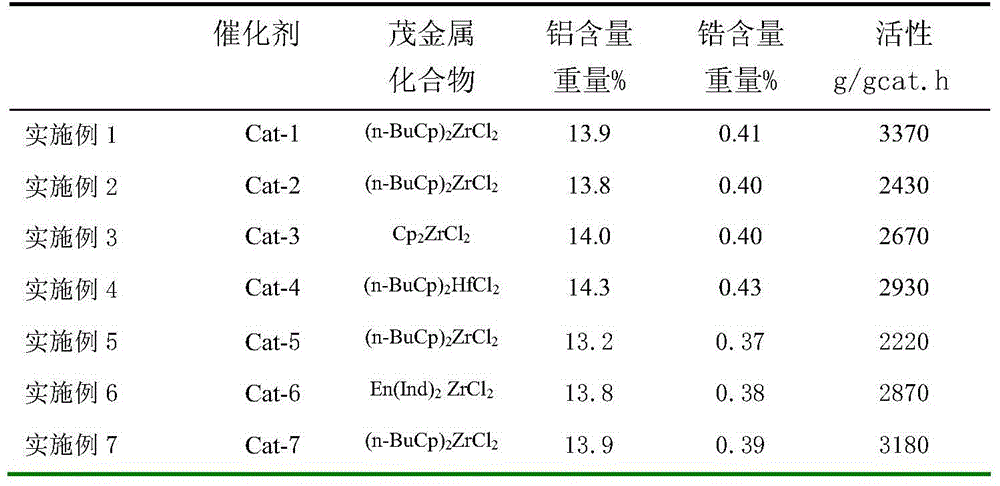

The invention relates to a metallocene catalyst system for olefin polymerization and a preparation method thereof. The catalyst is mainly prepared from an organic high-molecular polymer carrier, a co-catalyst and a metallocene compound, wherein the carrier is styrene-divinyl benzene-hydroxyethyl methylacrylate terpolymer; a molar ratio of aluminum Al in the co-catalyst to metal atom M in the metallocene compound is 50-300; and based on the molar percentage of aluminum Al, each gram of organic high-molecular polymer carrier contains 1-12mmol of co-catalyst. The preparation method mainly comprises the steps of synthesizing the organic high-molecular polymer carrier, and loading the metallocene catalyst. The preparation method is simple and environment-friendly, the prepared catalyst and polymer have good shape since a novel organic porous carrier is adopted, and the catalyst has relatively high activity.

Owner:PETROCHINA CO LTD

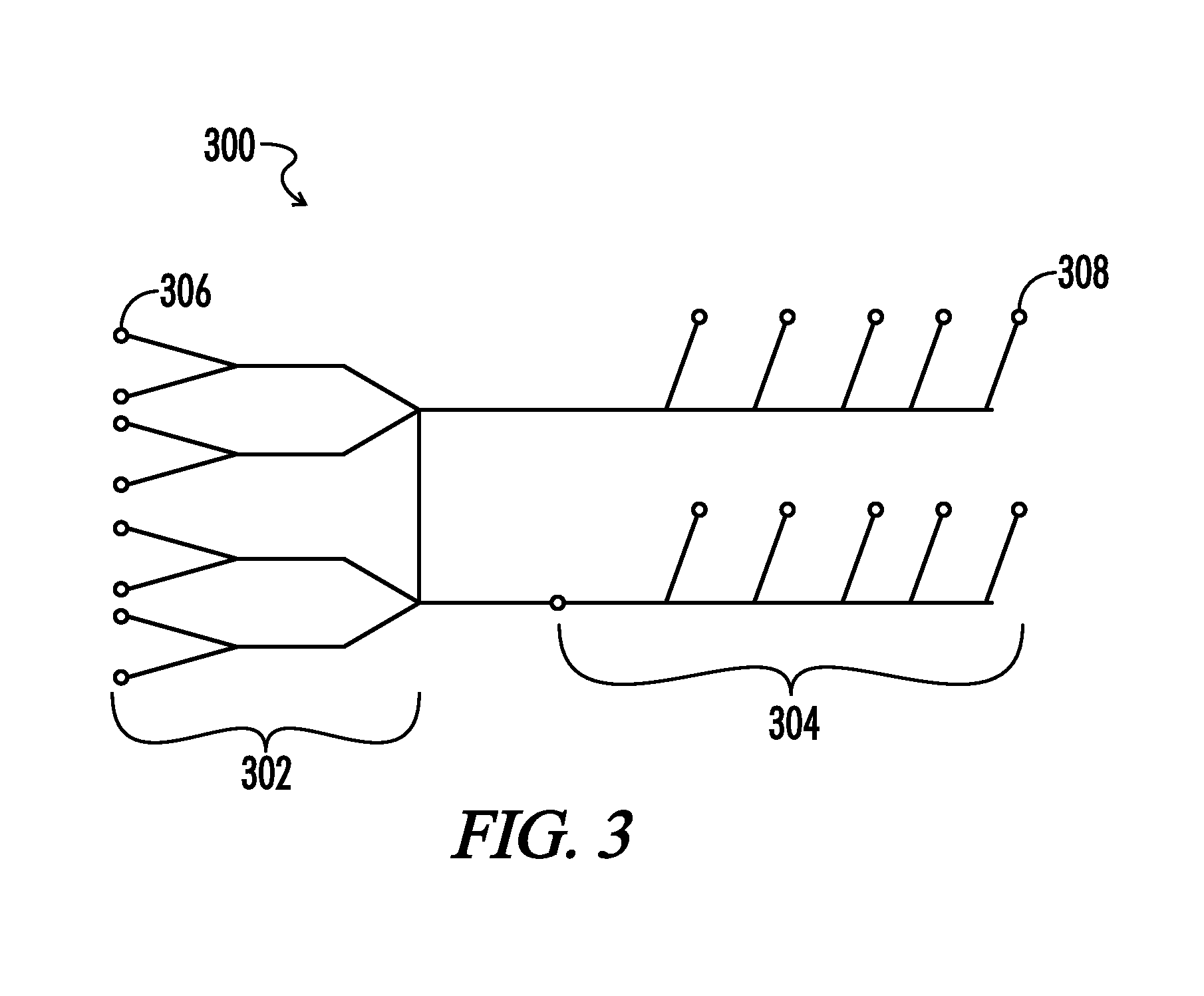

Class of Anti-adhesion hydrogels with healing aspects

ActiveUS20130196003A1Expand the scope of usePromoting tissue ingrowthBiocideOintment deliveryCrystallographyEnd-group

Disclosed are hydrogels polymerized with a biofunctional moiety, biodegradable and permanent, designed to be implantable in a mammalian body and intended to block or mitigate the formation of tissue adhesions. The hydrogels of the present invention are characterized by comprising four structural elements: a) a polymeric backbone which defines the overall polymeric morphology, b) linkage groups, c) side chains, and d) biofunctional end groups. The hydrophobicity of the various structural elements are chosen to reduce tissue adhesion and enhance the biofunctional aspect of the end groups. The morphology of these polymers are typically of high molecular weight and have shape to encourage entanglement. Useful structures include branching chains, comb or brush, and dendritic morphologies.

Owner:BVW HLDG

Supported nonmetallocene olefin polymerization catalyst, preparation method and use thereof

ActiveUS7875568B2High reactive groupReduced responseMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceAlcohol

The present invention provides a method for supporting a nonmetallocene olefin polymerization catalyst, comprising the following steps: a carrier reacts with a chemical activator to obtain a modified carrier; a magnesium compound is dissolved in a tetrahydrofuran-alcohol mixed solvent to form a solution, then the modified carrier is added to the solution to perform a reaction, then filtered and washed, dried and suction dried to prepare a composite carrier; a nonmetallocene olefin polymerization catalyst is dissolved in a solvent, and then reacts with said composite carrier, then is washed and filtered, dried and suction dried, to prepare a supported nonmetallocene olefin polymerization catalyst. The present invention further relates to a supported nonmetallocene olefin polymerization catalyst as prepared by this method. The present invention further relates to the use of the supported nonmetallocene olefin polymerization catalyst in an olefin polymerization and an olefin copolymerization between two or more different olefins. In one specific embodiment, the present invention relates to the use of the supported nonmetallocene olefin polymerization catalyst in a slurry ethylene polymerization. The present invention provides a new type of catalyst that improves the polymer morphology, increases polymer bulk density and enhances polymerization activity.

Owner:YANGZI PETROCHEM

Metallocene catalyst system and preparation method thereof

The invention relates to an olefin polymerized metallocene catalyst system and a preparation method thereof. The catalyst is mainly prepared from an organic high-molecular polymer carrier, a co-catalyst and a metallocene compound, wherein the carrier is monodisperse porous styrene-divinyl benzene-ethylene glycol dimethacrylate terpolymer; the co-catalyst (based on the molar percentage of aluminum Al) and the metallocene compound (based on the molar percentage of metal atom M in the compound) are in a molar ratio Al:M being 75-300; and based on the molar percentage of aluminum Al, each gram of organic high-molecular polymer carrier contains 1-12mmol of co-catalyst. The preparation method mainly comprises the steps of synthesizing the organic high-molecular polymer carrier, and loading the metallocene catalyst. The preparation method is simple and environment-friendly, the prepared catalyst and polymer have good shape since a novel organic porous carrier is adopted, and the catalyst has relatively high activity.

Owner:PETROCHINA CO LTD

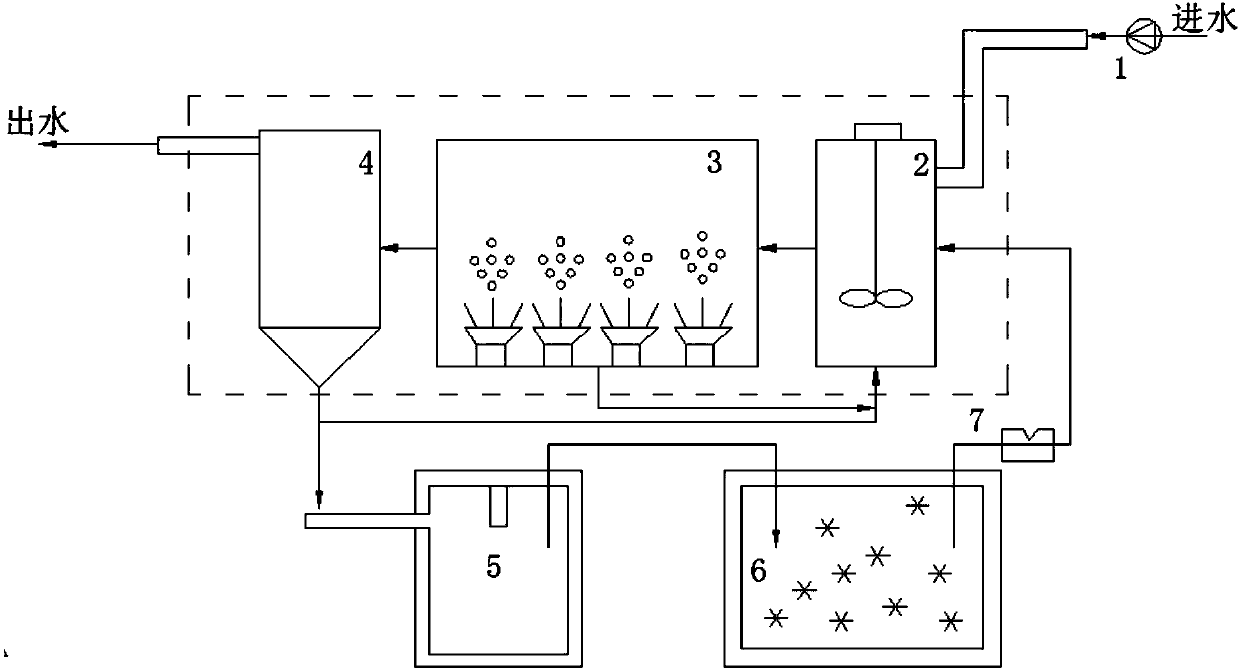

Ultrasonic/filler combined sludge decrement device and process

ActiveCN106698876ASmall particle sizeLarge specific surface areaSludge processingBiological sludge treatmentLysisPolymer morphology

The invention relates to an ultrasonic / filler combined sludge decrement device and process. The sludge decrement device comprises a main flow biological treatment component and a side flow sludge decrement component, wherein the main flow biological treatment component comprises an anoxic tank, an aeration tank and a sedimentation tank which are sequentially connected in the flowing direction of sludge, and the bottom of the sedimentation tank is connected back to the anoxic tank through a pipeline; and the side flow sludge decrement component comprises an ultrasonic unit and a biological decrement unit which are sequentially connected in the flowing direction of sludge, the inlet of the ultrasonic unit is connected to the pipeline at the bottom of the sedimentation tank, and the outlet of the biological decrement unit is connected back to the anoxic tank. Compared with the prior art, the ultrasonic pretreatment provided by the invention can change the morphology and composition of sludge extracellular polymers and reduce the particle size of sludge flocculating constituents, thereby contributing to accelerating the sludge hydrolysis and lysis process; and suspended fillers are thrown into the side flow sludge decrement component, so that habitats are provided for decrement functional microbes, and the hydraulic retention time is prolonged, thereby improving the sludge decrement efficiency.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Supported catalysts which reduce sheeting in olefin polymerization, process for the preparation and the use thereof

InactiveUS6884749B2Easy to operateReduce catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceGas phase

Olefin polymerization in the presence of heterogeneous supported catalysts is improved by incorporating into the supported catalyst a unifunctional hydrophobic tether comprising a hydrophobic portion containing no basic nitrogen and a univalent reactive group. The unifunctional hydrophobic tether reduces fouling and sheeting in gas phase polymerization processes and improves polymer morphology and bulk density in slurry polymerization processes, while substantially maintaining or enhancing catalyst polymerization activity.

Owner:EQUSR CHEM LP

Catalyst loaded with alpha-diimine metal complex and application of catalyst to olefin polymerization

The invention relates to application of a catalyst loaded with alpha-diimine metal complex to olefin polymerization. Hydroxyl at a diimine ligand can react with reactive groups on a chemically modified carrier to form covalent bonds, so that the alpha-diimine compound is firmly supported on the carrier by chemical bonding and is prevented from being detached from the carrier. The alpha-diimine exhibits high-temperature-resistant catalytic activity in the presence of a small steric hindrance group. Meanwhile, an aromatic group on an imine group in the alpha-diimine compound can be arbitrarily changed as needed. Moreover, the preparation of the alpha-diimine ligand is simple, thereby facilitating application of the alpha-diimine metal complex to polymerization of olefins. The load of the alpha-diimine metal complex can improve the problems of adherence to a kettle, control difficulty on polymer morphology, large usage amount of a co-catalyst, bad thermal stability and the like of a homogeneous alpha-diimine late transition metal catalyst in actual application in the prior art.

Owner:HEBEI UNIV OF TECH

A kind of supported metallocene catalyst system and preparation method thereof

The invention relates to a metallocene catalyst system for olefin polymerization and a preparation method thereof. The catalyst is mainly prepared from an organic high-molecular polymer carrier, a co-catalyst and a metallocene compound, wherein the carrier is styrene-divinyl benzene-hydroxyethyl methylacrylate terpolymer; a molar ratio of aluminum Al in the co-catalyst to metal atom M in the metallocene compound is 50-300; and based on the molar percentage of aluminum Al, each gram of organic high-molecular polymer carrier contains 1-12mmol of co-catalyst. The preparation method mainly comprises the steps of synthesizing the organic high-molecular polymer carrier, and loading the metallocene catalyst. The preparation method is simple and environment-friendly, the prepared catalyst and polymer have good shape since a novel organic porous carrier is adopted, and the catalyst has relatively high activity.

Owner:PETROCHINA CO LTD

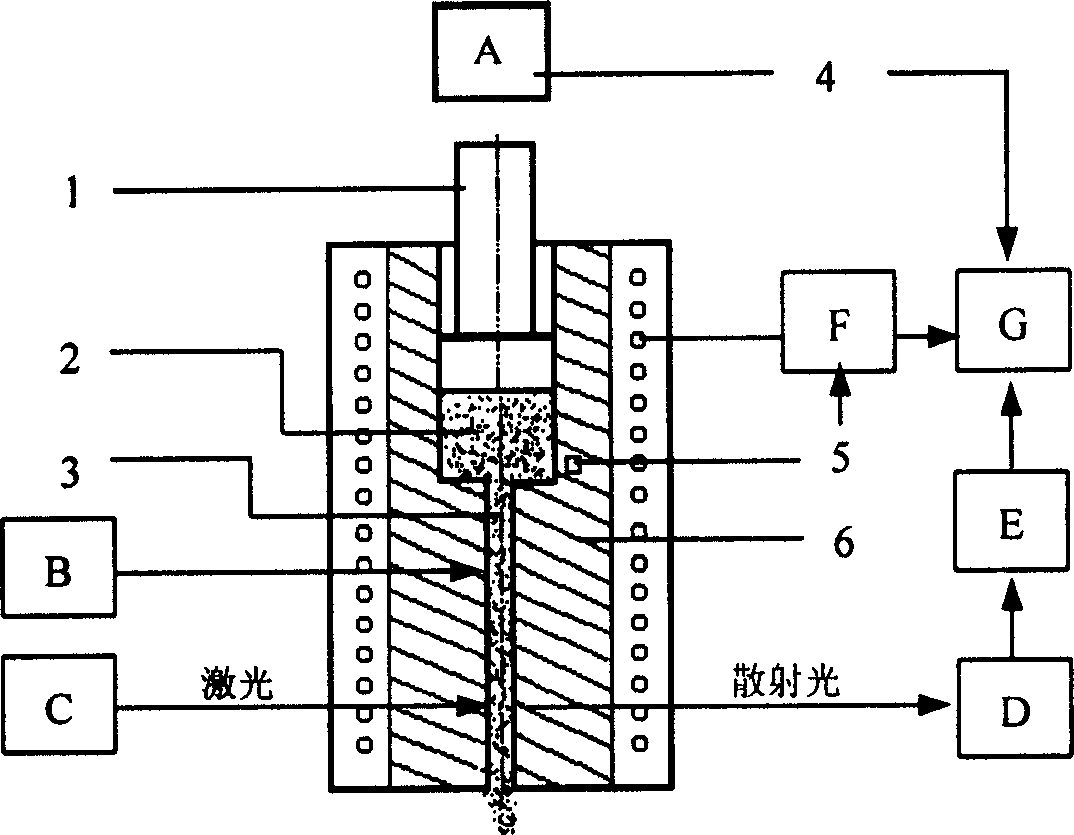

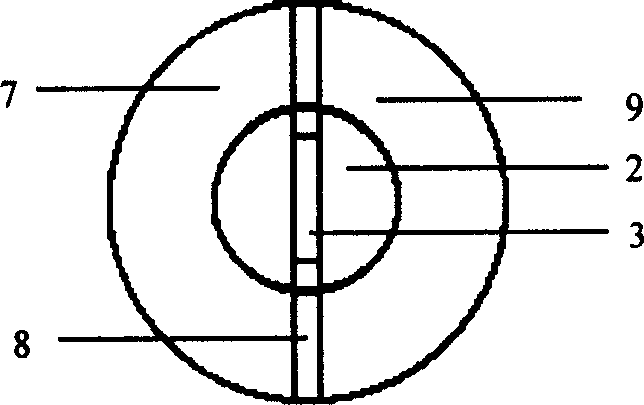

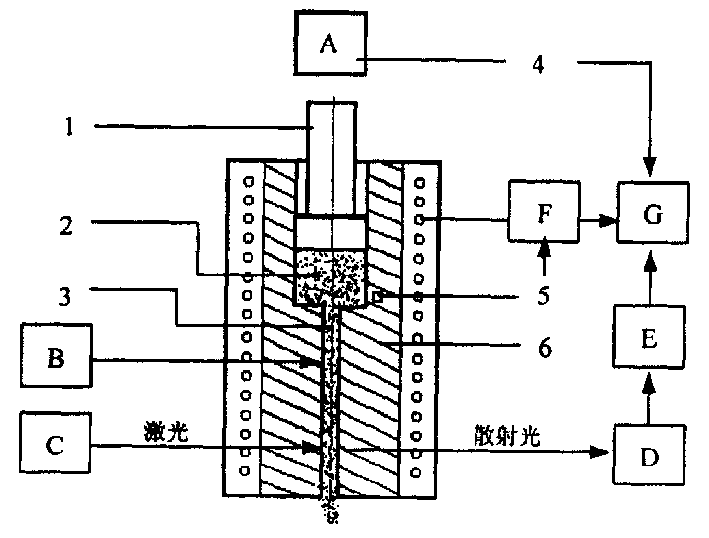

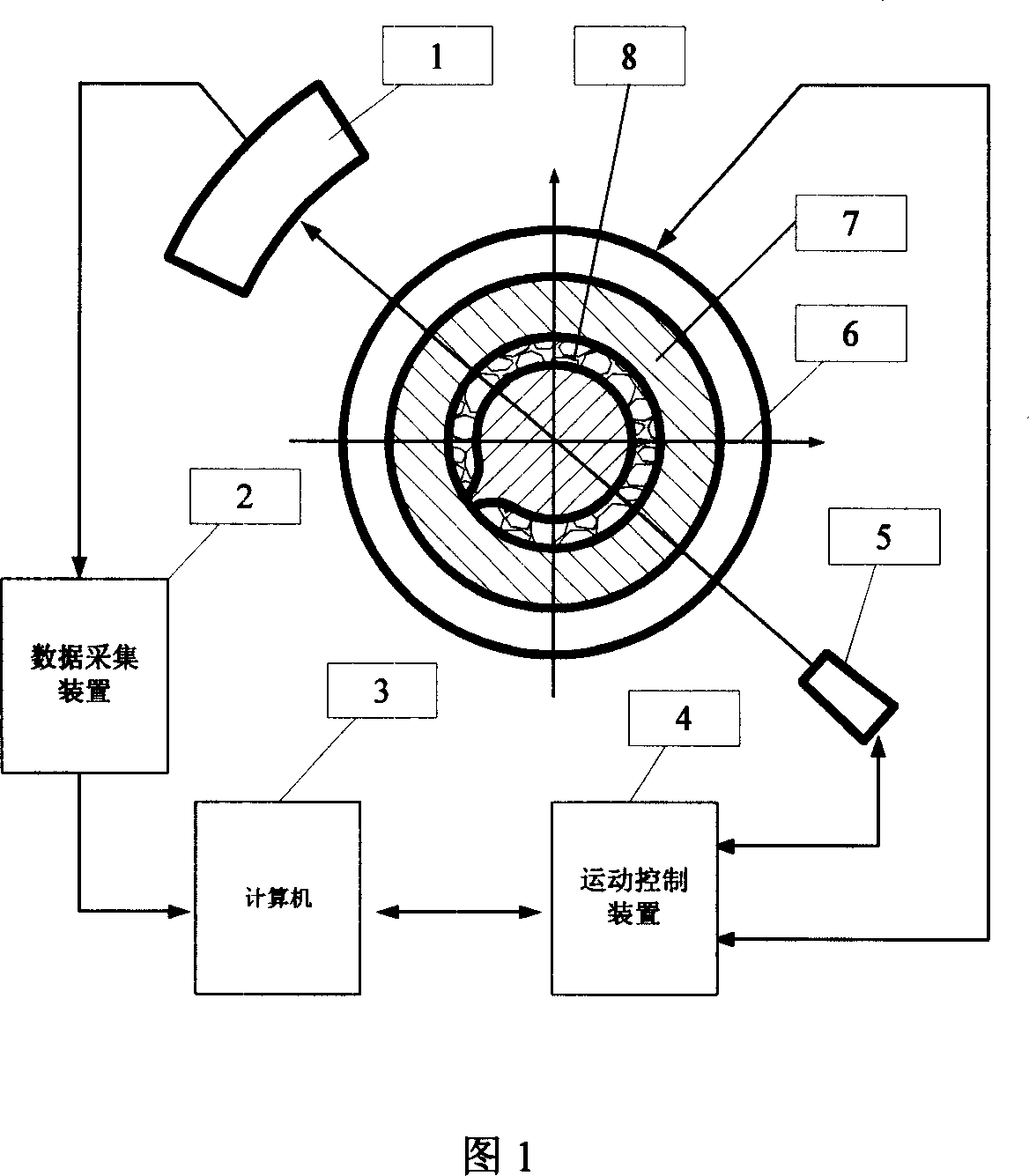

Ultrasonic wave vibration field slit flow small angle laser light scattering real time observation system

InactiveCN1475793AStable structureImprove performanceScattering properties measurementsPolymer morphologyHandling system

A real-time observing system for small-angle laser diffusion of slit in ultrasonic vibration field is composed of a die wound by heating winding and with lower slit and upper material cavity, temp sensor, displace sensor installed to plunger rod in said cavity ultrasonic generator, laser device, photoelectric detector, amplifier, temp control system and microcomputer.

Owner:ZHEJIANG UNIV

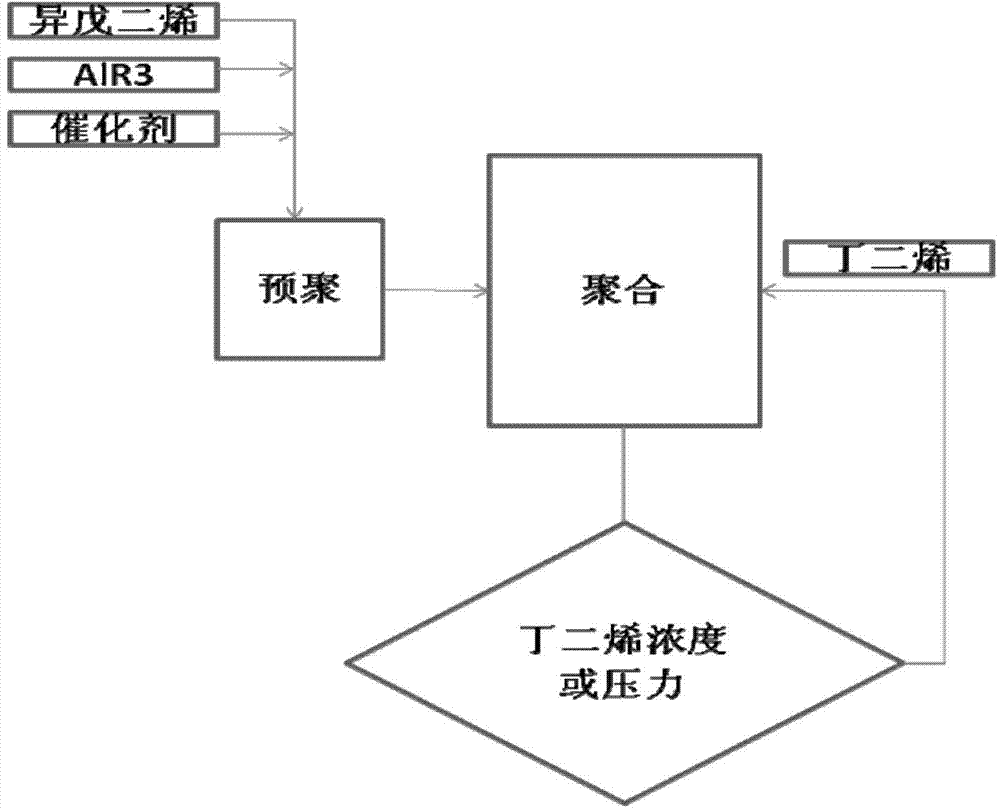

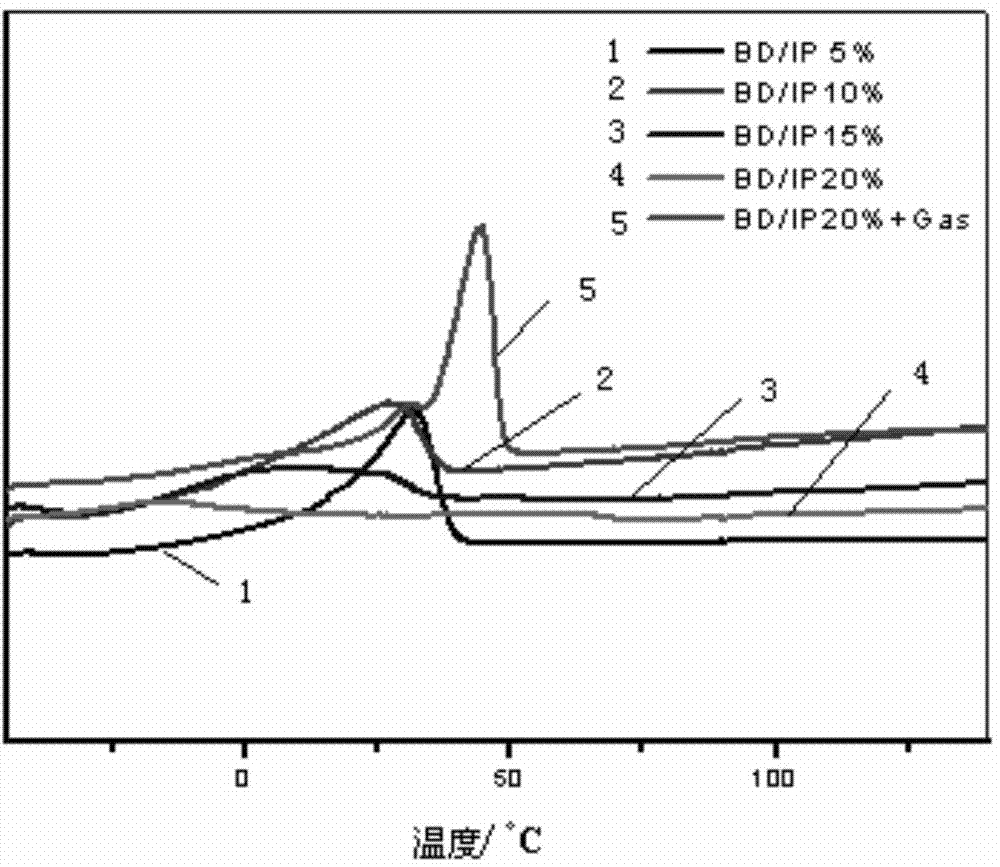

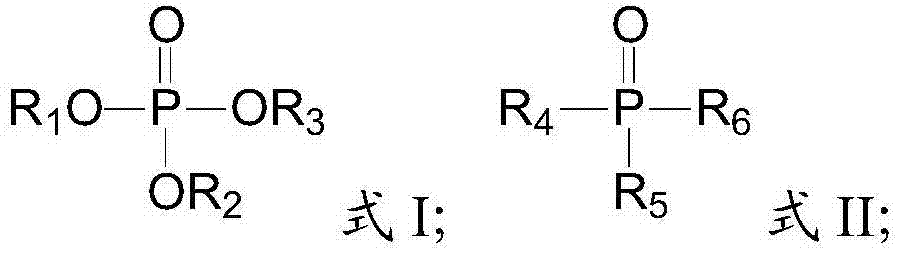

Preparation method of low-crystallinity high trans-1,4-polyisoprene

The invention provides a preparation method of low-crystallinity high trans-1,4-polyisoprene. The method comprises the following steps: sequentially mixing isoprene, a cocatalyst, a main catalyst and a comonomer; and respectively carrying out pre-polymerization reaction and polymerization reaction, so as to obtain the low-crystallinity high trans-1,4-polyisoprene, wherein the main catalyst contains a spherical support and an active component and a phosphate compound; the active component and the phosphate compound are loaded on the spherical support; the spherical support is a magnesium chloride alcohol compound or a spherical silicon dioxide; the comonomer is butadiene, pentadiene or 2,3-dimethyl-1,3-butadiene; and the molar ratio of the comonomer to the isoprene in the polymerization reaction is 2%-30%. The invention provides a method for preparing low-crystallinity high trans-1,4-polyisoprene. The problems of polymer morphology control, polymer liquidity and the like in a bulk precipitation polymerization process are effectively solved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

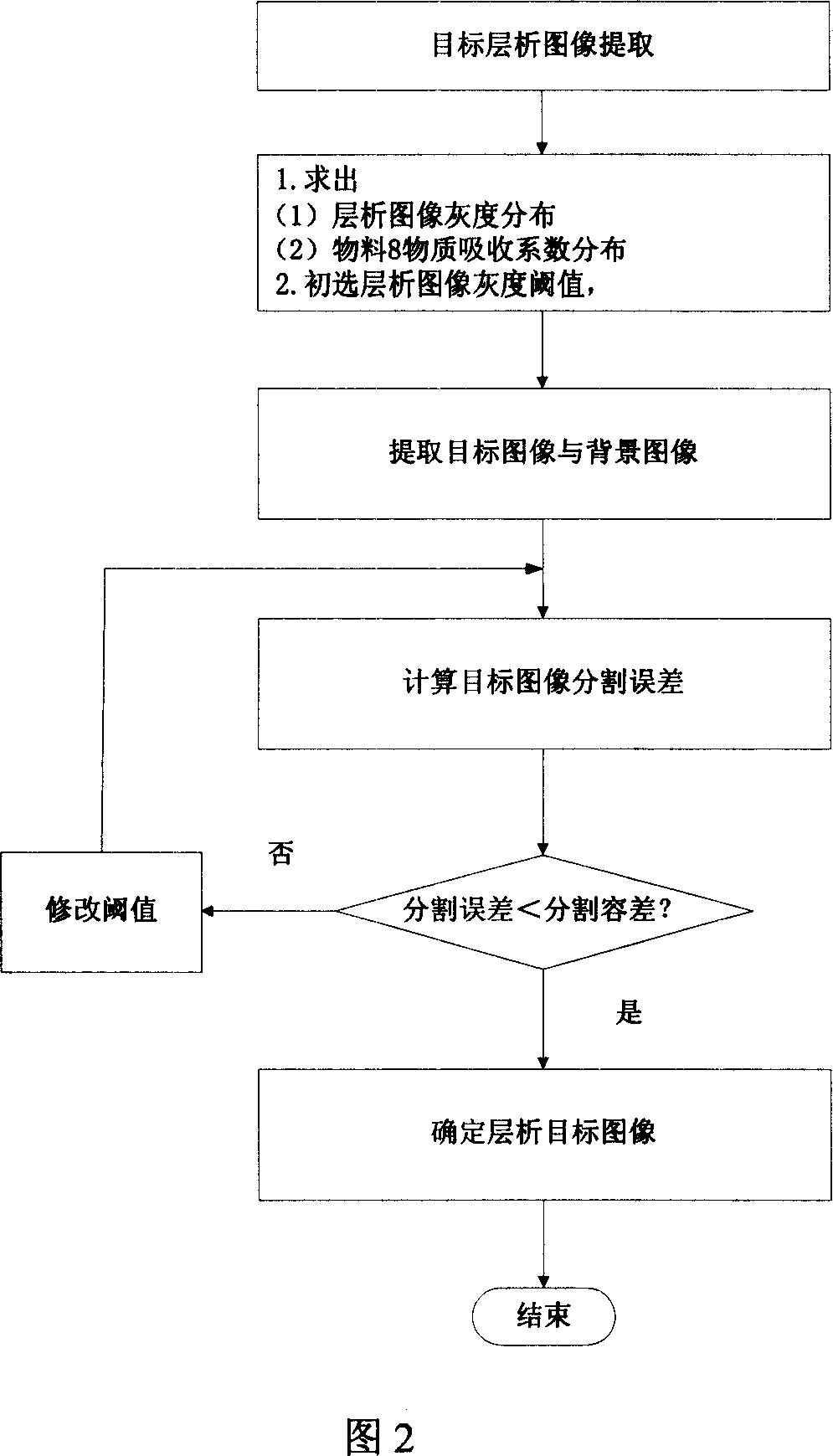

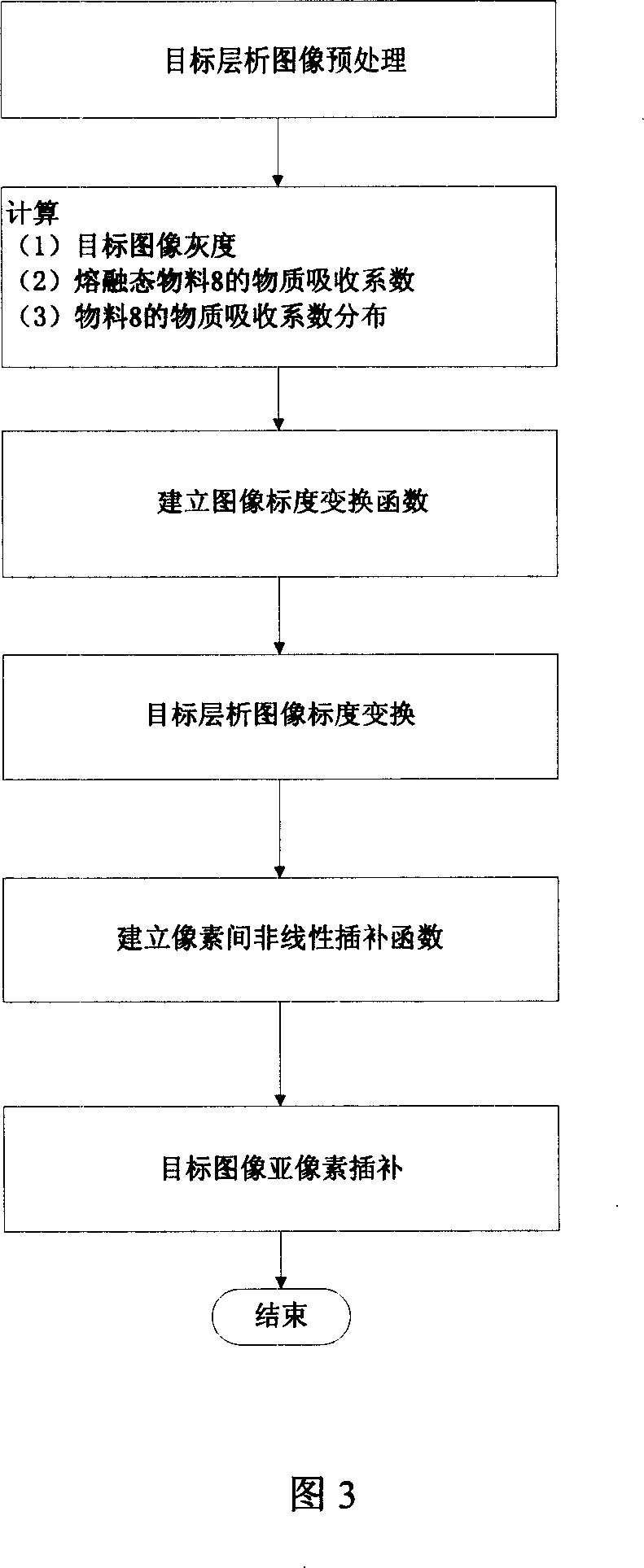

Tomographic image measuring method for shape of closed melting state material

InactiveCN101008623ASolving Problems with Polymer Morphology in the Molten StateSolve the problem of formImage enhancementImage analysisImage extractionNon destructive

This invention discloses one chromatography image test method in enclosed melt materials, which comprises the following steps: shaping space chromatography image; aim chromatography image extracting and pre-processing; aim image property extracting; aim image property identifying and measuring for melt materials enclosed. This invention solves the problems of difficult identification and measurement to provide one technique method for polymer shaping mechanism.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com